Introduction: Porous magnesium (Mg) has promising properties as a biodegradable material by the advantage of facilitating bone ingrowth and reducing the load shielding effect. However, there are limitations to the use of porous Mg because of its low mechanical strength and high corrosion rate[1]. Enhancement of mechanical strength can be achieved by bio-mimicking the bone structure. Bone has dense outer part and porous inner part where dense layer can enhance the mechanical strength suitable for load bearing application. Furthermore hydroxyapatite (HA) coating directly in aqueous solution is one of the effective ways to coat complex shape and improve corrosion resistance. This method also can improve biocompatibility of porous Mg due to the biocompatible HA coating layer[2].

Methods: Mg powder was mixed with 60% volume ratio of NaCl powder and densified with the press machine. The densified body was encapsulated with pure Mg powder. The total body was sintered by spark plasma sintering (SPS) method at 585 °C for 2h. After sintering, NaCl was dissolved in NaOH solution. Aqueous solution for HA coating was prepared by dissolving Ca(EDTA) and KH2PO4 in distilled water. The pH level of the solution was kept at 8.9, and the solution was heated to 90 °C[2]. Bone-mimetic porous Mg was immersed in the solution to coat with HA. Mechanical properties of porous Mg, dense Mg and bone-mimetic porous Mg were examined using compression tests. Corrosion behavior was observed by monitoring the change of pH after immersing bare and HA coated bone-mimetic porous Mg specimens in SBF solution at 37 °C.

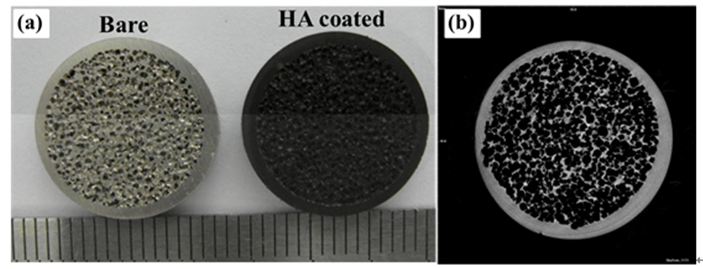

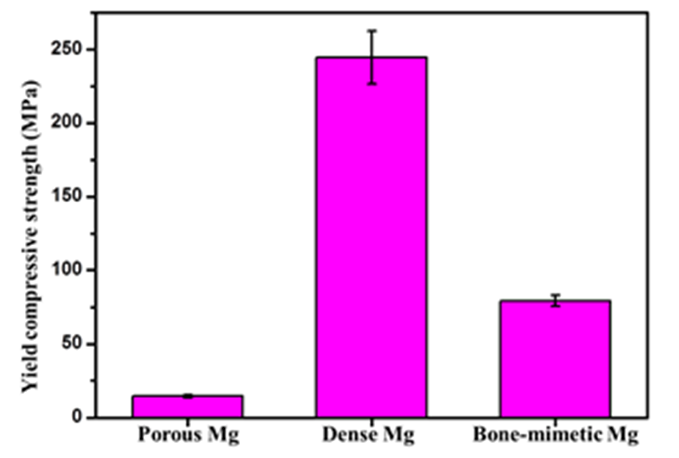

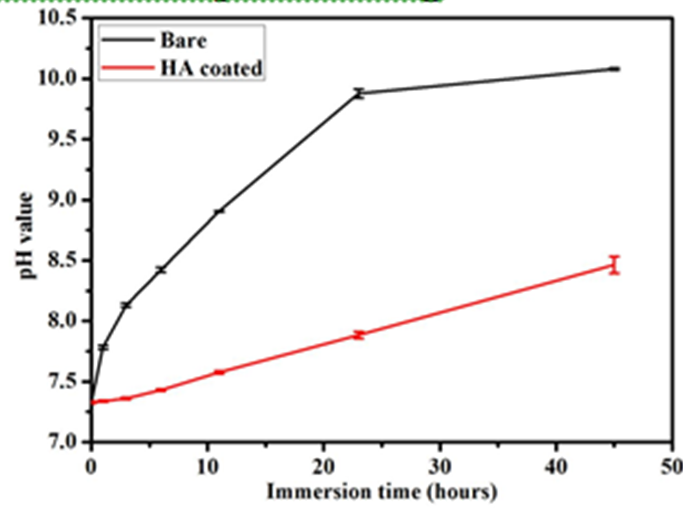

Results and discussion: Fig. 1 (a) shows optic images of bare and HA coated bone-mimetic porous Mg. The specimen was well coated with HA. Fig. 1 (b) is the u-CT image of biomimetic porous Mg. The cross sectional image shows that the specimen was well mimicking the dense outer part and porous inner part of bone structure. Fig. 2 shows the yield compressive strength of porous, dense and biomimetic porous Mg. Average compressive strength was 15, 244 and 79 MPa respectively. By bio-mimicking the bone structure, the strength was improved significantly compared with that of the porous Mg. Corrosion behavior was examined by the change of pH after immersing the bare and HA coated bone-mimetic porous Mg in SBF solution, cf. Fig 3. pH of bare porous Mg immersed SBF increased rapidly. However, after coating porous Mg with HA, the increment of pH slowed down remarkably and the specimen maintained its dimensions for a longer time.

Conclusion: Porous Mg bio-mimicking the bone structure was fabricated by the SPS and space holder method with NaCl as a spacer. By mimicking the bone structure mechanical strength of porous Mg was enhanced significantly. Also corrosion of bone-mimetic porous Mg was well restrained when HA coating by solution treatment was used. Further in vitro and in vivo evaluations are in progress and it is expected that biological properties of porous Mg with HA coating will be improved in comparison with those of bare Mg. Thus, HA coated bone-mimetic porous Mg is considered to be a promising material for load bearing biomedical applications.

Figure1. (a) Optic image of bare and HA coated bone-mimetic porous Mg and (b) u-CT image of bone-mimetic poruos Mg

Figure 2. Yield compressive strength of bare, dense and bone-mimetic porous Mg

Figure 3. pH change after immersing bare bone-mimetic porous Mg and HA coated bone-mimetic porous Mg in SBF

WPM Biomedical Materials-Implant Materials

References:

[1] M.H. Kang, H.D. Jung, S.W. Kim, S.M. Lee, H.E. Kim, Y.R. Estrin and Y.H. Koh, "Production and bio-corrosion resistance of porous magnesium with hydroxyapatite coating for biomedical applications," Materials Letters. Vol.108, Oct. 2013

[2] M. Tomozawa and S. Hiromoto, "Growth mechanism of hydroxyapatite-coatings formed on pure magnesium and corrosion behavior of the coated magnesium," Applied Surface Science. Vol. 257, Jul. 2011