In-vitro study of organosilane coated degradable magnesium dental mesh

Avinash

Patil1, 2,

Andrew

J.

Brown1, 2,

Samer

Zaky2, 3,

Charles

S.

Sfeir1, 2, 3 and

Elia

Beniash1, 2, 3

-

1

University of Pittsburgh, Department of Bioengineering, United States

-

2

University of Pittsburgh, Center for Craniofacial Regeneration, United States

-

3

University of Pittsburgh, Department of Oral Biology, United States

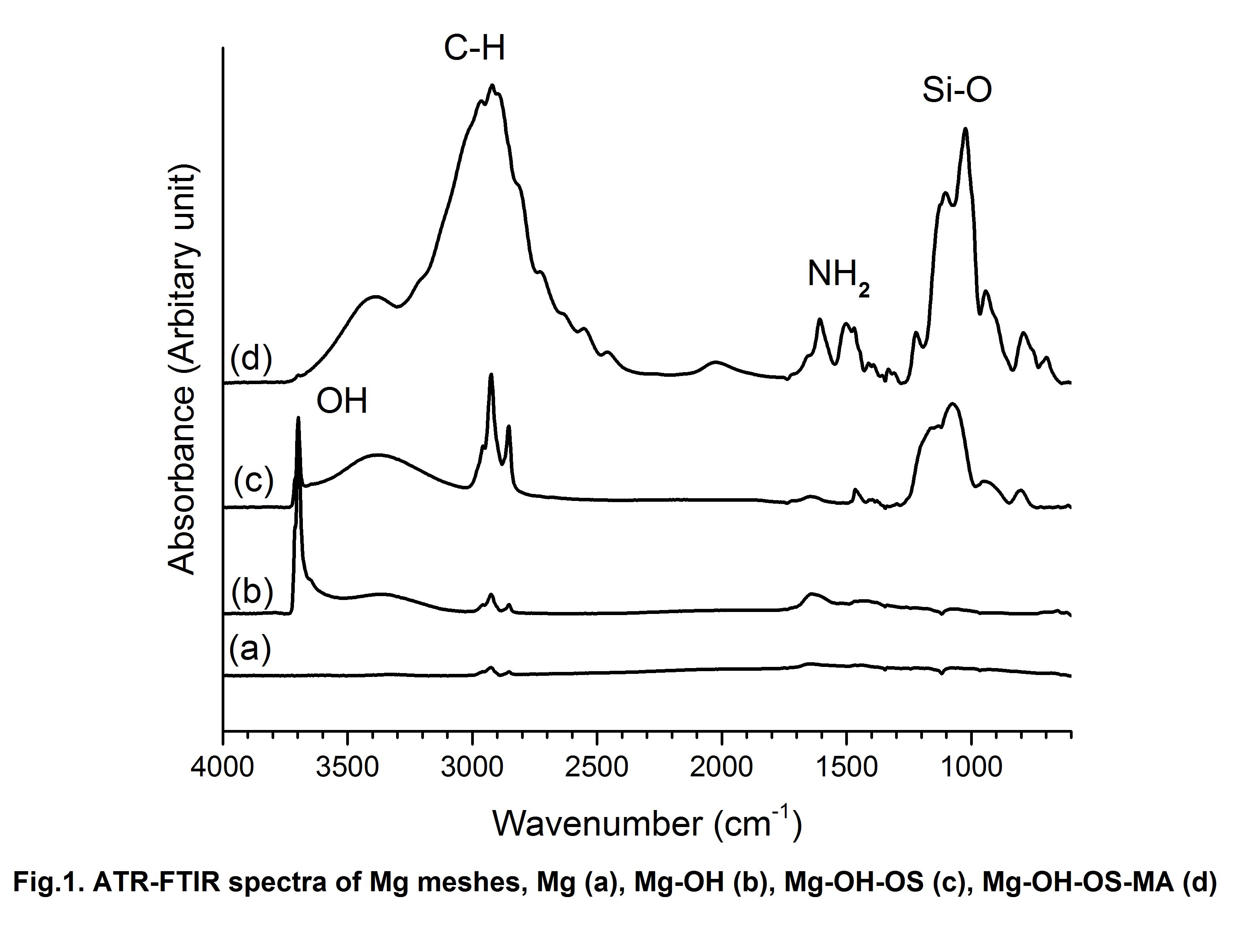

The metallic and biodegradable polymer dental meshes are currently used to secure the bone graft material and prevent the ingrowth of soft tissue at the bone defect site, a procedure known as guided tissue regeneration or GTR. The metallic meshes (Titanium) are non-degradable and require second surgery to remove them. Metallic meshes integrate with surrounding bone making it difficult to remove. Polymer meshes have poor mechanical stability as well as unpredictable degradation rate. Magnesium (Mg) and its alloys have a great potential as degradable dental mesh implant material for a number of reasons including light weight, biocompatibility and their mechanical properties closely matching those of bone. Most importantly, Mg dental meshes will degrade in the body in a span of a few months eliminating need for second surgery to remove the implant after the defect has been healed, thus reducing the cost of treatment. However, degradable Mg meshes require a controlled degradation rate to avoid an initial rapid corrosion burst leading to formation of gas pockets around the meshes. The goal of the study was to use of alkylsilane derived self-assembled multilayer coating on Mg dental meshes to regulate its corrosion rate. Mg meshes (Mg) without any treatment were used as control. Alkali treatment (NaOH) was given to meshes (Mg-OH) prior to coating to enhance adhesion of alkylsilane to oxide layer. The self-assembled coating was formed by co-polymerization of n-Decyltriethoxysilane (C10H21Si(OEt)3) (DTEOS) and Tetramethoxysilane (TMOS). A simple dip coating technique to deposit alkylsilane coating layer on alkali treated Mg meshes was used (Mg-OH-OS). Silane PEG Maleimide (MA) was used to functionalize Organosilane coated layer (Mg-OH-OS-MA) to conjugate Bone Morphogenic Protein (BMP-2) to Mg dental mesh. Functionalization of Mg dental meshes with osteogenic protein will help to get better clinical outcomes. Scanning electron microscopy (SEM) and light microscopy studies revealed a presence of smooth, homogenous defect free, micron thick coating. Fourier transform infrared (ATR-FTIR) spectroscopy confirmed the presence of Si-O-Si and C-H bond characteristic of alkylsilane polymer as shown in figure1.

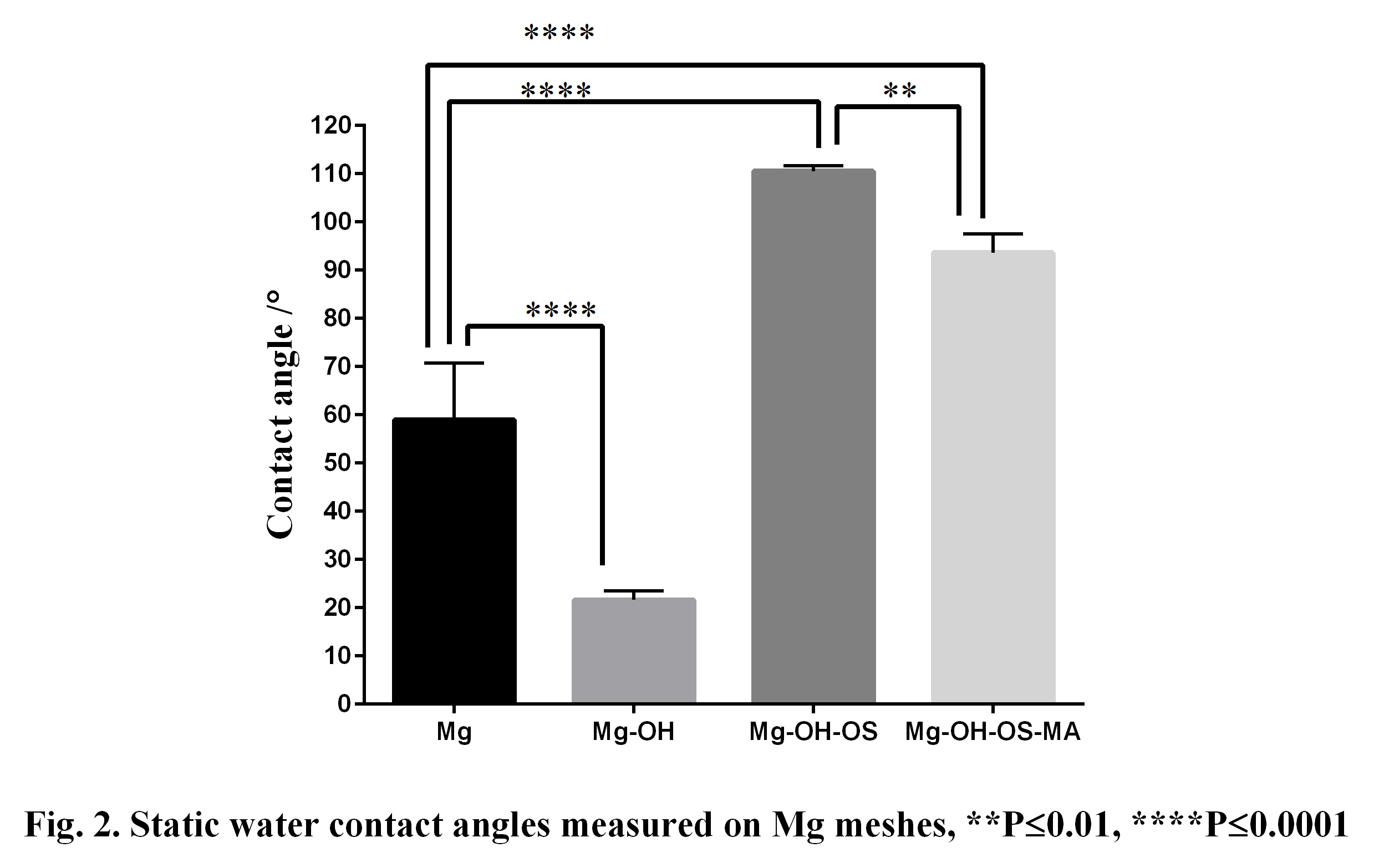

To assess the hydrophobicity of the coating we carried out the contact angle analysis of the Mg meshes as shown in figure 2.

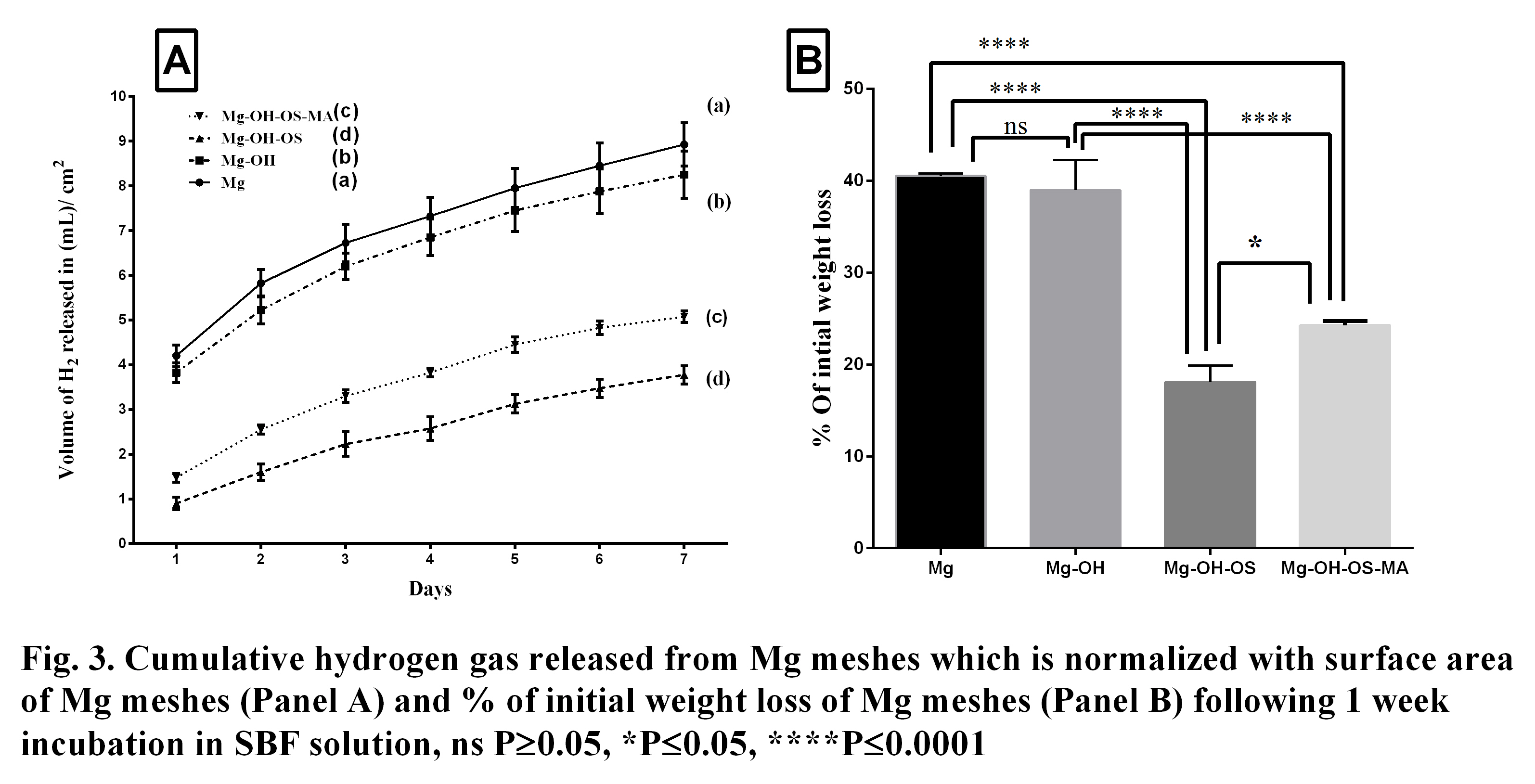

The contact angle of the coated Mg meshes was almost two times higher than uncoated Mg meshes indicating the presence of a fairly homogeneous coating. We also demonstrated that further functionalization of organosilane layer by MA reduces the hydrophobicity of organosilane coated Mg meshes. The corrosion resistance properties of the coating were assessed by hydrogen release study which showed a few fold reductions in the corrosion rate of organosilane coated vs non-coated Mg meshes as shown in figure 3.

This confirmed that organosilane coating reduces corrosion rate of Mg meshes. In conclusion, the organosilane self-assembled coating has significantly reduced the corrosion rate of Mg meshes compared to non-coated meshes. Furthermore, MA functionalization helped to conjugate BMP-2 to Mg meshes. We anticipate that this work will lead to a development of better coating strategies for resorbable mesh devices.

The authors acknowledge the financial support from NSF ERC Center for Revolutionizing Metallic Biomaterials # 0812348.

Keywords:

Implant,

clinical application,

Biodegradable metal,

biofunctional molecule

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomaterials in dental applications

Citation:

Patil

A,

Brown

AJ,

Zaky

S,

Sfeir

CS and

Beniash

E

(2016). In-vitro study of organosilane coated degradable magnesium dental mesh.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.02899

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.