Preparation of titanium/tricalcium phosphate bone implant materials by spark plasma sintering

-

1

Central South University, State Key Laboratory of Powder Metallurgy, China

Introduction:

It is the frontier and hotspot of biomaterials research to functionally design the bulk material and the surface of materials or even develop a new material based on the concept of bionic. The biomedical applications of Ti and Ti alloys have been limited because of the mismatching of Young’s modulus of Ti or Ti alloys with that of human bone and non-bioactivity. In this study, the resorbable tricalcium phosphate ceramic with Ti metal were combined to fabricate the Ti/Tricalcium phosphate (Ti/α-TCP) composite through spark plasma sintering (SPS). It is expected that the composite with sintered network structure of Ti and α-TCP ceramic can have excellent mechanical properties and bioactivity.

Materials and Methods:

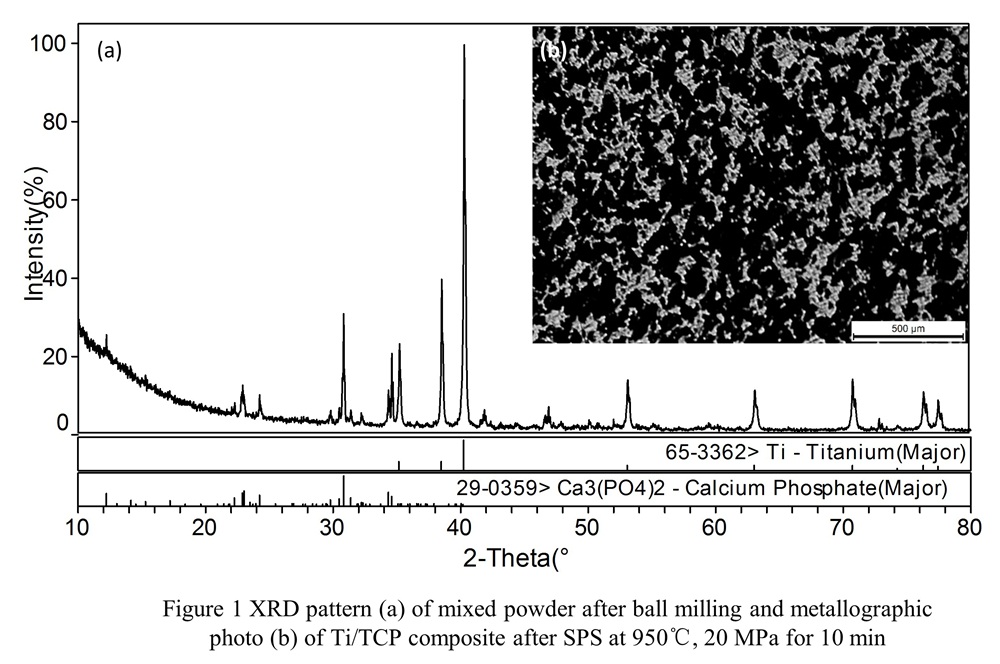

TCP powder was synthesized by chemical coprecipitation method. Calcium nitrate (Ca(NO)3)2·4H2O) and ammonium dihydrogen phosphate (NH4H2PO3) were used as Ca2+ solution and PO33- solution, respectively. Ca2+ solution was added into PO33- solution dropwise under stirring for 3 h. The pH value of the solution was adjusted to 7.5 by ammonia. After suction filtration, drying, grinding, calcination at 1250 ℃ for 2 h and quenching, TCP powder was obtained. Then TCP powder was mixed with commercial titanium powder by ball milling at the protection of argon gas. The mixed powder was pressed and sintered by SPS at different conditions. Characterization methods including metallographic analysis, XRD, and SEM were used. Mechanical properties of the composites were also tested.

Results and Discussion:

Pure α-TCP was successfully synthesized by chemical coprecipitation method. The XRD result shows that the mixed powder contains Ti and TCP after ball milling (Fig.1 (a)). A network structure was formed after SPS, as shown in Fig.1(b). The mechanical property results (table 1) show that the Ti/α-TCP composites exhibit similar strength and Young’s modulus to human bone. The compressive strength of the composite is decreasing with the increase of the sintering temperature. It may be because there was more interfacial reaction between Ti and TCP when sintered at higher temperature than at lower temperature. New phases that formed during the interfacial reaction may had detrimental effect on the compressive strength. The interfacial reaction between Ti and TCP during sintering at elevated temperature is hard to avoid. However, SPS method make it possible to prepare material at a much lower temperature, thus further decreasing the interfacial reaction. Other properties including degradability, bioactivity and biocompatibility of the composites are under study.

Conclusion:

To combine with TCP is beneficial for improving the performance and the long-term stability of titanium implants. Ti/α-TCP, which is bioactive, degradable, with similar strength and Young’s modulus to human bone, is a promising bone replacement material.

This work was financially supported by National Natural Science Foundation of China (No. 51504295); Training Program of Innovation and Enterpreneurship for Undergraduates (No. 201510533034) and (No. ZY2015618)

Keywords:

composite,

Calcium phosphate,

mechanical property,

Bone repair

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Composites: polymeric, ceramic and metallic

Citation:

Tan

Y,

Liu

Y,

Wu

Z and

Tang

H

(2016). Preparation of titanium/tricalcium phosphate bone implant materials by spark plasma sintering.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01442

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Yanni Tan, Central South University, State Key Laboratory of Powder Metallurgy, Chang Sha, China, tanyanni@csu.edu.cn

Dr. Yong Liu, Central South University, State Key Laboratory of Powder Metallurgy, Chang Sha, China, yonliu@csu.edu.cn

Dr. Zhenyu Wu, Central South University, State Key Laboratory of Powder Metallurgy, Chang Sha, China, Email1

Dr. Hanchun Tang, Central South University, State Key Laboratory of Powder Metallurgy, Chang Sha, China, Email2