Introduction: Two-photon polymerization (2PP) of natural polymers to mimic the extracellular matrix (ECM) has gained increasing interest over the years[1]-[4]. However, often resolution losses and swelling related deformations limit CAD reproducibility. In the present work, gelatin hydrogels were developed with additional crosslinkable functionalities to overcome these issues. To this end, both the primary amines and carboxylic acids in gelatin were modified with crosslinkable groups.

Materials and Methods: The primary gelatin B amines were reacted with methacrylic anhydride (2.5 eq) in phosphate buffer (10 w/v%, pH 7.8) yielding Gel-MOD (GM) with 97% substitution (DS). Next, the carboxylic acids were reacted with amino-ethylmethacrylate (AEMA, 2eq) using EDC/NHS coupling in DMSO (50°C) yielding gel-MOD-AEMA (GMA) with 48% DS. Characterization occurred via differential scanning calorimetry (DSC), gel-fraction, swelling, rheology and enzymatic degradation (collagenase) using GM as reference. Biocompatibility was assessed via live/dead staining and metabolic activity assays using HUVEC cells. Crosslinked films were obtained via film casting of gelatin solutions containing 2mol% Irgacure 2959 followed by 30 min UV crosslinking (365nm). 2PP was performed (800nm) on solutions (5-15wt%) containing 1 mmolar P2CK[5] photoinitiator. Microstructures were analyzed using laser scanning microscopy (LSM).

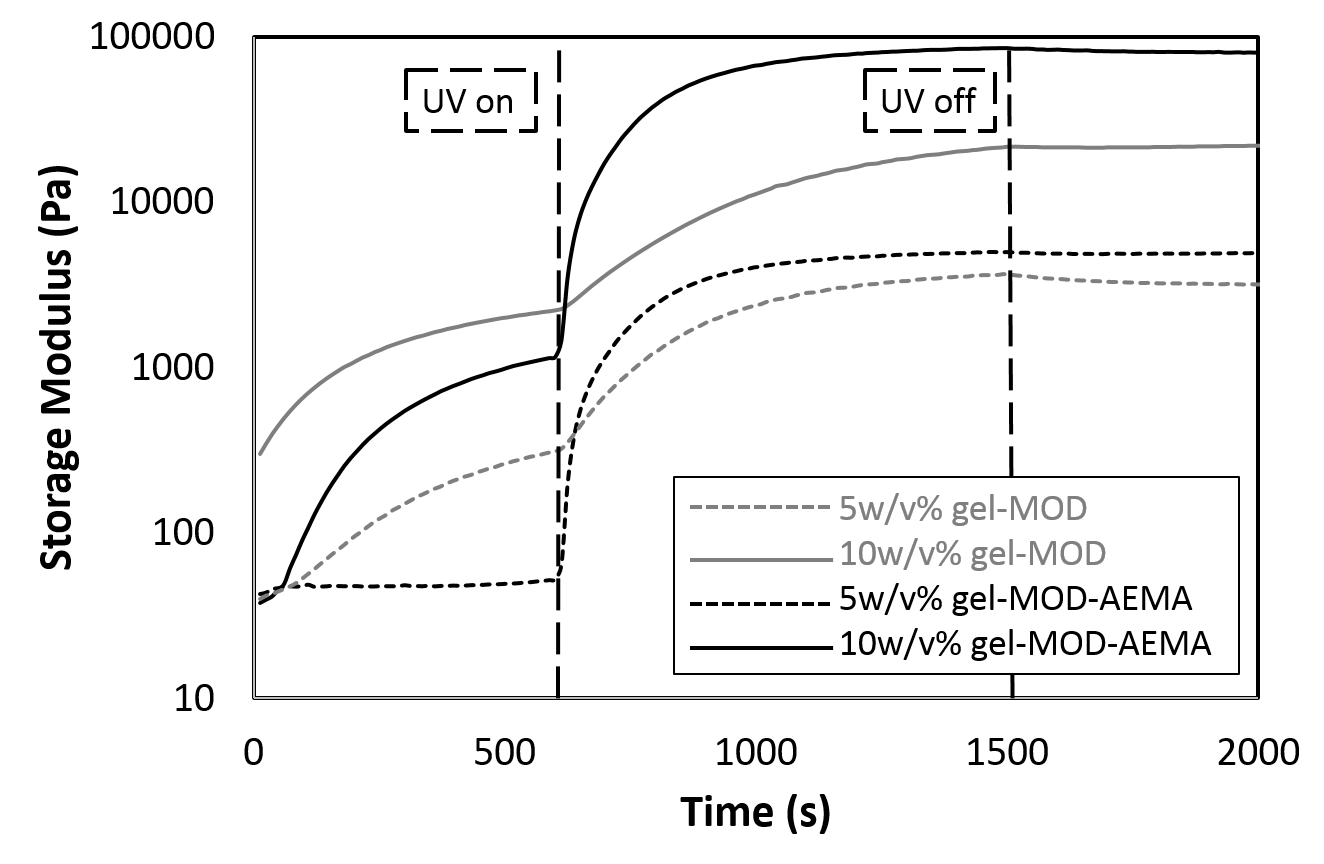

Results and Discussion: In contrast to GM, the GMA hydrogel precursor remains soluble at room temperature (RT). DSC indicated a reduction in the phase transfer energy for increasing gelatin modification. Rheological monitoring of UV-crosslinking indicated that (10w/v%) GMA reached higher storage moduli and faster crosslinking kinetics than GM. (see Figure 1).

Figure 1: Rheological monitoring of the photo-crosslinking reaction.

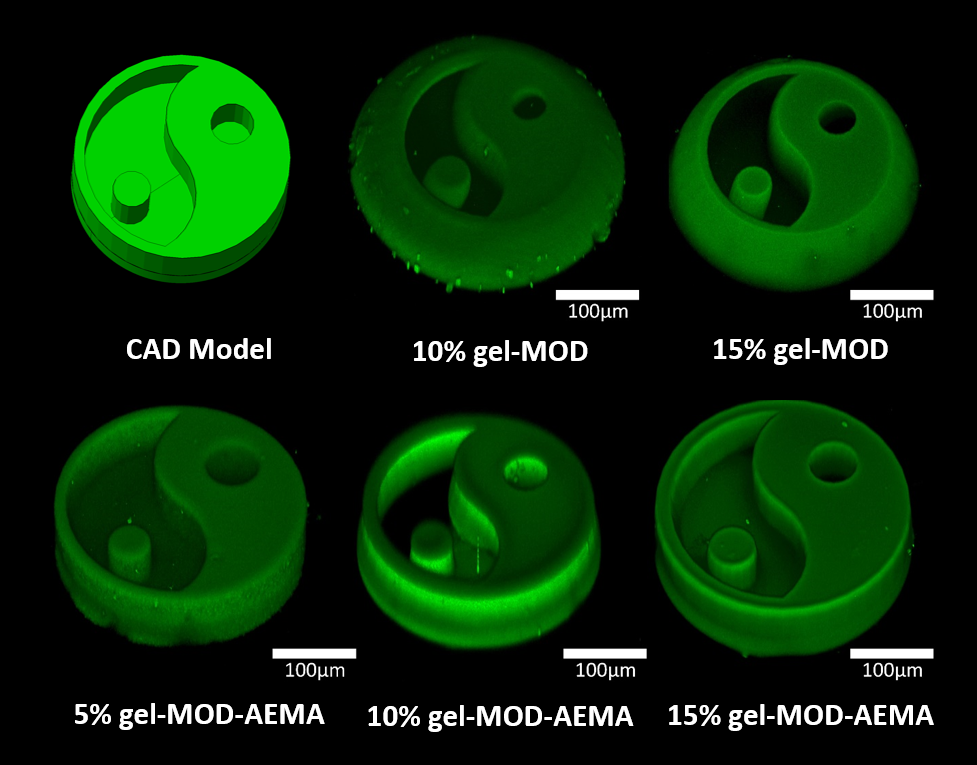

Moreover, (10w/v%) GMA is characterized by a lower water uptake capacity in comparison to GM (370% vs 590%) because of a denser crosslinked network. This was also assessed volumetrically on the 2PP microstructures: GMA exhibits no post processing swelling, whereas GM structures swell up to 90% in volume. Consequently, GMA enables better CAD model mimicry after development. (see Figure 2) Further, in contrast to GM, GMA can be processed at lower concentrations (<10wt%) via 2PP. Moreover, GMA remains fully degradable and preliminary assays indicate that it retains its cytocompatible character.

Figure 2: Processing range and swelling behaviour of gel-MOD and gel-MOD-AEMA.

Conclusion: Incorporating additional crosslinkable functionalities via carboxylic acid modification in GM provides an excellent method to increase structural integrity of gelatin hydrogels. This does not only result in a lower concentration processable by 2PP in comparison to GM (<10wt%), but also to better CAD model replication. Furthermore, preliminary biocompatibility tests indicate that the additional modification does not substantially preclude biocompatibility. Therefore, the proposed strategy is promising towards 2PP assisted ECM mimicry and could result in the ideal, structurally and mechanically tailored hydrogel scaffold for soft tissue engineering[2].

The authors would like to acknowledge the FWO Flanders and the European Research Council (Starting Grant-307701, A.O.) for financial support.

References:

[1] Qin, X.-H., Ovsianikov, A., Stampfl, J. & Liska, R. Additive manufacturing of photosensitive hydrogels for tissue engineering applications. BioNanoMaterials 15, 49–70 (2014).

[2] Ovsianikov, A. et al. Laser Fabrication of Three-Dimensional CAD Scaffolds from Photosensitive Gelatin for Applications in Tissue Engineering. Biomacromolecules 12, 851–858 (2011).

[3] Ovsianikov, A. et al. Laser Fabrication of 3D Gelatin Scaffolds for the Generation of Bioartificial Tissues. Materials (Basel). 4, 288–299 (2011).

[4] Ciuciu, A. I. & Cywiński, P. J. Two-photon polymerization of hydrogels – versatile solutions to fabricate well-defined 3D structures. RSC Adv. 4, 45504–45516 (2014).

[5] Li, Z. et al. Initiation efficiency and cytotoxicity of novel water-soluble two-photon photoinitiators for direct 3D microfabrication of hydrogels supporting info. RSC Adv. 3, 15939 (2013).