Background: Metals and ceramics have been widely used in dental surgery over the last 40 years. Dental implants applied as an alternative treatment method for the prosthodontic restoration of partially or fully edentulous patients. However, there are many reports about implant failures observed in 6% to 11% of cases[1]. A major factor that determines the success of dental implantation is osseointegration, which is the stable anchorage of an implant in living bone achieved by direct bone-to-implant contacts. High-quality osseointegration stand for an accelerated healing process, high stability, and durability of the dental implant. The main factors that can change osteointegration are alloy’s biomechanics and surface characteristics. The surface properties of implants are essential to the response of cells at biomaterial interface, affecting the growth and quality of newly formed bone tissue. In vitro studies have shown that osteoblastic cells attach, spread and proliferate more rapidly on smooth surfaces than on rough ones. However, osteoblasts present higher rate of differentiation and matrix mineralization and higher production of growth factors in the presence of rough substrates[2].

There are different methods to create nanostructured surfaces with high relevance for industry. Lithography techniques, such as electro-beam lithography, focused ion beam lithography and photolithography have been commonly used, but they are complicated, present high cost, and are time consuming. An alternative for the fabrication of nanostructures is the use of femtosecond laser, this is one of the most promising methods to modify the physical properties of materials[3].

The aim of our research was to evaluate tissue response in subcutaneous implantation of different alloys with laser lithography surface treatment.

Materials and Methods: In our experiment we used standard Ti and Zr alloy. The surface of materials was treated by laser lithography technique (LLT) to make grooves in nanoscale size (from 45 to 150 nm). Untreated alloy we used as a control group. Materials were implanted subcutaneous to 24 Wistar rats (6 for each alloy). After 10 days materials removed and studied by SEM.

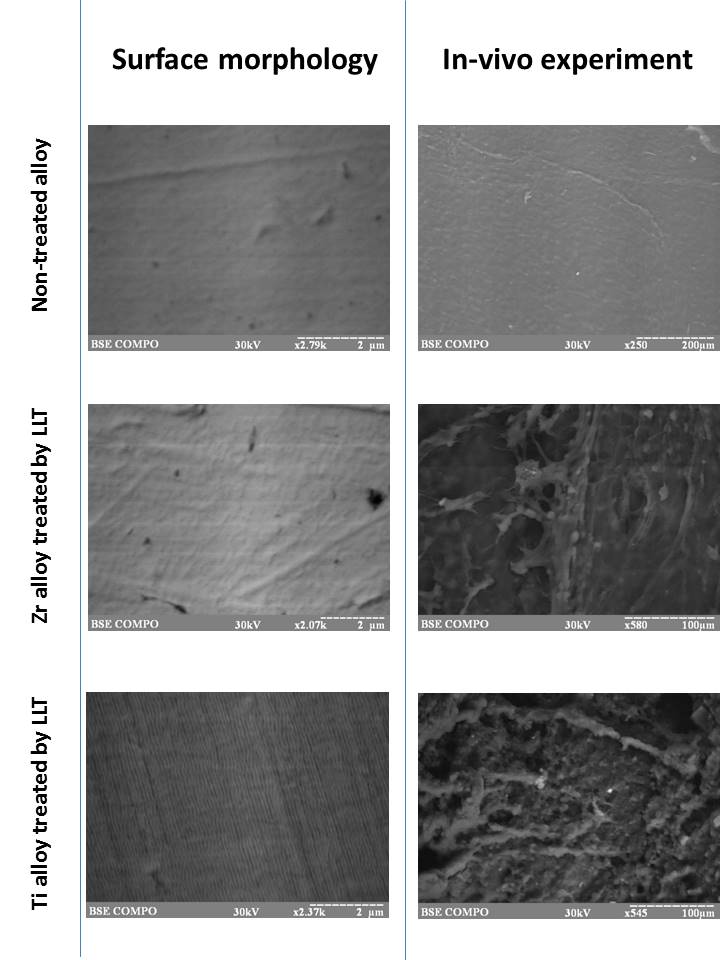

Results: LLT allows create rough surface on both Ti and Zr alloy with size from 45 to 150 nm. Using such technique we can generate faster and cheaper nanostructures in a single-step process. But standard LLT made more regular grooves on Ti alloy compare the Zr, and should be modified for different metals (fig. 1)

In 10 days after implantation non-treated, both Ti and Zr, alloys covered by thin connective tissue capsule and easy removed. Their surface has no cell attachment and only a few collagen fibers. Well-developed connective tissue growth around LLT-treated alloy in 10 days of experiment. After the alloy removed we can observe fibroblast and leucocytes attachment to the material surface. The fibroblasts have elongated processes that join cells with LLT-modified surface. Cell density does not depend on alloy type. Fibroblasts secret collagen fibers that random covers alloy surface (fig. 1).

Figure 1. SEM of Ti and Zr alloy before and after 10 days of subcutaneous implantation.

Conclusion: We have used the laser lithography technique to modify different metal alloy to made nanoscale rough surface. It leaded to optimization of connective tissue cell attachment and collagen secretion that could be used for medical implant improvement. The cell reaction did not depend on alloy type.

References:

[1] K. Shemtov-Yona, D. Rittel On the mechanical integrity of retrieved dental implants. Journal of the Mechanical Behavior of Biomedical Materials. 2015;49:290-299

[2] S. Ferraris, A. Bobbio, M. Miola, S. Spriano Micro- and nano-textured, hydrophilic and bioactive titanium dental implants. Surface and Coatings Technology. 2015;276:374-383

[3] Gustavo Mendonça, Daniela B.S. Mendonça, Francisco J.L. Aragão, Lyndon F. Cooper Advancing dental implant surface technology – From micron- to nanotopography. Biomaterials. 2008;29(28):3822-3835