Introduction: Manufacturing of porous materials is one of the most plausible routes to address some important drawbacks of Ti implants, like stress shielding risks[3]. The manufacture of graded materials is an important goal, which has multiple applications[2]. In this work, a novel device for manufacturing cylindrical porous cp Ti, implementing directional freeze casting has been developed[1]. The aim of this work was study the influence of the temperature gradient imposed (from -15, -10 and -5 °C to 20ºC) and the diameter of alumina tube used as a mold (8, 15 and 20 mm) on the directional growth of dendrite ice and titanium powder compaction.

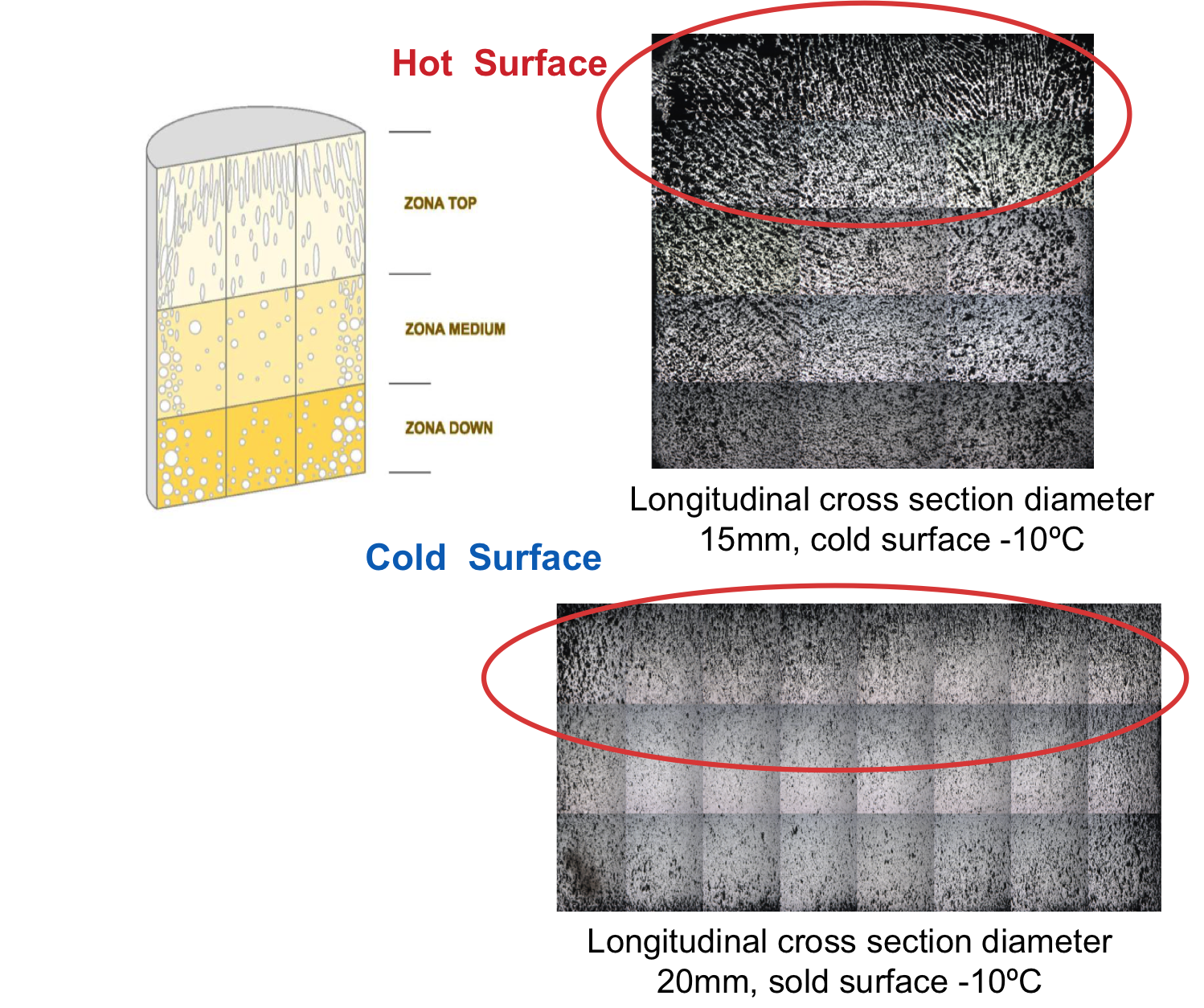

Materials and Methods: A cryogenic salt solution was used to cool the surface of an aluminum cylinder (-15, -10 and -5 °C), on which the mixture (cp Ti, dispersant and water) was poured. The lateral external surface of the ceramic cylinder containing the mixture was thermally isolated. The upper base was exposed to room temperature (20 °C). Ice sublimation was performed in a lyophilizer to -50 °C and 0.070 mbar for 24 h. Finally, porous green compacts (Fig.1) were sintered at 1250 °C for 5h under high vacuum (~10-5 mbar). Physical characterization (Archimedes’ method), microstructure (optical microscopy and image analysis include: total and interconnected porosity, equivalent diameter, morphology (aspect ratio), and average size of the pores.

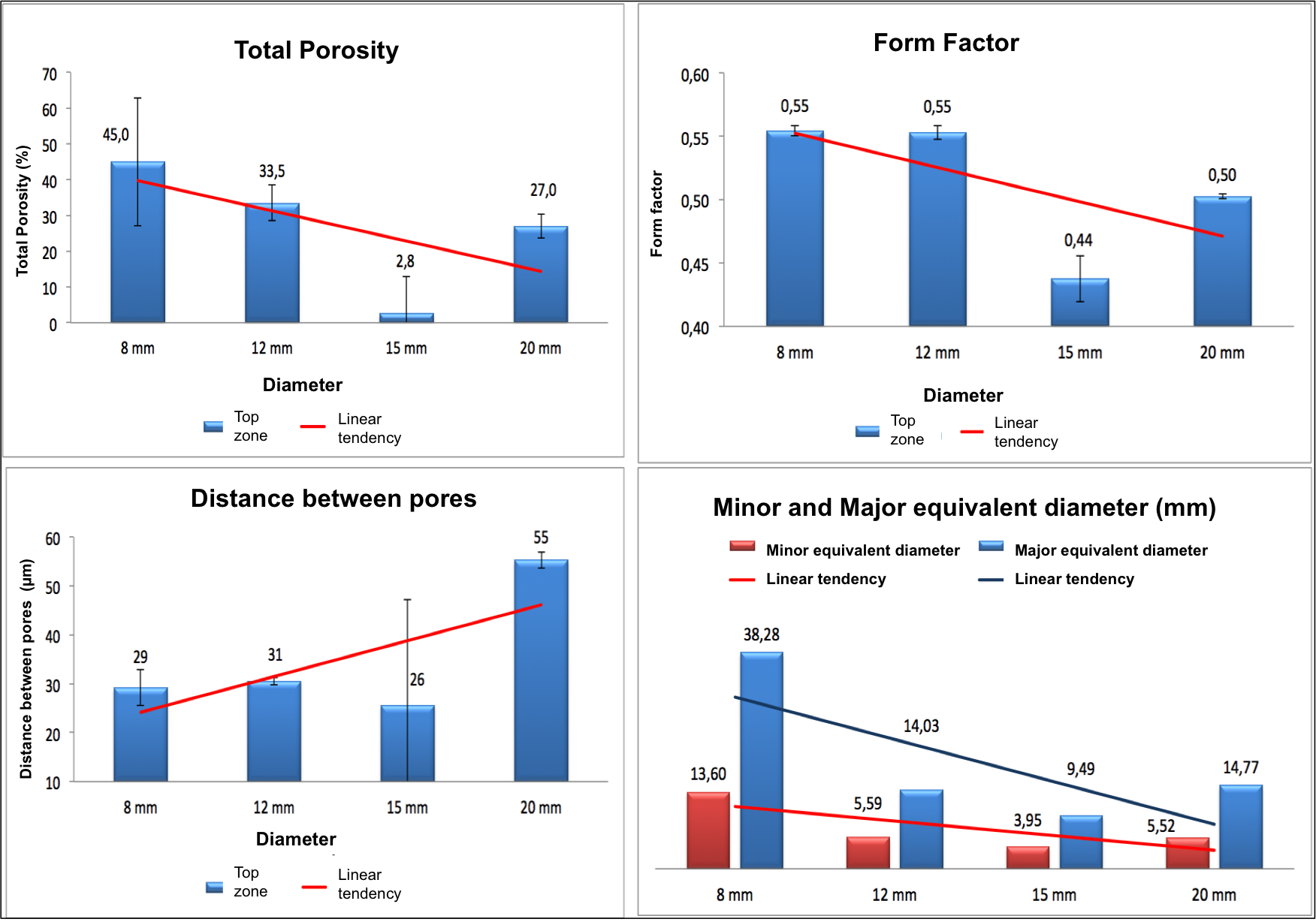

Results and Discussion: The results of Archimede's Method have shown the following findings: 1. In all cases, a higher diameter in the mold implies a lower porosity, with a higher density, which is consistent with the rate of solidification front because there is a larger contact surface with the aluminum bar. 2. In general, lower gradient temperature shows a higher porosity, with a lower associated density. This phenomenon is related to that slow velocity of solidification front, as well as with the easiest route for ice dendritic progression to push Ti particles out of ice dendrites. 3. The best balanced scenario seems to be for 15 mm and -10 ºC. Additionally,the results of Analysis Image have shown (Fig.2): 1. According to the theoretical model, the top of the sample exhibits a more elongated porosity. 2. The morphological parameters of pores (Fig.3) seems to be related not only with the diameter, but also with the temperature of de cold surface. It has been evaluated total porosity(%), elongation factor (Ff), distance between pores (l) and major and minor equivalents diameters (sizes major axis and minor axis). 3. In general, the higher diameter of mold used, the lower porosity is obtained, and the longer distance between pores and, which are smaller and elongated.

Conclusion: In this work, we were able to implement a new and simple process to produce porous Ti cilinders with controlled and designed elongated porosity. The freeze casting is a method very sensitive to composition of the initial slurry. Regarding the influence of the mold diameter on pores morphological parameters, it is noted that it reduces the porosity percentage, and elongated pores are softer.

This work was supported by the Ministry of Science and Innovation of Spain under Grant No. MAT2010-20855.; This work was supported by the Junta de Andalucía (Spain) / FEDER (EU), through the project Ref. P12-TEP-1401.

References:

[1] Directionally Freeze-cast titanium foam with aligned, elongated pores, Y. Chino, D. Dunand, Acta Materialia, 56 (2008) 105-113

[2] J. Currey, in Handbook of Biomaterials Properties, ed. by J. H. Black, G. Hastings (Springer– Verlag, London 1998), p. 3

[3] J. Banhart, Prog. Mater. Sci., 46(6), 559-632 (2001)