Rheological properties and 3D printability of alginate-based hydrogels for biofabrication

-

1

Nanyang Technological University, School of Mechanical and Aerospace Engineering, Singapore

In the field of tissue engineering, additive manufacturing or 3D printing makes it possible to create scaffolds with precise geometries and to control over pore interconnectivity and architectures that are not possibly made with conventional techniques. Hydrogels are important biomaterials for biofabrication due to their biocompatibility and similarities to biological tissues. The combination of 3D printing technologies and hydrogels is an exciting route in developing tissue engineering scaffolds. However, the printability of a hydrogel used as an ink or bio-ink for 3D printing is often a concern. Here, rheological properties of hydrogels are believed to play an important role in determining their printability. Therefore, it is worthy to study and understand the relations between 3D printability and rheological properties of hydrogels. In this work, alginate-based hydrogels were prepared and their rheological properties and 3D printability have been examined. In particular, we have investigated the effects of Ca2+ ions content and alginate concentration on the viscoelastic properties of the alginate hydrogels. The experimental results indicated that the alginate/calcium chloride hydrogels have a shear-thinning characteristic, which is desirable for 3D printing. The alginate/calcium chloride hydrogels could be printed into a scaffold-like structure. However there are various parameters (such as concentration of alginate, content of Ca+2 ions, viscoelastic properties of hydrogels before and after printing, diameter of the printing nozzle, extrusion speed, etc.) that could influence the characteristics of hydrogels, quality of 3D printing, and stability of a printed construct. These parameters may interact each other to affect the printability of a selected hydrogel. In this presentation, we will show the results and discuss these parameters in detail.

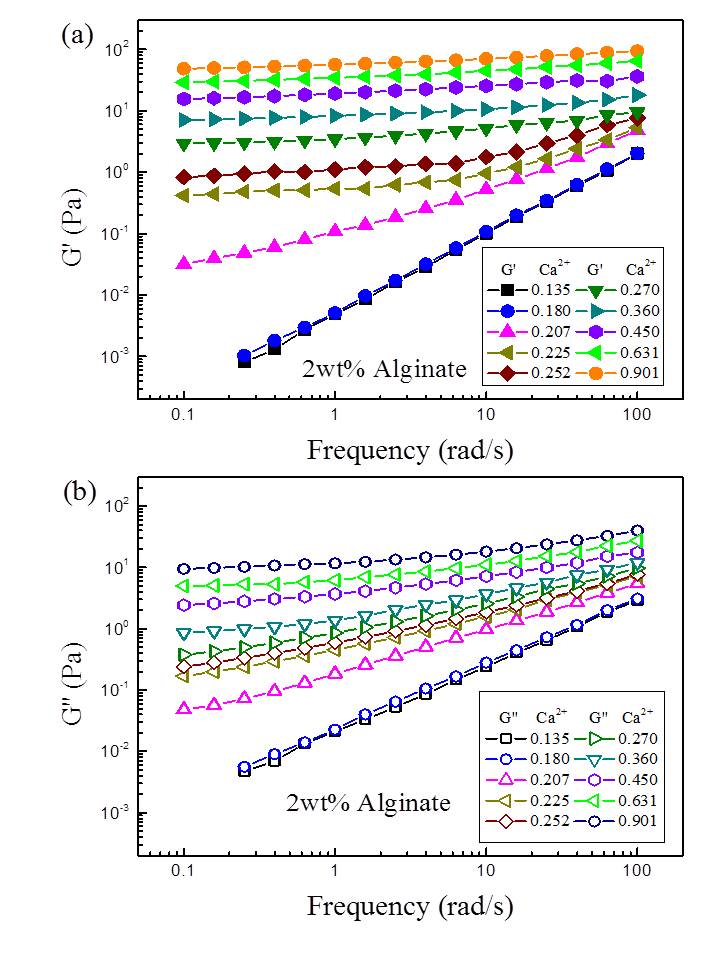

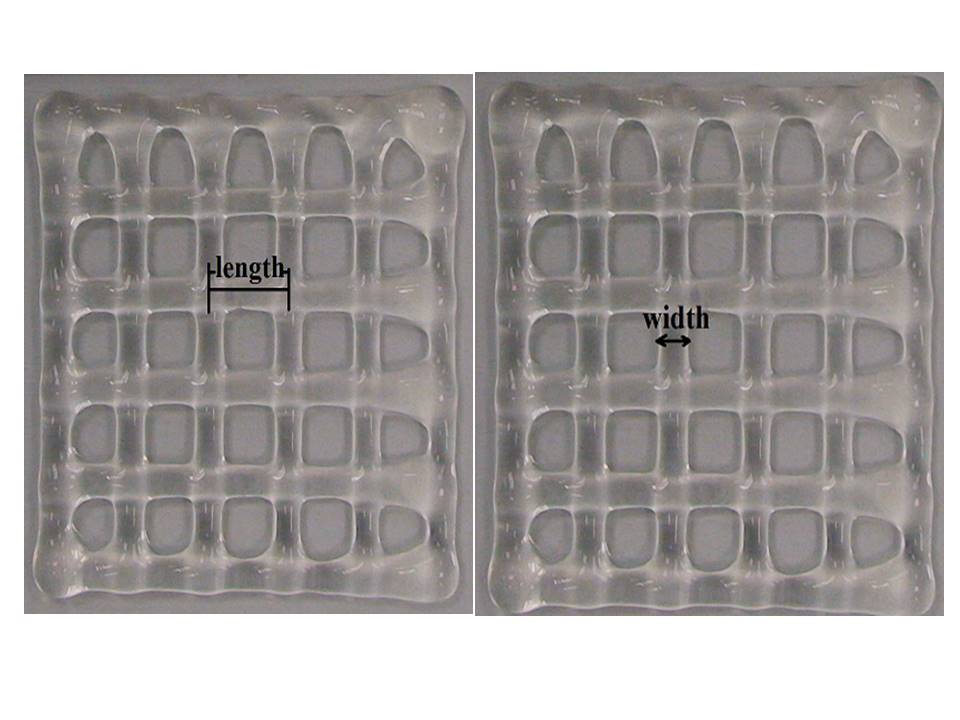

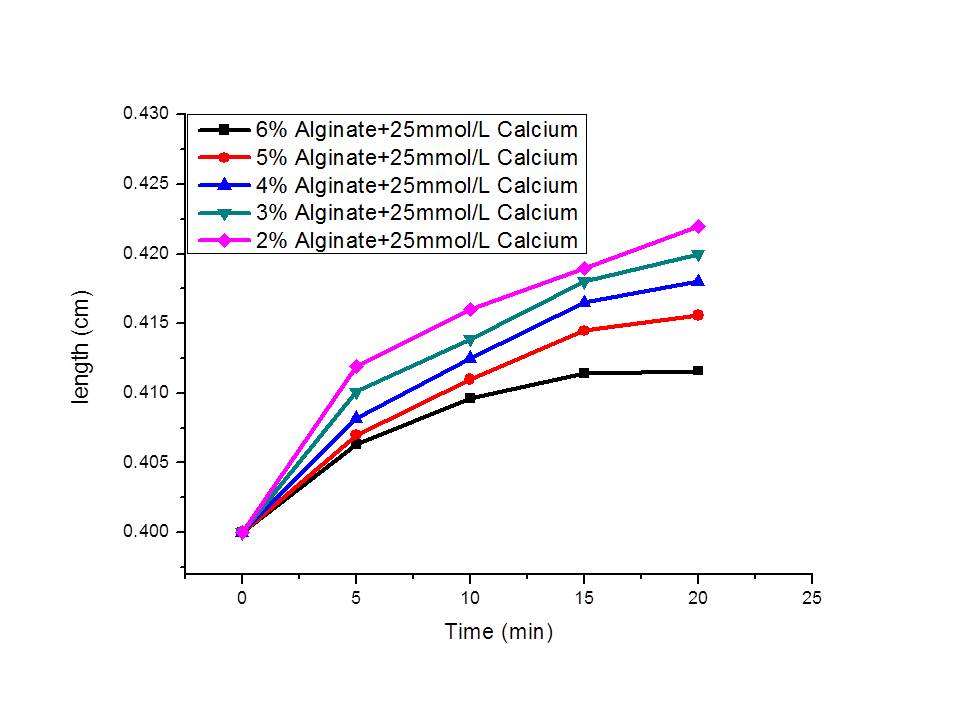

Some of the results are given as follows. Fig.1. shows the dependence of (a) dynamic moduli G' and (b) G" on angular frequency for 2 wt% alginate solution in the presence of various contents of Ca+2 ions at 20 oC and a shear strain amplitude of 1 %. Before and during printing, a liquid with low viscosity is preferred. However, after printing, a solid-like gel with high viscosity is desired. Fig.2 illustrates the definition and measurement of length and width for quantifying the printing quality of a 3D printed scaffold structure with alginate/Ca+2 hydrogel. Fig.3 is the relationship between length and time with varying alginate concentration. At a fixed concentration of Ca+2, with increasing alginate concentration, the dimensional stability of the 3D printed construct became better.

Ministry of Education, Singapore

References:

[1] S. Liu, H. Li, B. Tang, S. Bi, L. Li, Carbohydrate Polymers, in press, 2015.

Keywords:

Hydrogel,

polymer,

3D scaffold,

mechanical property

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomaterials in constructing tissue substitutes

Citation:

Li

L and

Li

H

(2016). Rheological properties and 3D printability of alginate-based hydrogels for biofabrication.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01814

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Lin Li, Nanyang Technological University, School of Mechanical and Aerospace Engineering, Singapore, Singapore, Email1