Introduction: Biodegradable Metals (also known as absorbable metals) have attracted great attention for their unique degradation properties[1]. The biggest challenge nowadays is to well understand the degradation and then tailor the degradation according to host environment. According to the discussed guide at at BIOMETALS 2015, currently the evaluation methods upon corrosion tests include electrochemical tests, immersion test and hydrogen evolution test[2]. Despite investigating instantaneous data or not, these degradation test methods all record the data of the large area of the exposured surface. However, localized corrosion and pitting corrosion are more detrimental to medical devices. Besides, it's been generally accepted that rate uniformity is considered to be the princeple concern. Therefore in situ monitoring localized corrosion/pitting corrosion along with time is in great demand. Here we propose SVET (scanning vibrating electrode technique) to monitor the corrosion process, getting localized corrosion/ pitting corrosion data instantaneously.

Materials and Methods: As-cast Mg-6Zn and Mg-2Sr were utilized. The materials have been mechanically polished up to 5000 grit and polished by electrichemical method. The microstructure was investigated via metalloscope. SVET test (Applicable Electronics Inc, USA) was carried out in Hank's solution. Pt-Ir wire probe as microelectrode was located 2000 um above the specimen to reduce the influence of hydrogen from the surface. SVET monitoring was conducted for 2 h.

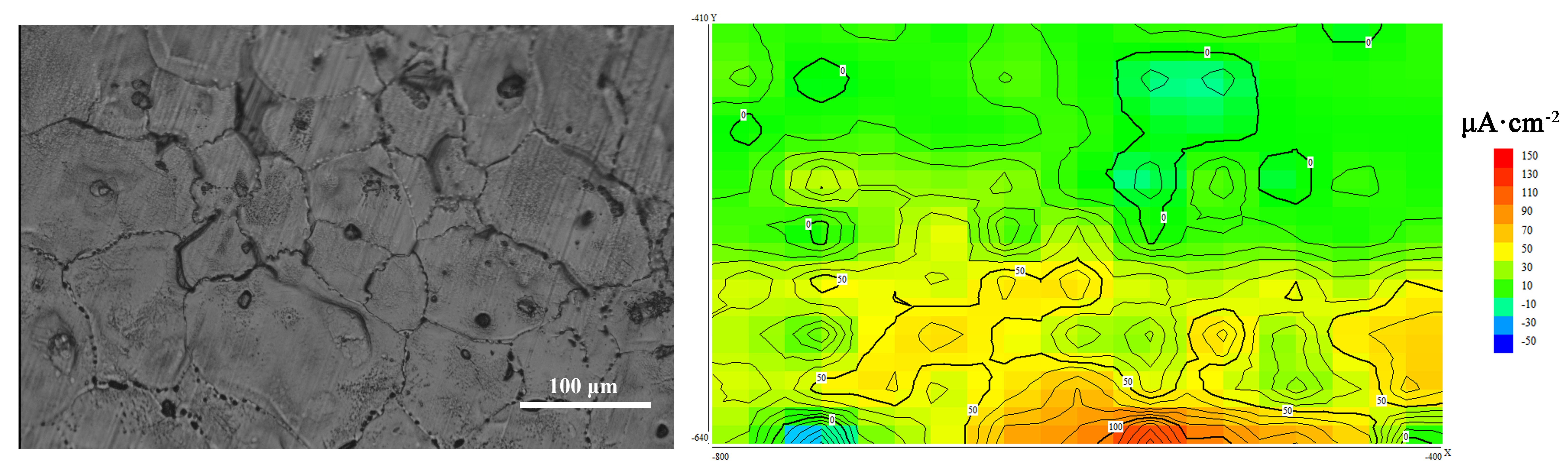

Results and Discussion: Figure 1 shows the microstructure and the corresponding SVET monitored corrosion current density distribution at 5 min. The grain boundary and the aggregates of second phase inside the grain define the corrosion current density range. Some particles in the grains possess cathodic corrosion current density, while some other particles and the grain boundaries perform anodic corrosion current density. This may be due to different Mg-Zn intermetallics and the impurities. Thereafter, the area where perform extremum in corrosion current density experience typical routine. SVET monitored corrosion rate continually increasing, and then slow down. Meanwhile, other parts of the surface randomly reach its highest corrosion current density and then decrease.

Figure 1. Microstructure and the corresponding SVET corrosion current density distribution of as-cast Mg-6Zn at 5 min in Hank's solution.

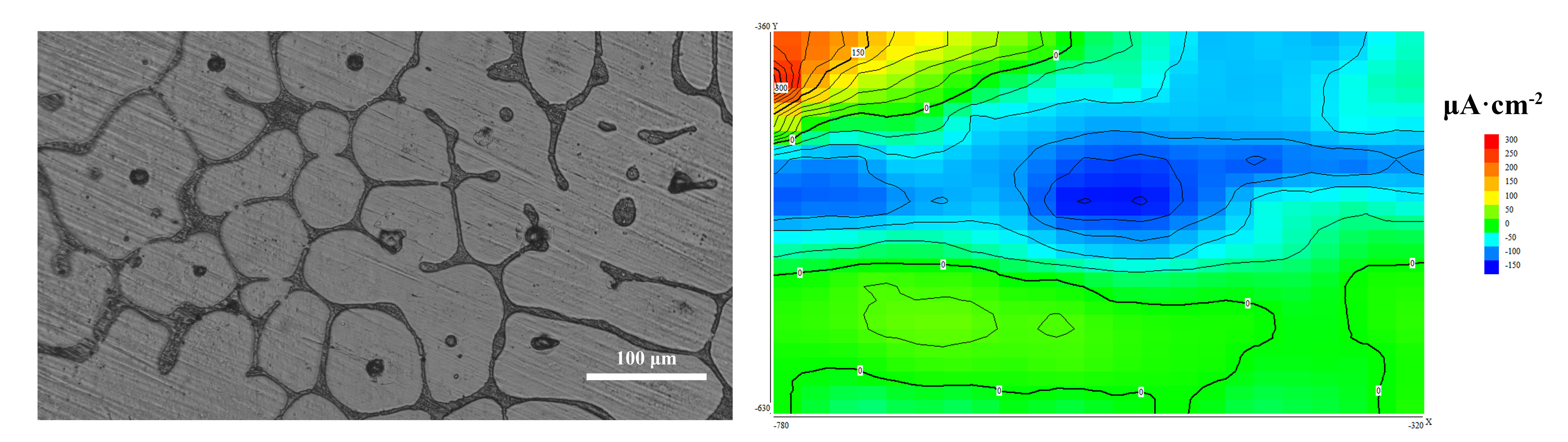

Figure 2 shows the microstrucuture and the corresponding SVET monitored corrosion current density distribution at 5 min. Sr is more active than Zn and it possesses a much lower solubility in Mg. High activety of Mg-Sr alloy leads to both high cathodic and high anodic corrosion current density. The local corrosion can even reach its highest corrosion rate of 500 μA·cm-2.

Figure 2. Microstructure and the corresponding SVET corrosion current density distribution of as-cast Mg-2Sr at 5 min in Hank's solution.

Conclusions: SVET makes in situ monitoring of local/pitting corrosion possible. It can help get a comprehensive depiction of the surface corrosion performance along with time, which can not be gotten by current-applied corrosion testing methods. Since localized corrosion and pitting corrosion are common but critical in biodegradable Mg alloys, we strongly recommend the apply of SVET/SIET as standard evaluation method for biodegradable metal corrosion.

National Basic Research Program of China (973 Program) (Grant No. 2012CB619102), National Science Fund for Distinguished Young Scholars (Grant No. 51225101), National Natural Science Foundation of China (Grant No. 51431002 and 31170909)

References:

[1] Y.F. Zheng, X.N. Gu, F. Witte, Biodegradable metals, Materials Science and Engineering: R: Reports, 77 (2014) 1-34.

[2] Standard Guide to In vitro Degradation Testing of Absorbable Metals. Biometals, 2015.