Reinforced thermoplastic composite materials for use in orthopaedics

-

1

Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Czechia

Introduction: In recent years, the development of fibre-reinforced thermoplastic composite materials has led to technological advances across a wide range of applications in modern orthopaedic medicine and in prosthetic devices. Composites typically possess a superior strength-to-weight characteristic to that of monolithic materials, and offer excellent mechanical properties[1]. The radiolucency of these materials and their high resistance against sterilization decomposition are also greatly appreciated[2]. Composite materials are, therefore, favourable for medical applications, and also for fracture fixation devices. It is therefore necessary to investigate the mechanical properties of these materials, especially when they are manufactured from pellets.

Materials and Methods: C/PPS thermoplastic composite material, based on polyphenylene sulfide matrix (PPS) and reinforced by carbon fibers, is manufactured from chopped pellets which are randomly oriented in the compression mould. Image processing methods are used to determine the relationship between the distribution of the local maxima and the angle of orientation of the pellets. First, a photograph of the C/PPS plate is transformed into a binary map. The map is discretized on facets with rotating abscissa, and this detects the direction of the pellets. The next step is an analytical calculation. The elastic properties of the composite are computed from the idealization that the randomly reinforced layer is a layer with a high number of thin layers oriented from 0° to 180°. The properties of the reinforced composite are then counted as the average properties of a fictitious isotropic laminate[3]. The last step is numerical simulation of a tensile test according to ASTM D3039[4], which is done using ABAQUS FE software with C3D8R elements. The material data obtained from an analytical calculation are used. Finally an experimental verification is performed. The plates made from C/PPS pellets are cut into specimens in two perpendicular directions. The tensile test is based on ASTM D3039[4]. Data from the strain gauges are analysed with DAQ Spider and CATMAN software.

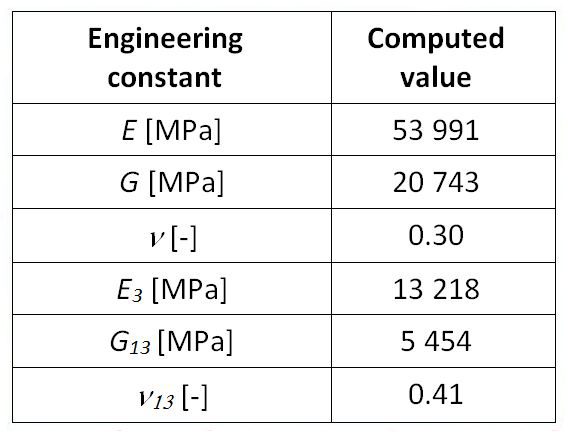

Results and Discussion: The image analysis that was executed proved that no direction of abscissa orientation prevails above the others, and the material was therefore considered as transversally-isotropic. The main parameters obtained from an analytical calculation are shown in the table.

From the tensile test, we obtained the average Young modulus E = 42,7 ± 18,7 GPa and the average ultimate stress 122,3 ± 34,2 MPa and the stress/strain curves, which were compared with the FE simulation.

Conclusion: The mechanical properties of C/PPS reinforced thermoplastic composite materials have been obtained. Image analysis data were used for an analytical calculation of the main parameters and for a mathematical simulation. The experiment provided a successful verification. The data that have been obtained show that thermoplastic composites are suitable from a mechanical point of view for use in designing fixation devices in orthopaedics.

This work has been supported by project TA03010209 of the Technological Agency of the Czech Republic and the Grant Agency of the Czech Technical University in Prague, grant No. SGS15/188/OHK2/3T/12

References:

[1] Scholz M. S. et al. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Composites Science and Technology 2011; 71: 1791–1803.

[2] Suchy T. et al. Radiolucent Composites Providing High Resistance against Sterilization Decomposition. Ceramics – Silikáty 2011; 55: 401-409

[3] Barbero E. J. Introduction to Composite Materials Design Second Edition, CRC Press, Boca Raton, 2011.

[4] ASTM D 3039 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials.

Keywords:

modeling,

biomaterial,

composite,

mechanical property

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Mechanical properties of biomaterials

Citation:

Sedlacek

R,

Padovec

Z,

Ruzicka

M,

Ruzicka

P and

Kral

M

(2016). Reinforced thermoplastic composite materials for use in orthopaedics.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01629

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Radek Sedlacek, Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Prague, Czechia, radek.sedlacek@fs.cvut.cz

Dr. Zdenek Padovec, Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Prague, Czechia, zdenek.padovec@fs.cvut.cz

Dr. Milan Ruzicka, Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Prague, Czechia, milan.ruzicka@fs.cvut.cz

Dr. Pavel Ruzicka, Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Prague, Czechia, pavel.ruzicka@fs.cvut.cz

Dr. Michal Kral, Czech Technical University in Prague, Faculty of Mechanical Engineering, Department of Mechanics, Biomechanics and Mechatronics, Prague, Czechia, michal.kral@fs.cvut.cz