Feasibility of titanium components additively manufactured by electron beam melting: Microstructural and mechanical considerations

-

1

Tohoku University, Institute for Materials Research, Japan

-

2

National Institute of Technology, Sendai College, Department of Materials and Environmental Engineering, Japan

Introduction: Electron beam melting (EBM) is a powder-bed-fusion additive manufacturing technology in which an electron beam is selectively scanned on a metal powder bed to fabricate metallic parts in a layer-by-layer fashion directly from a three-dimensional computer model. Titanium and its alloys with excellent corrosion resistance, low density, and excellent biocompatibility have been used to produce complex mesh or lattice structures made of titanium as scaffolds for bone tissue engineering. However, the mechanical properties of EBM-fabricated titanium components themselves have not been well characterized; in particular, the complex thermal history consisting of rapid cooling and subsequent high temperature exposure, which is realized by preheating the powder bed before melting, is crucial for ensuring the durability of implants. The aim of this study is to examine the microstructures and mechanical properties of commercially pure titanium (CP-Ti) and Ti−6Al−4V (Ti-64) alloy components additively produced by EBM and the feasibility of the EBM process as a manufacturing route of titanium implants is also discussed.

Materials and Methods: The CP-Ti and Ti-64 powders with average diameters of ~70 μm were used. The bulk coupons were produced using an Arcam A2X EBM system (Arcam AB, Sweden). The preheating of powder bed was conducted at 650°C and 730°C for CP-Ti and Ti-64, respectively. Microstructures were investigated by electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). Mechanical properties were evaluated by room temperature tensile testing. Fatigue tests of the as-built, heat-treated, and hot isostatic pressed (HIPed) Ti-64 samples were also performed.

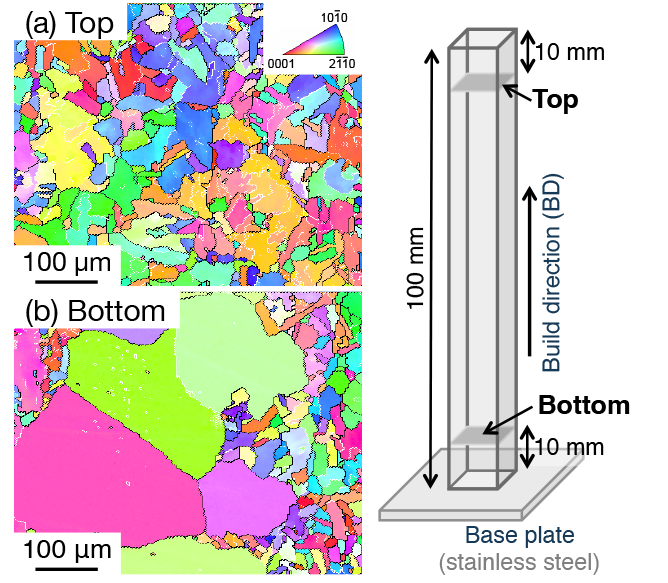

Results and Discussion: The fine, uniform α (hexagonal close-packed, hcp) grain microstructures with an average grain size of ~ 40 μm were observed at the top section of the as-built CP-Ti specimens (Fig. 1a). Surprisingly, the resulting strength was relative high and showed significantly reduced anisotropy compared with those of conventionally manufactured CP-Ti[1]. However, with increasing build height, very coarse grains (> 100 μm) became apparent, as shown in Fig. 1b. This indicates that abnormal grain growth (AGG) occurs during EBM process of CP-Ti, resulting in inhomogeneities in microstructures as well as mechanical properties along the build direction. The substructures developed by rapid cooling and subsequent high-temperature exposures were considered to be an origin for the AGG.

Figure 1. EBSD maps of the as-EBM-built CP-Ti.

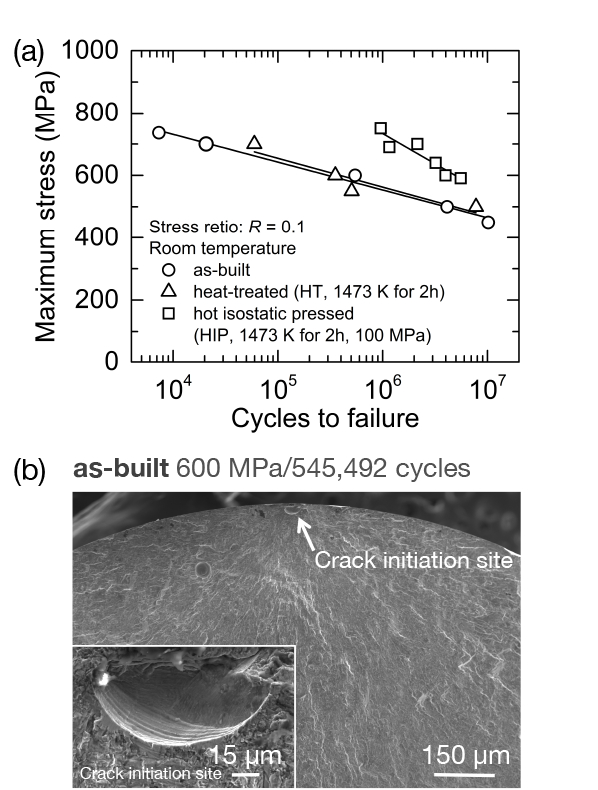

The as-built Ti-64 specimens also showed the relatively high strength due to their fine acicular microstructures (Fig. 2a). However, the fatigue properties of the as-built specimens were lower than those of conventionally prepared Ti-64 counterparts, even if the as-built samples had the relative densities as high as 100%. The fracture surface analyses and comparison in fatigue properties between the three kinds of samples mentioned above revealed that defects produced during EBM (e.g. pores, unmelted powders, and oxide inclusions) reduce the endurance limit of the components (Fig. 2b).

Figure 2. S−N curves for the EBM-built Ti-64 components.

Conclusions: The obtained results indicate that further optimization of building parameters (beam energy, scanning speed, etc.) and post-processing strategy is required for homogeneous characteristics and enhanced durability of biomedical titanium components.

References:

[1] Kenta Yamanaka, Wataru Saito, Manami Mori, Hiroaki Matsumoto, Akihiko Chiba, Preparation of weak-textured commercially pure titanium by electron beam melting, Additive Manufacturing (2015) DOI: 10.1016/j.addma.2015.09.007

Keywords:

biomaterial,

microstructure,

Rapid prototyping,

mechanical property

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

General Session Oral

Topic:

Layer-by-layer deposition techniques

Citation:

Yamanaka

K,

Shui

X,

Wang

X,

Mori

M and

Chiba

A

(2016). Feasibility of titanium components additively manufactured by electron beam melting: Microstructural and mechanical considerations.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01195

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Kenta Yamanaka, Tohoku University, Institute for Materials Research, Sendai, Japan, Email1

Dr. Akihiko Chiba, Tohoku University, Institute for Materials Research, Sendai, Japan, Email2