Introduction: Tissue engineering approaches provide crucial exogenous support for tissue regeneration and reparative processes, particularly for the maintenance of tissue integrity during restoration of the damaged or lost one .These endeavors have to overcome varied challenges especially to mimic target tissue micro-environment with bio-compatible construct. In this juncture, alginate has been used due to its good biocompatibility and mechanical strength[1]. Foremost challenge remains in controlling fast degradation of membranes under in vitro and in vivo conditions due to lack of proper stability coming from disoriented entanglement of fibers. Present study focuses on the aforesaid optimization, thorough physical & chemical characterization of the membranes and subsequent application on acute wound animal model to check therapeutic efficacy[2].

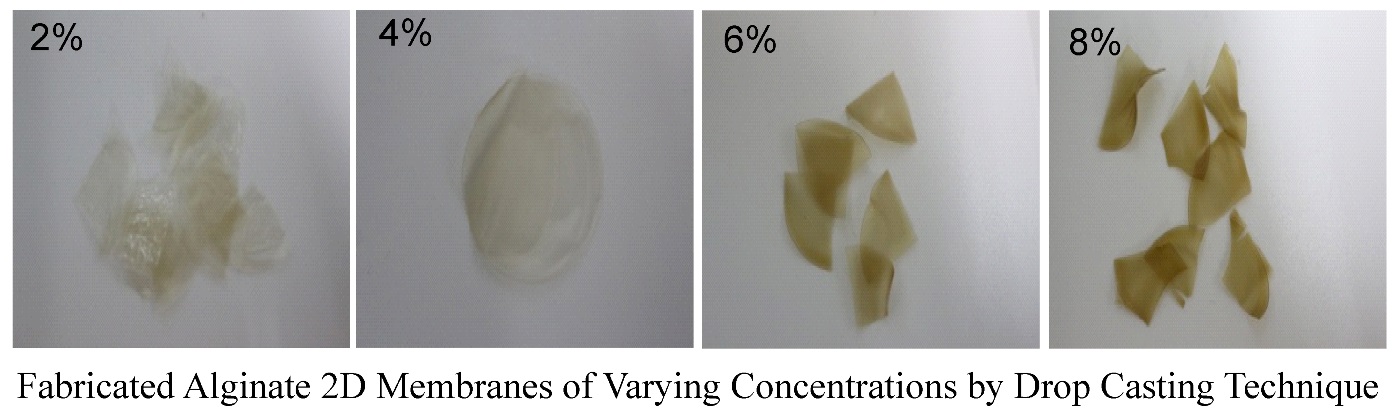

Materials and Method: In this study, alginate 2D membranes of 2, 4, 6 and 8% concentrations were fabricated by drop casting technique.

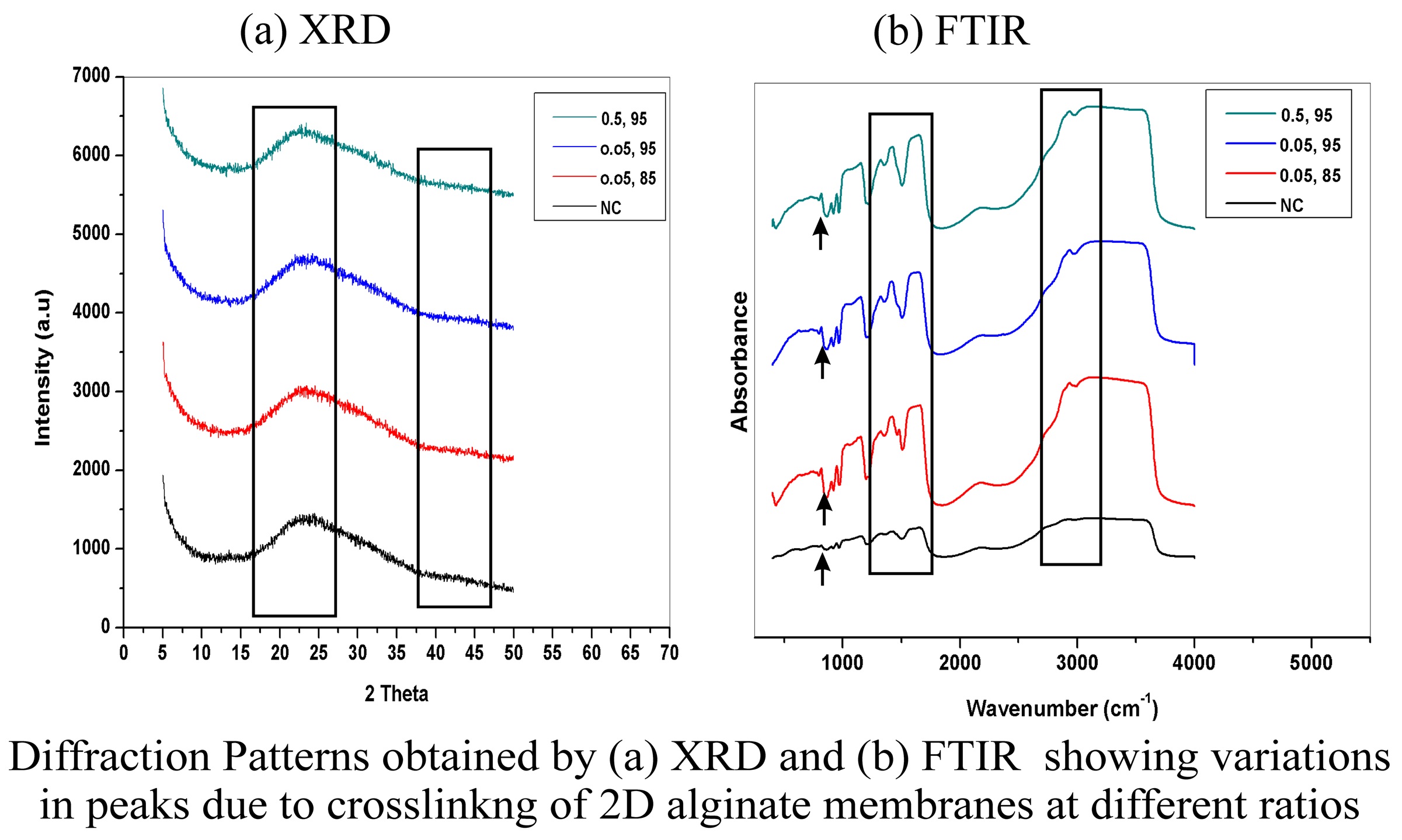

The membranes were optimized by different ratios of Carbodiimide crosslinker and ethanol concentrations. Fabricated membranes were further characterized physicochemically for surface topography, mechanical strength, degradation, swelling behavior and chemical integrity by SEM, Utensile Testing Machine (UTM), FTIR and XRD, respectively[3]. MTT assay was carried out for 7 days to assess the biological activity of cells on optimized membranes[4].

Results and Discussion: The present study illustrates 4% alginate concentration to be with sufficient amount of molecular entanglement contributing to sublime stability after being crosslinked with a mixture of 85% ethanol and 0.05mM carbodiimide which was optimized by trying with varied concentrations by FTIR and XRD.

Optimized membrane demonstrated enhanced tensile strength, swelling behavior and slow biodegradability rate with graduation of time. In comparison to other concentrations, 4% showed good biocompatibility on optimized membranes along with improved proliferation rate of cells at all considered time points.

Conclusion: The crosslinked 2D alginate membrane with enhanced physical, chemical and biological properties ensures their future application as a suitable external bioscaffold in regenerative medicine and tissue engineering field.

Non-Invasive Characterization Of Healing And Non-Healing Wounds And Development Of Honey-Biomaterial And Stem Cell Based Wound Therapy (NIC), Indian Institute Of Technology, Kharagpur, West Bengal

References:

[1] Barui A, Banerjee P, KumarDas R, Dhara S, Chatterjee J. Honey based fibrous scaffold for tissue engineering application. Life Science Systems and Applications Workshop (LiSSA), 2011 IEEE/NIH: IEEE; 2011. p. 83-5

[2] Lee KY, Mooney DJ. Alginate: properties and biomedical applications. Progress in polymer science 2012;37:106-26

[3] N. Bhattarai, Z. Li, D. Edmondson, M. ZhangAlginate-based nanofibrous scaffolds: structural, mechanical, and biological properties Adv. Mater., 18 (2006), pp. 1463–1467

[4] G. Skjåk-Braek Alginates: biosynthesis and some structure–function relationships relevant to biomedical and biotechnological applications Biochem. Soc. Trans., 20 (1992), pp. 27–33