Statement of Purpose: Dermal fillers have been widely used for cosmetic applications such as wrinkle management and plastic surgery. Hyaluronic acid (HA) has been regarded as the best candidate for dermal fillers due to its non-immunogenicity and biodegradability[1]. HA for commercial dermal fillers is often chemically cross-linked by 1,4-butanediol diglycidyl ether (BDDE) for enhanced mechanical properties and biostability[2]. However, BDDE-crosslinked HA fillers is known to lose their mechanical integrity within 6 months in vivo by enzymatic degradation[3]. Therefore, in this study, we have incorporated polyethylene glycol diglycidyl ether (PEGDE) into HA hydrogels as a chemical cross-linker to further enhance mechanical and biological stability as compare to BDDE. Moreover, we investigate in vitro and in vivo biological behavior of PEGDE-crosslinked HA fillers.

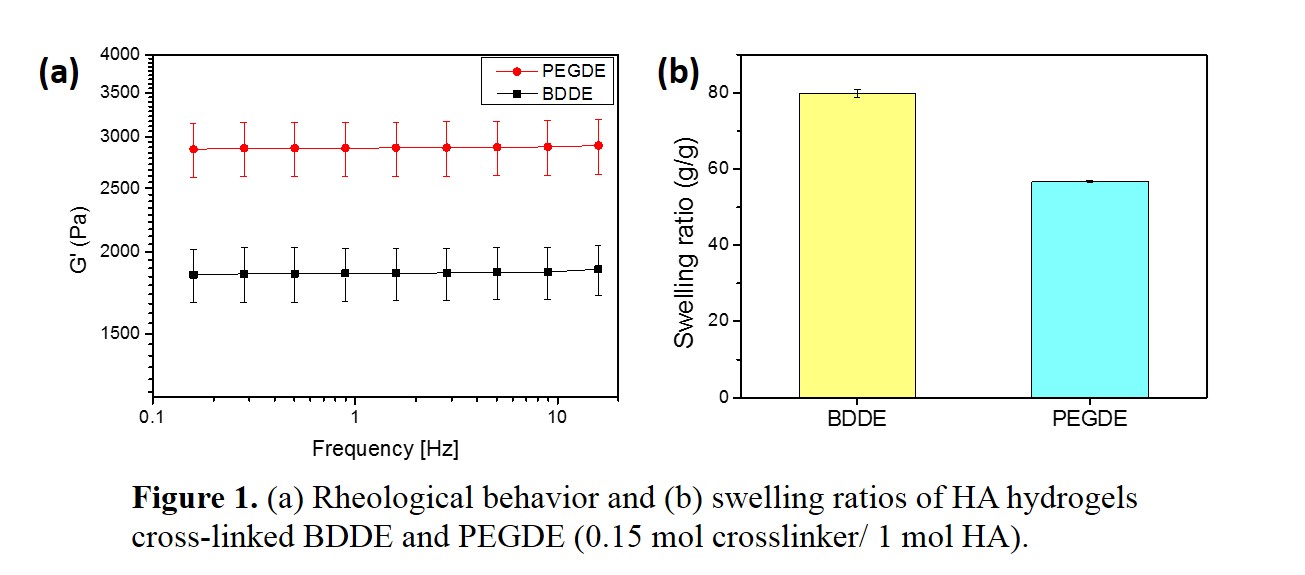

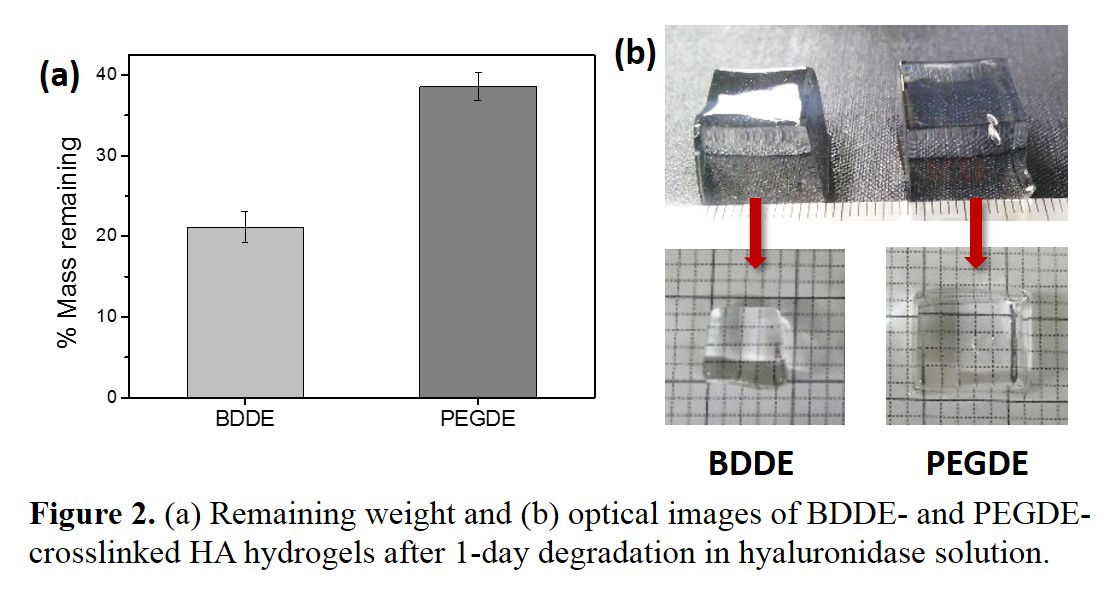

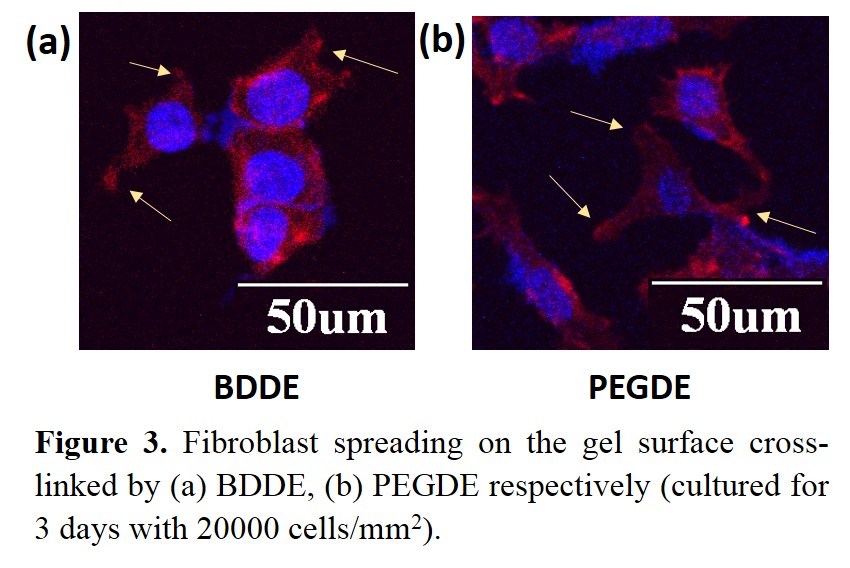

Methods: HA hydrogels were cross-linked using PEGDE (Mn = 2000 Da) or BDDE. 20 wt. % HA solution was prepared by dissolving 0.1 g HA (Mn = 2.2 MDa) in 0.5 mL 0.3 N NaOH aqueous solution. 5 µL BDDE was added to the HA solution. Likewise, the molar equivalent amount (0.15 mol crosslinker/ 1 mol HA) of PEGDE to BDDE was added to the HA solution. The reactions were performed at 25 oC for 24 h. Rheology measurement was carried out using parallel plate rheometer. Swelling test was performed with fully swollen samples in PBS at 37 ºC. In vitro degradation was performed in Hyaluronidase/PBS (100 U/ml) solution. In vitro cell test was performed by culturing L929 fibroblasts on the gel surface.

Results: Rheological behavior of cross-linked HA hydrogels by BDDE and PEGDE were shown in Fig. 1a. The storage modulus of PEGDE-cross-linked HA hydrogel was higher than that of BDDE-crosslinked HA hydrogel, meaning higher elasticity in PEGDE-cross-linked HA hydrogel. Swelling behavior was inversely correlated to storage modulus (Fig. 1b). Degradation stability by hyaluronidase was evaluated by volumetric and shape change, showing PEGDE-cross-linked HA hydrogel is more resistant to degradation than BDDE-cross-linked HA hydrogel (Fig. 2). Between time intervals, the hydrogels maintained their initial shape. Cell spreading was observed for both gels (Fig. 3). On PEGDE-cross-linked HA hydrogel, fibroblasts spread well almost “spindle-like” phenotype, whereas “spherical” shape on BDDE-cross-linked HA hydrogel, implying cell-matrix interaction is higher on PEGDE-cross-linked HA hydrogel surface.

Conclusions: PEGDE-cross-linked HA hydrogel was fabricated with more efficient cross-linking effect as compared to BDDE-cross-linked HA hydrogel. Higher elasticity and biostability can be obtained by using PEGDE rather than BDDE. Moreover, the hydrogel can controllable in mechanical properties and degradability by the amount of cross-linker with minimally modified. Exploiting great biocompatibility of PEG/HA hydrogel can be a good candidate for long-lasting dermal filler applications.

Small and Medium Business Administration, Republic of Korea (S2174750)

References:

[1] S. Dastoor et al. J Oral Implantol 2007; 33(4):191-204.

[2] C.E. Schante et al. Carbohydrate Polymers 85 2011; 469–489

[3] A. Tezel et al. J. Cosmet. Laser Ther. 2008; 10, 35–42.