Introduction: Hydrogels are widely used as ECM mimetic three dimensional (3D) matrices for cell encapsulation. They can also be designed to comply with 3D printing technologies, opening the possibility to create hierarchical tissue-like structures. The number of available printable hydrogels is however still limited[1]. Here we introduce a novel 3D printable hydrogel based on polyglycidols and hyaluronic acid, cross-linked via thiol-ene click chemistry. We present dispense plotting, cell loading into the gels and in vitro evaluation up to 21 days, and in vivo evaluation for biocompatibility in small and large animal models.

Materials and Methods: Thiol-functionalized hyaluronic acid (HA-SH) and Poly(glycidyl-co-allylglycidylether) (P(G-co-AGE)) were synthesized based on literature[2],[3] and characterized by NMR and GPC. For hydrogel formation both polymers were mixed with Irgacure 2959 in PBS buffer and cross-linked by UV irradiation at 365 nm. Gels were prepared with different polymer ratios and characterized regarding swelling, morphology (cryo-SEM) and mechanical properties. For cell loading, human mesenchymal stem cells (hMSCs) were added to the hydrogel solution directly before cross-linking. For 3D printing, the formulation was systematically optimized regarding rheological properties.

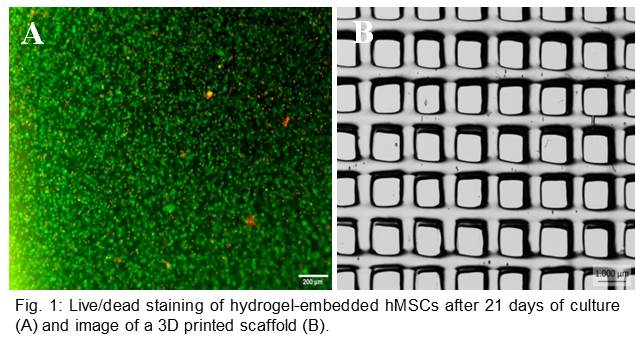

Results and Discussion: Thiol-ene cross-linking yielded uniform P(AGE-co-G) / HA-SH hydrogels that allowed for vital encapsulation of hMSCs with high cell survival after 21 d (Fig. 1a). Through optimization of rheological properties, hydrogel formulations could be obtained that exhibit very good printability with dispense plotting and homogeneous scaffolds with defined structures could be prepared (Fig. 1b). The gels (non-printed and printed) underwent biocompatibility screening in vivo in mice, minipigs and in horses, demonstrating good compatibility of the gels in all species.

Conclusion: We present a new hybrid hydrogel system based on thiol-functional hyaluronic acid and allyl-functional poly(glycidol)s, cross-linked through thiol-ene chemistry, allowing for vital encapsulation of hMSCs over at least 21 days, 3D printing via dispense plotting and exhibiting biocompatibility in different animal models. It thus presents a promising new bio-ink that is at the moment evaluated for more complex morphologies.

We thank the European Union (FP7) for funding under grant agreement no. 309962 (project HydroZONES).

References:

[1] J. Malda et al., Adv. Mater. 2013, 25, 5011-5028.

[2] X. Z. Shu et al., Biomacromolecules 2002, 3, 1304-1311.

[3] J. Groll et al., Journal of Polymer Science Part A: Polymer Chemistry 2009, 47, 5543.