Introduction: Many factors may affect in vitro and in vivo degradation of an absorbable medical device. One of such factors is pH value of buffer solutions used in in vitro studies. A through study of the literatures in the related areas has showed a mixed result. For example some research showed the strength decreased faster in acidic condition if compared to the standard pH7.4, while others gave the opposite results. To gain an in-depth understanding of their degradation mechanism under different pH conditions we have conducted this study which is to evaluate effects of pH on in vitro degradation of two experimental poly(glycolide-co-L-lactide) (PGL) braided multifilament materials. This presentation reports our findings from the study.

Materials and Methods: The experimental materials were two in-house prepared drawn, braided multifilament fibers (dyed and undyed), based on a copolymer of ~90 mol% glycolide and ~10 mol% L-lactide (PGL 90/10). The materials were annealed to give a crystallinity of ~45%. For experiments the fibers (diameter =~0.33mm) were cut into 5-in long specimens. Phosphate buffer solution (PBS) of pH7.3 was prepared with sodium phosphate and potassium phosphate solutions. Two acids (HCl and H3PO4) were used to reduce pH7.3 to pH6-pH3, while NaOH was used to obtain pH higher than pH7.3. Fiber specimens were then placed in PBSs with different pH, but under constant temperature 37°C. At each pre-determined time interval, 8 specimens were removed from the in vitro bath and tensile-tested at room temperature immediately on an Instron tester with gage length 1 inch and crosshead speed 1 in/min. The molecular weight (Mw) was determined by gel permeation chromatography (GPC) analysis on Waters 2695, Wyatt Optilab rEx Refractometer, Wyatt HELEOS II Multi-angle Laser Light Scattering Detector, Columns-PL HFIPgel columns (2) with Mobile phase-HFIP with 0.01 M LiBr (0.2% H2O).

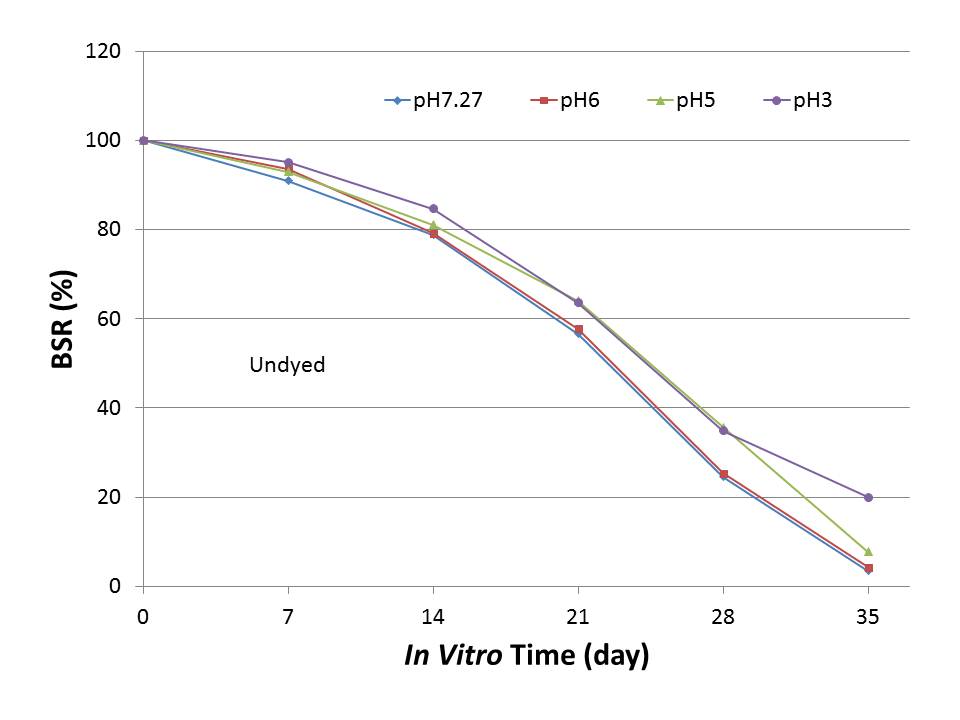

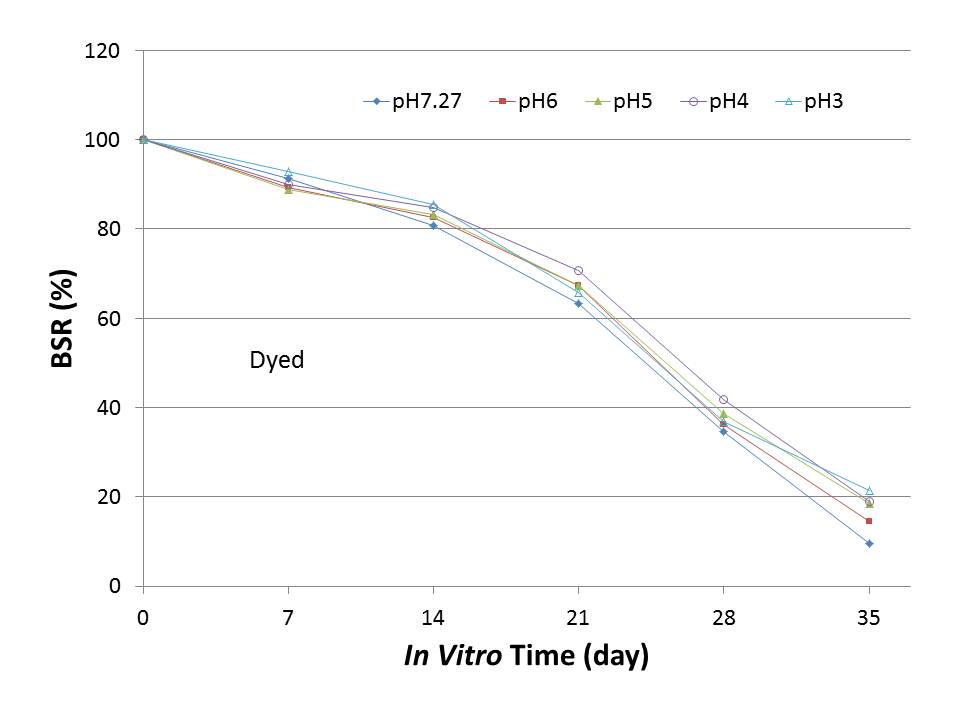

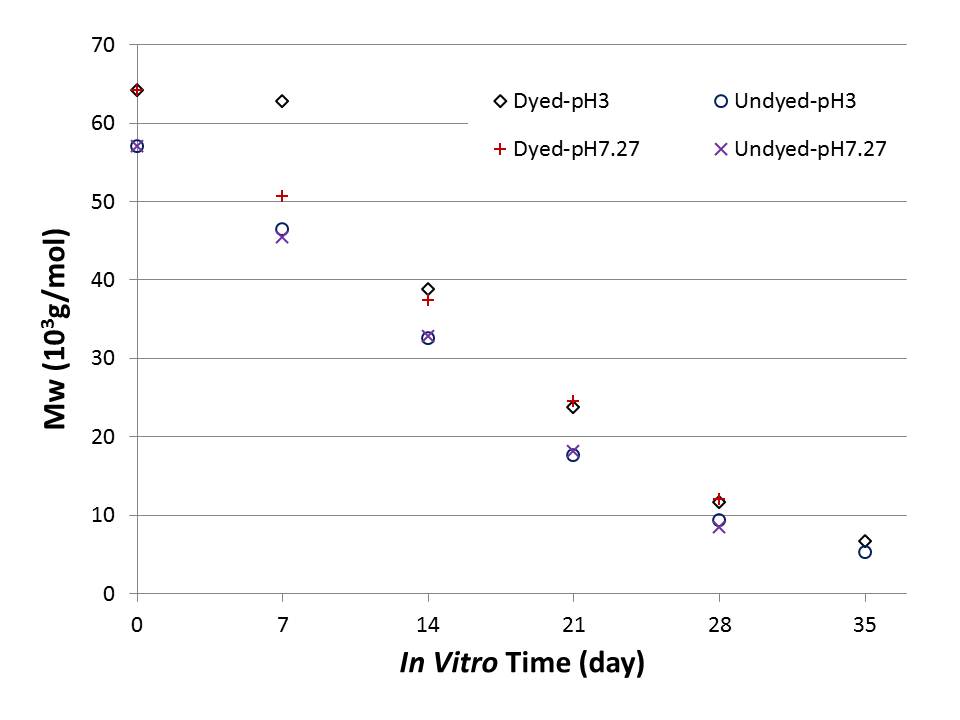

Results and Discussion: Figs 1 and 2 show the changes of tensile breaking strength retention (BSR) of two fibers with pH value. As expected, the BSR decreased with increasing exposure time, with the undyed degraded slightly faster than the dyed sample. At 4 weeks in vitro the dyed and undyed samples still had at least 25% strength remaining. The acidic conditions (from pH6 to pH3) seem to yield a slightly higher BSR compared to pH7.3, which is different from the basic conditions. Fig 3 illustrates effects of pH on molecular weight and again low pH hardly had any effects on Mw reduction rate during the in vitro degradation, which is in agreement with the tensile strength results. For a different polymer (e.g. PDO), however, our previous result did show that low pH conditions may accelerate the in vitro degradation.1 It was found that the formula can be used to illustrate the relationship between molecular weight and tensile strength for the fibers during in vitro degradation, and pH had no effect on this relationship.2 Although not presented in this abstract, the experimental data showed that high pH (e.g. pH10) tended to accelerate the in vitro degradation of the fiber materials. Finally it was also found that tensile moduli and tensile breaking elongation decreased significantly with the in vitro time.

Summary: Effects of pH on in vitro degradation of two PGL fibers were investigated. While high pH accelerated the in vitro degradation, low pH conditions had less effect on the degradation of the materials. A good relationship exists between BSR and Mw for the polymer fibers during in vitro degradation [1],[2].

Table 1. Initial Properties of Experimental Fibers

Fiber Strength (N) Modulus (GPa) Strain at Break (%) Mw (x1000g/mol)

Undyed 68.34±1.59 8.727±0.496 29.2±1.5 57.0±0.3

Dyed 68.77±1.47 7.990±0.359 30.8±1.5 64.2±1.8

The authors want to thank Dr. Richard Skula and Robert Tannhauser for reviewing the abstract.

References:

[1] SFB, p216 (2014)

[2] Biomaterials, 26, p4327 (2005)