Introduction: Moisture transport characteristics of porous materials play an important role in many industries. For instance, membranes which are used in in-vitro permeation studies in skin care industry; and electrospun nanofibers for polymeric scaffolds are of particular interest.

Materials and Methods: Three model membranes, namely CarboSil® , Polyurethane and were used in this work. Moisture vapor flux obtained from these model membranes were subsequently compared to that of a human trypsinized stratum corneum. Electrospun polymers were extruded from a solution of Poly ε-caprolactone (PCL) for a final thickness of 300μm.

Payne style diffusion cell was designed and developed to measure the permeability/rate of diffusion of a thin film using a Dynamic Vapor Sorption (DVS) instrument. Moisture Vapor Transmission Rate (MVTR) describes the rate of water permeating through a test specimen into the headspace volume of a container which differs in relative humidity. Zeolite was employed as moisture scavenger for the MVTR experiments.

Results and Discussion: Payne diffusion cell loaded with membrane sample was subjected to changes in RH. Change in mass of zeolite at the desired RH refers to the diffusion of water vapor through the membrane via the cell opening. Therefore, in-vitro trans-membrane water vapor diffusion rate can be calculated from the slope of the moisture uptake by zeolite. Subsequently, the water vapor flux was determined by taking into account the area of the cell opening.

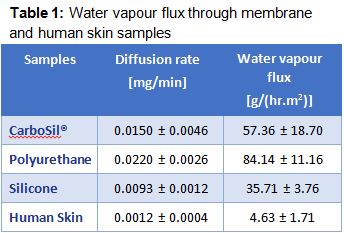

Among the tested membranes, Polyurethane was the most permeable barrier to water vapor, with faster kinetics and much higher moisture uptake. This was followed by CarboSil® membrane , while Silicone membrane was the least permeable. Comparing to the human skin measurement, it clearly has a lower moisture diffusion rate (Table 1).

Water vapuor flux results show very high moisture vapour permeability of electrospun PCL membrane, as summarized in Table 2. The diffusion rate is significantly influenced by the change in humidity. This is due to the fact that a higher humidity corresponds to a higher gradient between the two sides of the PCL membrane. As anticipated, the permeability rate was reduced with increased thickness, but, the reduction of the permeability rate for the thicker sample was minor (less than 1% in reduction). Therefore, it can be concluded that the moisture permeability is not strongly dependent on the sample thickness of PCL membrane. On the other hand, temperature was a significant variable as increasing the temperature (up to 45°C) accelerated the vapor permeability rate, possibly due to the rearrangement/ expansion of the PCL fibers at elevated temperatures. The water vapor flux through the PCL membrane was significantly increased by nearly 50%.

Conclusions: This study note has shown that Payne diffusion cell, coupled with DVS instrument can be used to determine the moisture permeability properties of membrane samples. Similar experiments could also be performed on other thin polymer films such as those found in packaging industry, and membrane in filtration applications.