Manufacturability of custom endosteal dental implants by selective laser melting

-

1

École de technologie supérieure, Canada

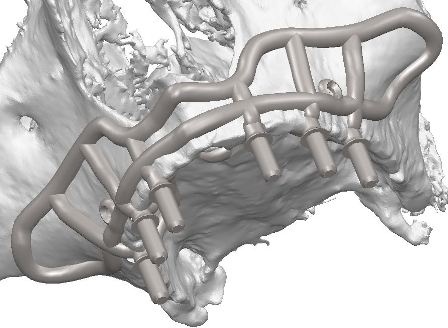

Introduction: Edentulism is a self-aggravating condition; inadequate restoration of the masticatory function and load transmission to the jawbones will induce progressive bone resorption and increase prosthesis failure risk, further reducing the patient’s quality of life[1]. Severely atrophic jaws require patient-specific solutions to support the dental prosthesis assembly (bar, dentition), such as the custom endosteal dental implant (CEI) (figure 1).

The intricate geometry of the parts involved has exposed the limitations of the current manufacturing method (computer numerical control milling), whose poor accuracy in critical regions requires design trade-offs and post-manufacturing reworks detrimental to fit and function (figure 2).

The intricate geometry of the parts involved has exposed the limitations of the current manufacturing method (computer numerical control milling), whose poor accuracy in critical regions requires design trade-offs and post-manufacturing reworks detrimental to fit and function (figure 2).

Thus, the objectives of the present study are to determine if selective laser melting (SLM) can be used to manufacture CEIs and bars with increased dimensional accuracy in critical regions, and to assess inherent limitations of the method and the adaptation required to the design and finishing processes.

Materials and Methods: Three-dimensional modeling (Powershape, Delcam) was performed according to realistic clinical requirements, originating from anatomical structures reconstructed from computed tomography data and oral surgeon guidance.

SLM system (EOSINT M 280, EOS) and material (Ti-6Al-4V ELI) requirements included achievable mechanical properties, accuracy, surface roughness and biocompatibility. Given the parts’ geometrical complexity and the system’s layerwise, support-adding building method, the effect of the model orientation relatively to the manufacturing platform had to be studied. As such, parts were analysed (Magics, Materialise) as to find orientations minimizing support structures (quantity, position and volume) and exempting functional surfaces.

Pilot parts were SLM-built in two orientations using Al-Si-10Mg, preferred to Ti-6Al-4V ELI for economical reasons and to enhance the authors’ understanding of the effects of thermal and mechanical property variation. The parts were then heat treated to relieve internal stresses and separated from the support plate.

They were then optically scanned (3series, Dental Wings) and compared to their original CAD counterparts (Powershape, Delcam) to assess deviations in transmucosal post parallelism and dimensional accuracy in areas typically poorly reproduced by CNC-milling.

Results and Discussion: Aligning the mating components’ longitudinal axis to the vertical axis of the buildplate with the bone (CEI) and assembly (bar) interfaces facing upward resulted in optimal reproduction of those surfaces, but also in unsatisfactory preservation of the CEI posts. While the addition of part-specific combinations of polar and azimuthal rotations has reduced this effect, design modifications are deemed necessary.

The parallelism deviations observed between the posts (µ=0.72°, min=0.36°, max=1.22°, σ=0.30°) were commensurate to the values observed on CNC-milled implants. The dimension variations observed (µ=110µm, min=65µm, max=182µm, σ=44µm) were in line with the achievable accuracy (±100μm) and within the clinically-acceptable tolerance (±200μm).

Conclusion: The results give the authors confidence in the manufacturability of CEIs and bars by SLM. The next steps, using the material intended for the application, will include design optimisation, surface roughness analysis and fatigue testing of finished parts to adapt modeling, manufacturing and finishing processes and to enhance clinical decision-making.

References:

Thus, the objectives of the present study are to determine if selective laser melting (SLM) can be used to manufacture CEIs and bars with increased dimensional accuracy in critical regions, and to assess inherent limitations of the method and the adaptation required to the design and finishing processes.

Materials and Methods: Three-dimensional modeling (Powershape, Delcam) was performed according to realistic clinical requirements, originating from anatomical structures reconstructed from computed tomography data and oral surgeon guidance.

SLM system (EOSINT M 280, EOS) and material (Ti-6Al-4V ELI) requirements included achievable mechanical properties, accuracy, surface roughness and biocompatibility. Given the parts’ geometrical complexity and the system’s layerwise, support-adding building method, the effect of the model orientation relatively to the manufacturing platform had to be studied. As such, parts were analysed (Magics, Materialise) as to find orientations minimizing support structures (quantity, position and volume) and exempting functional surfaces.

Pilot parts were SLM-built in two orientations using Al-Si-10Mg, preferred to Ti-6Al-4V ELI for economical reasons and to enhance the authors’ understanding of the effects of thermal and mechanical property variation. The parts were then heat treated to relieve internal stresses and separated from the support plate.

They were then optically scanned (3series, Dental Wings) and compared to their original CAD counterparts (Powershape, Delcam) to assess deviations in transmucosal post parallelism and dimensional accuracy in areas typically poorly reproduced by CNC-milling.

Results and Discussion: Aligning the mating components’ longitudinal axis to the vertical axis of the buildplate with the bone (CEI) and assembly (bar) interfaces facing upward resulted in optimal reproduction of those surfaces, but also in unsatisfactory preservation of the CEI posts. While the addition of part-specific combinations of polar and azimuthal rotations has reduced this effect, design modifications are deemed necessary.

The parallelism deviations observed between the posts (µ=0.72°, min=0.36°, max=1.22°, σ=0.30°) were commensurate to the values observed on CNC-milled implants. The dimension variations observed (µ=110µm, min=65µm, max=182µm, σ=44µm) were in line with the achievable accuracy (±100μm) and within the clinically-acceptable tolerance (±200μm).

Conclusion: The results give the authors confidence in the manufacturability of CEIs and bars by SLM. The next steps, using the material intended for the application, will include design optimisation, surface roughness analysis and fatigue testing of finished parts to adapt modeling, manufacturing and finishing processes and to enhance clinical decision-making.

References:

[1] Nordquist, W, Nicholson, C. (2015). Restoration of Severely Atrophic Jaws. Retrieved from http://www.dentistry2day.com/dtnewsline/implants/10054-restoration-of-severely-atrophic-jaws

Keywords:

Implant,

device,

biomedical application,

Bone repair,

endosteal dental implants

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

General Session Oral

Topic:

Biomaterials in dental applications

Citation:

Lafreniere

J,

Brailovski

V,

Timercan

A,

Poirier

M and

Wagnac

É

(2016). Manufacturability of custom endosteal dental implants by selective laser melting.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01819

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Jerome Lafreniere, École de technologie supérieure, Montréal, QC, Canada, jerome.lafreniere@v2rbiomedical.com

Dr. Vladimir Brailovski, École de technologie supérieure, Montréal, QC, Canada, Vladimir.Brailovski@etsmtl.ca

Dr. Anatolie Timercan, École de technologie supérieure, Montréal, QC, Canada, timanatol@gmail.com

Dr. Michel Poirier, École de technologie supérieure, Montréal, QC, Canada, michel.poirier@v2rbiomedical.com

Dr. Éric Wagnac, École de technologie supérieure, Montréal, QC, Canada, Eric.Wagnac@etsmtl.ca