Introduction: High temperature melting (HTM) of ultrahigh molecular weight polyethylene (UHMWPE) (280 - 330°C) can improve elongation and toughness[1]. Radiation cross-linking of UHMWPE is used to lower its wear as a bearing surface in total joint arthroplasty[2]. We hypothesized that HTM could also improve the toughness of cross-linked UHMWPE.

Materials and Methods: Medical grade 0.1wt% vitamin E- blended GUR1020 UHMWPE was electron beam irradiated to 100,125, 140, 160 or 175 kGy. After irradiation, HTM was performed in a convection oven under nitrogen at 280, 300 or 310°C for 5 hours.

A terminal vinyl index was calculated using Fourier Transform Infrared Spectroscopy (FTIR) on thin sections using the absorbance at 880-920 cm-1. The IZOD impact strength was determined by double notching and testing according to ASTM F-648. Type V tensile testing was done according to ASTM-638 with a crosshead speed of 10mm/min. Pin-on-disc (POD) wear testing was performed on cylindrical pins (dia. 9 mm, height 13 mm)[3] at 2 Hz for 1.2 million-cycles (MC). The oxidation induction time (OIT) was determined using a differential scanning calorimeter. Statistical significance was reported using the student’s t-test at p < 0.05.

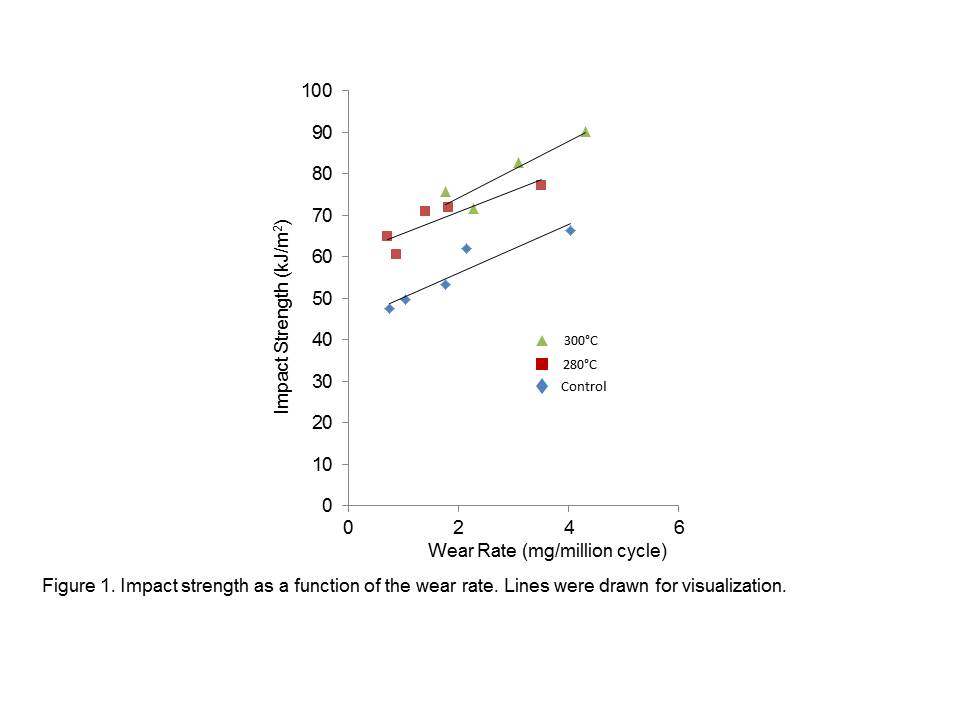

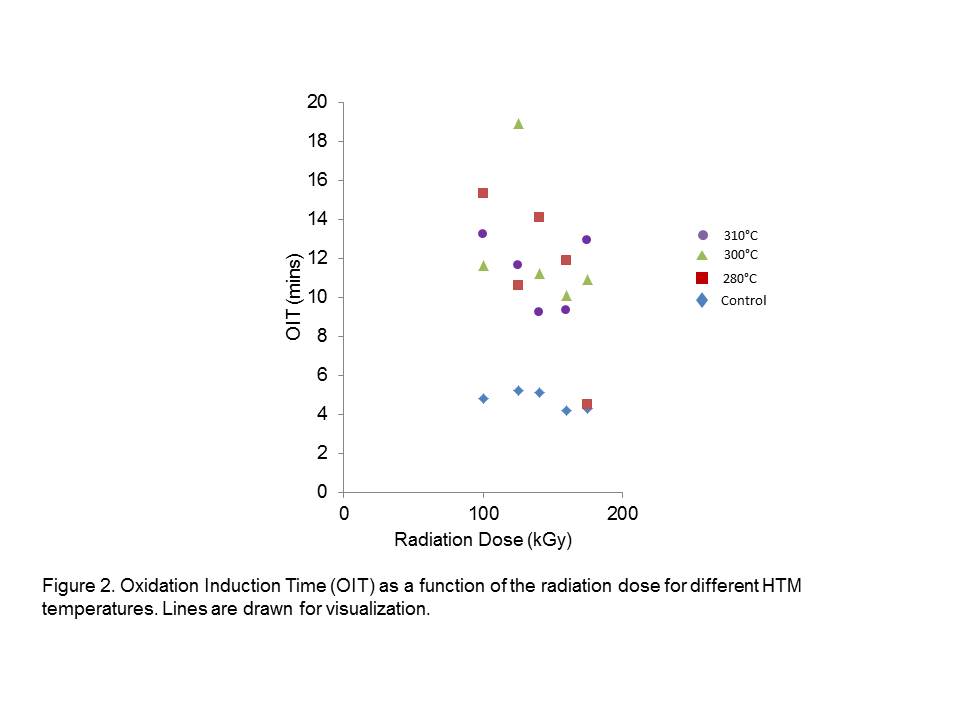

Results: The vinyl index increased with increasing HTM temperature from 280 - 310°C. The ultimate tensile strength (UTS) did not change after HTM compared to that of the non-HTM control (p= 0.70, 0.72 and 0.61 for 280°C, 300°C and 310°C respectively). The elongation at break (EAB) increased (p= 0.23, 0.01 and 0.006 for 280°C, 300°C and 310°C respectively). The impact strength increased with increasing HTM temperature compared to that of the non-HTM control (p= 0.02, 0.003 and 0.002 for 280°C, 300°C and 310°C respectively; Fig 1). The wear rate decreased with increasing radiation dose; but did not change as a result of HTM. The oxidation induction time (OIT) increased after HTM (p = 0.02, 0.007 and 0.001 for 280, 300 and 310°C respectively; Fig 2).

Discussion: The impact strength increase after HTM compared to non-HTM was 25, 40 and 37 % for HTM at 280°C, 300°C and 310°C respectively without a clear trend with respect to radiation dose. The decrease at 310°C suggested that there is a VI threshold around 0.05 beyond which increased scissioning (suggested by increasing terminal vinyl groups) leads to degradation.

The wear rate slightly increased with HTM at the higher temperatures, but at a given wear rate, the impact strength increase due to HTM was significant (Fig 1). These results suggested that HTM of radiation cross-linked UHMWPE at around 300°C increased its impact toughness by about 40% without sacrificing its wear resistance. Oxidation resistance was also improved tremendously after HTM (Fig 2). The mechanism for this increase is not yet known.

Conclusion: High temperature melting of radiation cross-linked vitamin E blended UHMWPEs showed improved toughness and can be used as an alternative method to fabricate joint implant bearing surfaces for applications requiring improved toughness and high wear resistance.

References:

[1] Fu et al. Polymer 51 (2010) 2721-2731

[2] Kurtz et al. Clin Orthop Rel Res 469 (2011) 2262-2277

[3] Bragdon et al. J Arthroplasty 16 (2001) 658-665.