Introduction: 3D printing techniques have been adapted to print novel polymers and biological gels into complex tissue engineering scaffolds. Here, we report a new method of creating high porosity foams with complex shapes by using open source, solid freeform fabrication (SFF) technology and emulsion inks developed in our lab. High internal phase emulsions (HIPE) prepared from hydrophobic photopolymers exhibit shear thinning behavior that permits extrusion, and a high zero-shear viscosity sufficient for shape retention after deposition. Each layer is actively polymerized with a UV Cure-on-Dispense (CoD) technique. In this study, the effects of emulsion viscosity and cure rate on print fidelity were studied.

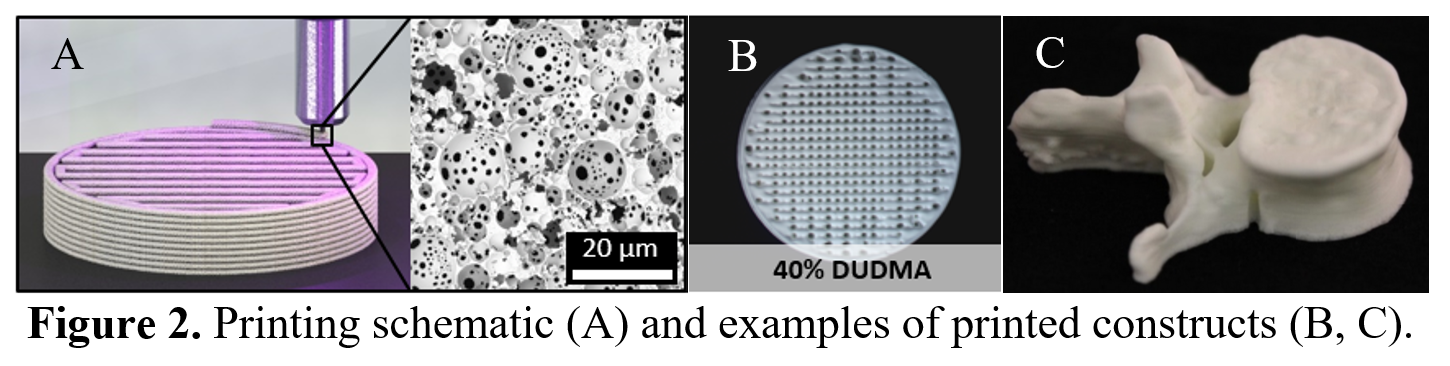

Materials and Methods: HIPEs were fabricated using a FlackTek Speedmixer DAC 150 FVZ-K according to a protocol adapted from Moglia et al[1]. Poly(propylene glycol) dimethacrylate (PPGDMA, 560 Da), was used as the main HIPE macromer and diurethane dimethacrylate (DUDMA, 471 Da), was used to increase the viscosity of the emulsion. Shapes were designed in Solidworks and exported into the STL file format. Printer G-code was created with Slic3r v1.2.6. Infill (50%, 70%), layer height (0.2 mm), extrusion width (0.6 mm), and a print speed of 10 mm/s were crucial for the formation of accurate, cohesive constructs. Objects were printed on a modified HYREL 3D printer utilizing Arduino Mega+RAMPS v1.4 electronics. An emulsifiable extruder (EMO-25) by HYREL with a 22 gauge dispensing tip were used to deposit the HIPE material. Four, 3 watt UV LEDs mounted to the extruder cure HIPE material as it is dispensed. Cylinders were printed to evaluate the ability to create high fidelity constructs and single lines of extruded material were examined with SEM to evaluate shape retention after extrusion.

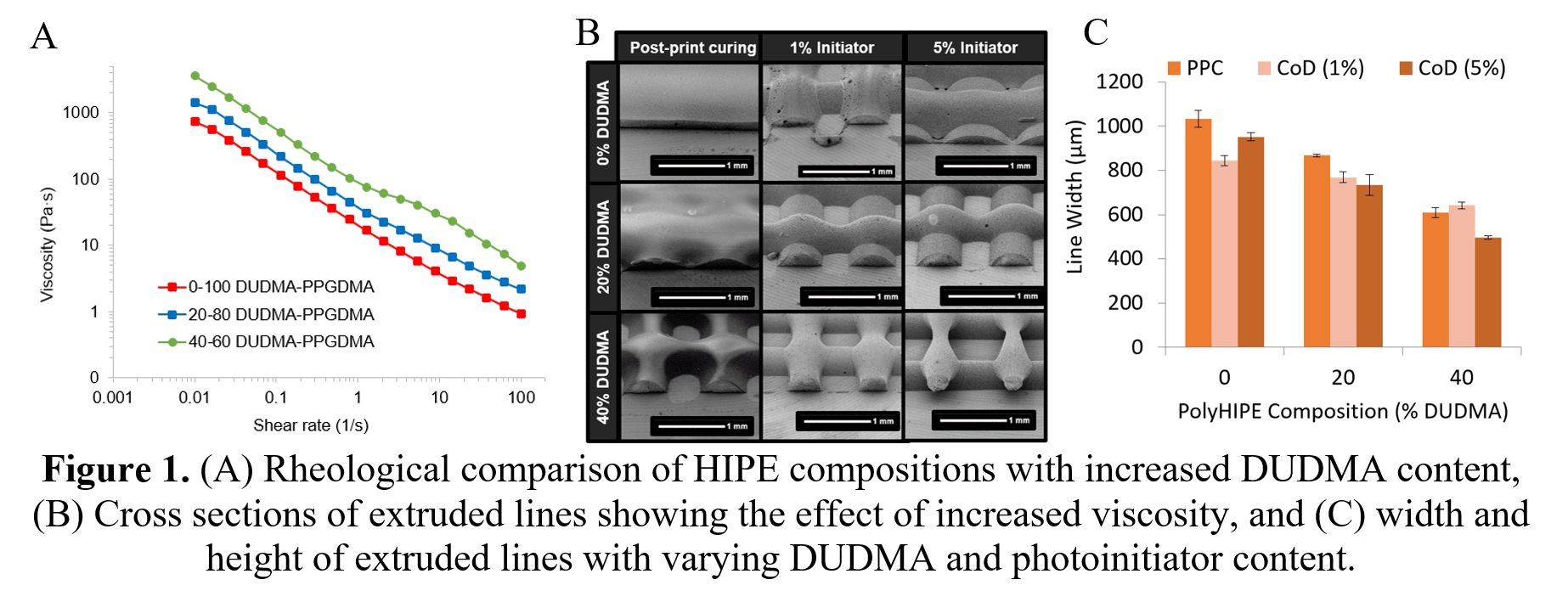

Results and Discussion: Uncured HIPEs exhibited low viscosity at typical printing shear rates, (10 Pa*s at 50 1/s), allowing for precise dispensing. Increasing the viscous component, DUDMA, increased the viscosity of the macromer phase, resulting in increased emulsion zero-shear viscosity, (up to 3500 Pa*s at 0.01 1/s) while retaining shear-thinning characteristics, Figure 1 (A). Increased viscosity decreased printed line slumping and improved print fidelity (B). Cure-on-dispense printing increased print fidelity relative to post-print curing, but increasing photoinitiator to 5% showed a smaller decrease in line spreading and increase in shape retention (C). HIPEs with sufficient viscosity produced tall, complex scaffolds with an internal lattice structure and hierarchical porosity, Figure 2.

Conclusion: These findings indicate that the viscosity of emulsion inks and cure rate play important roles in print fidelity. Overall, the demonstrated ability to print porous materials using emulsion inks and CoD technology advance current additive manufacturing efforts to generate custom porous materials for tissue engineering and drug delivery applications.

References:

[1] Moglia, R.S., et al., Injectable polyHIPEs as high-porosity bone grafts. Biomacromolecules, 2011. 12(10): p. 3621-3628.