Nanofibres, due to their highly desirable properties such as size, high surface-to-volume ratio and well defined porosity are increasingly being adapted for applications in such diverse fields as tissue engineering, drug delivery, filtration, conducting composites, photonics and fuel cells[1]. Polymeric nanofibres have widely been produced by electrospinning but limitations including high voltage costs and low output rate has prevented its upward transition into efficient method for industrial scale production[2]. An alternate approach to producing nanofibres, based on simultaneous use of pressure and gyration[3] has been used for the production of mucoadhesive nanofibres to be used as starting materials for drug delivery systems. A significant proportion of mucoadhesive polymers such as polysaccharides, due to their chain structure cannot be easily spun into fibres. In this study[4], the possibility of producing mucoadhesive nanofibers from such polymers is demonstrated, thus contributing to the efforts in obtaining suitable materials for design of more efficient vaginal drug delivery systems.

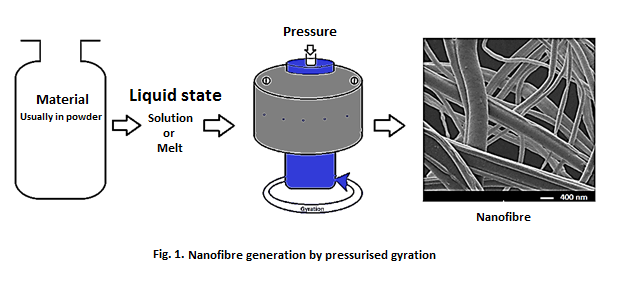

Blends prepared from polyethylene oxide (PEO) functioning as spinning agent and mucoadhesive polymers sodium alginate (ALG) or polyacrylic acid (PAA) or carboxymethyl cellulose (CMC) were prepared. These blends were optimised by adjusting their viscosities and surface tension and spun into nanofibres as illustrated in Fig.1. 3ml solution was placed in the aluminium vessel and spun at a rotational speed of 24,000 rpm and working pressure of 0.1, 0.15 and 0.2 MPa. Samples were obtained manually by simply collecting the ejected fibres. Physical properties including fibre diameter were studied by scanning electron microscopy (SEM) while their mucoadhesive behaviour was investigated using a combination of texture analyser and atomic force microscopy (AFM). The force required to break up a gel mixture of the fibres and mucin in simulated vaginal fluid were measured. Furthermore, the extent of hydration preceding the fibre-mucin interaction which is useful for understanding mucoadhesive behaviour was analysed using AFM[5].

SEM analyses showed structurally well-defined fibres with diameters from less than 100nm upwards. Quantitative relationships between fibre diameters and blend properties such as viscosity and surface tension, specifically an inverse correlation was observed.

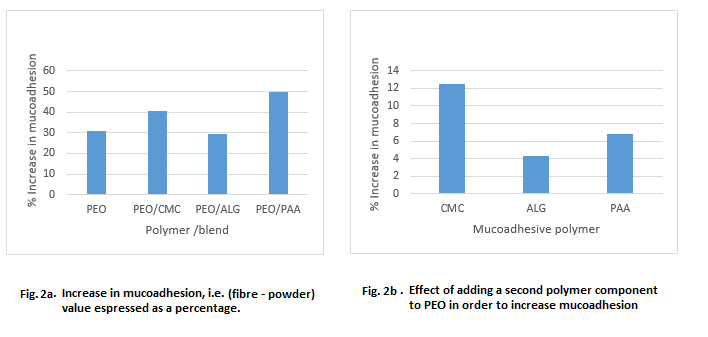

Use of fibre rather than powder enhanced mucoadhesive behaviour by up to 50% as surface area available for interaction with mucin appreciably increased (Fig. 2a). In addition, blends incorporating the mucoadhesive polymers showed up to 12% more mucoadhesion potential than fibres containing only PEO (Fig. 2b).

In conclusion, the novel pressurised gyration method has been used for the first time to generate well-defined, uniformly cylindrical, structurally robust nanofibres with superior mucoadhesive properties from blends combining mucoadhesive polymers and spinning agent. Blends containing CMC demonstrated the highest mucoadhesive capabilities. Subsequently, PEO and PEO/CMC nanofibres encapsulating progesterone were produced. By optimising solvent systems, varying particle size of the drug, using different formulation approach including emulsification and improving solution rheology, nanofibres with progesterone content up to 25% has been achieved. By demonstrating the feasibility of manufacturing bioadhesive nanofibres at high yield and capability of efficient drug encapsulation, the development of a wide range of tissue-adherent dosage forms becomes greatly facilitated.

FB thanks University College London and Health Access Network-Ghana for supporting his PhD reserach

References:

[1] ALUIGI, A., et al. 2008. European Polymer Journal, 44, 2465-2475.

[2] LU, Y., et al. 2013. European Polymer Journal, 49, 3834-3845.

[3] MAHALINGAM, S. & EDIRISINGHE, M. 2013. Macromolecular Rapid Communications, 34, 1134-1139.

[4] BRAKO, F., et al. 2015. European Polymer Journal, 70, 186-196.

[5] SMART, J. D. 2005. Advanced Drug Delivery Reviews, 57, 1556-1568.