Direct metal laser sintering (DMLS) for application in manufacture using prostheses of mandibular customized condyles coated with sub microstructured zirconia

-

1

State University of Campinas, Faculty of Chemical Engineering, Brazil

-

2

State University of Campinas, Department of Maxillofacial Surgery, Faculty of Piracicaba, Brazil

-

3

INCT/BIOFABRIS, Biofabrication, Brazil

-

4

State University of Campinas, Faculty of Economy, Brazil

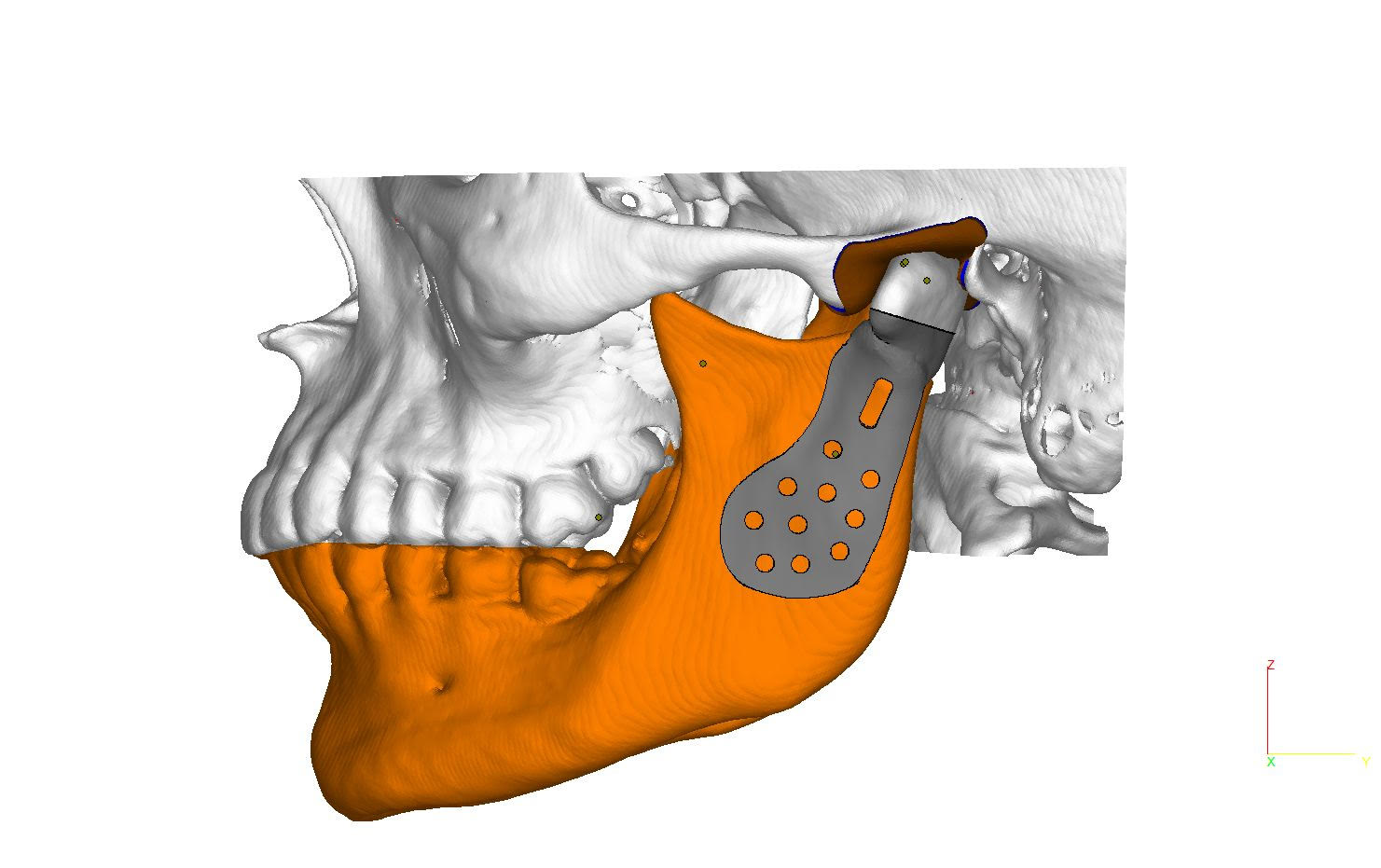

The aim of this study is present informations about Direct Metal Laser Sintering (DMLS) process and its application in manufacture using prostheses of mandibular customized condyles coated with sub microstructured zirconia which has as a result an improvement of the mechanical properties. Changes in the regions of the mandibular condyles may be related with fractures, ankylosis and disease. Usually the treatment used to restore this situations are conservative and consist in the repositioning of the condyle and when necessary the utilization of autogenous grafts, biomaterias and stabilizing with miniplates. When these procedures are not possible to large bone loss in regions of the condyles by different causes (fractures accidents, ankylosis and disease) it is necessary the reconstruction using prostheses of mandibular customized condyles. These areas are submitted to biomechanical efforts of high intensity of chewing forces and these prostheses must have high resistance to fracture in these areas. The Direct Metal Laser Sintering process consists in printing prostheses in 3D techniques with titanium powder in process. It is necessary acquisition of tomographic images (CONE BEAM) in DICOM files and its conversion to STL files using the InVesallius program and to model the bone defect is performed the reconstruction of 3D virtual images of condyle following mandibular symmetry when one of the mandibular condyles are in normal conditions or when required the reconstruction of images from the both sides. These images are used for the manufacture of customized condyle prostheses and titanium alloy used in this process is Ti-6Al-4V powder. The process of prostheses manufacture is to enter the equipment with titanium alloy powder and distribute this well in layers that are laser synthesized. After synthesis of all layers the prostheses are subjected to heat treatment for stress relief. The bioceramics of yttria zirconia exhibit superior resistance to fracture of alumina and greater biocompatibility with bone and soft tissue. This material (yttria zirconia) when submitted to the milling process present in its microstructure smaller particles (0,3μm) and results in an increase of their mechanical properties. The Direct Metal Laser Sintering for application in manufacture using prostheses of mandibular customized condyles coated with sub microstructured zirconia showed adequate results and the adaptation of the custom condyle prosthesis to original anatomical regions is very important to restore functional, physiological and aesthetic like original structures to the patient`s health but is very important the correct indication by surgical team and their surgical skills.

References:

[1] Roman K. Rahimi –Nedjat; Keyvan Sagheb; Christian Valter. Concomitant Dental Injures in Maxillofacial Fractures - A Retrospective Analysis of 1219 pacients. Dental Traumatology 2014; 30: 435-441; doi: 10.1111/edit 12118.

[2] Roman K. Rahimi –Nedjat; Keyvan Sagheb; Christian Valter. Concomitant Dental Injures in Maxillofacial Fractures - A Retrospective Analysis of 1219 pacients. Dental Traumatology 2014; 30: 435-441; doi: 10.1111/edit 12118.

Keywords:

Implant,

Bioprinting,

Rapid prototyping,

medical application

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomaterials in dental applications

Citation:

Almeida

F,

Bernardes

L,

Moraes

M,

Jardini

A,

Martins

E and

Filho

R

(2016). Direct metal laser sintering (DMLS) for application in manufacture using prostheses of mandibular customized condyles coated with sub microstructured zirconia.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.00851

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.