Introduction: Hydroxyapatite with low endotoxin gelatin has been developed to mimic the biochemical and biomechanical properties of natural bone (Chang et al., 2003)[2]. Recently, polydopamine-laced hydroxyapatite gelatin-calcium silicate (PDHGCS) has been developed to address the processability of the hydroxyapatite nanocomposite for the application of bone regeneration (Ko et al., 2014)[1]. Dopamine consisting of two functional groups (catechol and ethyl amine) forms interconnected polymeric network to enhance physical property by increasing long range interactions within the material (Dyke et al., 2014)[3]. We hypothesize that either increasing carbon length of amine group in dopamine or using a co-polymer P(LLA-co-PC) functionalized with catechol can further improve the mechanical property of PDHGCS.

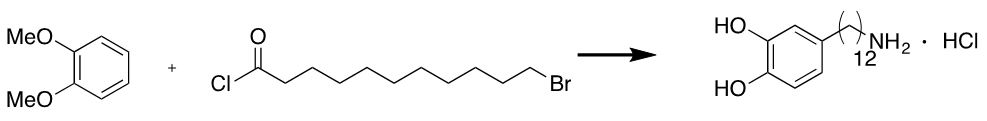

Methods and Materials: Synthesis of 12C-Dopamine: Synthesis is started with 1,2-dimethoxybenzene from which catechol function group was recovered to form the 12C-dopamine (Fig. 1).

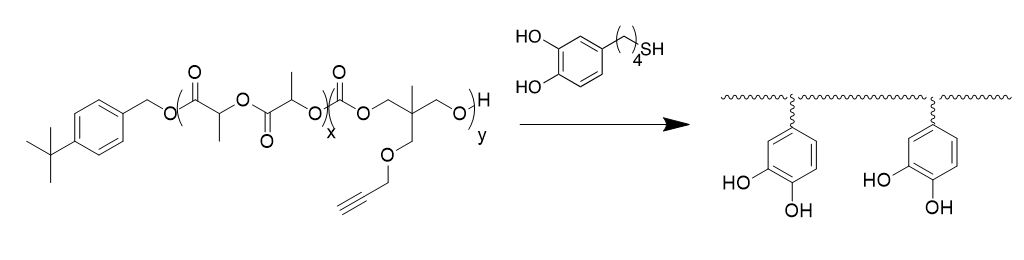

Synthesis of P(LLA-co-PC)-catechol: Copolymer was synthesized according to the previously reported method (Jason’s 2012 Paper). Catechol-4C-SH was covalent attached to the polymer backbone through “thiol-yne” click chemistry (Fig. 2).

Preparation of PDHGCS Composites: Briefly, 150 mg Hap-Gel, 100 mg of Ca(OH)2 powder, and a series of predetermined amounts of dopamine or 12C-dopamine and P(LLA-co-PC)-catechol powders were mixed with 383 μL of 62% enTMOS on a -20 °C slab, followed by addition of 40 μL of 7.5% ammonium persulfate solution in room temperature3. The central composite design was used to determine the amount of dopamine and P(LLA-co-PC)-catechol. The mixture was then injected onto a mold to create cylindrical sample for compression tests.

Results: The maximum compressive strength (~100 MPa) occurred around dopamine at 5 mg and co-polymer at 12.5 mg. The preliminary outcome suggests that the polymer was not significantly associated with the compress strength, and that the strength was a quadratic function of dopamine (p-value=0.047). Similarly, 12C-dopamine did not significantly increase the mechanical strength of the composite.

Discussion and Conclusion: The low endotoxin gelatin can be incorporated into PDHGCS. Dried powder form of 12C-dopamine and P(LLA-co-PC)-catechol does not increase compressive strength of PDHGCS. Whether these constitutes can improve tensile strength remains to be tested. The incorporation of solution form (12C-dopmaine and co-polymer) is under investigation. (Supported in part by NIH R01DE022816).

Low endotoxic gelatin was provided by Nitta Gelatin Inc., Osaka, Japan; NIH/NIDCR R01DE022816

References:

[1] Ko CC et al. Design, synthesis, and evaluation of polydopamine-laced gelatinous hydroxyapatite nanocomposites. In Advances in Bioceramics and Biotechnologies II. 2014: Vol 247:135-148.

[2] Chang MC et al. Preparation of hydroxyapatite-gelatin nanocomposite. Biomaterials. 2003, 24:2853-62.

[3] Dyke J et al. The role of temperature in forming sol-gel biocomposites containing polydopamine. J. Mater. Chem. 2014, 2, 7704-7711.