Introduction: Anionic polysaccharide-based gels, such as alginate gels, are common in biomaterials science. Photo-polymerization is an attractive method for preparation of hydrogels as it allows for incorporation of cells into the gel matrix[1]. However, alginate-based gels do not support cell adhesion and the most common approach has been to covalently modify the gel matrix with adhesion peptides. We propose here an alternative strategy for functionalization of alginate gels by incorporating filler particles, specifically polyelectrolyte complexes (PEC) and nano-sized hydroxyapatite (HAP) particles with the potential additional benefit of enhancing the mechanical properties of the alginate matrix.

Materials and Methods: Medium viscosity alginate was modified with methacrylic anhydride to form methacrylate alginate (MA-ALG) with degree of substitution of 10 % as verified by diffusion edited 1H NMR. Photo-polymerization was done using the photo-initiator Irgacure 2959 (0.05 %) in a 2.5 w/v % solution of MA-ALG. PEC fillers were produced from alginate-di-aldehyde and chitosan[2] and HAP fillers by a solution precipitation method[3]. Bilayer hydrogels were prepared by crosslinking a HAP suspension in a solution of MA-ALG followed immediately by gently pouring a second solution on top of the HAP hydrogel and further cross-linking.

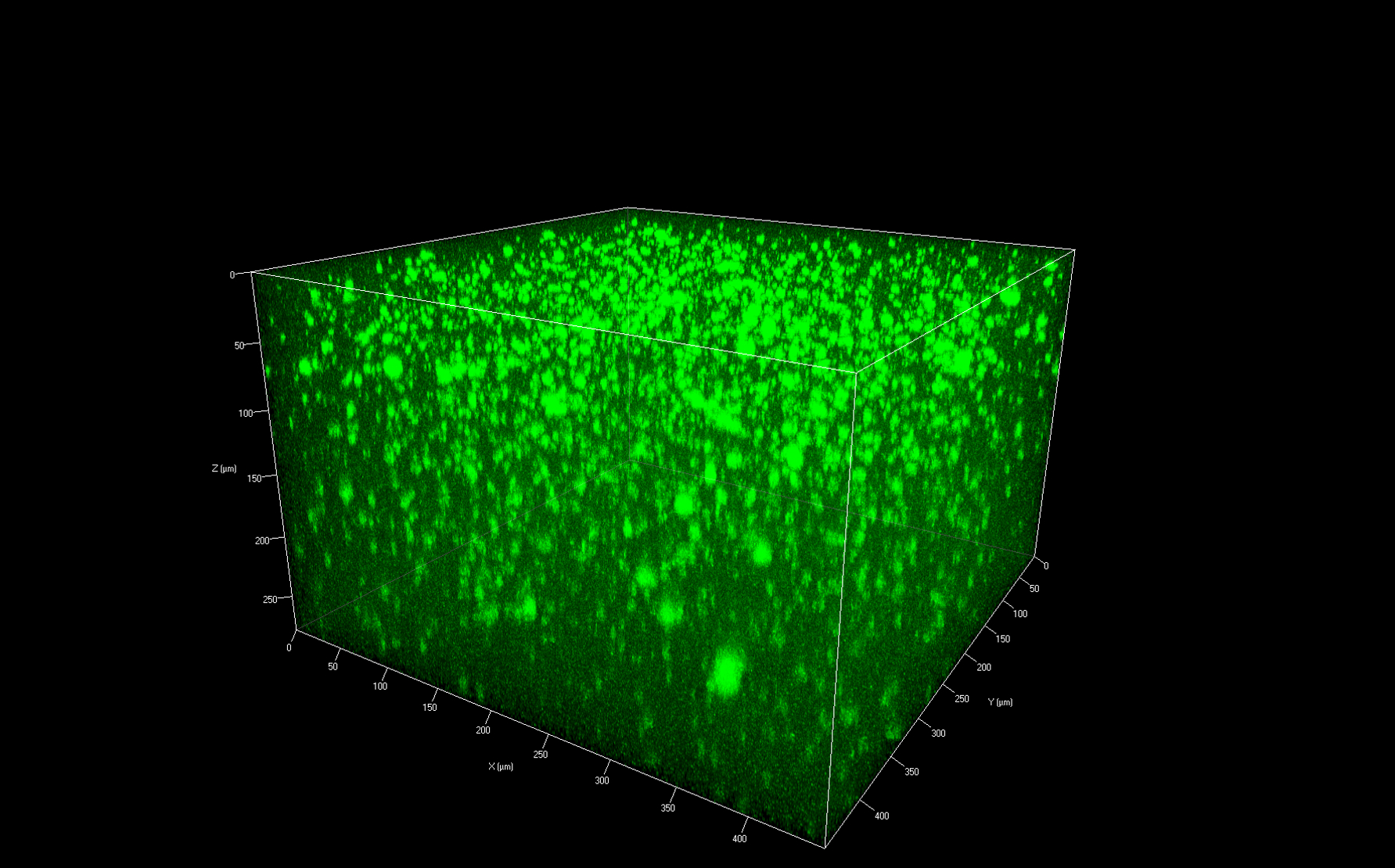

Results and Discussion: The PEC filler particles could be incorporated into the alginate gel up to a loading of 25 w/w% while HAP could be incorporated up to 20 w/w%. Loadings were restricted to these levels due to overall crosslinking efficiency. Distribution of the PEC within the alginate matrix could be evaluated using confocal microscopy of a FITC-labelled chitosan-based PEC. An example of the PEC distribution obtained is shown in Figure 1 (PEC made from FITC-labelled chitosan).

The compressive modulus (after 24 hours of immersion in an ionic salt solution) was found to depend not only on the filler content but also on the filler type. For the PEC composite gels an increase in the compressive modulus was seen with increasing filler loading leading to a near four times increase with 25% loading. For these gels the polymer density overall changed from 25 to 31 mg mL-1 and as such, the enhancement in the mechanical properties can be, at least in part, attributed to the polymer density. For the HAP composite gels of 1 mm thickness the compressive modulus at a loading of 5 w/w% was significantly enhanced relative to the pure alginate gel while for 3 mm gels no enhancement in properties was observed up to 20 w/w% loading. Mineralisation studies of a 10 w/w% HAP composite gel showed a threefold mass increase after 1 week of immersion in SBF[4]. The process of composite gel fabrication could be extended to bilayer hydrogels with different types of fillers in the two layers which opens up for use of these materials in many applications.

Conclusion: This work has demonstrated the feasibility of incorporation of filler particles into single photo-crosslinked alginate gels as well as into bilayer gel materials. Mechanical performance with inclusion of filler particle was either unchanged or enhanced depending on loading and/or filler type.

R. Aston would like to thank the Australian government for awarding an Australian Postgraduate Award; R. Aston would like to thank the Queensland Government for PhD Scholarship Funding

References:

[1] K Y Lee & D J Mooney, Alginate: Properties and biomedical applications. Prog Polym Sci 37 (2012) 106

[2] R Aston, M Wimalaratne, et al., Interactions between Chitosan and Alginate Dialdehyde Biopolymers and Their Layer-by-Layer Assemblies. Biomacromolecules 16 (2015) 1807

[3] C Goonasekera, K Jack, et al., Attachment of poly(acrylic acid) to 3-aminopropyltriethoxysilane surface-modified hydroxyapatite. J Mater Chem B 1 (2013) 5842

[4] T Kokubo, H Takadama. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27 (2006) 2907