In this paper, multi-biomaterials with a novel crosslinking process (combination of pre-chemical and physical crosslinking method ) were used to form a bioink to produce 3D cell-laden constructs by 3D bioprinting for skin tissue engineering. The skin constructs produced by the bioink showed an improved mechanical strength that matched the human skin compared with the bioink by physical crosslinked only. Prolonged degradation rate was also achieved. The bioink was also biocompatible, high cell surviving rate was achieved.

Introduction: 3D bioprinting has shown a great promise in fabricating 3D complex multicellular tissues analog living architecture by delivering a precisely cell population encapsulated by bioinks to a targeted location. However, the limited choice of 3D-printable bioinks for cell encapsulation and supporting scaffolds is the main obstacle for 3D bioprinting[1],[2]. In this paper, a composition of Collagen, Hyaluronic Acid (HA) and Chitosan was chosen to develop a biocompatible bioink. Two crosslinking methods, named pre-chemical crosslinking before printing and physical crosslinking after printing, were applied to achieve desired mechanical strength and biocompatibility. Fibroblasts (FBs) were dispersed into the bioink to produced 3D cell-laden living constructs.

Materials and Methods: Chitosan\HA\Collagen mixtures were blended with different weight ratios. 3 wt%, 6 wt% and 9 wt% of Tyrosinase in deionized water were added to the mixtures before printing to test the pre-chemical crosslinking process, the samples were denoted as Chs\HA\Col -T, samples without Tyrosinase pre-chemical crosslinking were denoted as Chs\HA\Col. 3D constructs of Chs\HA\Col and Chs\HA\Col-T scaffolds were fabricated by a 3D bioplotter (EnvisionTEC, Germany). Sterilized sodium tripolyphosphate (STPP) solution (15 wt%) was nebulized to physically crosslink the hydrogels for 15min for each layer.

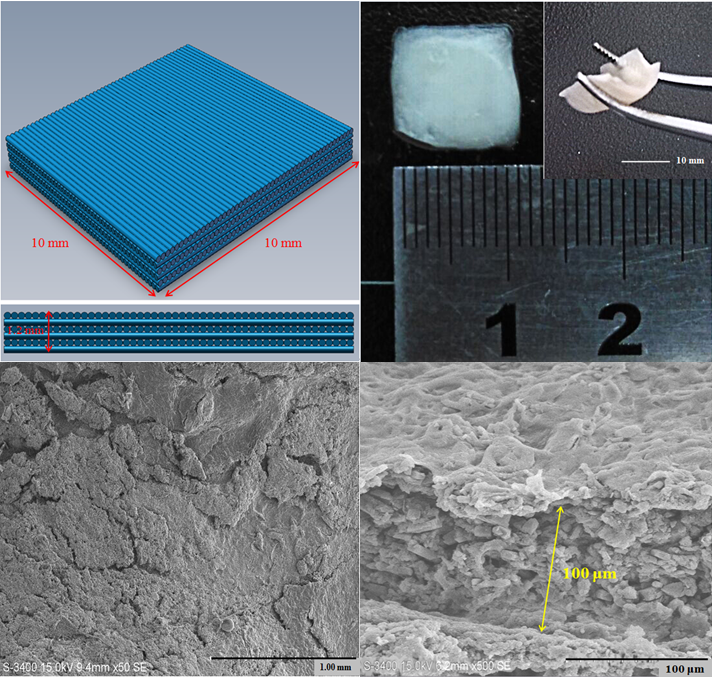

Results: The composition of the bioink of chitosan of 8 wt%, HA of 0.5 wt%, and 10wt% of collagen was chosen to produce skin constructs. The morphology of the constructs resembled human skin and had a layered structure as shown in Figure 1. The tensile strength of Chs\HA\Col and Chs\HA\Col-T were 29.9 and 39.1kPa, respectively. The Young’s modulus of Chs\HA\Col and Chs\HA\Col-T were 0.170 and 0.313MPa. These results indicated that Chs\HA\Col-T offered an improved mechanical strength that matched the human skin[3] due to chemical-induced cross-linking by tyrosinase.

Figure 1

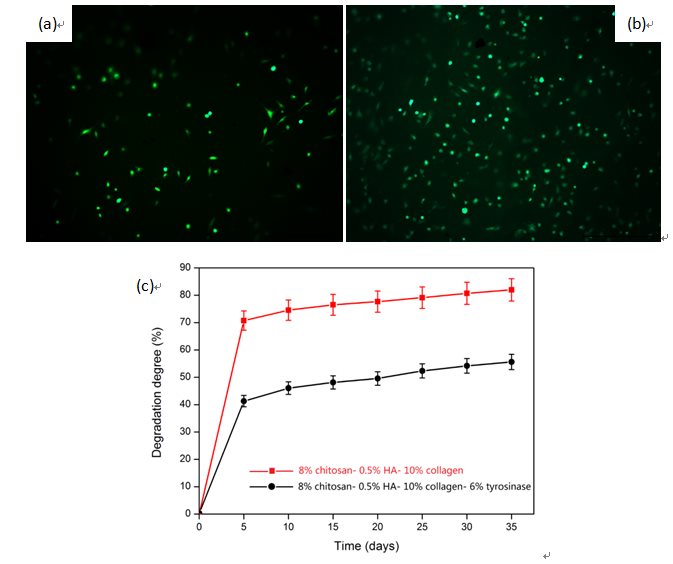

The degradation rates of Chs\HA\Col and Chs\HA\Col-T in 35 days were 81.99% and 55.34%, respectively. It indicated that using tyrosinase pre-chemical crosslinked hydrogel could slow down the degradation of the skin constructs as shown in Figure 2a, b. The cell-culture showed that the skin constructs are biocompatible and have a high cell surviving rate as shown in Figure 2c.

Figure 2

Conclusions: A novel bioink for 3D bioprinting was obtained by a pre-chemical crosslinking method combined with physical crosslinking of multi-biomaterials to produce skin substitutes. The results showed that the skin constructs by this novel crosslinking process exhibited good mechanical properties and biocompatibility. The mechanical strength and degradation rate can be tailed by the concentration of tyrosinase. Thus, this novel cross-linking method is promising is soft tissue engineering, such as skin, cartilage tissue engineering.

References:

[1] A. L. Rutz , K.E. Hyland , A. E. Jakus , W. R. Burghardt , and Ramille N. Shah, A Multimaterial Bioink Method for 3D Printing Tunable, Cell-Compatible Hydrogels, Advanced Materials, 2015, 27, 1607–1614.

[2] F. M. Wood, Skin regeneration: The complexities of translation into clinical practice, The International Journal of Biochemistry & Cell Biology 56, 2014, 133–140.

[3] F. H.Zulkifli, F. S Hussain,M. S. Rasad, M. M. Yusoff , Nanostructured materials from hydroxyethyl cellulose for skintissue engineering, Carbohydrate Polymers 114 (2014) 238–245.