Introduction: Silk fibroin (SF) and konjac glucomannan (KGM) are natural polymers considered promising in bioengineering field due to their characteristics of low toxicity, biocompatibility and biodegradability.

SF is a structural protein, which consists of heavy and light chains. It can present three main types of secondary structure conformations: α-helix and random coil (silk I) and β-sheets (silk II). The silk transaction, silk I to silk II, may be accomplished by physical (high temperatures) and chemical treatments (organic solvents).

KGM is a natural polysaccharide composed of the monomers D-mannose and D-glucose. It is a hydrophilic molecule, but its solubility in water is a function of the degree of acetylation of the polymer and physical process.

The aim of this study was to evaluate the combination of SF and KGM to improve the mechanical properties and cell viability in spherical scaffolds.

Materials and Methods: Silk fibroin solution (2.5%) was produced by the method proposed by Nogueira et al[1]. KGM (Konjac Foods, China) solution (1%) was prepared in calcium hydroxide (1.5 mM) in ultra-pure water. The proportions of the SF/KGM blends were 75:25, 50:50 and 75:25 (v/v). These solutions were dropped into liquid nitrogen to form the spheres, followed by freeze-drying. As a post treatment, the dried spheres were immersed in ethanol 95% (v/v) and freeze-dried again.

The mechanical resistance of the spheres was assessed in a texture analyzer with 50 Kg load cell and the cell viability assay was performed by MTT reduction by the method proposed by Mosmann, T[2]. and lineage used was human keratinocyte HaCat.

Results and Discussion: The compressive strength of KGM/SF spheres (figure 1) shows that the blends of these polymers turn the material more resistant than pristine ones. One hypothesis to explain this improvement is the occurrence of intermolecular interactions between natural polymers by hydrogen bonding, providing a more stable structure[3],[4].

The treatment with ethanol also presents improvement in the compression strength, because it aids in deacetylation process of KGM molecule, facilitating the hydrogen bond formation and hydrophobic interactions between their chains[5]. Regarding SF, the ethanol dehydrates its chains favoring hydrogen bonds, which results in change of conformation, silk I to silk II[6].

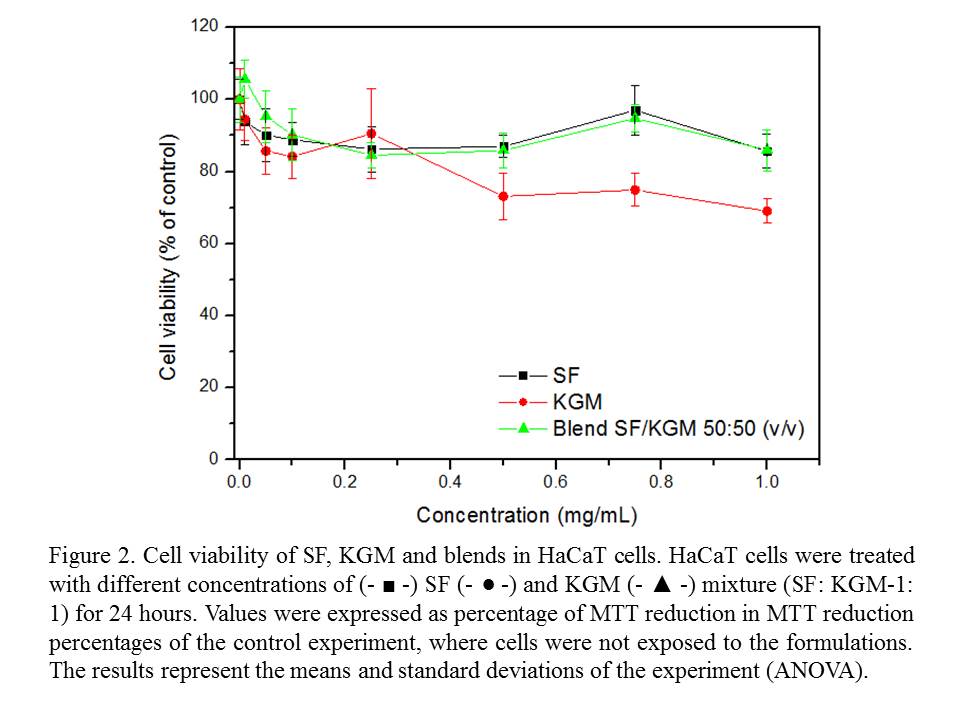

The pure polymer and the blend (figure 2) did not show cytotoxicity after 24 hours of incubation, whereas the decrease in viability was approximately 30%.

SF alone presented the best cell viability (97-85%) against KGM (94-69%). The blends showed cell viability very close to SF’s (105-85%). Cytotoxicity results showed all solutions are not toxic to cells.

Conclusion: This study demonstrated that the combination of SF and KGM can be promising for applications in tissue engineering as scaffolds. These blends spheres are more resistant to compression than the pure ones and presented a non-cytotoxic profile with cell viability above 85%.

Laboratory and Chemical Engineering Products (LEQUIP); National Counsel of Technological and Scientific Development (CNPq); São Paulo Research Foundation (FAPESP)

References:

[1] NOGUEIRA, G. M. et al. Preparation and characterization of ethanol-treated silk fibroin dense membranes for biomaterials application using waste silk fibers as raw material. Bioresource Technology, v. 101, n. 21, p. 8446-8451, 2010.

[2] MOSMANN, T. Rapid colorimetric assay for cellular growth and survival - Application to proliferation and cyto-toxicity assays. Journal of Immunological Methods, v. 65, n. 1-2, p. 55-63, 1983.

[3] LIANG, C. X.; HIRABAYASHI, K. Improvements of the physical-properties of fibroin membranes with sodium alginate. Journal of Applied Polymer Science, v. 45, n. 11, p. 1937-1943, 1992

[4] SHANG, S.; ZHU, L.; FAN, J. Intermolecular interactions between natural polysaccharides and silk fibroin protein. Carbohydrate Polymers, v. 93, n. 2, p. 561-573, 2013. LI, J. et al. Preparation and characterization of heterogeneous deacetylated konjac glucomannan. Food Hydrocolloids, v. 40, p. 9-15, 2014.

[5] LI, J. et al. Preparation and characterization of heterogeneous deacetylated konjac glucomannan. Food Hydrocolloids, v. 40, p. 9-15, 2014.

[6] PUTTHANARAT, S. et al. Effect of processing temperature on the morphology of silk membranes. Polymer, v. 43, n. 12, p. 3405-3413, 2002. Keywords: