Introduction: Dental resin composites represent an important family of biomaterials that have been evolving in response to the needs in biocompatibility and mechanical properties. These are composite materials consisting of mostly inorganic fillers and additives bound together with a polymer matrix. A large number of fillers have been studied, but much of the work remains proprietary in the industrial sector. This work examines the effect of different sizes of monodisperse silica particles on the mechanical and optical properties of the materials.

Materials and methods: Several sizes of silica particles were synthesized using the Stöber method, and were subsequently surface functionalized using γ-methacryloyl trimethoxysilane. Particles of 70, 100, 125, and 500 nm were tested in addition to polydisperse commercially available silica. The particles were characterized by dynamic light scattering and scanning electron microscopy. These particles were then combined with the commercial monomers bisphenol A glycerolate dimethacrylat0e (BisGMA) and triethyleneglycol dimethacrylate (TEGDMA) using a three roll mill to obtain the fully blended composite pastes. These were then photopolymerized using a dental lamp, and mechanical testing of the composites measured flexural strength using the three point bending geometry. Optical testing was performed by measuring the transmittance and reflectance of the samples. Finally, depth of cure was evaluated by measuring hardness of composite samples at different depths.

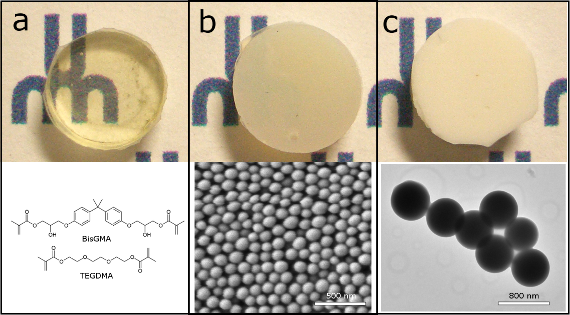

Results: The silica particles of different sizes were obtained by varying the amount of water, silicate, and basic catalyst, and were characterized using dynamic light scattering and scanning electron microscopy. Particles of different sizes produced composites of different viscosities such that the smallest particles could not reach the same filler loading as the largest, at 60% for the smallest, and 70% for the largest. The largest particles produced similar flexural strength at identical filler loading, but allowed more loading and therefore displayed superior mechanical properties. Hybrids of the larger and smaller silica particles allowed the highest filler loading, which produced the best mechanical properties, but at the cost of transparency (Figure 1).

Figure 1 - Composite disks 2 mm thick made from a) resin only 1:1 wt BisGMA:TEGDMA, with monomer structures b) 60 % filled with methacrylate functionalized 125 nm silica filler with SEM image of filler particles, and c) 70% filled with 500 nm methacrylate functionalized silica, with TEM image of filler particles.

Conclusion: The composites yielding the best mechanical properties were shown to be the 500 nm silica particles. These materials, however, had low transparency, which lead to lower depth of cure. The optical properties were most favorable with the smallest particles, showing materials that were almost fully transparent, and showed the greatest depth of cure. Therefore while the nanometer silica showed inferior mechanical properties, the impressive increase in depth of cure more than compensated for this decrease.

CHRP program funded by NSERC and CIHR (CHRPJ 385852-10)