Introduction: Electrically conductive polymeric materials have recently attracted considerable interest from researchers to explore their potential in biomedical applications such as in biosensors, biomedical implants and tissue engineering[1],[2]. Polyurethanes (PUs) composites incorporating conductive particles are of particular interest to make conductive materials because of their good biocompatibility, processability and excellent mechanical properties[3],[4]. In the present work, composites of graphene and a siloxane PU (Elast-Eon™) were prepared for the first time for potential use in biomedical applications. Elast-Eon™ was chosen because of its well established biostability and use in implant devices[5]. The composites were evaluated for their electrical conductivity, mechanical properties, thermal stability and cell viability.

Materials and Methods: Elast-EonTM (E2A) and graphene were obtained from Aortech Biomaterials and ACS Materials, respectively. The composites were prepared by solution mixing method using THF and compression moulded into films of ~100 µm thickness. The electrical conductivity was determined using a two-point probe method using Ag electrodes to facilitate electrical contact. Tensile testing was carried out with an Instron 5565 Testing Machine and a Mettler Toledo TGA/SDTA 851 was used for thermogravimetric analysis (TGA). The in vitro cytotoxicity was assessed using an MTT assay and live-dead viability kit was used to examine the cell adhesion (L929 cells) on the surface of composite films

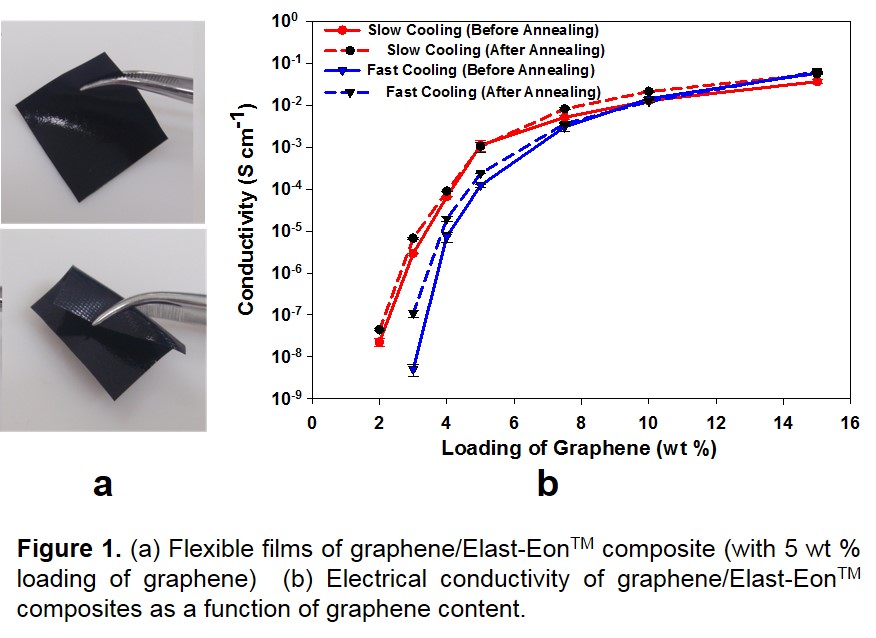

Results and Discussion: The graphene/PU composites were prepared using different methods i.e. solution mixing, melt processing and in situ polymerisation. The solution mixing method was found to be best because it resulted in the composites with higher electrical conductivity. Using this method, composites were prepared with varying content of graphene and their electrical conductivity was determined (Figure 1).

A conductivity of 1.1 × 10-3 S cm-1 was achieved with 5 wt% loading of graphene and a maximum conductivity of 5.9 × 10-2 S cm-1 was obtained for composites with graphene content of 15 wt%. In an attempt to improve the conductivity of composite films we examined the effect of cooling rate during compression moulding as well as annealing of composite films (Figure 1). Both of these approaches were found to significantly improve the conductivity of composites with lower graphene content (≤5 wt%). The enhanced conductivity may be attributed to the re-alignment of graphene sheets which promotes the formation of macroscopic conductive networks[6].

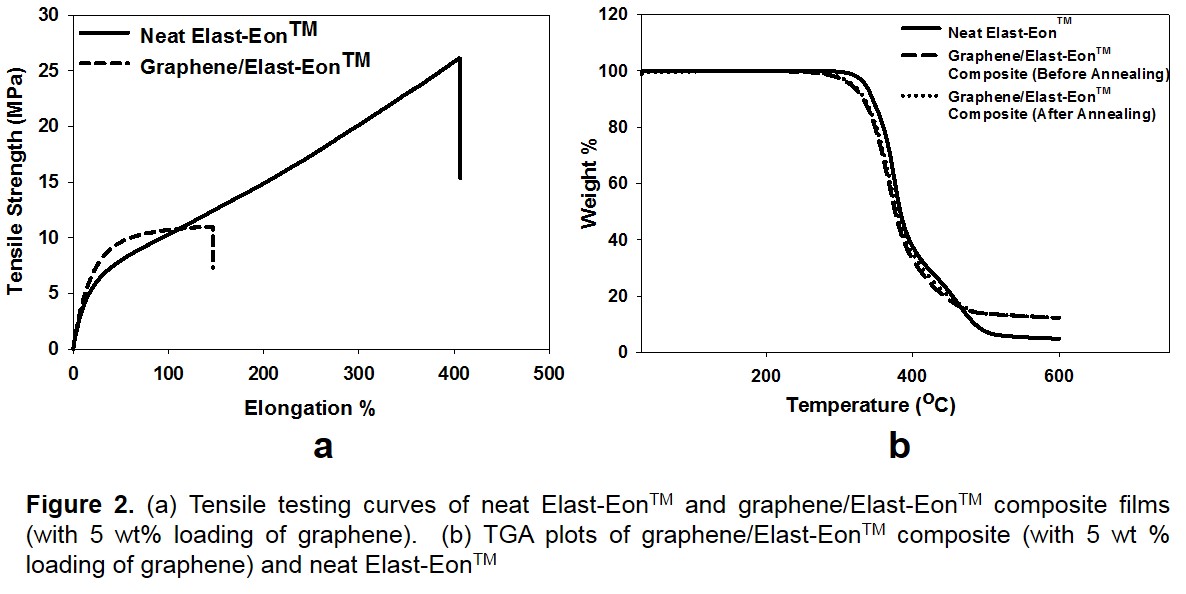

The tensile test results showed that composites possessed a tensile strength of about 11 MPa, 58% less compared to control PU. The modulus of the composites was found to increase to 48 MPa as expected due to graphene sheets working as fillers (Figure 2a).

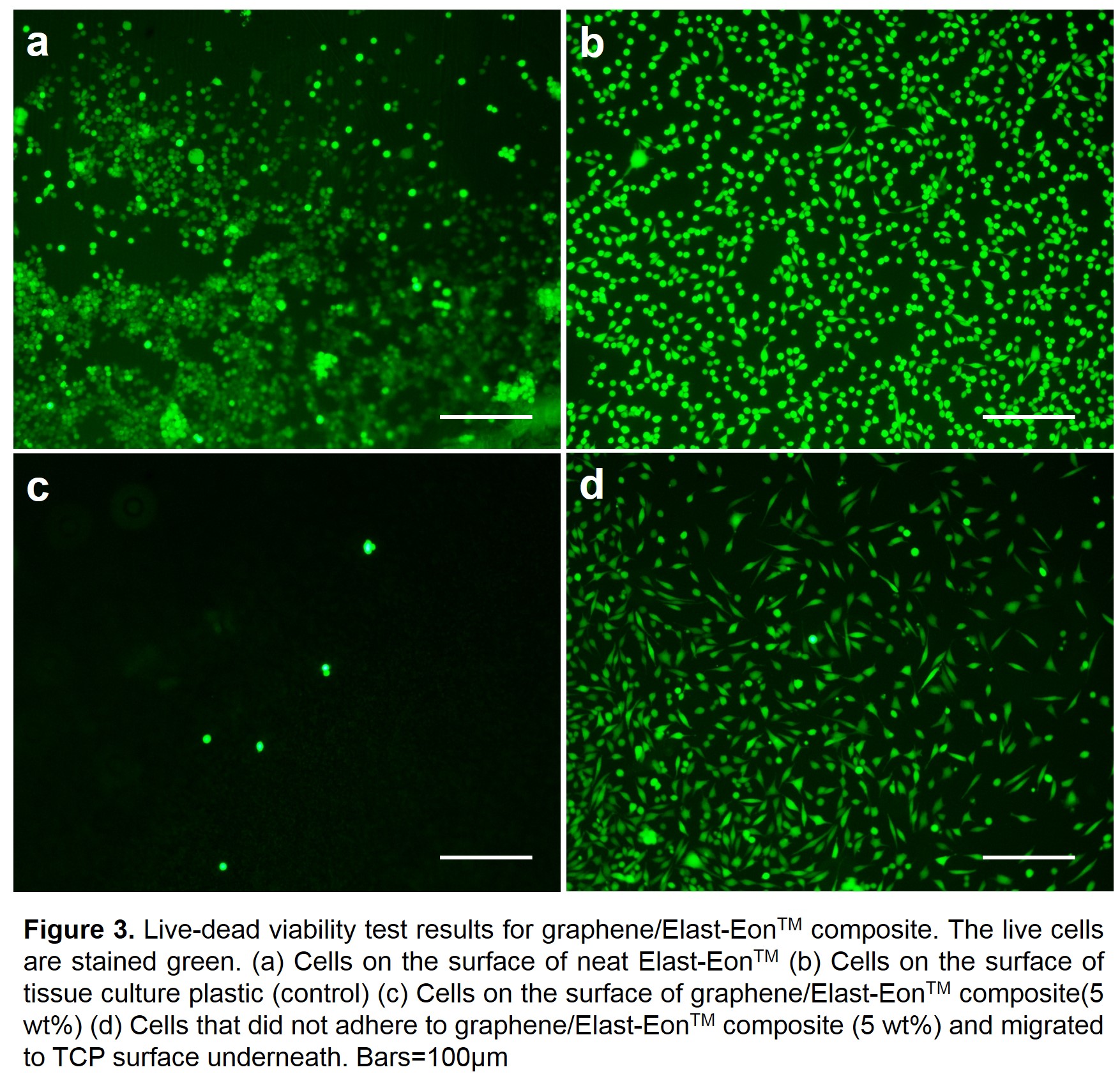

The TGA results showed that the film was thermally stable up to ~250 °C (Figure 2b). Furthermore, the films did not show significant cytotoxicity in indirect cytotoxicity tests. The in vitro cell viability assay tests also suggested that although the composite surface was not ideal for cell adhesion, the graphene/PU composite surface was not cytotoxic to living cells (Figure 3).

Conclusions: Conductive composites of graphene and a siloxane polyurethane were prepared using solution mixing. The composites exhibited good mechanical and thermal properties with an electrical conductivity of 1.1 × 10-3 S cm-1 with 5 wt% loading of graphene. In addition, cell-based cytotoxicity tests showed that composites were not cytotoxic.

The authors would like to acknowledge the financial support provided by CSIRO Office of Chief Executive Postdoctoral Program. The authors would also like to acknowledge Dr Ajay Padsalgikar of St Jude Medical for providing Elast-Eon™ Samples and Dr Gavin Collis for his advice and fruitful discussions.

References:

[1] J. Jagur-Grodzinski, E-Polymers, 2012, 12, 722-740.

[2] G. Kaur, R. Adhikari, P. Cass, M. Bown and P. Gunatillake, RSC Adv., 2015, 5, 37553-37567.

[3] S. Gogolewski, Colloid. Polym. Sci., 1989, 267, 757-785.

[4] A. Silvestri, P. M. Serafini, S. Sartori, P. Ferrando, F. Boccafoschi, S. Milione, L. Conzatti and G. Ciardelli, J. Appl. Polym. Sci., 2011, 122, 3661-3671.

[5] A. Simmons, J. Hyvarinen, R. A. Odell, D. J. Martin, P. A. Gunatillake, K. R. Noble and L. A. Poole-Warren, Biomaterials, 2004, 25, 4887-4900.

[6] J. Yu, L. Q. Zhang, M. Rogunova, J. Summers, A. Hiltner and E. Baer, J. Appl. Polym. Sci., 2005, 98, 1799-1805.