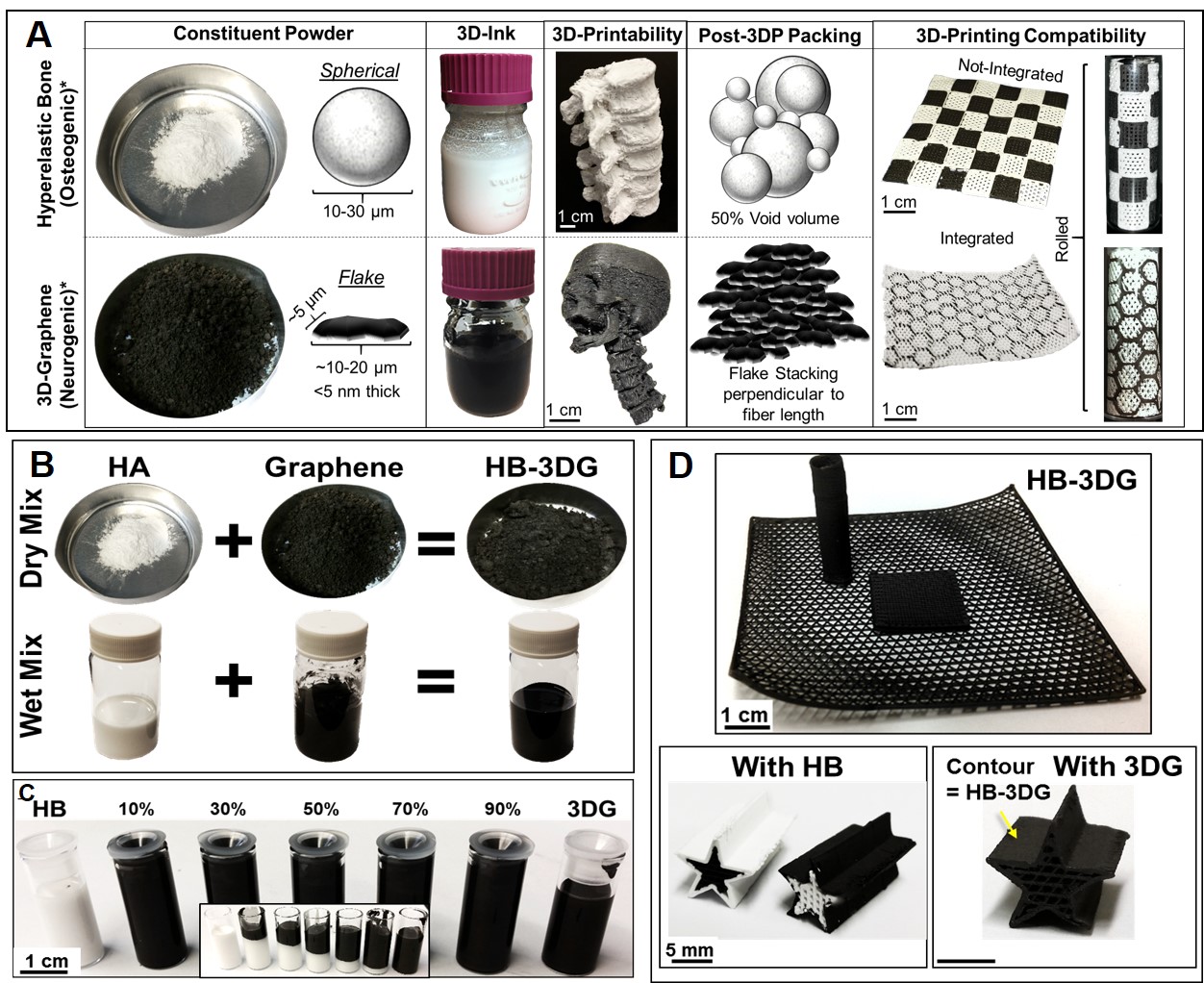

With the emergence of 3D-printing as a vital tool in tissue engineering and medicine, there is an ever growing need to develop new biomaterials that can be 3D-printed and also emulate the compositional, structural, and functional complexities of human tissues and organs[3],[4]. In this work, we probe the combination of two recently established, functional 3D-printable particle-laden biomaterial inks: one that contains hydroxyapatite (HA) microspheres (Hyperelastic Bone, HB)[1] and another that contains graphene nanoflakes (3D-Graphene, 3DG)[2]. 3D-printed HB alone is comprised of ~75 vol% HA and ~25 vol% polylactic-co-glycolic acid (PLGA) and is highly elastic and osteogenic[1]. 3DG is comprised of 60-70 vol.% graphene and 30-40 vol% PLGA, is flexible, electrically conductive, and neurogenic[2]. These two distinct material systems (Fig. 1A) can be combined to create a broad spectrum of 3D-printable HA-graphene inks (Figs. 1B,C). This work focuses on evaluating the properties of a hybrid ink comprised of 35:35:30, HA:graphene:PLGA by volume, which remains just as 3D-printable as HB and 3DG alone and can be co-3D-printed with HB and 3DG to fabricate complex structures (Fig. 1D).

The resulting 3D-printed HB-3DG hybrid exhibits mixed characteristics of the two distinct HB and 3DG systems (Fig. 2). Microstructurally, the surface of 3D-printed HB-3DG fibers is dominated by graphene, and in cross-section, HA microspheres can be observed physically encapsulated and interspersed within a percolating graphene nanoflake matrix (Fig. 2A). Mechanically, HB-3DG exhibits mixed characteristics, with a tensile modulus and strain to failure (Fig. 2B) in between that of HB and 3DG; however, under compression, HB-3DG does not elastically deform like HB, but rather, plastically deforms similar to 3DG. Electrically, HB-3DG is still conductive; however, its electrical conductivity is significantly lower than expected based on graphene content, compared to 3DG (Fig. 2C). This is hypothesized to be due to the presence of the HB microspheres, which act like electrical defects (or voids) within the percolating graphene network, thereby decreasing the expected overall conductivity of the material.

In vitro assessment of HB-3DG using mesenchymal stem cells (MSCs) demonstrates the hybrid material supports cell viability (Fig. 3A) and proliferation (Fig. 3B), as well as significantly upregulates both osteogenic and neurogenic gene expression over 14 days (Fig. 3D). There are no distinct neuron-like morphologies observed on HB-3DG (Fig. 3C) by day 14 as seen on 3DG alone[2], and osteogenic and neurogenic gene expression is much lower than that of pure HB or 3DG, respectively. Nonetheless, the fact that this material can induce both osteogenic and neurogenic gene expression of MSCs, as well as have combined mechanical properties of the two individual systems, may indicate that HB-3DG (or variations of it) can serve as a candidate biomaterial for transition zones between two distinct tissue types, mimicking the compositional, structural, mechanical, and biological gradients present in natural multi-tissue interfaces.

This work illustrates that we can use these new particle-laden 3D printable ink systems to create new composite biomaterials with tailored properties towards being able to economically and rapidly fabricate 3D printed graded, multi-compositional, and multi-functional constructs for complex composite tissue engineering.

Northwestern University's International Institute for Nanotechnology (NU# SP0030341); Northwestern University's McCormick Research Catalyst Award; A. Jakus was supported by a Postdoctoral research fellowship through The Hartwell Foundation

References:

[1] A.E. Jakus, R.N. Shah et al. "Hyperelastic Bone: Discovering New Materials Through 3D-Printing". Biomaterials. Under Review. 2015

[2] A.E. Jakus, R.N. Shah et al. "Three-Dimensional Printing of High-Content Graphene Scaffolds for Electronic and Biomedical Applications". ACS Nano. 9(4), 2015. Cover.

[3] A.E.Jakus, A.L. Rutz, R.N. Shah. "Advancing the field of 3D biomaterial printing". Biomedical Materials. 10th Anniversary Special Issue. In Press.

[4] A.L. Rutz, R.N. Shah et al. "A Multimaterial Bioink Method for 3D Printing Tunable, Cell-Compatible Hydrogels". Advanced Materials, 27. 2015.