Introduction: Among the available biomaterials, calcium phosphate cements, such as hydroxyapatite (HA) and brushite, are of high interest due to their many advantages, e.g. bioactive, osteoconductive, osteotransductive, injectable and self-setting in vivo. Still, although they are biodegradable, degradation rate is a problem since the very slow degradation of HA inhibits bone ingrowth and the rapid degradation of brushite disrupts mechanical stability. Recently, some attempts to produce biphasic cements composed by HA and β-tricalcium phosphate (β-TCP) have been performed[1],[2]. However, no improvement in dissolution rate was found[2]. The answer might be adding an even more soluble phase, e.g. brushite. This work aims at designing new multiphasic calcium phosphate cements (MCPCs) with improved degradative properties.

Materials and Methods: All cements were based on a HA cement prepared by mixing α-tricalcium phosphate (α-TCP) with a 2.5 wt% Na2HPO4-solution (L/P = 0.35 ml/g). Two different methods were used to produce the MCPCs: 1) 20 mol% monocalcium phosphate monohydrate:ß-TCP (1:1 molar ratio) was added to the powder phase (80 mol% HA); 2) 35 wt% or 50 wt% of crushed set brushite[3] particles (SBPs) were added to the powder phase (L/P was adjusted to 0.20 and 0.19 ml/g, respectively). Specimens were let to set in PBS for 48 h. Setting times were determined with Gillmore needles. Wet specimens were tested in compression. Phase composition was analysed with XRD and Rietveld refinement using Profex. An accelerated mass degradation was attained by placing cement samples in a solution of pH = 2 containing hydrochloric acid for 8 h. The weight of the samples was monitored over time.

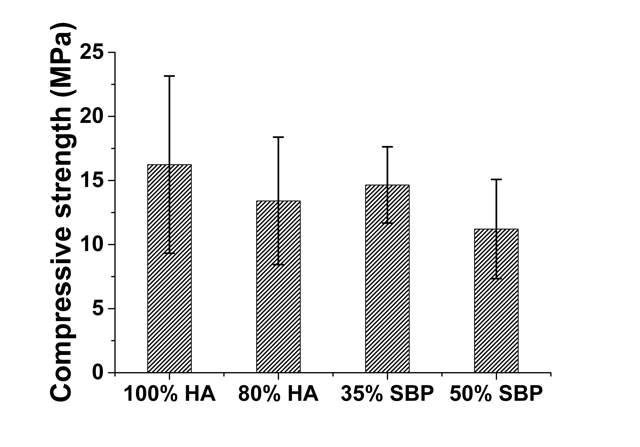

Results and Discussion: Both methods resulted in mouldable cements. Setting times for the MCPCs were comparable or slightly shorter than those for the pure HA cement. The compressive strength of the MCPCs was in general slightly lower, however the cement containing 35 wt% SBP had a comparable strength to the pure HA.

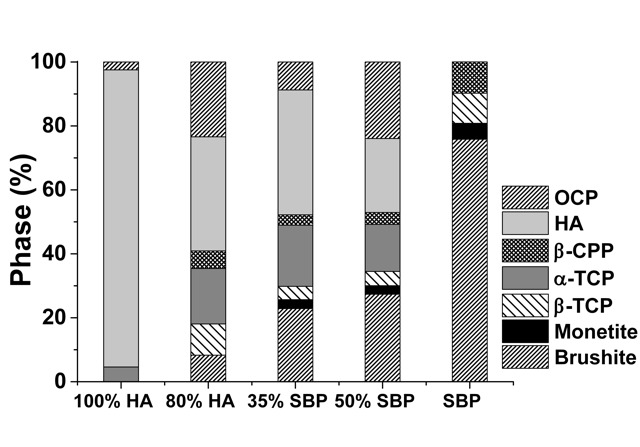

Rietveld refinement reviled that the MCPCs were not only biphasic but multiphasic.

All three compositions did not only consist of HA and brushite, but octacalcium phosphate (OCP) and unreacted α-TCP and ß-TCP were also present. Small amounts of beta-dicalcium pyrophosphate (ß-SPP) were also found, due to impurities in the ß-TCP powder. OCP is a precursor of hydroxyapatite and would probably have transform into HA if the samples had been let to set for a longer time[4]. All samples started to dissolve in the degradation solution.

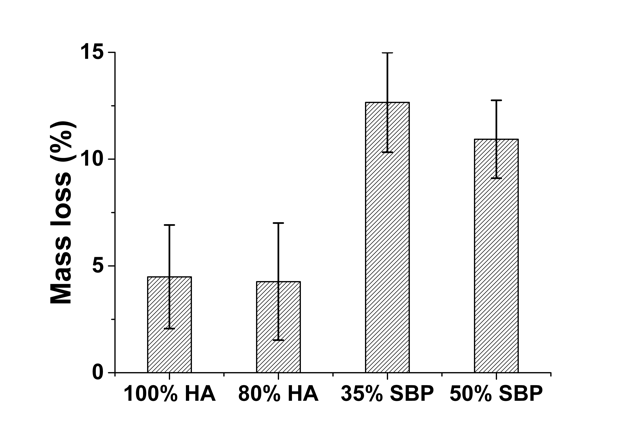

Furthermore, the samples containing SBP degraded significantly faster than the pure HA and the 80 mol% HA samples.

Conclusions: It was possible to obtain multiphasic calcium phosphate cements with two different methods. The cement containing 35 wt% of set brushite particles showed promising preliminary results. It maintained approximately the same setting times and compressive strength as pure HA, at the same time as an increased degradation rate was achieved. However, further studies to optimise and fully characterise this multiphasic calcium phosphate cement are needed.

This work was supported in part by Carl Tryggers Stiftelse (grant CTS 13:533).

References:

[1] Lopez-Heredia et al. Acta Biomater. 2012; 8(9): 3500-3508.

[2] Gallinetti et al. J. of Am. Ceram. Soc. 2014; 97(4): 1085-1073.

[3] Unosson et al. Bioceram Dev Appl 2014; 4: 074.

[4] Ginebra et al. Biomaterials. 2004; 25(17):3453–3462.