Introduction: While pluripotent stem cells have the potential to overcome many problems in areas such as tissue engineering and cell replacement therapies, their use is hindered by the difficulty of producing the large amounts of high quality cells required. Current culture methods are labour intensive, low throughput, and may rely on animal derived factors. Therefore, there is a strong requirement for a method that can produce high quantities of reliable pluripotent stem cells under fully defined conditions.

3D cell culture offers a viable method for scaled up production. 3D scaffolds need to provide structural support, allow cell migration and maintain pluripotency. PolyHIPEs are a potential 3D scaffold. They are produced by polymerising a high internal phase emulsion (HIPE) to produce a porous foam (polyHIPE). They possess interconnected, porous structure that is suitable for cell culture as it allows the migration of cells, the delivery of nutrients, and removal of waste. The pore size of polyHIPEs can be tuned easily via heating, shear rate or addition of destabilising agents[1].

PolyHIPEs have been shown to support cell growth[2], and are open to modifications that may allow them to support the unique requirements of pluripotent cells. Addition of ECM peptides, for example, can mimic the stem cell niche and help maintain pluripotency.

Methods: PolyHIPEs are produced via a photo-initiated reaction between a thiol and a multi-functional acrylate in emulsion with water. The resulting emulsion is cast in a mould and exposed to high intensity UV light. This method allows the polyHIPE to be made in any shape up to 5cm thickness. The final shapes can be cut using a microtome.

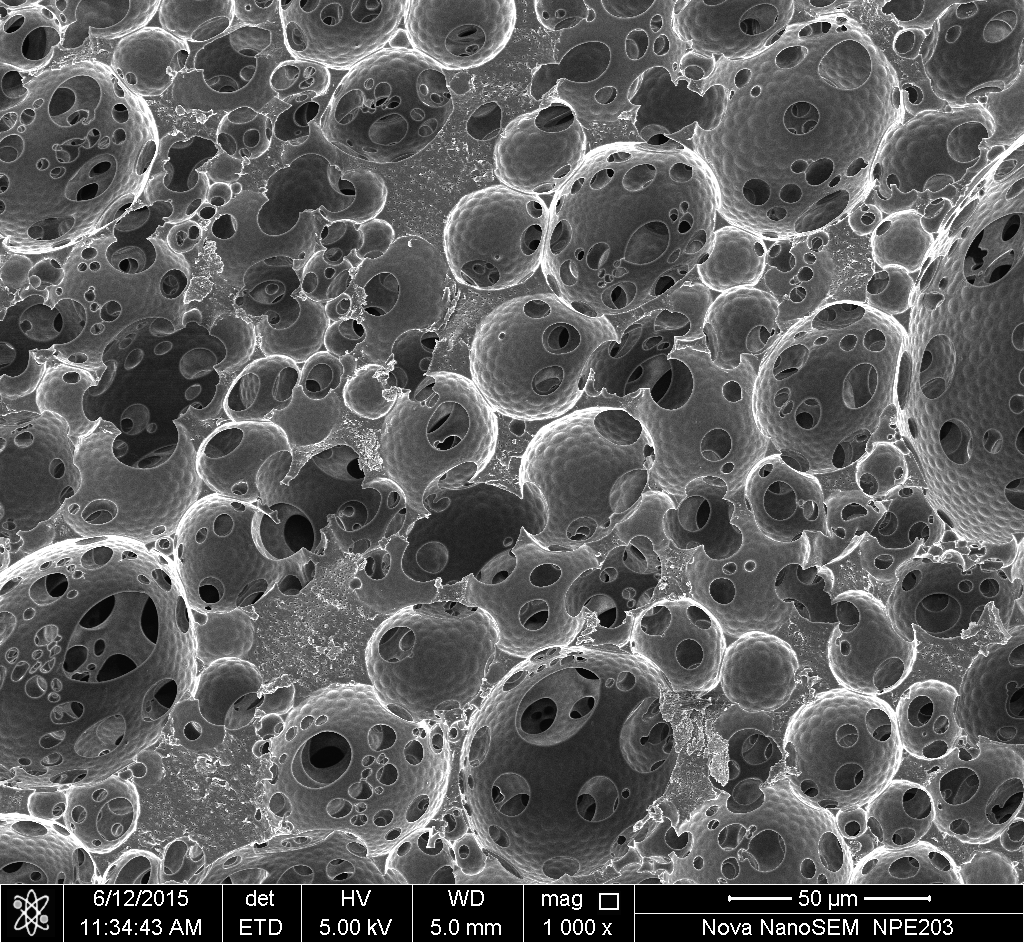

Morphology is determined using SEM. Pore size is calculated by SEM image analysis using ImageJ processing software.

After confirming the void morphology is suitable, the surface is functionalised. Currently, maleimide is being attached via a Michael reaction with residual surface thiols. This process is being optimised with the aim towards functionalising the polyHIPE with molecules which promote cell attachment, growth and pluripotency.

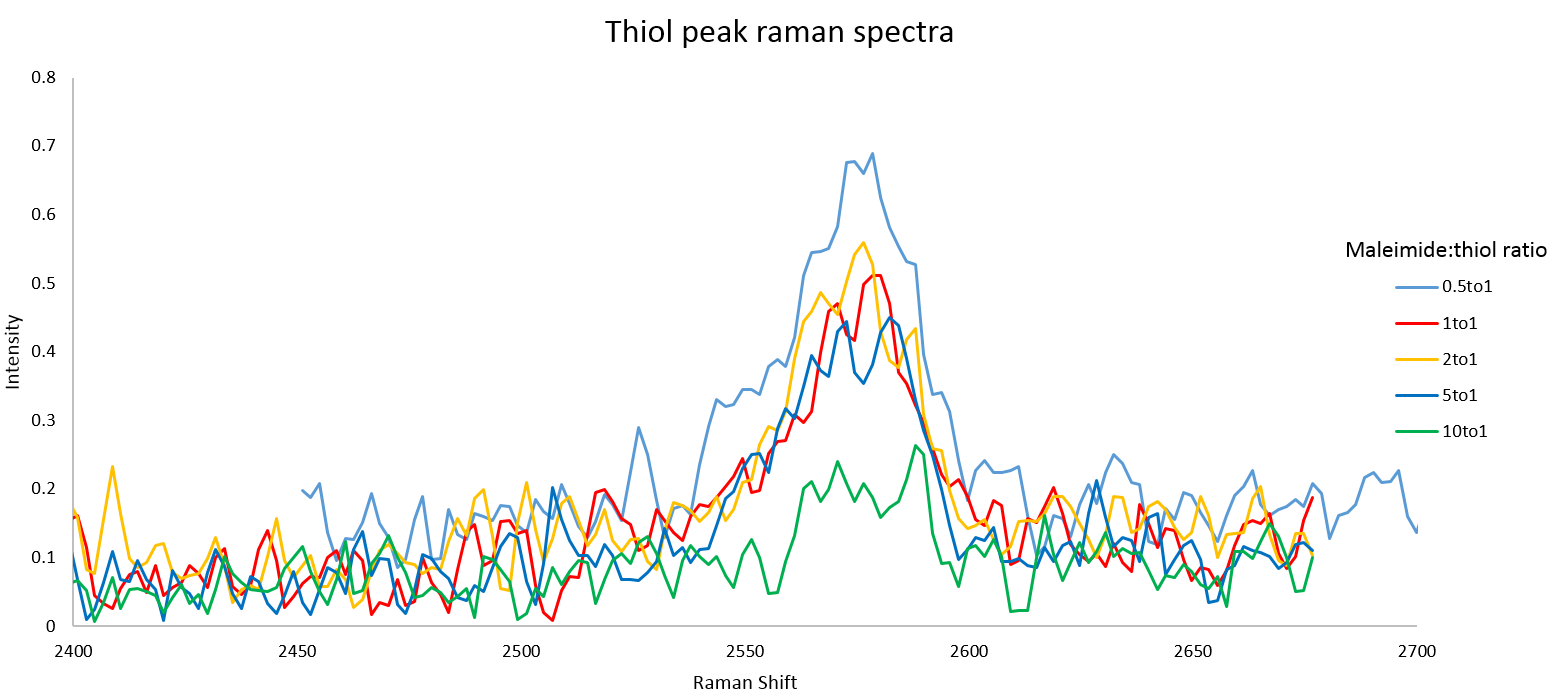

Chemistry is monitored with FTIR-Raman, XPS and an Ellman’s colorimetric assay.

Results and Discussion:

Figure 1: SEM image of as-synthesised polyHIPE

Figure 1 shows the typical morphology of the thiol-acrylate polyHIPE. The larger cavities are referred to as ‘voids’ and the smaller connecting holes are known as ‘windows’. The average void size is 38±16μm. The large pores and interconnectivity of the scaffold are suited for cell attachment and migration.

Figure 2: Raman spectra showing the decrease in the thiol peak at different maleimide attachment ratios.

Raman spectroscopy was used to track the surface functionalisation with maleimide. Figure 2 shows the decrease in the scaffold thiol peak as the maleimide ratio is increased. This trend was confirmed using XPS, and quantified using Ellman’s assays.

Conclusion: The polymer scaffolds investigated in this project have already proven suitable for 3D cell culture, and with further modification could be tailored to better mimic the niche environment of pluripotent stem cells. The ability to culture such cells in 3D while maintaining pluripotency would have a strong downstream impact on tissue engineering, cell replacement, toxicology screening and other technologies that make use of pluripotent stem cells.

This work was funded by Monash University and CSIRO.

References:

[1] C. R. Langford, D. W. Johnson, and N.R. Cameron, Chemical functionalization of emulsion-templated porous polymers by thiol–ene “click” chemistry. Polymer Chemistry, 2014. 5(21): p. 6200-6206.

[2] Caldwell, S., et al., Degradable emulsion-templated scaffolds for tissue engineering from thiol-ene photopolymerisation. Soft Matter, 2012. 8(40): p. 10344-10351.