Exploring educational simulation platform features for addressing complexity in Industry 4.0: a qualitative analysis of insights from logistics experts

- 1Institute for the Future of Education, Tecnologico de Monterrey, Monterrey, Mexico

- 2Industrial Engineering Department, Lamar University, Beaumont, TX, United States

Introduction: This study explores the transformative impact of Industry 4.0 on industrial operations, emphasizing the integration of advanced technologies like AI, IoT, and Big Data Analytics to enhance process optimization, automation, and connectivity. Despite its potential for efficiency, Industry 4.0 introduces significant complexities, challenging existing operational and decision-making frameworks. Addressing these challenges, the research investigates the role of simulation platforms in logistics, seeking to identify their critical attributes for effective complexity management. It highlights the need for innovative tools in system evaluation, performance measurement, and skill development, aiming to equip the workforce with essential Industry 4.0 competencies. Through qualitative insights from logistics experts, the study aims to offer practical recommendations for educators and industry professionals, contributing to the design and implementation of educational simulations that align with the intricate demands of Industry 4.0 logistics.

Methods: This study employs a qualitative content analysis approach to develop an Industry 4.0-adapted logistics simulator, leveraging the Asteraceae framework for digital game co-design and pedagogical reflection. Data were collected from six industry and academia experts through semi-structured interviews, designed around the framework’s key steps to explore simulator design, decision-making, impact, and skill development. Utilizing convenience sampling, the research engaged participants with experience in educational logistics platforms and simulators. Interviews were conducted online, with ethical considerations including informed consent. Transcription used OpenAI’s API for accuracy, followed by manual review. The analysis combined qualitative content with frequency analysis, employing Atlas.ti software to identify and code key simulation features as informed by expert insights. This methodology underscores a comprehensive approach to understanding and innovating logistics education for Industry 4.0, aiming to equip learners with necessary competencies through targeted simulation tools.

Results: The study’s findings emphasize the critical role of simulation tools in Industry 4.0 logistics for risk mitigation, operational planning, and decision-making. Experts pointed out the significant benefits of simulations in providing safe spaces for experimentation, especially valuable for SMEs with limited access to advanced technologies. They advocated for simulators to incorporate current technological and e-commerce trends, suggesting a customizable business model based on diverse logistics requirements. Key insights included the necessity for adaptable simulation architectures to handle various operational variables, the importance of integrating multidisciplinary competencies like data analytics and strategic management, and the role of performance metrics in evaluating simulations and logistics operations. The analysis revealed essential features for an educational logistics simulator, highlighting the importance of operational knowledge, predictive analytics, and the need for a comprehensive tool that integrates technology, strategy, operations, and data analysis. This approach aims to equip users with the skills necessary for navigating the complexities of modern logistics, promoting a deep understanding of systems thinking and complex reasoning skills.

Discussion: The discussion centers on the essential requirement for a multidisciplinary approach in creating an educational logistics simulator for Industry 4.0, emphasizing the need for technological adaptability and operational efficiency. It highlights the importance of integrating advanced technologies and collaborative paradigms to enhance logistics operations and improve decision-making processes. The utility of simulation-based learning as a pedagogical tool is acknowledged, with an emphasis on its role in developing complex thinking and practical skills relevant to the digital transformation of the logistics sector. The discussion suggests that educational simulations are poised to play a pivotal role in preparing the workforce for Industry 4.0 challenges by bridging technological advancements and pedagogical strategies. However, it also points to the limitations of the current study, such as its sampling method and regional focus, and calls for future research to explore broader applications and the integration of comprehensive strategies to ensure the educational simulator’s effectiveness and relevance in a global context.

1 Introduction

The concept of Industry 4.0 signifies a transformative phase in industrial operations, characterized by the integration of technologies such as Artificial Intelligence, the Internet of Things, and Big Data Analytics (Javaid et al., 2022). This paradigmatic shift aims to optimize processes through automation, real-time data analytics, and enhanced connectivity (Zizic et al., 2022). Although the vision of Industry 4.0 promises to bring about unprecedented efficiencies, it also introduces layers of complexity that challenge traditional operational models and decision-making processes (Pacheco-Velazquez and Aguilar-Avalo, 2019).

These complexities pose a challenge to current decision-making models and call for innovative tools in system evaluation, performance measurement, and human capital development (Mukhuty et al., 2022). Classical paradigms are increasingly seen as lacking the precision and adaptability needed to address the intricate interactions and rapid decision-making characteristic of Industry 4.0 settings (Oluyisola et al., 2022). Business simulation in higher education and employee training enhances decision-making and understanding of dynamic logistical scenarios (Pacheco-Velazquez, 2022).

The general objective of this study is to examine simulation platforms’ attributes that can effectively address the complexity introduced by Industry 4.0, with a specific focus on the logistics domain. This encompasses the simulation capacity to faithfully replicate real-world processes, support decision-making on complex system behaviors, scale to adapt to increasing complexities, ensure accessibility and ease of use, and seamlessly integrate with Industry 4.0 technologies. Additionally, the study aims to extend its implications into the field of educational simulations, recognizing their importance in equipping the emerging workforce with essential skills for Industry 4.0, and to provide practical recommendations for educators, policymakers, and industry professionals based on qualitative insights from industry experts. Ultimately, the research seeks to contribute to the development of an integrated model for selecting, designing, and implementing educational simulation platforms that meet the technical, pedagogical, and real-world demands of Industry 4.0 logistics.

Research questions are:

Q1: What design elements and features do logistics experts prioritize for addressing Industry 4.0 complexities in education?

Q2: What attributes and functionalities, as per logistics experts, should be integrated into educational simulation platform designs for effective preparation in Industry 4.0 logistics challenges?

The article is organized as follows. The next section contains Background literature describing the core competencies needed to address complexity, especially in Industry 4.0, and explores the benefits of educational games and simulators in logistics education. Next, the Methods section details the research approach, emphasizing interviews with logistics experts, participant selection criteria, and the analytical framework used. In the next section, the Results are presented, categorized into five key dimensions: technological adaptability, educational objectives, industry-specific elements, user experience, and development of reasoning skills. These findings are examined in depth in the Discussion section, highlighting their practical implications in logistics education and the broader context of Industry 4.0. Finally, the article ends with the Conclusion, which summarizes the importance of the key findings in bridging academia and industry, particularly in logistics education, and its implications for curriculum development and the design of tools adapted to meet the demands of the educational and industrial development.

2 Background

In the realm of education, Information and Communication Technologies (ICTs) are considered tools that can promote learning opportunities and enhance students’ skills. Various instances of ICT utilization are evident in educational platforms and virtual environments. Notably, the integration of Serious Games (SGs) and simulators has become a favored choice in classroom settings, as learners’ participation in these games has demonstrated the ability to induce changes in their attitudes, beliefs, and behaviors (Tilvawala et al., 2019). As a result, SGs and simulators are now employed as a strategy to support learning across diverse domains, including medicine, logistics, military training, nursing, among others (Pacheco-Velazquez et al., 2023).

One noteworthy advantage of utilizing these tools is the capacity to create motivational factors that significantly enhance student learning (Naul and Liu, 2020). Additionally, researchers contend that these tools contribute to the development of critical thinking skills, improve retention, foster creativity, and enhance skills associated with problem-solving and decision-making (Saleem et al., 2022). SGs and simulators integrate instructional content within gameplay, offering immersive environments where users can practice and apply knowledge and skills. By incorporating game elements such as challenges, rewards, and immersive storytelling, SGs capture students’ attention and sustain their interest over extended periods. Furthermore, SGs provide a unique context for learning, placing knowledge acquisition within meaningful and practical scenarios (Lameras et al., 2017). Learning occurs within the game’s environment, enabling students to directly apply and practice what they have learned. This concept of situated cognition enhances the relevance and applicability of the acquired knowledge.

2.1 Simulation-based pedagogies and Education 4.0

In contemporary educational paradigms, the combinations of simulations, and innovative experiences plays an indispensable role in preparing professionals for complex business terrains (González-Pérez and Ramírez-Montoya, 2022). These simulations serve as vital pedagogical scaffolds across diverse domains, enhancing complex skill sets required for problem-solving (Chernikova et al., 2020). In particular, the domain of logistics benefits from gamified modeling and simulation frameworks, optimizing real-world logistic issues and enhancing planning methodologies (Hubl and Fischer, 2017). Business simulation games not only serve as effective tools for higher education but also find applications in workforce training, contributing to improved decision-making, and a comprehensive understanding of dynamic logistic scenarios (Jiang et al., 2020; Barykin, 2021).

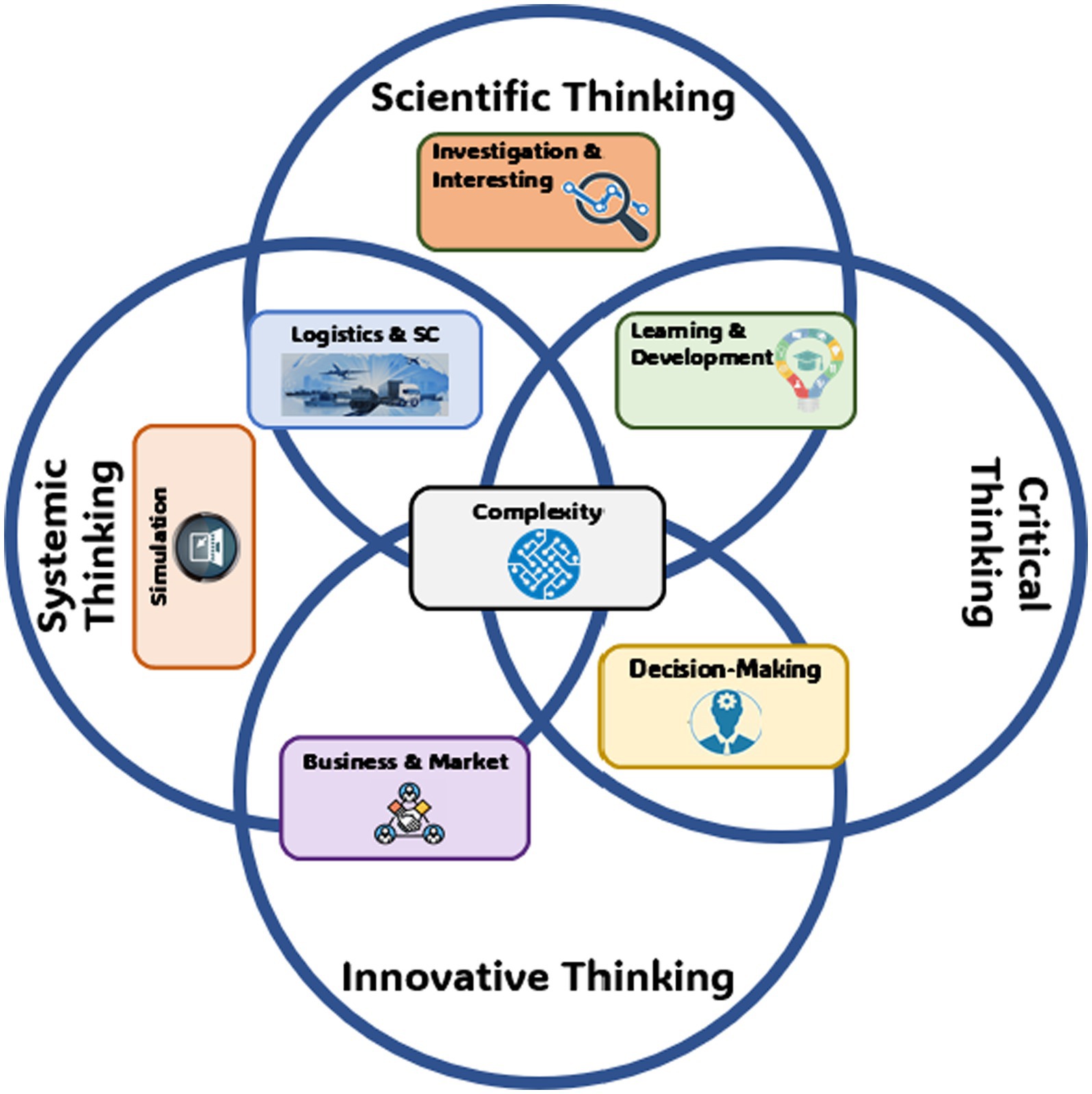

Education 4.0 uniquely emphasizes the cultivation of reasoning abilities tailored to manage complexity, thereby accentuating the value of collaborative challenges and knowledge sharing (González-Pérez and Ramírez-Montoya, 2022). This pedagogical shift aims at nurturing a holistic set of cognitive proficiencies, spanning scientific, critical, innovative, and systemic thinking. Such an expansive skillset facilitates a learner’s capacity to engage in comprehensive problem-solving, for continuous learning relevant to current societal challenges.

Research has cast a spotlight on the remarkable efficacy of game-based learning and active learning environments in elevating knowledge retention, skill cultivation, and engagement across an array of disciplines. Furthermore, the incorporation of game-based methodologies extends its influence into diverse domains, encompassing Industry 4.0 challenges. These methodologies foster critical thinking, informed decision-making, and collaborative prowess, nurturing a learner-centric paradigm that primes individuals to surmount real-world trials. This underscores simulations potential to revolutionize conventional education, equipping students to navigate the challenges that characterize the Industry 4.0 (Agarwal and Biswas, 2019; Hansen and Elbæk, 2019; Tseng et al., 2019; Bastos, 2020; Lezama et al., 2020; Sincharoenkul et al., 2020; Mahmood et al., 2021; Buzady et al., 2022; Cruz-Martínez et al., 2022; Cecchi et al., 2023; Pacheco-Velazquez et al., 2023).

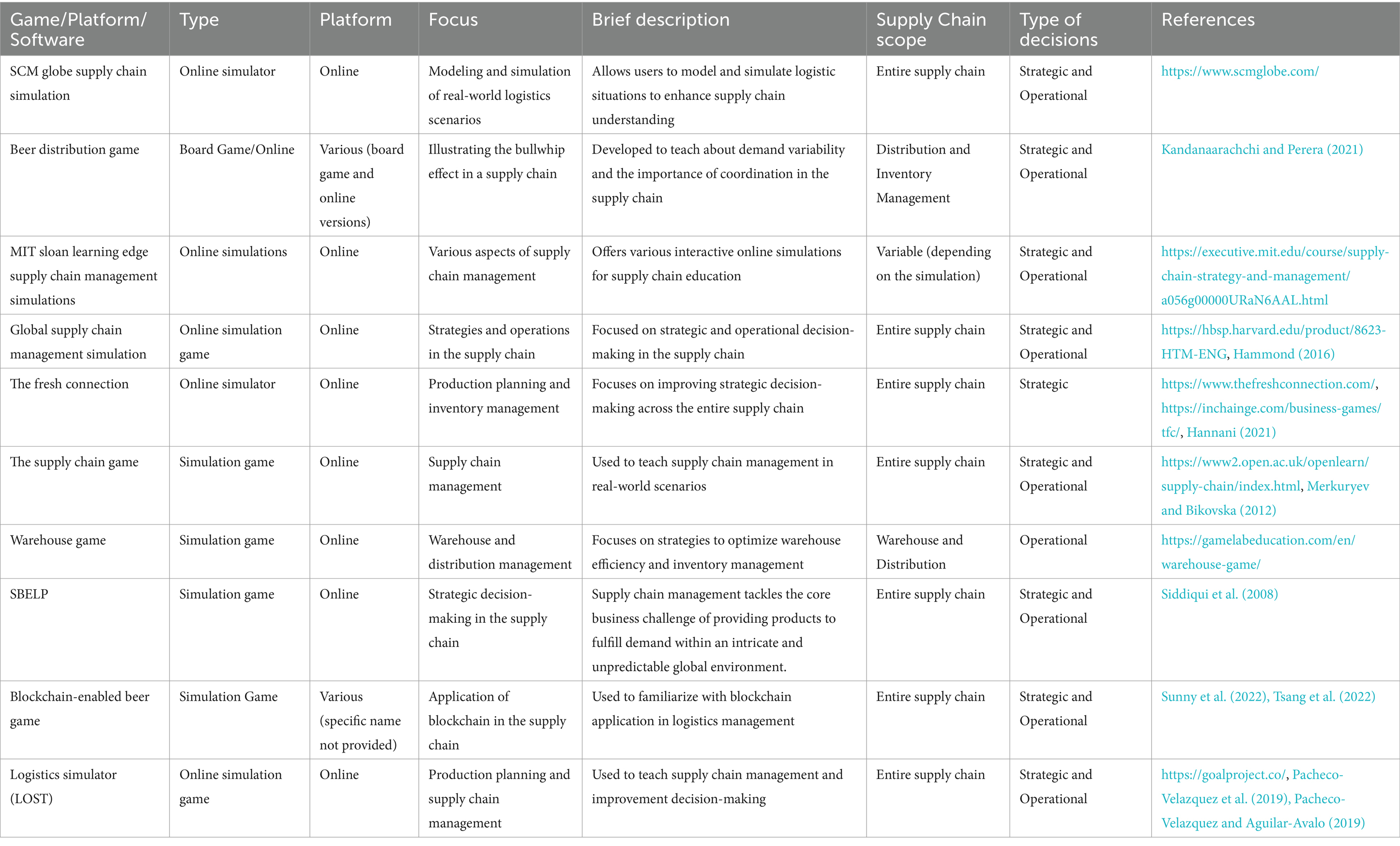

The availability of simulation games for teaching logistics and supply chain management is limited (Pacheco-Velazquez et al., 2019). The most widely recognized game is the “beer game,” originally developed at MIT in the 1960s to demonstrate the bullwhip effect in a supply chain. Initially, it was a board game for classroom use, and later, computer-based versions were created by Jacobs (2000), Sparling (2002), and Simchi-Levi et al. (2008) available online. Despite these advancements, the beer game focuses solely on illustrating the bullwhip effect and its causal relationships within the supply chain. Currently, there are some modifications to the beer game that have allowed blockchain elements to be integrated into inventory management (Sunny et al., 2022; Tsang et al., 2022). Another variant of the beer game can be found in the Beer Distribution Game, which illustrates the coordination and consequences that the bullwhip effect has on the distribution of products (Kandanaarachchi and Perera, 2021).

“Global Supply Chain” is a single-player asynchronous simulation developed by Harvard. Participants oversee the supply chain for a global mobile phone company, involving tasks such as demand forecasting, supplier selection, and production allocation. Players can modify their decisions in response to unexpected events over four simulated years. The game features a single scenario, and the objective is to accumulate the highest profit (Hammond, 2016).

“The Supply Chain Game” is a team-based simulation by Chopra and Afeche (Feng and Ma, 2008). Teams control a virtual company producing an industrial chemical, making decisions on demand forecasting, inventory control, production, transportation, and supply network design. The game offers two scenarios, and in each, the objective for student teams is to maximize their cash balance. The team with the highest cash balance at the end wins.

“The Fresh Connection” is a team simulation of a perishable fruit juice manufacturer (Hannani, 2021). This computer game has a high level of complexity, assigning different roles to players. Students interact with the materials and data provided in the game, requiring prior knowledge in logistics and supply chain. The simulation typically runs in a full-day session.

“Warehouse Game” is a game focused on warehouse operation, where students will experience the challenges of managing a distribution center. The main challenge in this simulation is to achieve the reception and dispatch objectives at the lowest possible cost.

The Logistic Simulator (abbreviated as LOST) serves as a serious game designed to enable students to swiftly and enjoyably develop and apply logistics concepts. It provides a unique opportunity tocomprehend the intersections of various logistics topics. LOST is crafted as a game with the goal of emulating the operations of a small supply chain. The simulation revolves around a hypothetical enterprise specializing in the production of balls for various sports. This game is integrated into an online platform known as the “GOAL Project,” dedicated to making the learning of logistic concepts an engaging and entertaining experience (Pacheco-Velazquez et al., 2020).

Supply Chain Bullwhip Effect Learning Platform (SBELP) simulates a supply chain scenario where the player assumes the role of an electronic equipment manufacturer. Despite featuring various built-in functions like inventories and backorders, the primary objective of the game is to illustrate the Bullwhip effect resulting from fluctuations in demand. The player’s success is evaluated based on the total cost incurred in the supply chain, with an emphasis on minimizing both inventory and backorder costs (Siddiqui et al., 2008).

In addition to these games that are focused on teaching logistics, we can also mention some educational platforms such as, for example, MIT Sloan Learning Edge Supply Chain Management, or GOAL Project (associated with the LOST game). It would also be convenient to mention some software dedicated to the simulation of logistics scenarios, such as SCM Globe Supply Chain Simulation. A brief summary of these games, platforms and software is seen in Table 1.

2.2 Simulation platform features and Industry 4.0

Existing research on the development, integration, and application of Industry 4.0 simulation technologies across diverse sectors such as manufacturing, automotive, and supply chain management has been marked by the emergence of intelligent manufacturing, the convergence of the Internet of Things (IoT), Artificial Intelligence (AI), digital twins, and augmented reality, representing a significant paradigm shift. In the exploration of these new technologies, the synergistic integration of the Internet of Things (IoT) and Artificial Intelligence (AI) has been shown to markedly enhance operational efficiency in manufacturing systems (Javaid et al., 2022; Zizic et al., 2022). Simultaneously, innovations in the realms of digital twins and augmented reality facilitate the construction of virtual replicas of these systems for more refined control and decision-making processes. These advancements collectively underscore the indispensable role of intelligent manufacturing and virtual system modeling in improving operational efficacy and control (Mourtzis et al., 2022; Siyaev et al., 2023) and necessary strategies for integrating digital technologies into logistics and supply chain management (Longo et al., 2019).

Researchers have explored the consequences of Industry 4.0 technology adaptations and sector-specific challenges have been examined (Kučera et al., 2022), as well as frameworks that allow the systematic evaluation of technological maturity in congruence with the industrial requirements (Yurci and Durakbasa, 2021). Studies on decision-making mechanisms within industrial environments and data-based techniques with simulation models to optimize production processes also stand out (Lang et al., 2018; Mourtzis et al., 2019; Williams and Olajide, 2020; Sekaran and Hildas, 2023). In terms of sector-specific adaptations, the emphasis on manufacturing and automation for Industry 4.0 addresses the convergence of physical and virtual systems, digital twins, and virtual reality applications in the manufacturing sector (Simon et al., 2021; Diniz et al., 2022), lean manufacturing and AI-driven efficiency (Eriksson et al., 2021; Helmold et al., 2022). The automotive and aerospace sectors are also looking at the transformative impacts of digitalization within these sectors (Sorger et al., 2021; Hoover et al., 2022).

These trends also show the preparation and adaptations of small and medium-sized enterprises (SMEs) in the context of Industry 4.0 (Grisales-Palacio et al., 2022; Manbachi et al., 2022) offering comprehensive frameworks and assessment tools that enhance the understanding the challenges and opportunities intrinsic to the integration of Industry 4.0 within SMEs.

2.3 Industry 4.0 and education

Human capital training strategies have also been applied to adapt to Industry 4.0. For instance, Flaga and Pacholczak (2022) conducted studies on integrating project-based learning into engineering curricula, highlighting the need to equip future professionals with relevant skills. In addition, the investigations of Gonzalez-Hernandez et al. (2020) and Zolotová et al. (2020) focused on the use of virtual laboratories to spread the principles of Industry 4.0, as well as the efforts to equip students with both theoretical and practical skills for innovative problem-solving in diverse fields like manufacturing, agriculture, robotics, and aerospace (Hernandez-de-Menendez et al., 2020).

Research on the multiple dimensions of Industry 4.0, ranging from its implications for manufacturing and sector-specific adaptations to educational curricula. Within the scope of competencies, the adaptation of curricular frameworks is observed to adapt to the changing demands of Industry 4.0 (Pacheco-Velazquez et al., 2019; Mahmood et al., 2021) promoting the alignment of educational competencies with the standards of the industry, highlighting the importance of pedagogical redesign in the context of the fourth industrial revolution. In the line of competencies, the integration of innovative educational technologies is also identified, such as virtual and remote laboratories, which meet pedagogical objectives and at the same time function as substitutes for technological interfaces (Bolanowski and Paszkiewicz, 2021). On the other hand, Ramírez-Montoya et al. (2022) points out the need to develop competencies associated with reasoning for complexity, in particular, four fundamental sub-competences are highlighted: critical, systemic, scientific, and innovative thinking.

In terms of educational technologies, Virtual Reality (VR) and Augmented Reality (AR) have been prominently discussed as pedagogical tools (Daniela, 2020; Sharifpour et al., 2022) underlining their usefulness in developing skills and immersive learning experiences, as well as the integration of such technologies into engineering education and manufacturing simulations (Pacheco-Velazquez et al., 2019; Pizzuto et al., 2022). Of particular interest are the studies that adopt non-traditional or innovative approaches to Industry 4.0, seeking to integrate these new technologies with educational innovation (Cortes et al., 2020) as the incorporation of IoT devices in training medical (Al-Emran et al., 2020).

In addition, the broader social, organizational, and environmental implications of Industry 4.0 are discussed, where studies on organizational and cultural aspects shed light on the myriad factors that influence technology adoption and the role of education in its sustainable integration (Bongomin et al., 2020; Takahashi et al., 2020; Vanduhe et al., 2020; Marmier et al., 2021), identifying various ways in which emergent technologies are impacting sectors, shaping educational paradigms and redefining sociotechnical systems.

3 Methods

Amid rapid and transformative changes in various Industry 4.0 sectors, the logistics field faces an imperative to cultivate people with competencies to adapt to emerging complexities. The main objective of this study was a needs analysis aimed at developing a logistics simulator adapted to current needs. Through qualitative content analysis, we integrated the knowledge of logistics experts, to identify features of educational simulators adapted to the demands of Industry 4.0 in said sector. The goal is to design a simulator that contributes to the formation of human capital to thrive in the complex landscape of logistics.

3.1 Instruments

The theoretical-methodological framework Asteraceae (Romero et al., 2020) was adopted, enabling the comprehensive pedagogical reflection approach to digital game iterative co-design and application. Following in Figure 1 the comprehensive Asteraceae framework and its ten steps are presented.

Figure 1. Asteraceae approach. Ten steps to integrate Digital Games for Learning extracted from Romero et al. (2020).

An interdisciplinary research team carried out co-design instances of qualitative data collection instruments aimed at logistics experts to identify needs. As a result, two semi-structured interviews scripts were designed, one for individuals and one for groups, divided into four sections, each corresponding to the steps 1 (Learning Objectives), 2 (Context, Learners Needs, Pedagogical integration), 7 (Development and Personalization), and 8 (Distribution and Business model) of the Asteraceae framework.

The topics covered in the semi-structured interview script were related to the development of a logistics simulator, encompassing areas such as the design and features of the simulator, the types of decisions players should make, the potential impact of the simulator, and the competencies and skills that can be developed through its use. Additionally, the conversation also included discussions about potential business models for the platform, the educational opportunities it can provide, and the structure and design of the platform. The application concluded with a request for demographic data and any final comments or suggestions.

3.2 Participants and data collection

The theoretical sample comprised six experts from both industry and academia, including one woman and five men. In this study, a convenience sampling approach was adopted, primarily chosen due to participants’ familiarity with the simulation software. The participants included two university professors specializing in engineering and logistics (one from Mexico and the other from Colombia), two SME specialist from a regional government secretariat in Mexico, and two consultants specialized in entrepreneurship. One of the consultants owns a transnational consulting firm, while the other is the director of logistics and operation of a transnational company.

The main selection criterion was that participants had actively engaged in educational platforms dedicated to logistics for teaching, training, and/or consulting purposes. Additionally, participants were also required to have experience in using logistics simulators. While this sampling method facilitated access to a group of experts well-versed in the subject, it is important to note that the findings should be interpreted with caution, considering potential limitations associated with convenience sampling.

During the month of April 2023, two individual interviews and one group interview were conducted, which lasted in total more than 6 h. The data collection instrument was applied online, using Zoom, to the experts who provided recommendations on the logistics and decision-making simulator for process optimization, logistics chains, and intelligent production and logistics systems for Industry 4.0. The execution of data collection adhered rigorously to the ethical guidelines outlined by the Mexican national board of ethics. A fundamental ethical requisite was the acquisition of informed consent from participants, which was obtained verbally and recorded prior to conducting the interviews, ensuring participants’ comprehension of the research’s purpose, procedures, and their voluntary involvement.

The transcription was carried out using OpenAI’s API, which employs artificial intelligence. It discerned linguistic characteristics in the audio and transcribed it using open-source technology. Following the automated transcription, a manual revision was undertaken to further ensure the precision, reliability, and coherence of the transcribed content.

3.3 Analysis

The methodological approach combined qualitative content analysis with frequency analysis to effectively extract and quantify the perspectives of logistics experts on simulation systems in Industry 4.0. It highlighted the key areas and themes of greatest relevance according to professionals in the field.

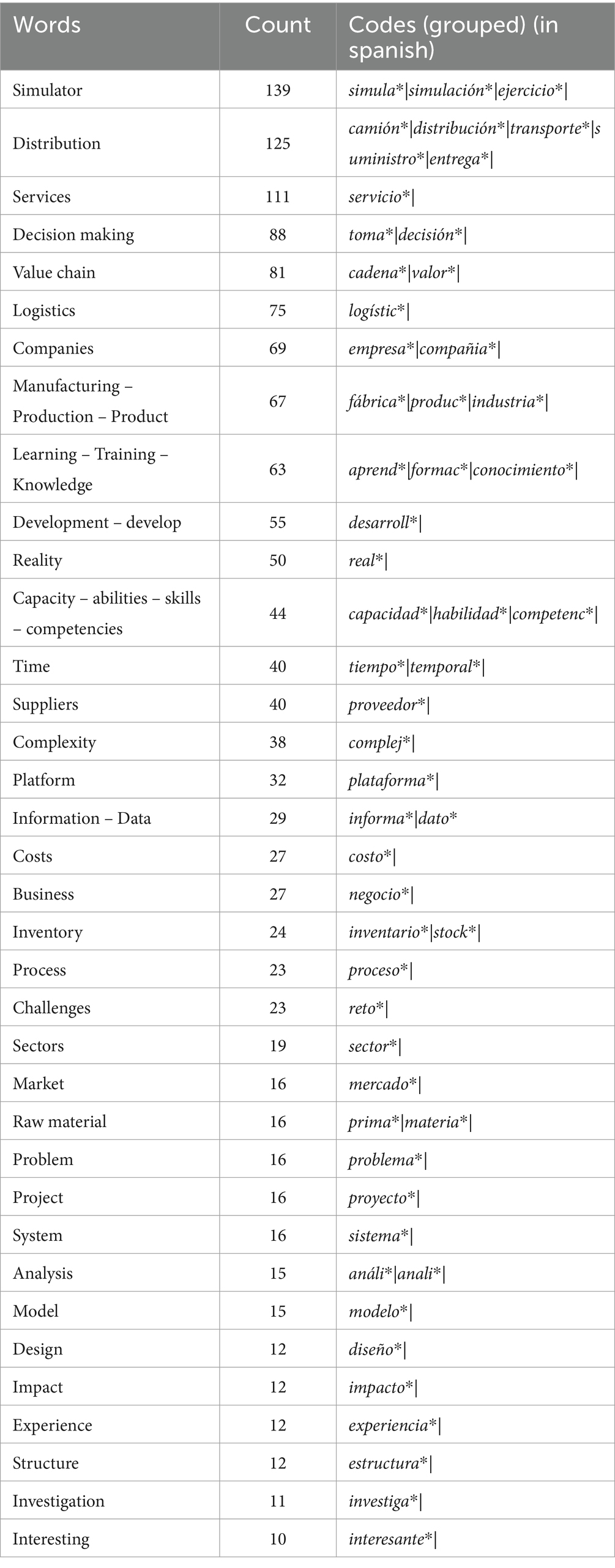

Firstly, an exploratory word frequency analysis was conducted. This analysis involved examining the transcriptions of structured interviews with these experts. An automated word count was performed using Atlas.ti. software. After excluding terms irrelevant to our study, we generated a list of words that appeared more than seven times, as detailed in Table 2.

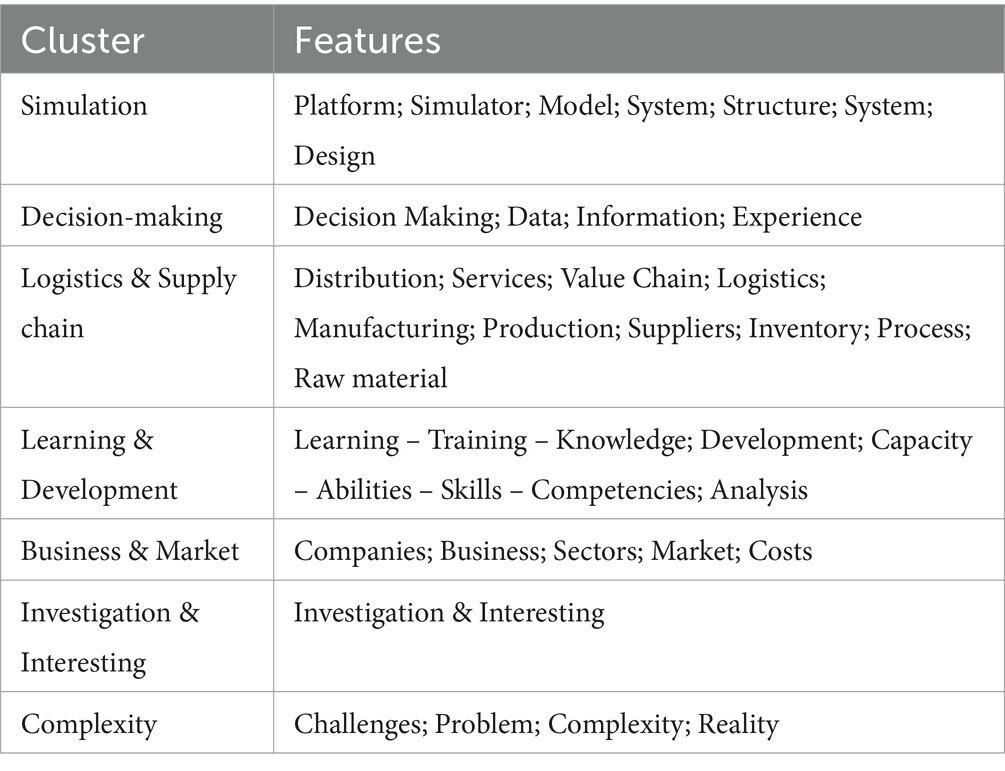

The process of analyzing this set of words enabled us to develop a series of codes related to the fundamental characteristics of simulation systems in Industry 4.0. This coding was carried out automatically using Atlas.ti., grouping several words identified in the previous process into a single code, as shown in Table 3. From this process, we created a list of 36 codes.

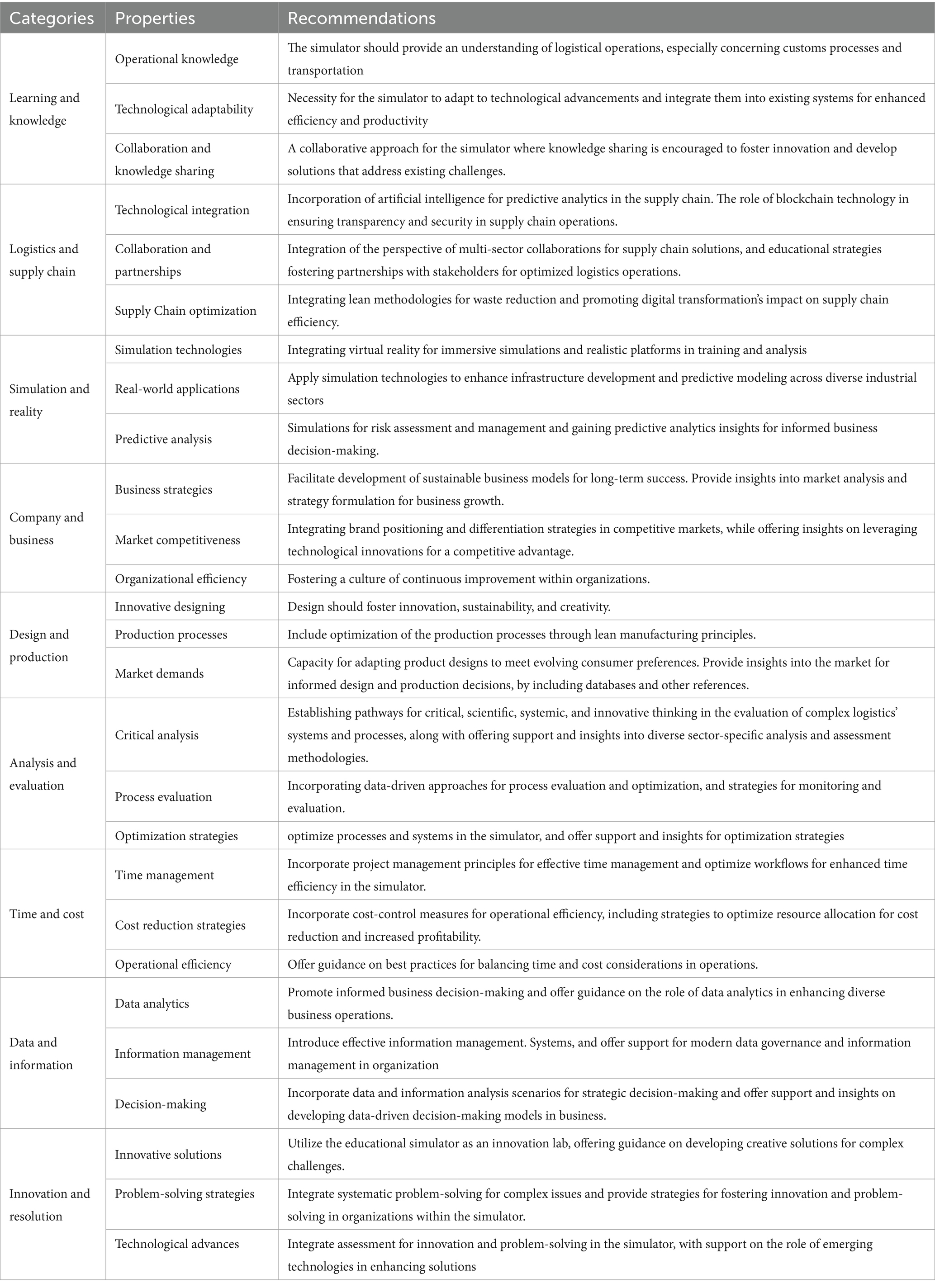

Finally, it was performed conventional content analysis on the transcriptions, a research method that involves the systematic classification and coding of text data to identify themes or patterns, enabling the subjective interpretation of the content (Hsieh and Shannon, 2005). The qualitative analysis involved a three-step process: open coding, axial coding, and selective coding, resulting in the creation of emergent categories and their properties that represented prevalent themes and concepts from experts’ discourse (Miles and Huberman, 1989). Results of this step of the analysis methodology can be seen in the next section, in Table 4.

4 Results

4.1 Logistics experts’ insights

The professionals interviewed supported the instrumental role of simulation as a risk mitigation tool in decision-making and operational planning, particularly highlighting its value in creating a safe space for experimentation. Additionally, they emphasized the importance of solid protocols to mitigate the inherent uncertainties characteristic of logistics operations. An important emerging finding was the greater usefulness that experts assign to simulators for small and medium-sized enterprises (SMEs), which are often prevented from taking advantage of more sophisticated optimization algorithms.

The insights extended to technological advances within Industry 4.0 and trends in e-commerce, advocating their incorporation into a logistics simulation framework. The experts proposed a tiered business model for simulation that could be customized to the specific logistics needs of various companies. They also underlined the critical importance of performance metrics to evaluate both the effectiveness of the simulation tool and the logistics operations themselves. Additionally, experts emphasized the need for the simulation architecture to adapt to a large number of variables, ranging from various transportation modalities to specialized conditions, such as temperature-controlled supply chains for pharmaceuticals. Educational possibilities were also a point of attention since the interviewed experts envisioned the inclusion of pedagogical functionalities to contribute to an understanding of the complexity of the mechanics of supply chains.

Finally, the experts highlighted the essential incorporation of multidisciplinary competencies into the logistics simulation tool. This includes skill sets in data analytics, finance, and strategic management that they argued are critical to navigating the complexities endemic to logistics operations. Collaboration with a broader range of stakeholders was highlighted as a vital component to the successful development and implementation of a logistics simulator that is contextually relevant and effective. In summary, the insights derived from these expert dialogs accentuate the broad potential of logistics simulation tools, especially in managing the complexities and uncertainties inherent to logistics operations. These tools exhibit marked flexibility across a variety of business models and user groups and will benefit significantly from alignment with contemporary technology trends, performance metrics, and multidisciplinary competencies.

4.2 Simulation platform features for complexity management

Following Table 2, “Qualitative word count and set of codes,” summarizes the results of the exploratory word frequency analysis and the codes constructed in the content analysis from the interviews with the experts in the field of logistics, related to the essential characteristics of a simulation system designed for Industry 4.0. Each row of the table represents a different thematic group, constructed by the most frequent words, together with a numerical representation that indicates its recurrence during the interviews, and the correspondent set of codes constructed during the content analysis. These codes, identified through the qualitative analysis phase, account for the concepts and terms emphasized by the experts during the interviews.

Simulator, a category with a frequency of 139, is the most relevant, obviously due to the centrality of the topic in the interviews. This is followed by Distribution, with a frequency of 125, covering terms that represent various facets of distribution logistics, including transportation and delivery modes. Services have been a key and distinctive element, mentioned 111 times, and summarizes several dimensions of services within the industry, highlighting the importance assigned to a concentration on the optimization and integration of service functionalities in the simulation system. Categories such as “Decision Making,” “Value Chain,” and “Logistics,” with respective frequencies of 88, 81, and 75, suggest a network of decision-making processes, value optimization strategies, and logistics coordination, which are expected to be fundamental characteristics within the simulation system.

Toward the last part of the table, we observe categories such as “Design,” “Impact,” and “Research” with lower frequencies, which implies that these aspects, although they were considered during the conversation about the characteristics necessary in the development of the simulator, may not be the focal points according to experts.

Table 2 provides a first representation of experts’ perspectives on the critical components that should be incorporated into a simulator for the development of a tool consistent with industry expectations.

Based on the words presented in Table 2, an affinity diagram was constructed, grouping the related words and assigning appropriate names to the clusters. The result of this affinity diagram is shown in Table 3, “Game Components revealed by affinity diagram.”

Based on the codes and the affinity diagram, a set of categories and their properties were constructed, grounded on the conventional content analysis of the experts’ discourse. Table 4 “Categories and properties for Logistics Simulator for Industry 4.0”, outlines the main categories for building an educational logistics simulator, identified by experts in the field. This table summarizes the thematic categories that emerged from the experts’ discourse, further segmented into specific properties that highlight critical focal areas suggested by the interviewed. These areas are expected to significantly influence the development of an educational simulator adapted to the logistics sector. The last column summarizes the most relevant recommendations made by the experts regarding each category and property.

Table 3 provides key themes identified by experts in the field for the construction of a logistics simulation educational tool for the context of Industry 4.0. It integrates general categories into specific properties, thus providing subconstructs that experts anticipate will inform the development trajectory of a logistics simulation tool designed for educational purposes. Each category and its respective properties together establish a matrix to conceptualize, design, and implement educational logistics simulators. The categories and properties reflect a dual focus on experience in the practical domain and agility in technological incorporation, as well as the vertical and horizontal integration necessary for effective logistics operations. It suggests a convergence between the simulated environment and real-world operational requirements while incorporating aspects of strategic management and data-driven decision-making, highlighting the role of the simulator in facilitating organizational efficiency and market competitiveness. Experts advocate a comprehensive approach to the development of an educational logistics simulator. From fostering domain-specific competencies like “Operational Knowledge” to advocating for advanced features like “Predictive Analytics,” the table reflects an integrative perspective. It requires the synergy of technology, strategy, operations, and data analysis to create an educational simulator that not only captures the complexities and dynamics inherent in contemporary logistics but also provides students with the skillset necessary for an evolving sector. It also highlights the need for systems thinking that considers a multiplicity of stakeholders and the demands of constant technological and market changes. Therefore, this matrix provides a view of what constitutes an advanced, pedagogically sound, and industry-relevant educational logistics simulator.

Previous results presented above in Tables 2–4, converge in a conceptual model to address the complexities inherent in creating an educational game designed specifically for logistics and supply chain management. More than a mere inventory of game features, it is a conceptual map, for clarifying the interaction between the technological dimension, pedagogical objectives, operational concerns, user participation, and broader economic realities. Below, Figure 2 shows how the game components are related to the development of the sub-competences that make up the skill of complex thinking development.

The “Investigation & Interesting” cluster is related to Scientific Thinking because it involves the fundamental principles of exploration, inquiry, and curiosity inherent in scientific endeavors. The “Logistics & SC” Cluster is related to scientific thinking as supply chain management involves scientific and logistical processes based on data and analysis. However, it also encompasses a significant component of systemic thinking, as the supply chain is inherently a complex system. The “Learning & Development” cluster is closely linked to both Scientific Thinking and Critical Thinking due to its emphasis on systematic exploration, evidence-based learning, and analytical reasoning. The authors consider that “Simulation” cluster is intricately connected to Systems Thinking due to its inherent focus on modeling and understanding complex interrelationships within a system, “Simulation” involves creating models that replicate real-world processes or systems, include interconnected variables, and there is a focus on identifying and understanding causal relationships. The “Decision Making” cluster is intricately connected to both Critical Thinking and Innovative Thinking due to its involvement in thoughtful analysis, evaluation, and the potential for creative problem-solving and exploration of alternatives. The “Business & Market” cluster is closely tied to both Systems Thinking and Innovative Thinking due to its involvement in understanding complex interconnections within the business ecosystem and fostering creative approaches to market challenges.

Technologically, the model highlights the importance of adaptability and response capacity in real-time, while in pedagogy, it reflects an educational philosophical perspective that transcends the mere transfer of knowledge and advocates the development of cognitive skills. Advanced, such as decision-making and critical analysis. Operationally, the model emphasizes a commitment to experiential learning by reflecting the complexities of real-world logistics, thus serving as an argument for a game design that does not simply simulate but actively engages the user in practical and realistic problem-solving. In terms of user experience, it promotes a design approach that balances complexity and accessibility, aiming to cultivate metacognitive skills such as strategic planning and problem identification which are crucial in logistics and supply chain management. Broadly, within the economic and business landscape, the model recognizes the transdisciplinary nature of logistics, interweaving aspects related to market dynamics and resource allocation, thus recognizing the potential usefulness of the game not simply as an isolated learning tool. But as an integrative system that can help understand the complex interaction between logistics, broader business strategies, and market behaviors. This transdisciplinary establishes the relationship with a dynamic, complex and interconnected world, with significant changes in the skills that must be developed in professionals who belong to the logistics area, as well as in the workforce, considering the development of reasoning for complexity in individuals. Therefore, Figure 2 provides a model to articulate the attributes and characteristics of a pedagogical tool that integrates academic rigor with practical relevance, synthesizing a variety of educational and operational objectives within the environment of logistics, development of desirable skills for the future workforce, and supply chain management in Industry 4.0.

5 Discussion

The current demand for a multidisciplinary framework for the construction of an educational logistics simulator adapted to the specificities of Industry 4.0, emerges as an indisputable imperative. This need for an integrative approach finds empirical support in “technological adaptability” and “operational efficiency” which serve as constructs in Table 3. While Javaid et al. (2022) and Zizic et al. (2022) emphasize the indispensability of technological fluency and operational effectiveness, Longo et al. (2019) raise the complementary need for collaborative paradigms. This manifests itself in the “Collaboration and Partnerships” and “Supply Chain Optimization” categories. In the same sense, Williams and Olajide (2020) and Sekaran and Hildas (2023) expand the requirement for the necessary agility in data analysis and information management in simulation systems. About the pedagogical dimensions, the usefulness of simulation-based learning in the context of Industry 4.0 is a recurring motif in contemporary research. The works of González-Pérez and Ramírez-Montoya (2022) is a foundation for simulations as viable pedagogical instruments in various sectors, integrated with the macro-competence of complex thinking, as well as the “Simulation and Reality” dimension in Table 3, which in turn integrate to broader paradigms in the Education 4.0 (Cruz-Martínez et al., 2022; Cecchi et al., 2023). Furthermore, the categories of “Analysis and Evaluation” and “Time and Cost” are conceptually aligned with studies that emphasize systematic evaluation and optimization, particularly those by Lang et al. (2018) and Mourtzis et al. (2019). These insights validate the claim that an educational logistics simulator based on Table 3 would benefit from a comprehensive methodology, combining core logistics functionalities with broader educational objectives and novel technologies.

Educational games, when designed with an integrated framework that incorporates technological features, educational objectives, industry-specific elements, and user experience, show great promise as pedagogical tools in complex disciplines such as logistics and supply chain management. As presented in Table 3, the incorporation of Industry 4.0 technologies, particularly when complemented by Artificial Intelligence (AI) and the Internet of Things (IoT), improves operations and efficiencies in the logistics and logistics sectors. Supply chain (Javaid et al., 2022; Zizic et al., 2022). However, these advances pose new challenges for assessing technological maturity and adaptation strategies (Yurci and Durakbasa, 2021). At the same time, in the pedagogical field, the effectiveness of project-based learning and virtual laboratories for training in skills relevant to Industry 4.0 has been supported (Gonzalez-Hernandez et al., 2020; Zolotová et al., 2020; Flaga and Pacholczak, 2022), although the need for technological advances to make the necessary pedagogical redesign invisible is highlighted (Mahmood et al., 2021).

The model detailed in Figure 2 serves as a pedagogical and theoretical tool for future research. It allows the development of specialized educational games in the logistics and supply chain sectors for Industry 4.0. Furthermore, Figure 2 relate the development of reasoning competence for complexity to the components of the game. The sub-competences systemic, scientific, critical, and innovative thinking, Ramírez-Montoya et al. (2022) are important for the development of the workforce with characteristics that impact Industry 4.0. In addition, it highlights the need for interdisciplinary research that explores the interactions between technological advances, pedagogical philosophies, and real-world logistical challenges, and for a rethinking of the design, implementation, and evaluation of educational tools in the age of the fourth industrial revolution.

This study comes with its set of limitations and opens avenues for future investigation. One notable limitation lies in the adoption of convenience sampling, emphasizing the involvement of experts well-versed in simulator usage. Furthermore, the study exclusively involved participants from the Latin American region, and these participant characteristics may potentially influence the study’s outcomes. Additionally, most participants boast backgrounds in academic, consulting, and business management roles, raising concerns about the applicability of the recommendations to real-world scenarios where operational logistics are central. Future research could explore the seamless integration of simulator modules focused on market analysis and strategy formulation to ensure sustained business viability and competitiveness, particularly for SMEs. An examination of the impact of incorporating project management principles, specifically those related to time and cost management, on operational efficiency is also warranted. Ideally, the simulator should serve as an innovation hub, incorporating systemic strategies for effective problem-solving. Subsequent research endeavors will delve deeper into these dimensions, providing insights into the optimal design of educational simulation platforms that cater to both educational and operational needs within an Industry 4.0 framework.

6 Conclusion

In response to the central objectives of the study, the research emphasizes the crucial role of well-designed educational games in complex domains such as logistics and supply chain management, especially within the framework of Industry 4.0. The articulated multidimensional model provides a matrix that, (a) specifies technological characteristics designed to be adaptable to emerging innovations; (b) outlines educational objectives, prioritizing operational knowledge and fostering a collaborative ecosystem; (c) incorporates industry-specific elements, including customs processes and transportation modalities; (d) accentuates the importance of user experience through the use of large-scale data analysis and information management systems; and (e) underlines the need for the development of sub-competencies associated with reasoning for complexity. These various components act together to improve both the educational outcomes and operational efficiency of a simulator.

The growing complexity of logistics and supply chain management demands specific features for simulation platforms. Guided by the model developed in this study, these simulators can provide a dynamic environment to model, assess, and optimize complex logistics operations. Consequently, these tools not only serve as educational spaces for skill acquisition but also offer a theoretical foundation for future interdisciplinary research. As a result, the findings of this study can inform logistics educational curricula and the development of operational tools, integrating academic perspectives with industry-relevant applications.

Finally, concerning practical and research implications, the study suggests forming teams with interdisciplinary approaches in the design of educational games, integrating pedagogical and technological aspects, and fostering collaboration between game designers and logistics experts to ensure an effective integration of knowledge. Additionally, it recommends designing data collection instruments that address key areas such as learning objectives, pedagogical integration, and business models, utilizing questionnaires and interviews to thoroughly explore the needs and expectations of users in the logistics context. The study also underscores the importance of including participants with diverse roles in the logistics chain, from operators to managers, to ensure a comprehensive understanding of this complex system. Furthermore, the study encourages a focus on developing competencies and practical skills relevant to modern logistics, suggesting the design of game scenarios that simulate critical decisions in the supply chain and logistics management.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving humans were approved by the Institute for the Future of Education. The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

EP-V: Conceptualization, Funding acquisition, Project administration, Supervision, Validation, Writing – original draft, Writing – review & editing. VR-P: Conceptualization, Investigation, Methodology, Software, Supervision, Writing – original draft, Writing – review & editing. AM-U: Supervision, Validation, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The authors would like to thank the financial support from Tecnologico de Monterrey through the “Challenge-Based Research Funding Program 2022.” Project ID # I005 – IFE001 – C2-T3 – T. The authors would like to acknowledge the financial support from Writing Lab, Institute for the Future of Education, Tecnologico de Monterrey, México.

Acknowledgments

The authors would like to acknowledge the academic support from Writing Lab, Institute for the Future of Education, Tecnologico de Monterrey, México.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Agarwal, V., and Biswas, S. (2019). Discerning critical competencies in industry 4.0: an expert opinion based group decision making framework.

Al-Emran, M., Malik, S. I., and Al-Kabi, M. N. (2020). “A survey of Internet of things (IoT) in education: opportunities and challenges” in Toward social Internet of things (SIoT): Enabling technologies, architectures and applications, studies in computational intelligence. eds. A. E. Hassanien, R. Bhatnagar, N. E. M. Khalifa, and M. H. N. Taha (Cham: Springer International Publishing).

Bastos, L. E. M. (2020). “Industry 4.0 in pumping applications: achievements and trends.” In Advances in logistics, operations, and management science, eds. F.R. George Leal Jamil, A. M. SilvaDa, and S. M. Lopes IGI Global.

Bolanowski, M., and Paszkiewicz, A. (2021). “Sustainable development in the field of IoTfocused network engineer education based on simulation tools.” 37th Information Systems Education Conference, ISECON 2021, 28–46.

Bongomin, O., Nganyi, E. O., Abswaidi, M. R., Hitiyise, E., and Tumusiime, G. (2020). Sustainable and dynamic competitiveness towards technological leadership of industry 4.0: implications for east African community. J. Eng. 2020, 1–22. doi: 10.1155/2020/8545281

Buzady, Z., Wimmer, A., Csesznak, A., and Szentesi, P. (2022). Exploring flow-promoting management and leadership skills via serious gaming. Interact. Learn. Environ., 1–15. doi: 10.1080/10494820.2022.2098775

Cecchi, L. A., Rodríguez, J. P., and Dahl, V. (2023). “Logic programming at elementary school: why, what and how should we teach logic programming to children?” in Prolog: the next 50 years. eds. D. S. Warren, V. Dahl, T. Eiter, M. V. Hermenegildo, R. Kowalski, and F. Rossi (Cham: Springer Nature Switzerland) Lecture Notes in Computer Science.

Chernikova, O., Heitzmann, N., Fink, M. C., Timothy, V., Seidel, T., and Fischer, F. (2020). Facilitating diagnostic competences in higher education—a Meta-analysis in medical and teacher education. Educ. Psychol. Rev. 32, 157–196. doi: 10.1007/s10648-019-09492-2

Cortes, D., Ramirez, J., Villagomez, L., Batres, R., Vasquez-Lopez, V., and Molina, A. (2020). “Digital pyramid: an approach to relate industrial automation and digital Twin concepts.” In 2020 IEEE international conference on engineering, technology and innovation (ICE/ITMC), Cardiff, United Kingdom: IEEE.

Cruz-Martínez, G., Soto, Ó., and Benito, A. B. (2022). Learning about political systems while Playing: testing short-term knowledge retention through a role-play classroom game. Revista Española de Ciencia Política 60, 53–83. doi: 10.21308/recp.60.02

Daniela, L. (2020). New perspectives on virtual and augmented reality: Finding new ways to teach in a transformed learning environment. 1st New York: Routledge.

Diniz, F., Duarte, N., Amaral, A., and Pereira, C. (2022). “Industry 4.0: individual perceptions about its nine technologies” in Digitalization of society, economics and management. eds. E. Zaramenskikh and A. Fedorova (Cham: Springer International Publishing) Lecture Notes in Information Systems and Organisation.

Eriksson, K., Branneby, E., and Hagelin, M. (2021). “An educational model for competence development within simulation and Technologies for Industry 4.0.” In 2021 winter simulation conference (WSC), Phoenix, AZ, USA: IEEE.

Feng, K., and Ma, G. (2008). Learning supply chain management with fun: an online simulation game approach. California. J. Oper. Manag. 6, 41–48.

Flaga, S., and Pacholczak, K. (2022). Demonstrator of a digital Twin for education and training purposes as a web application. Adv. Sci. Technol. Res. J. 16, 110–119. doi: 10.12913/22998624/152927

Gonzalez-Hernandez, H. G., Cantu-Gonzalez, V., Mora-Salinas, R. J., and Reyes-Avendano, J. A. (2020). “Challenge-based learning and traditional teaching in automatic control engineering Courses: a comparative analysis.” In 2020 IEEE global engineering education conference (EDUCON) Porto, Portugal: IEEE.

González-Pérez, L. I., and Ramírez-Montoya, M. S. (2022). Components of education 4.0 in 21st century skills frameworks: systematic review. Sustain. For. 14:1493. doi: 10.3390/su14031493

Grisales-Palacio, V. H., García-Zaragoza, U., and Forero-Correa, H. (2022). “Connecting industry and academy through cyber-physical Systems for Disruptive Education in machine automation” in Industry practices, processes and techniques adopted in education. eds. K. MacCallum and D. Parsons (Singapore: Springer Nature Singapore)

Hansen, R.E., and Elbæk, L. (2019). “Educating for the 21st century with role play in event design.” In Proceedings of the 12th European conference on game based learning, 39. ACPI.

Helmold, M., Yılmaz, A. K., Flouris, T., Winner, T., Cvetkoska, V., and Dathe, T. (2022). Lean management, Kaizen, Kata and Keiretsu: best-practice examples and industry insights from Japanese concepts, management for professionals. Cham: Springer International Publishing.

Hernandez-de-Menendez, M., Morales-Menendez, R., Escobar, C. A., and McGovern, M. (2020). Competencies for industry 4.0. Int. J. Interact. Des. Manuf. 14, 1511–1524. doi: 10.1007/s12008-020-00716-2

Hoover, W., Guerra-Zubiaga, D. A., Banta, J., Wandene, K., Key, K., and Gonzalez-Badillo, G. (2022). “Industry 4.0 trends in intelligent manufacturing automation exploring machine learning” in ASME International Mechanical Engineering Congress and Exposition (Columbus, Ohio, USA: American Society of Mechanical Engineers). 86649:V02BT02A028.

Hsieh, H.-F., and Shannon, S. E. (2005). Three approaches to qualitative content analysis. Qual. Health Res. 15, 1277–1288. doi: 10.1177/1049732305276687

Hubl, A., and Fischer, G. (2017). “Simulation-based business game for teaching methods in logistics and production.” 2017 Winter Simulation Conference (WSC), Las Vegas, NV: IEEE.

Jacobs, F. R. (2000). Playing the beer distribution game OVER the INTERNET. Prod. Oper. Manag. 9, 31–39. doi: 10.1111/j.1937-5956.2000.tb00321.x

Javaid, M., Haleem, A., Singh, R. P., Suman, R., and Gonzalez, E. S. (2022). Understanding the adoption of industry 4.0 Technologies in Improving Environmental Sustainability. Sustain. Operat. Comp. 3, 203–217. doi: 10.1016/j.susoc.2022.01.008

Jiang, P., Wang, Y., Liu, C., Yi-Chung, H., and Xie, J. (2020). Evaluating critical factors influencing the reliability of emergency logistics systems using multiple-attribute decision making. Symmetry 12:1115. doi: 10.3390/sym12071115

Kandanaarachchi, T., and Perera, H. N. (2021). Gamified learning of supply chain optimization through the beer distribution game. IEEE Int. Conf. Indus. Eng. Eng. Manag. 2021, 503–507. doi: 10.1109/IEEM50564.2021.9672844

Kučera, E., Haffner, O., Drahoš, P., and Cigánek, J. (2022). Educational case studies for pilot engineer 4.0 Programme: monitoring and control of discrete-event systems using OPC UA and cloud applications. Appl. Sci. 12:8802. doi: 10.3390/app12178802

Lameras, P., Arnab, S., Dunwell, I., Stewart, C., Clarke, S., and Petridis, P. (2017). Essential features of serious games design in higher education: Linking learning attributes to game mechanics: Essential features of serious games design. British Journal of Educational Technology, 48, 972–994. doi: 10.1111/bjet.12467

Lang, S., Reggelin, T., Jobran, M., and Hofmann, W. (2018). “Towards a modular, decentralized and digital industry 4.0 learning factory.” In 2018 Sixth International Conference on Enterprise Systems (ES), Limassol: IEEE.

Lezama, P., Bonerge, O., Manotas, E. N., and Mercado-Caruzo, N. (2020). Analysis of design patterns for educational application development: serious games. Proc. Comp. Sci. 175, 641–646. doi: 10.1016/j.procs.2020.07.093

Longo, F., Nicoletti, L., and Padovano, A. (2019). Ubiquitous knowledge empowers the smart factory: the impacts of a service-oriented digital Twin on enterprises’ performance. Annu. Rev. Control. 47, 221–236. doi: 10.1016/j.arcontrol.2019.01.001

Mahmood, K., Otto, T., Kuts, V., Terkaj, W., Urgo, M., and Haidegger, G. (2021). Development of virtual learning factory toolkit for production engineering education. IOP Conf. Ser. Mater. Sci. Eng. 1140:12039. doi: 10.1088/1757-899X/1140/1/012039

Manbachi, M., Jay Nayak, M., Hammami, A., and Bucio, G. (2022). “Virtualized experiential learning platform for substation automation and industrial control cybersecurity.” In 2022 IEEE Electrical Power and Energy Conference (EPEC), Victoria, BC, Canada: IEEE.

Marmier, F., Deniaud, I., Rasovska, I., and Michalak, J.-L. (2021). Towards a proactive vision of the training for the 4.0 industry: from the required skills diagnostic to the training of employees. IFAC-PapersOnLine 54, 1144–1149. doi: 10.1016/j.ifacol.2021.08.135

Merkuryev, Y., and Bikovska, J. (2012). Business simulation game development for education and training in supply chain management. Sixth Asia Modell. Symp. 2012, 179–184. doi: 10.1109/AMS.2012.12

Miles, M., and Huberman, M. (1989). Some procedures for causal analysis of multiple-case data. International Journal of Qualitative Studies in Education, 2, 55–68. doi: 10.1080/0951839890020106

Mourtzis, D., Angelopoulos, J., and Panopoulos, N. (2022). “Digital Manufacturing” in The digital supply chain (pp. 27–45). (Amsterdam: Elsevier).

Mourtzis, D., Tsakalos, D., Xanthi, F., and Zogopoulos, V. (2019). Optimization of highly automated production line: an advanced engineering educational approach. Proc. Manufact. 31, 45–51. doi: 10.1016/j.promfg.2019.03.008

Mukhuty, S., Upadhyay, A., and Rothwell, H. (2022). Strategic sustainable development of industry 4.0 through the Lens of social responsibility: the role of human resource practices. Bus. Strateg. Environ. 31, 2068–2081. doi: 10.1002/bse.3008

Naul, E., and Liu, M. (2020). Why Story Matters: A Review of Narrative in Serious Games. Journal of Educational Computing Research, 58, 687–707. doi: 10.1177/0735633119859904

Oluyisola, O. E., Bhalla, S., Sgarbossa, F., and Strandhagen, J. O. (2022). Designing and developing smart production planning and control Systems in the Industry 4.0 era: a methodology and case study. J. Intell. Manuf. 33, 311–332. doi: 10.1007/s10845-021-01808-w

Pacheco-Velazquez, E. (2020). “Using gamification to develop self-directed learning.” In Proceedings of the 2020 International Conference on Education Development and Studies, Paris France: ACM.

Pacheco-Velazquez, E. (2022). Effects of the use of simulators and an online platform in logistics education. Int. J. Interact. Des. Manuf. (IJIDeM) 16, 439–457. doi: 10.1007/s12008-021-00791-z

Pacheco-Velazquez, E. A., and Aguilar-Avalo, M. (2019). “GOAL: generating learning opportunities in logistics.” In 2019 IEEE Global Engineering Education Conference (EDUCON), Dubai, United Arab Emirates: IEEE.

Pacheco-Velazquez, E., Montoya, M. S. R., and Salinas-Navarro, D. (2023). Serious games and experiential learning: options for engineering education. Int. J. Serious Games 10, 3–21. doi: 10.17083/ijsg.v10i3.593

Pacheco-Velazquez, E., Palma-Mendoza, J., Arana-Solares, I., and Cotera-Rivera, T. (2019). “LOST: a serious game to develop a comprehensive vision of logistics.” In Proceedings of the 12th European Conference on Game based Learning, 64. ACPI.

Pizzuto, G., Wang, H., Fakhruldeen, H., Peng, B., Luck, K. S., and Cooper, A. I. (2022). “Accelerating laboratory automation through robot skill learning for sample scraping.”

Ramírez-Montoya, M. S., Castillo-Martínez, I. M., Sanabria-Z, J., and Miranda, J. (2022). Complex thinking in the framework of education 4.0 and open innovation—a systematic literature review. J. Open Innov. Technol. Mark. Complex. 8:4. doi: 10.3390/joitmc8010004

Romero, M., Dumont, L., Daniel, S., Barma, S., Ferrer, M., and Hénaire, V. (2020). Digital games and learning. JFD Editions.

Saleem, A. N., Noori, N. M., and Ozdamli, F. (2022). Gamification Applications in E-learning: A Literature Review. Technology, Knowledge and Learning, 27, 139–159. doi: 10.1007/s10758-020-09487-x

Sekaran, J. F., and Hildas, R. (2023). Implementation of an industrial automation remote lab (IARL) and validation using a deep learning approach during the COVID pandemic. Comp. Appl. Eng. Educ. :cae.22663. doi: 10.1002/cae.22663

Sharifpour, H., Ghaseminezhad, Y., Hashemi-Tabatabaei, M., and Amiri, M. (2022). Investigating cause-and-effect relationships between supply chain 4.0 technologies. Eng. Manag. Product. Serv. 14, 22–46. doi: 10.2478/emj-2022-0029

Siddiqui, A., Khan, M., and Akhtar, S. (2008). Supply chain simulator: a scenario-based educational tool to enhance student learning. Comput. Educ. 51, 252–261. doi: 10.1016/j.compedu.2007.05.008

Simchi-Levi, D., Kaminsky, P., and Simchi-Levi, E. (2008). Designing and managing the supply chain: Concepts, strategies, and case studies. 3rd Edn. Boston: McGraw-Hill/Irwin.

Simon, J., Hošovský, A., and Sárosi, J. (2021). Neural network driven automated guided vehicle platform development for industry 4.0 environment. Tehnicki Vjesnik - Technical Gazette 28, 1936–1942. doi: 10.17559/TV-20200727095821

Sincharoenkul, K., Tongtep, N., and Boonlamp, L. (2020). “Supervised classification of board games for active learning to enhance business knowledge and skills.” In 2020 17th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand: IEEE.

Siyaev, A., Valiev, D., and Geun-Sik, J. (2023). Interaction with industrial digital Twin using neuro-symbolic reasoning. Sensors 23:1729. doi: 10.3390/s23031729

Sorger, M., Ralph, B. J., Hartl, K., Woschank, M., and Stockinger, M. (2021). Big data in the metal processing value chain: a systematic digitalization approach under special consideration of standardization and SMEs. Appl. Sci. 11:9021. doi: 10.3390/app11199021

Sparling, D. (2002). Simulations and supply chains: strategies for teaching supply chain management. Supp. Chain Manag. Int. J. 7, 334–342. doi: 10.1108/13598540210447782

Sunny, J., Pillai, V. M., Nath, H. V., Shah, K., Ghoradkar, P. P., Philip, M. J., et al. (2022). Blockchain-enabled beer game: a software tool for familiarizing the application of blockchain in supply chain management. Ind. Manag. Data Syst. 122, 1025–1055. doi: 10.1108/IMDS-10-2021-0609

Takahashi, K., Muraoka, R., and Otsuka, K. (2020). Technology adoption, impact, and extension in developing countries’ agriculture: a review of the recent literature. Agric. Econ. 51, 31–45. doi: 10.1111/agec.12539

Tilvawala, K., Sundaram, D., and Myers, M. D. (2019). Serious Games for Sustainable Development: A Decision-driven Transformative Approach. British Journal of Educational Technology.

Tsang, Y. P., Wu, C. H., and Lee, C. K. M. (2022). BlockTrainHK: an online learning game for experiencing blockchain concepts. SoftwareX 19:101167. doi: 10.1016/j.softx.2022.101167

Tseng, C.-Y., Doll, J., and Varma, K. (2019). “Exploring evidence that board games can support computational thinking.” Hong Kong.

Vanduhe, V. Z., Nat, M., and Hasan, H. F. (2020). Continuance intentions to use gamification for training in higher education: integrating the technology acceptance model (TAM), social motivation, and task technology fit (TTF). IEEE Acc. 8, 21473–21484. doi: 10.1109/ACCESS.2020.2966179

Williams, O. C., and Olajide, F. (2020). “A technological approach towards the measurement of Enterprise agility.” In 2020 15th Iberian Conference on Information Systems and Technologies (CISTI), Sevilla, Spain: IEEE.

Yurci, C., and Durakbasa, N. M. (2021). “A brief general industrial virtual reality applications overview including a simple factory VR simulation” in Digital conversion on the way to industry 4.0. eds. N. M. Durakbasa and M. Güneş Gençyılmaz (Cham: Springer International Publishing) Lecture Notes in Mechanical Engineering.

Zizic, M. C., Mladineo, M., Gjeldum, N., and Celent, L. (2022). From industry 4.0 towards industry 5.0: a review and analysis of paradigm shift for the people, organization and technology. Energies 15:5221. doi: 10.3390/en15145221

Keywords: serious games, simulators, logistics education, Industry 4.0, complex thinking, educational innovation, higher education

Citation: Pacheco-Velazquez E, Rodes-Paragarino V and Marquez-Uribe A (2024) Exploring educational simulation platform features for addressing complexity in Industry 4.0: a qualitative analysis of insights from logistics experts. Front. Educ. 9:1331911. doi: 10.3389/feduc.2024.1331911

Edited by:

Antonio Martínez-Arboleda, University of Leeds, United KingdomReviewed by:

Y. P. Tsang, Hong Kong Polytechnic University, Hong Kong SAR, ChinaLine Have Musaeus, Aarhus University, Denmark

Copyright © 2024 Pacheco-Velazquez, Rodes-Paragarino and Marquez-Uribe. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ernesto Pacheco-Velazquez, epacheco@tec.mx

Ernesto Pacheco-Velazquez

Ernesto Pacheco-Velazquez Virginia Rodes-Paragarino

Virginia Rodes-Paragarino Alberto Marquez-Uribe2

Alberto Marquez-Uribe2