Introduction: The unique advantage of surface modification is that the surface properties can be selectively improved while the bulk properties of the materials are maintained. The attachment strategy based on polydopamine coating has attracted much attention in the modification of biomedical devices due to its outstanding subatrate- and shape-independent properties. Thus, dopamine and hexamethylendiamine (HD) are used to synthesize an amine-rich, biocompatibility copolymer (PDAM/HD), providing platform for further desirable modification. In this work, target molecules such as heparin (Hep), disulfide (3,3-disulfodipropionic acid, S-S) and diselenide (3,3-diselenodipropionic acid, Se-Se) were conjugated onto PDAM/HD coating to obtain multifunctional coating.

Materials and Methods: The PDAM/HD coating was deposited by immersing substrate into dopamine and HD reaction solution. Then Heparin, S-S and Se-Se were conjugated onto PDAM/HD coating. The chemical structures were analyzed by FTIR, XPS and MALDI-TOF MS. The hemocompatibility, endothelial cell (EC) and smooth muscle cell (SMC), tissue response evaluations were performed as described[1]. The NO release catalyzed by S-S@PDAM/HD and Se-Se@PDAM/HD were tested via Griess method[2].

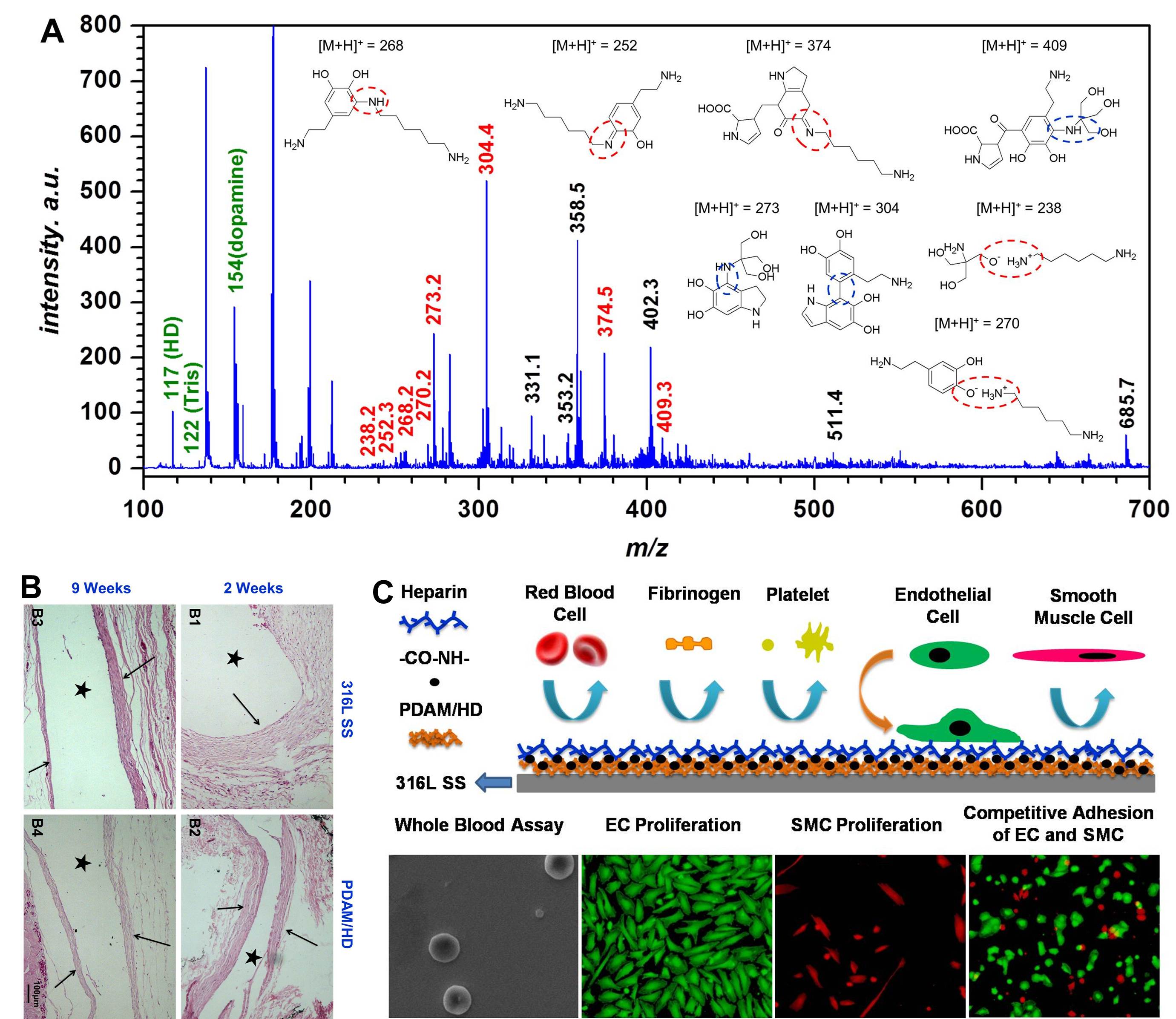

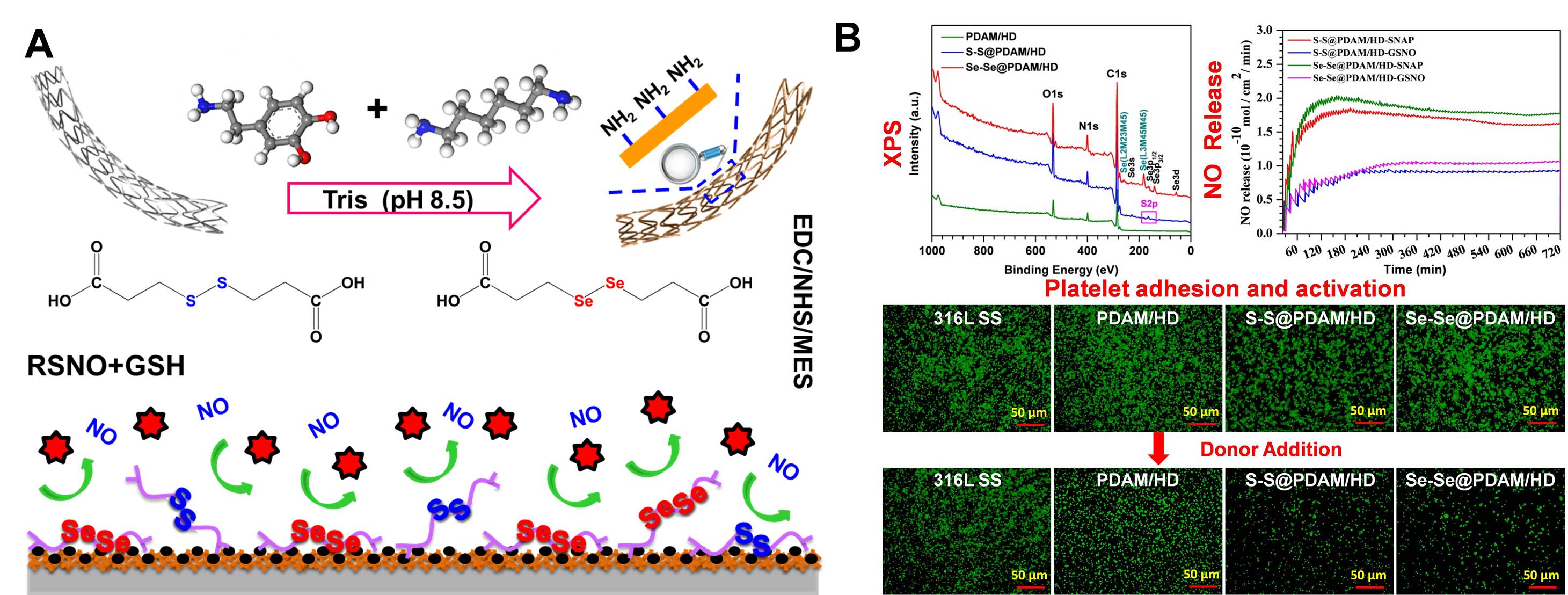

Results and Discussion: The PDAM/HD coating technology provided a feasible approach to prepare an amine-rich polymer coating. The possible polymerization mechanism was involved with oxidative polymerization with the formation of covalent bonding and physical self-assembly (Fig 1A). As shown in Fig 1B, it is included that the PDAM/HD coating showed acceptable and attenuated tissue response compared to 316L SS, with less granulation tissue and thinner fibrous capsule formation. This is a valuable characteristic for a functional coating used as surface modification of biomedical devices. To establish a multifunctional coating, heparin was immobilized on PDAM/HD coating. The Hep-PDAM/HD coating not only showed remarkable improvement in hemocompatibility but also considerable enhancement in EC proliferation, meanwhile substantial inhibition in SMCs migration and proliferation. Moreover, the coating provided a beneficial platform for competitive adhesion in ECs over SMCs. These results suggest the promising potential of the Hep-PDAM/HD coating to avoid vascular stent associated complications. NO-catalytic bioactive coatings were fabribated through covalent immobilization of Se-Se and S-S onto PDAM/HD coating. Both NO-catalytic coatings exhibited remarkable inhibition effects on platelet adhesion, aggregation and activation via cGMP signal pathway (Fig 2). These results suggest that the NO-catalytic coatings possess huge potential applications in blood-contacting devices.

Conclusion: Multifunctional coatings could be constructed via PDAM/HD coating. The PDAM/HD coating was rich in amine groups with accepted tissue response. By immobilization of heparin, S-S or Se-Se molecules, we could get the various basic requirements of the design of blood-contacting biomedical devices (eg. vascular stent), including excellent hemocompatibility, promotion of EC, suppresstion of SMC, acceptable tissue response, suggesting the potential platform for developing multifunctional coating for desirable surface modification of biomedical devices.

Figure 1. (A) MALDI-TOF MS spectrum of PDAM/HD coating. (B) HE staining for subcutaneous tissues. (C) The responses of whole blood, EC and SMC proliferation, competitive adhesion of EC and SMC on Hep-PDAM/HD coating.

Figure 2. (A) Schematic of NO catalytic coatings. (B) XPS wide scans, NO release amount and rate, representative images of P-selectin stained platelets of samples.

the National Natural Science Foundation of China Project 81271701, 51173149, 31270020 and 31300787; the Ministry of Science and Technology of China (Key Basic Research Project No. 2011CB606204); NSFC Key Program 81330031; the Science and Technology Innovation Project of Sichuan Province 2014-121; the Excellent Doctorial Dissertations Cultivation Project of Southwest Jiaotong University 2014-7

References:

[1] Yang Y, Qi P K, Wen F, et al. Mussel-Inspired One-step Adherent Coating Rich in Amine Groups for Covalent Immobilization of Heparin: Hemocompatibility, Growth Behaviors of Vascular Cells and Tissue Response. ACS applied materials & interfaces, 2014, 6: 14608-14620.

[2] Yang Z L, Yang Y, Xiong K Q, et al. Nitric oxide producing coating mimicking endothelium function for multifunctional vascular stents. Biomaterials, 2015, 63: 80-92.