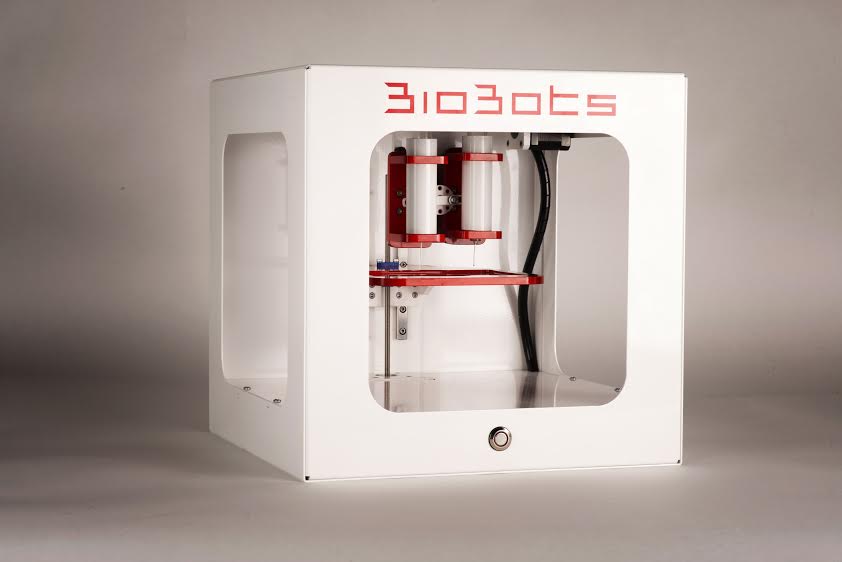

Introduction: Bioprinters have been arising in all shapes, sizes, and prices around the world as scientists, engineers, and industry begin to acknowledge their value to fabricate 3D tissues using a wide range of materials [1]. Before the BioBots Beta, researchers had to choose to either purchase large, expensive, and difficult to use 3D bioprinters or hack away at their own units to access the power of a 3D bioprinter [2]. For the past year we have placed 50 BioBots Beta units into the hands of researchers around the world and incorporated that feedback to bring the tissue engineering community the BioBot 1TM – a perfect blend between versatility and accessibility. Here, we demonstrate the BioBot 1’s ability to easily design new constructs and print with a wide range of standardized materials to achieve the next generation of tissues.

Materials and Methods: Designs were created on SOLIDWORKS 2015 and processed using a .stl file. 100 μm lines separated by 20 μm, lattices, and solid walls were created and sliced using open-source Slic3r on the BioBots Software user interface. Different pressures were applied at a 0.2 PSI resolution on both extruders and shown to control line thickness. Designs were printed out using BioPCLTM, which is manufactured polycaprolactone (PCL), at 120 oC from the first extruder and BioGelTM, which is manufactured from gelatin methacrylate containing 0.5% (w/v) BioKey, which is manufactured lithium phenyl-2,4,6 trimethylbenzoylphosphinate, at 30 oC from the second extruder. Lattices were created with a combination of BioPCL and a 10% aqueous solution of HepG2 cell-laden BioGel. HepG2 cells were cultured in monolayers at 37 °C and 5% of CO2 until bioprinting and encapsulated in BioGel before printing.

Results: Using the BioBot 1 and BioGel, results showed consistent line printing with 100 μm resolutions and a distance of 30 μm a part line with thickness growing by 20 μm size with step wise increases in pressure. Using this information, lattices and complex geometries were achieved. Further, HepG2 cells were successfully encapsulated and bioprinted, with high cell viability at 24 hours and 1 week time points as depicted using LIVE/DEAD viability staining.

Discussion: BioBots, Inc. and the BioBot 1 arose from the Maker Movement and continues to embody that spirit. It is an accessible, standardized, and easily usable tool that is pushing the field of tissue engineering and regenerative medicine forward. It is empowering researchers around the world to leverage 3D bioprinting technology in their own labs and educating the next generation of tissue engineers.

Conclusions: The results presented confirm the BioBot 1’s ability to easily design tissue constructs, finely control the extrusion of those designs, and create complex geometries with high post-print tissue viabilities. This work is significant because it moves the field forward to provide the world’s most versatile yet accessible 3D bioprinter, which enables future innovation and progress in the field of tissue engineering.

References:

[1] Nature Biotechnology 32, 773–785 (2014)

[2] Nature Materials 11, 768–774 (2012)