- 1Section for Sustainable Biotechnology, Department of Biotechnology, Chemistry and Environmental Engineering, Aalborg University, Copenhagen, Denmark

- 2Technology Futures Institute, School of Science & Engineering, Teesside University, Tees Valley, UK

Rhamnolipids—Brief Outline

Biosurfactants, widely known as surface-active agents of biological origin, have carved a niche for themselves in the market due to their unique environment-friendly properties. They have come a long way since first biosurfactant “surfactin” was purified and characterized by Arima et al. (1968). Biosurfactants have been researched thoroughly and satisfactorily since then by many research groups across the world yet there are aspects that elude our understanding. There are five major categories of biosurfactants viz. glycolipids, phospholipids and fatty acids, lipopeptides and lipoproteins, polymeric biosurfactants and particulate biosurfactants that have found applications in agricultural, pharmaceutical, food, cosmetics, and detergent industries. Data reveals there are more than 250 patents obtained on these wonder biodegradable molecules so far (Shete et al., 2006; Rahman and Gakpe, 2008). It has also been observed that microbial biosurfactants are advantageous over plant-based surfactants because of the scale-up capacity, rapid production, and multi-functional properties. Several plant-based biosurfactants for example saponins, lecithins, and soy proteins have excellent emulsification properties but are expensive to produce at industrial scale and have other debatable issues such as solubility and hydrophobicity (Xu et al., 2011).

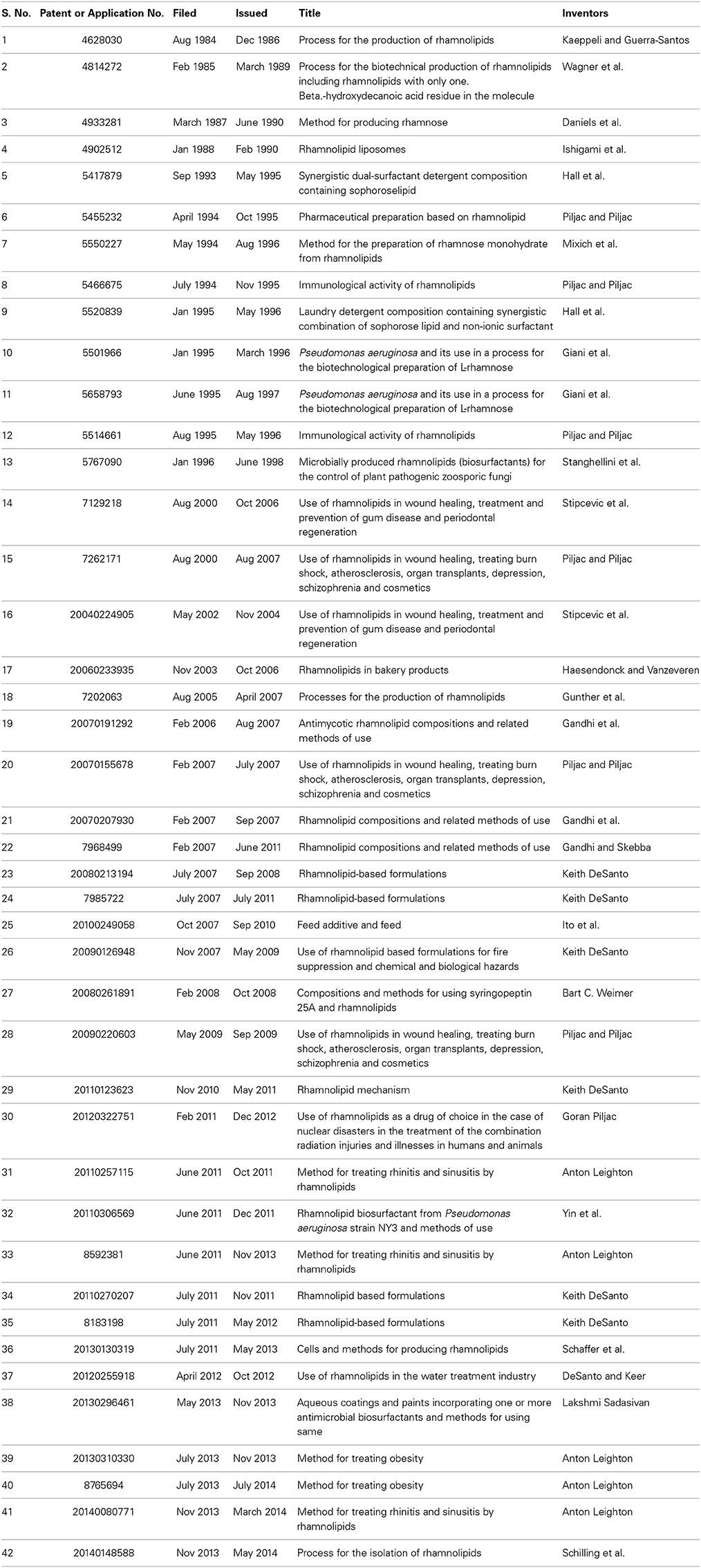

Among the various categories of biosurfactants the glycolipid biosurfactants “rhamnolipids” stand apart. Rhamnolipid, primarily a crystalline acid, is composed of β-hydroxy fatty acid connected by the carboxyl end to a rhamnose sugar molecule. Rhamnolipids are predominantly produced by Pseudomonas aeruginosa and classified as: mono and di-rhamnolipids. Other Pseudomonas species that have been reported to produce rhamnolipids are P. chlororaphis, P. plantarii, P. putida, and P. fluorescens. Some bacteria are known to produce only mono-rhamnolipids while some produce both. The ratio of mono and di-rhamnolipid can also be controlled in the production method. There are enzymes available that can convert mono-rhamnolipids into di-rhamnolipids. In 1984, the first patent for the production of rhamnolipids was filed by Kaeppeli and Guerra-Santos (US 4628030) and obtained in 1986 for their work on Pseudomonas aeruginosa DSM 2659 (Kaeppeli and Guerra-Santos, 1986). Subsequently, Wagner et al. filed a patent (US 4814272) in 1985 for the biotechnical production of rhamnolipids from Pseudomonas sp. DSM 2874 and obtained the same in 1989 (Wagner et al., 1989). In the past close to three decades, there has been a great body of research work carried on rhamnolipids revealing many of their astonishing applications and making them reach the pinnacle of popularity among all the categories of biosurfactants in the global market. The reason behind the current global interest in rhamnolipid production owes to their broad range of applications in various industries along with many spectacular “eco-friendly” properties.

The current critique articulates to present opinion on rhamnolipid research and is an attempt to retrospect what brings rhamnolipids in the forefront. This article is a bird's-eye view on a timeline of rhamnolipids story so far and also a critical analysis on why despite so many patents and research work rhamnolipids still do not rule the global biosurfactant market.

Inimitable Applications of Rhamnolipids

Over the years rhamnolipids are becoming broadly pertinent in various industries and are posing a serious threat to the synthetic surfactants. Before venturing into the current production economics of rhamnolipids it is imperative to evaluate the major applications of rhamnolipids that make them noticeable among other biosurfactants. A list of five major applications of rhamnolipids that cater to the wide range of industrial demands includes:

(1) Bioremediation and enhanced oil recovery (EOR): Rhamnolipids show excellent emulsification properties, efficiently remove crude oil from contaminated soil and facilitate bioremediation of oil spills (Rahman et al., 2003; Costa et al., 2010).

(2) Pharmaceuticals and therapeutics: Rhamnolipids show low toxicity, surface active properties and antimicrobial activities against several microbes (Bacillus cereus, Micrococcus luteus, Staphylococcus aureus, Listeria monocytogenes) thereby showing promising applications in pharmaceuticals and therapeutics (Magalhaes and Nitschke, 2013).

(3) Cosmetics: Rhamnolipid as an active ingredient is found to be effective for several skin treatments i.e., wound healing with reduced fibrosis, cure of burn shock, treatment of wrinkles hence are in demand in the health and beauty industry (Piljac and Piljac, 2007).

(4) Detergents and cleaners: Rhamnolipids are natural emulsifiers and surface active agents leading to their wide spread usage in detergent compositions, laundry products, shampoos and soaps (Parry et al., 2013).

(5) Agriculture: Rhamnolipids are already used for soil remediation for improving soil quality and are now further getting explored for plant pathogen elimination, for aiding the absorption of fertilizers and nutrients through roots and as biopesticides (Sachdev and Cameotra, 2013).

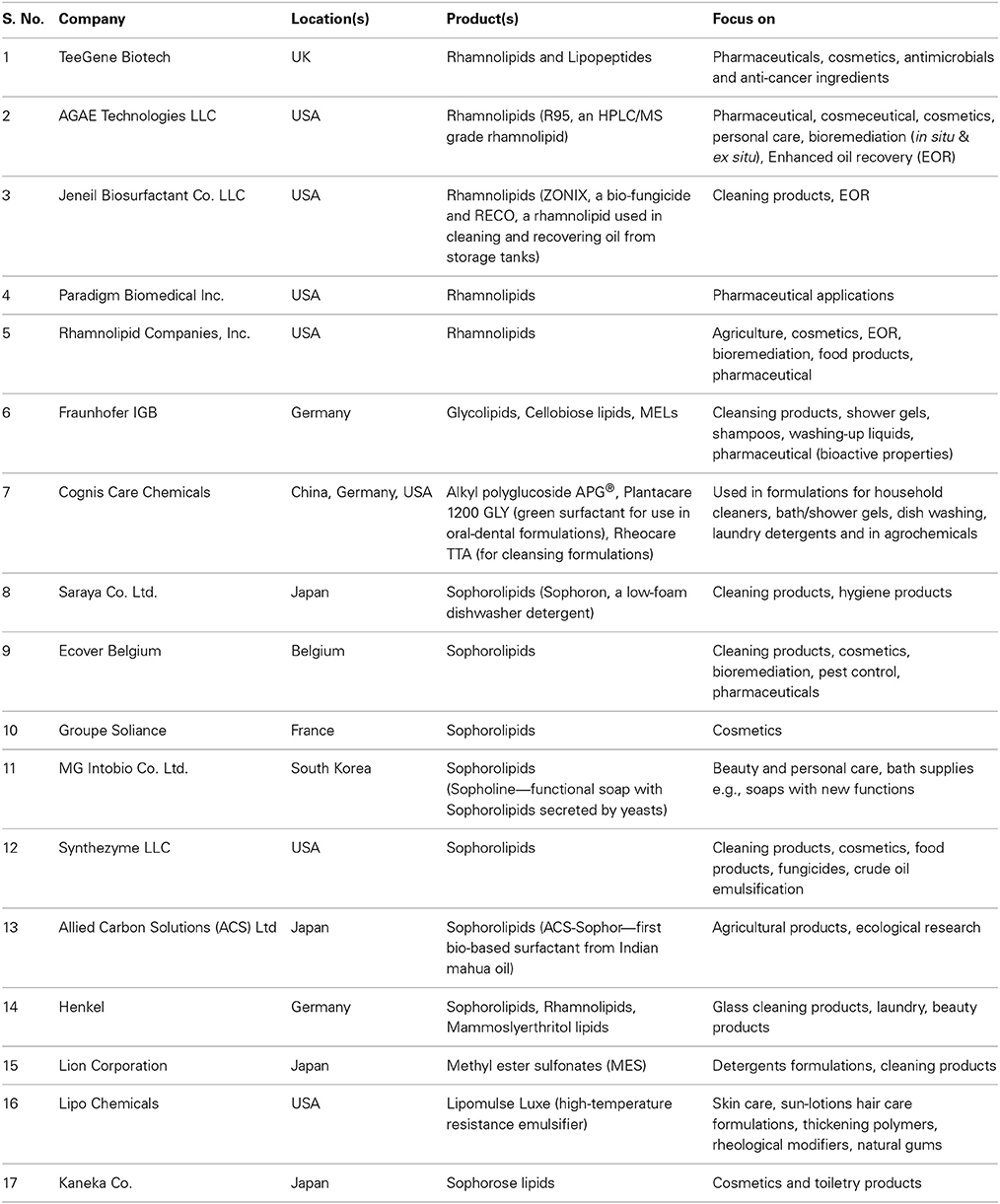

Biosurfactant Producing Companies—with Focus on Rhamnolipids

Rhamnolipids are highly applicable in various activities with some researchers advancing the technology from laboratory to higher scale. However, there still are very limited companies in the field which are producing biosurfactants at a marketable scale. We tried to compile a list of biosurfactant producing companies around the globe (Table 1). The compilation evidently defines which biosurfactants are mostly researched and produced at higher scale.

Availability of Feedstock and its Impact on Biosurfactants

Biodiesel is produced by the trans-esterification of vegetable oils and fats with methanol in the presence of a catalyst. Glycerol is received as a by-product from this reaction. The production of 1 ton biodiesel generates about 100 kg of glycerol. Hence, the European biodiesel industry might release about 600 Kiloton glycerol per year with an increasing tendency in Europe and worldwide. Oversupply of glycerol, essentially due to increasing biodiesel production, leads to decreasing prices and weak markets.

The price of pure glycerol varied from $0.50 to $1.50/lb and crude glycerol from $0.04/kg to $0.33/kg over the past few years. The price of glycerol in the market will continue to drop in such an over saturated market. Currently, the main supply of glycerol coming into the market is from the rapidly growing biodiesel industry. Estimated production of glycerol would reach 5.8 billion pounds in 2020. This is due to demand of biodiesel that is projected at 8 billion gallons in 2020 (Ayoub and Abdullah, 2012). Hence new outlets for glycerol are urgently needed, particularly in the case of crude glycerol released by the biodiesel processes. As glycerol is a nontoxic, edible, biodegradable compound, it will provide important environmental benefits to the new platform products.

In case of biosurfactant production, dramatically rising in biodegradable, non-toxic and eco-friendly alternative for chemical surfactants and the re-discovered opportunity of biosurfactants that gave rise to invention and investment ahead of the typical rigors of techno-economic modeling for the use of glycerol as a feed stock, leading typically to unmet expectations. Bacteria produce biosurfactants if grown on carbon sources such as glucose, glycerol, and various vegetable oils. Our research on biosurfactant production by bacteria indicates that glycerol can be used efficiently for biosurfactant production (Rahman et al., 2002).

The considerable interest in biosurfactants in the recent years is also due to their low toxicity, biodegradable nature and specificity, which would be very suitable to meet the European Surfactant Directive. Regulation EC No.: 648/2004 requires clear and precise description of the biodegradability of the surfactant and test methods to give assurance of its aerobic biodegradability. This regulation establishes rules designed to achieve the free movement of detergents and surfactants for detergents in the internal market while, at the same time, ensuring a high degree of protection of the environment and human health.

Surfactants constitute an important class of industrial chemicals and are widely used in almost every sector of modern industry. Most of the commercially available surfactants are chemical surfactants mainly, petroleum-derived. However, rapid advances in biotechnology and increased environmental awareness among consumers combined with expected new environmental legislation has provided further impetus for serious consideration of biological surfactants as possible alternatives to existing products.

Biosurfactant's Economic Feasibility—What it Takes to Become a Market Leader?

As described in the previous section, there is enormous awareness among the consumers these days with regard to sustainability and global warming. The demand for bio-based technologies is ever increasing and “green solutions” are sought for every process. Rhamnolipids have promising properties and fulfill the eco-friendly criteria, one of the main drivers, but are still struggling to become market leaders. The economics of production is a major bottleneck in the outburst of commercialization of rhamnolipids and other biosurfactants (Table 2). There is still no downstream technology economical and convincing enough to recover and purify rhamnolipids at industrial scale. In case of biosurfactant production the downstream processing accounts for 70–80% of the entire production costs.

Table 2. Cost of biosurfactant per liter of solution (diluted and the CMC based cost calculation carried out by Connolly et al., 2010).

It is a no-brainer that in order to gain higher profit at commercial scale it requires access to very cheap feedstock. There are some other key parameters that need thorough consideration in order to make any product economically feasible. Technological fit and process optimization are among the main drivers. Fermentation time is another key to success. Fermentation performance and scale impact process economy as it is directly related to the yield, titer, and productivity. High cost of production especially because of the expensive substrates and down-stream processes makes it difficult to bring down the price of these environment friendly biomolecules. In order to compete with the synthetic detergents or surfactants the cost of production must be brought down to £1.70 per liter which is in itself a challenging task. As there are many barriers in the commercialization of biosurfactants, there seems no dearth of opportunities in this field. Cost comparison of various technologies viz. enzymatic, continuous, shake flask, batch, and fed-batch used for biosurfactant production pinpoint the requirement of innovative methods wherein rhamnolipids can be produced in static conditions to reduce the fermentation cost. The operating costs can be brought down by robust wild-type strains or recombinant mutant strains. Testing the possibility of co-products and/or enzymes is another attractive solution to surge the net profit—for example: esterases released during the production of lipopeptides by Bacillus strain and its recombinants (Sekhon et al., 2011, 2012). Co-products and by-products are value drivers and increase the economic viability of any business. The search of cheap and easily accessible raw material or substrate for biosurfactants production has been going on for years. The utilization of by-products, even if from a different process could be another smart solution—for example: glycerol, which is a by-product of biodiesel production, is available in surplus amount in the global market (Albarelli et al., 2011) which might be a cheap alternative for biosurfactant production.

Rhamnolipids are well-characterized and scientifically proven biosurfactants which are slowly and steadily becoming highly sought after biomolecules. Among other biosurfactants rhamnolipids have the highest number of patents (Table 3) and research publications. However, cost-competitiveness is one of the major factors that is holding rhamnolipids back from becoming the champions of their field. Research needs to be focused on suitable vigorous production strains, cheap substrates and nominal bioreactor technology. The current market price of rhamnolipid (R-95, 95%) is $227/10 mg (Sigma-aldrich) and $200/10 mg (AGAE technologies, USA) calling for strenuous research. Rhamnolipids have favorable applications in various sectors and if made economically sustainable nothing can stop these biomolecules to rule the surface-active compounds market.

Concluding Remarks

As the Health and Safety in the bioprocessing become paramount for large scale production there are significant interests in the search for novel non-pathogenic rhamnolipid producers. The numbers of cultured organisms from the environmental samples are only a tiny fraction (0.001%) of the actual microbial diversity. There are significant number of microbial isolates that needs to be explored and exploited for rhamnolipid and other bioproduct manufacturing. Biosurfactant producing probiotic organisms will play a key role in the future of biosurfactant market. Edible emulsifiers from these processes would be applicable to many applications including food, cosmetic, environmental clean-up, biomedical and natural therapy. Rhamnolipid could be a potential alternative for the synthetic surfactant molecules and an important platform chemical cluster with the market value of $2.8 billion in 2023 (Grand View Research Inc., 2014). There is a significant need for the discovery of novel non-pathogenic rhamnolipid producers with enhanced production capacity and efforts to scale up through bioprocess engineering are important to meet the future predictions of biosurfactants market.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Albarelli, J. Q., Santos, D. T., and Holanda, M. R. (2011). Energetic and economic evaluation of waste glycerol cogeneration in Brazil. Braz. J. Chem. Eng. 28, 691–698. doi: 10.1590/S0104-66322011000400014

Arima, K., Kakinuma, A., and Tamura, G. (1968). Surfactin, a crystalline peptide-lipid surfactant produced by Bacillus subtilis: isolation, characterization and its inhibition of fibrin clot formation. Biochem. Biophys. Res. Commun. 31, 488–494. doi: 10.1016/0006-291X(68)90503-2

Ayoub, M., and Abdullah, A. Z. (2012). Critical review on the current scenario and significance of crude glycerol resulting from biodiesel industry towards more sustainable renewable energy industry. Renew. Sust. Energ. Rev. 16, 2671–2686. doi: 10.1016/j.rser.2012.01.054

Connolly, H. E., Rahman, P. K. S. M., Banat, I. M., and Lord, R. A. (2010). “Resource recovery and reduction of oily hazardous wastes via biosurfactant washing and bioremediation,” in Trends in Bioremediation and Phytoremediation, ed P. Grazyna (Trivandrum, India: Research Signpost), 157–172.

Costa, S. G. V. A. O., Nitschke, M., Lepine, F., Deziel, E., and Contiero, J. (2010). Structure, properties and applications of rhamnolipids produced by Pseudomonas aeruginosa L2-1 from cassava wastewater. Process Biochem. 45, 1511–1516. doi: 10.1016/j.procbio.2010.05.033

Grand View Research Inc. (2014). Biosurfactants Market by Product (Market Research Report Code: GVR20). Available online at: http://www.grandviewresearch.com/industry-analysis/biosurfactants-industry

Kaeppeli, O., and Guerra-Santos, L. (1986). Process for the Production of Rhamnolipids. Patent no. US 4628030 A.

Magalhaes, L., and Nitschke, M. (2013). Antimicrobial activity of rhamnolipids against Listeria monocytogenes and their synergistic interaction with nisin. Food Control. 29, 138–142. doi: 10.1016/j.foodcont.2012.06.009

Parry, A. J., Parry, N. J., Peilow, C., and Stevenson, P. S. (2013). Combinations of Rhamnolipids and Enzymes for Improved Cleaning. Patent no. EP 2596087 A1.

Rahman, K. S. M., Rahman, T. J., Kourkoutas, Y., Petsas, I., Marchant, R., and Banat, I. M. (2003). Enhanced bioremediation of n-alkane in petroleum sludge using bacterial consortium amended with rhamnolipid and micronutrients. Bioresour. Technol. 90, 159–168. doi: 10.1016/S0960-8524(03)00114-7

Rahman, K. S. M., Rahman, T. J., McClean, S., Marchant, R., and Banat, I. M. (2002). Rhamnolipid biosurfactant production by strains of Pseudomonas aeruginosa using low-cost raw materials. Biotechnol. Progr. 18, 1277–1281. doi: 10.1021/bp020071x

Rahman, P. K. S. M., and Gakpe, E. (2008). Production, characterization and applications of biosurfactants—review. Biotechnology 7, 360–370. doi: 10.3923/biotech.2008.360.370

Sachdev, D. P., and Cameotra, S. S. (2013). Biosurfactants in agriculture. Appl. Microbiol. Biotechnol. 97, 1005–1016. doi: 10.1007/s00253-012-4641-8

Sekhon, K. K., Khanna, S., and Cameotra, S. S. (2011). Enhanced biosurfactant production through cloning of three genes and role of esterase in biosurfactant release. Microb. Cell. Fact. 10:49. doi: 10.1186/1475-2859-10-49

Sekhon, K. K., Khanna, S., and Cameotra, S. S. (2012). Biosurfactant production and potential correlation with esterase activity. J. Pet. Environ. Biotechnol. 3:133. doi: 10.4172/2157-7463.1000133

Shete, A. M., Wadhawa, G., Banat, I. M., and Chopade, B. A. (2006). Mapping of patents on bioemulsifier and biosurfactant: a review. J. Sci. Ind. Res. 65, 91–115. doi: 10.4172/2157-7463.1000133

Wagner, F., Syldatk, C., Matulowic, U., Hofmann, H.-J., Sewe, K.-U., and Lindorfer, W. (1989). Process for the Biotechnical Production of Rhamnolipids Including Rhamnolipids with only one β-Hydroxydecanoic Acid Residue in the Molecule. US Patent number: 4814272.

Keywords: biosurfactants, rhamnolipids, market Access, surfactants, sustainability

Citation: Sekhon Randhawa KK and Rahman PKSM (2014) Rhamnolipid biosurfactants—past, present, and future scenario of global market. Front. Microbiol. 5:454. doi: 10.3389/fmicb.2014.00454

Received: 23 June 2014; Accepted: 11 August 2014;

Published online: 02 September 2014.

Edited by:

Peter Neubauer, Technische Universität Berlin, GermanyReviewed by:

Johannes Scholten, Microbiology, USAMartin Siemann-Herzberg, University Stuttgart, Germany

Copyright © 2014 Sekhon Randhawa and Rahman. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) or licensor are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: kamalsekhon80@yahoo.com; p.rahman@tees.ac.uk

Kamaljeet K. Sekhon Randhawa

Kamaljeet K. Sekhon Randhawa Pattanathu K. S. M. Rahman

Pattanathu K. S. M. Rahman