Exploring the efficiency and emission characteristics of hydroxy-boosted canola biodiesel in comparison to traditional diesel fuels

- Department of Mechanical Engineering, Burdur Mehmet Akif Ersoy University, Burdur, Türkiye

In this research, we experimentally examined how incorporating HHO into blends of 20% canola biodiesel with 80% diesel and 40% canola biodiesel with 60% diesel impacts the engine’s performance and its emission traits. Canola oil, widely used in Europe, served as the biodiesel base. The addition of HHO, recognized for its potential to improve combustion efficiency and reduce emissions which were deteriorated by biodiesel addition. The findings revealed decrement on fuel consumption as 5.74% and 4.43% and rise in thermal efficiencies as 3.92% and 3.97% with HHO addition compared to B20 and B40, respectively. Besides that, CO emissions were reduced significantly up to 35.43%, while CO2 emissions decreased moderately up to 14.93% compared to diesel fuel. On the other hand, biodiesel and HHO addition increased NOx emissions as 49.80%. Utilization of biodiesel and HHO in diesel engines offers a straightforward way to reduce emissions and enhance fuel efficiency, addressing environmental issues and promoting sustainable transportation.

Introduction

Energy is the leading field in the economic growth of a country in the world. The International Energy Agency states in its reports that the world’s energy needs will increase nearly 40 percent by 2040. In the majority of countries, limited fuel reserves lead to dependence on imported fossil fuels, which has a dramatic impact on the country’s economy (Geo Varuvel, 2023). In the industries, diesel engines is the most prominent engine due to their better efficiencies and reliabilities. The increasing demand for fossil fuels day by day and the resulting rapid depletion of petroleum-based fuel, which is the main fuel source of diesel engines, poses a significant problem.

The major drawbacks of diesel engines are the release of significant amounts of smoke and nitrogen oxides (NOx) emissions. During the combustion of diesel fuel, carbon monoxide (CO), NOx, and hydrocarbon (HC) emissions occur (Elumalai and Ravi, 2023). Emissions such as particulate matter (PM), HC, CO, and NOx resulting from diesel engines also pose a danger to human health. Due to the drawbacks of diesel engines, the discovery of a renewable and environmentally friendly fuel for diesel engines becomes critical (Ming et al., 2018). Biodiesel fuels have a promising potential to replace fossil-based fuels. Biodiesel is one of the most popular alternative fuels to conventional diesel fuel due to the advantages of being sustainable, biodegradable, and can be produced from all kinds of organic materials, including waste, and can reduce exhaust gases such as HC, CO, and smoke when used in internal combustion engines (Kukana and Jakhar, 2022), (Gowrishankar and Krishnasamy, 2023). Biodiesel contributes to reducing the risk of global warming by reducing the life cycle of CO2. Biodiesel fuel can also be used in various areas such as aircraft engines, agricultural machinery, mobile engines, small-scale energy production, marine engines, and process heating. There is a chemical reaction in the biodiesel process. The chemical reaction that converts vegetable or animal oil into biodiesel is called transesterification. Production is carried out by using alcohol such as methanol or ethanol to bond to vegetable oil or animal fat chemically. While the fatty acid profile in biodiesel corresponds to the profile of the main oil or fat from which it is obtained, the main parts in biodiesel fuels include straight-chain fatty acids including 16 and 18 carbon atoms. The methanol, free fatty acids, acylglycerols, and glycerol contained in biodiesel are restricted to biodiesel norms such as European EN 14214 and ASTM (American Society for Testing and Materials) D6751, as well as other norms being developed worldwide (Masera and Hossain, 2023), (Riyadi et al., 2023). Along with its general positive features as a transportation fuel, biodiesel also has another eventual usage areas, but these usage areas are not at a level that can contend with the fuel in terms of volume. Biodiesels are used as plasticizers, lubricants, heating oil, power generation, various solvent applications, and high-boiling adsorbents for cleaning gaseous industrial emissions. Other advantages of biodiesel are its low or no sulfur content, lack of aromatic content, high flash point, natural lubricity, reducing of most adjusted exhaust emissions, miscibility with petrodiesel in all mixture rates, and conformity with existent fuel dispersion substructure. In addition to its advantages, biodiesel also has disadvantages with its oxidation stability, cold flow features, and corrosiveness to automotive fuel system materials. The biggest obstacle to the commercialization of biodiesel is seen as the high feed stock cost. While biodiesel is sold at more economical prices compared to diesel fuel in European countries due to the tax advantages given by governments, in other countries the cost of biodiesel is much higher than diesel due to the lack of such tax deductions (Sorate and Bhale, 2015), (Kanth et al., 2022). Sources of obtaining biodiesel are listed as waste oils, animal fats, vegetable oils, and algae. Inedible and edible vegetable oils used for conversion to biodiesel include canola, sunflower, rubber seed, soybean, rapeseed, mahua, karanja, linseed, corn, and tobacco (Geo Varuvel, 2023); (Akcay et al., 2020); (Hong et al., 2015). It is considered essential to grow oily plants with high oil content in obtaining biodiesel. Countries also produce biodiesel by growing oil crops most suitable for their own climate and soil conditions. One of the oils used in biodiesel production is canola oil. Canola production has increased sharply in the world in the last 40 years and ranks second after soybean production in terms of oil grains with the highest harvest. While canola is one of the most critical oilseed crops in Europe and Canada, its processing for oil constitutes a significant portion of the overall canola sector in the countries (Adewole et al., 2016); (Martins et al., 2020).

In recent years, hydrogen has been preferred as a suitable alternative in fuels in compression ignition engines owing to its merits such as not having a carbon structure, not damaging the fuel, and having a high calorific value. Although hydrogen also stands out for its rapid ignition, clean consumption, and reuse properties, those with higher nitrogen oxide properties are restricted by explosion and hazardous applications (Kanth and Debbarma, 2021), (Kanth et al., 2020). It has been stated that integrating H2 into diesel injection engines shows a significant reduction in CO2, HC, and CO emissions, while increasing the H2 ratio increases the heat release rate and cylinder pressure, thus increasing NOx emissions. Although emissions vary based on the hydrogen fraction and experimental cases, it has been stated that smoke reductions of up to 100% or specific particulate matter reductions of up to 80% have been observed. However, by adding hydrogen to the fuel, a variability between a 25% increase and a 50% relative decrease in NOx emissions was detected (Adebisi et al., 2023), (Chiriac and Apostolescu, 2013). Hydroxy (HHO) gas is usually produced via electrolysis, involving the dilution of an electrolyte (like NaCl, KOH, or NaOH) in water. This method leads to the generation of oxygen and hydrogen gases at the anode and cathode, respectively. (Forero, 2021). The chemical reactions involved in the electrolysis of water have been described in numerous investigations. When the gas is fuel a diesel engine, it has similar advantages to hydrogen addition.

Using different energy sources as fuel has been investigated by many researchers. Adding biodiesel to diesel is seen as a possible alternative solution found in many studies. Simsek and Uslu (Simsek and Uslu, 2020) added biodiesel obtained from animal fats and vegetable oils to diesel fuel at a rate of 50% and tested it as 100% biodiesel in a four-stroke, single-cylinder, air-cooled, and direct injection compression ignition engine. They found that fuel mixtures containing vegetable oil provide better results in the way of emission and performance. In many searches by researchers, it is stated that biodiesel mixtures with small content in volumes can replace diesel in helping to control air pollution and greatly reduce the amount of use of limited resources, without suffering a significant loss in engine power and economy (Xue et al., 2011). Ozturk and Can (Öztürk and Can, 2022) examined the impacts of gas recirculation, injection retardation, and ethanol addition on emission and performance characteristics by running a fuel mixture of 10% canola biodiesel and 90% diesel in a diesel engine. While the lowest smoke emissions were achieved with the addition of 2% ethanol, they found that the addition of 2% ethanol at the delayed injection timing had no visible effect on performance. Sanli and Uludamar (Şanli and Uludamar, 2020) tested normal diesel, canola biodiesel, and hazelnut biodiesel fuels in a diesel engine and carried out exergy and energy analyses. According to fuel kinds, the top rates in exergy and thermal efficiency were found in diesel fuel. The exergy and thermal outputs of hazelnut biodiesel were determined as 37.93% and 35.33%, respectively, the efficiencies of canola biodiesel were 37.23% and 34.67%, respectively, and the energy and exergy outputs of diesel fuel were 38.85% and 36.45%, respectively. has been made Öztürk (Öztürk, 2015) created a fuel by mixing hazelnut soap stock biodiesel with canola oil biodiesel to improve some properties and reduce fuel costs. In a mixture of 5% and 10% biodiesel, 5% addition to diesel increased NOx emissions, while a decrease in total hydrocarbon, CO, and smoke emissions was detected. At 10% addition, total hydrocarbon, CO, and smoke emissions increased, while NOx emissions decreased. The study by EL-Kassaby et al. (EL-Kassaby et al., 2016) aimed to enhance engine performance and reduce emissions by adding HHO gas to gasoline fuel. Their optimized HHO generation system led to a 10% increase in engine thermal efficiency, a 34% decrease in fuel consumption, and significant reductions in CO, HC, and NOx emissions, showcasing the potential of HHO gas as a performance improver.

Recently, many researchers have been examining the engine performance and emission characteristics by adding different alternative fuels such as compressed alcohol, hydrogen, and natural gas to biodiesel. Özcanlı et al. (Ozcanli et al., 2017) using hydrogen and hydroxy enriched castor oil methyl ester diesel mixture, engine performance characteristics and emissions were compared with normal diesel engines and castor oil methyl ester fueled engines without hydrogen addition. They discovered that specific fuel consumptions and CO emissions were significantly reduced with the supplementation of hydrogen and hydroxy compared to pure castor oil methyl ester and a diesel engine. Reddy and Sarangi (Rami Reddy and Sarangi, 2023) tested the fuel they created by adding aluminum oxide and titanium oxide nanoparticle additives to diesel fuel along with the biodiesel they created with mango seed methyl esters, in a water-cooled four-stroke diesel engine. They also examined engine emissions and performance by introducing hydrogen as a secondary fuel in a dual-fuel concept. Their outputs show that the fuel mixture containing 20% mango seed methyl esters, 10% water, 70% diesel, and 75 ppm Al2O3 and TiO2 by volume can substituted for normal diesel fuel without any major changes to the engine if the restrictions in nanoparticle phase stabilization can be avoided.

The study by Demir et al. (Demir et al., 2024) investigates the enhancement of diesel fuel with graphene and HHO gas to address the increasing energy demand and environmental concerns. By mixing diesel with fuel oil and adding graphene particles, and integrating HHO gas into the fuel blend, they aimed to improve combustion efficiency and reduce emissions. Tests conducted at various engine torques showed that these additions significantly improved thermal efficiency and reduced harmful emissions, offering a promising alternative fuel strategy to mitigate fossil fuel depletion and environmental impact.

Zaho et al.’s (Zhao Z. et al., 2022) research demonstrates that adding HHO gas to a spark ignition engine improves performance and emissions. “The research contrasts gasoline port injection with the addition of HHO (GPI + HHO) against gasoline direct injection supplemented with HHO (GDI + HHO), discovering that GDI + HHO superiorly boosts engine performance, diminishes HC and CO discharges, yet marginally elevates NOx emissions. GDI + HHO is identified as the optimal method for integrating HHO gas into gasoline engines.

Recent advancements have not only focused on biodiesel but have also extended to exploring the efficacy of HHO gas enrichment—a product of water electrolysis—on diesel engine performance. HHO gas, known for its clean-burning properties, offers a pathway to reducing harmful emissions from diesel engines. In line with this, Praveenkumar et al. (Praveenkumar et al., 2024) delved into current technologies for energy recovery from waste, highlighting the potential of integrating such technologies with traditional fuel systems to reduce polyaromatic hydrocarbons and advocate for recycling strategies. Their research provides a comprehensive view on how novel approaches, including HHO enrichment, can contribute to a more sustainable energy future. Furthermore, Sekar et al. (Sekar et al., 2024) investigated the performance enhancements in diesel engines using nanomaterials and chlorella vulgaris microalgae blends, augmented with biogas. This study presents an innovative approach to fuel blending that can significantly improve engine performance while minimizing environmental pollutants, suggesting a synergistic effect when combining multiple bio-based additives with HHO gas enrichment. Wu et al. (Wu et al., 2024) explored the use of waste tyre pyrolysis oil as a fossil fuel substitute in diesel engines, complemented by constant hydrogen injection via the air intake manifold. Their findings underscore the viability of integrating HHO gas with other alternative fuels to optimize engine performance and emission profiles, thereby offering a multi-faceted approach to addressing the challenges posed by conventional diesel fuels. In the aviation sector, the role of hydrogen—including HHO gas—as an alternative fuel has been studied by Manigandan et al. (Manigandan et al., 2023). Their analysis of hydrogen storage, adaptability to different fuels, stability of combustion, and the decrease in emissions within gas turbine engines highlights the revolutionary capability of hydrogen and gases rich in hydrogen to fuel future aviation with a significantly reduced environmental impact.

Collectively, these studies illustrate the diverse and innovative strategies being pursued to enhance diesel engine efficiency and reduce emissions. By integrating findings from research on biodiesel, HHO gas enrichment, and other novel fuel additives, this body of work contributes to the evolving narrative on sustainable energy solutions for the automotive and aviation industries. These efforts are critical in the transition towards cleaner, more renewable sources of energy that can support global environmental goals and mitigate the impact of climate change.

This research innovates by assessing engine performance metrics including fuel efficiency per brake horsepower, thermal efficiency under load, and temperature of exhaust gases through experiments with five distinct fuels: standard diesel, two varieties of biodiesel blends (B20 and B40) made from canola oil enhanced with HHO (Hydroxy) gas. Additionally, the impact on emissions such as carbon monoxide, carbon dioxide, and nitrogen oxides with the integration of biodiesel and HHO gas was analyzed.

Materials and methods

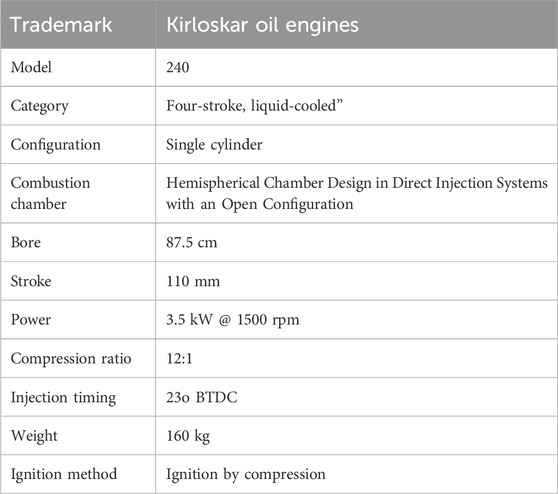

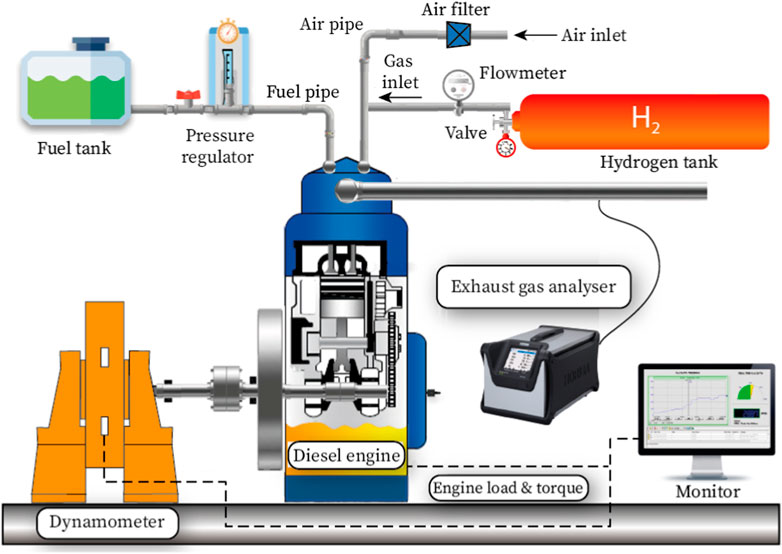

In this study, biodiesel fuel was produced by canola oil. The biodiesel was mixed with conventional low sulphur diesel fuel as 20% (B20) and 40% (B40), by volume. Moreover, during the experimental diesel engine was fueled with HHO gas from intake manifold. Table 1 thoroughly details the diesel engine’s technical specifications employed in this research. The experimental setup is depicted in Figure 1. The engine tests were conducted in triplicate, and the mean values of the collected data were utilized.

In the research, hydraulic dynamometer was used to load the test engine. Performance data of the engine was collected through the software of the dynamometer. Before entering the mixing chamber, the gas flow amount of HHO gas was detected with flowmeters. To determine exhaust emissions, data was stored using custom MRU software with an MRU Delta 1600 V gas analyzer connected to the main computer.

In the research, the HHO (Hydroxy) system is described as the process of electrolyzing distilled water using an electrolyte composed of substances with free ions to enhance electrical conductivity. The acquisition of HHO involved procedures that encompassed the electrolysis of water. The ion conductivity in this study was supported by potassium hydroxide (KOH).

Production of canola biodiesel

The canola oil underwent a transesterification process, utilizing CH3OH as reactant and KOH as catalysts, resulting in the conversion of canola oil into canola biodiesel. This manufacturing technique is a widely recognized procedure that entails combining canola oil with an alcohol, usually methanol or ethanol, under the influence of a catalyst such as sodium hydroxide or potassium hydroxide. This chemical process converts the triglycerides present in canola oil into biodiesel, which is typically in the form of methyl or ethyl esters, along with glycerol as a byproduct. The method of transesterification includes blending canola oil with 15% methanol and 5% potassium hydroxide, in terms of weight, at a temperature of 60°C for a duration of 75 min. After the transesterification reaction completed, the resulting products (crude glycerine and methyl ester) were placed in a separation funnel. The crude glycerine located at the bottom due to the density difference was easily separated from the crude methyl ester after a certain waiting period around 8 hours. Following the division process, the raw methyl ester underwent a triple wash until the rinse water appeared transparent. Subsequently, it was subjected to drying at 110°C for 1 hour. Finally, the biodiesel underwent filtration to eliminate minor contaminants.

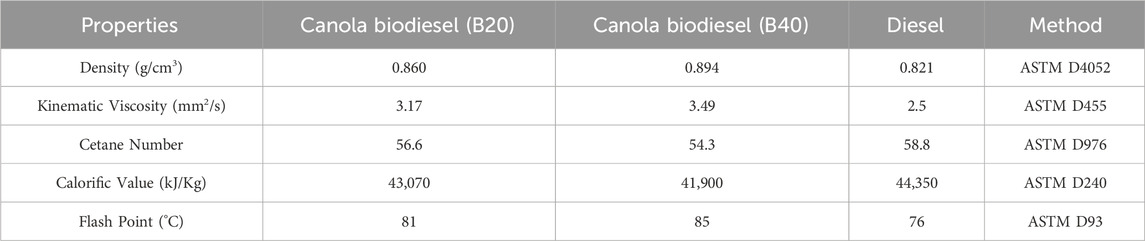

Table 2 provides the essential parameters of canola biodiesel (B20 and B40) and diesel, determined according to ASTM standards (Thiruselvam et al., 2023).

Results and discussion

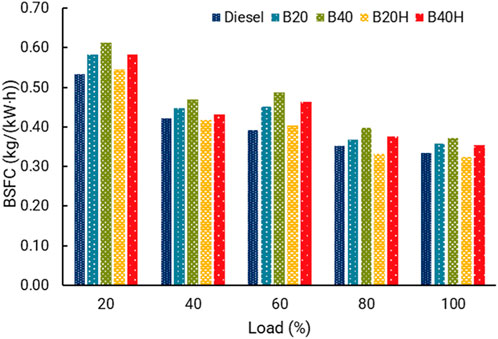

Brake specific fuel consumption (BSFC)

Figure 2 gives the brake specific fuel consumptions of tested fuels. The high viscosity properties in canola biodiesel led to high specific fuel consumption under all load conditions tested. With the increment of engine load, BSFC decreased to overcome the engine loads as a result of consumption of fuel increment (Qenawy et al., 2024). The average BSFC rate of B20 and B40 is respectively 6.67% and 12.1% higher than diesel fuel. This situation was also seen in previous studies (Roy et al., 2013), (Raghavulu et al., 2020) where canola biodiesel was added to diesel fuels. Previous studies (Öztürk et al., 2020) have shown two main reasons for the increase in BSFC. The first of these is that biodiesel has a low calorific value and requires more fuel to obtain the same power as a fuel with a lower heat capacity. The other is increased surface tension, density, and viscosity, which requires more fuel injection by mass and causes an increase in line pressure.

Introducing HHO gas to the intake air while running the engine on canola biodiesel significantly reduced the BSFC) by 5.74% for B20H and 4.43% for B40H, in comparison to their B20 and B40 counterparts, respectively. This decrease in BSFC is attributed to the enhanced mixture of air and HHO gas in the cylinders, which leads to increased power output with reduced fuel usage. The addition of HHO gas also enhances the speed of flame propagation, contributing to better mix quality. This causes temperature values to increase and combustion to improve, as well as an increase in in-cylinder pressure values. Therefore, it is stated that there is a decrease in BSFCs (Akcay et al., 2020). Enhanced combustion within the cylinder enabled the high-viscosity canola biodiesel blend to ignite more easily. Nonetheless, with the introduction of enriched HHO, the combustion chamber experiences a limitation in the high flow rate due to the constrained compression ratio.

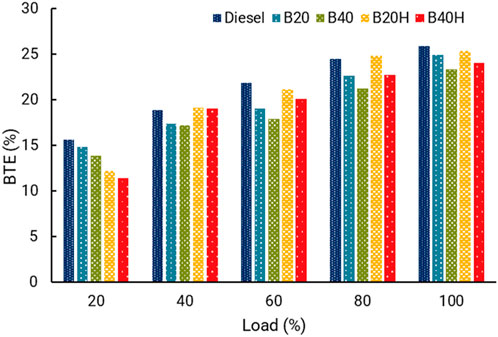

Brake thermal efficiency (BTE)

Figure 3 displays the outcomes for brake thermal efficiency of the fuels under examination. The data reveal that adding HHO to B20 increases the average BTE by 3.92%, and adding HHO to B40 increases the average BTE by 3.97%. HHO gas provides better combustion conditions under high engine speed conditions with its high flame speed, wide ignition range, and short extinguishing distance, preventing the disadvantageous characteristics of biodiesels (Kenanoğlu et al., 2020), (Xia et al., 2021). Compared to diesel fuel, B20 and B40 have averagely decreased the values as 7.39% and 12.33%, respectively compared to diesel fuel. It is stated that biodiesel has lower BTE due to its lower heating value, lower cetane index, higher BSFC, and higher viscosity which affects the atomization of fuel (Hasan and Rahman, 2017).

Exhaust gas temperature

Figure 4 displays the exhaust gas temperature measurements for the fuels under examination. There’s a notable trend where the temperature of the exhaust gas in the fuels tested rises with an increase in load. This escalation in load leads to greater fuel usage, which in turn elevates the temperature of both the engine and its exhaust emissions (Varatharajan and Cheralathan, 2012). Although the biodiesel decreases the values as 0.57% and 1.77% for B20 and B40, respectively, due to its calorific values and improper fuel mixture, adding HHO increased the exhaust temperatures as 0.33% and 0.51%, respectively compared to B20 and B40 since HHO gas adding a faster-burning component to the fuel, shortening the combustion time and making the process more constant volume (Cecrle et al., 2012); (Zhao B. et al., 2022).

Carbon monoxide emission (CO)

CO emission result values of the tested fuels are displayed in Figure 5. When the engine load is moderate, CO emissions are lower. In B20 and B20H, CO emissions were determined to be averagely 7.77% and 29.66% less than diesel, respectively. In B40 and B40H, averagely, 15.21% and 35.43% less than diesel, respectively. It is stated that this situation is caused by the formation of local areas with excess oxygen in the fuel-air mixture during the combustion of canola and HHO gas (Li et al., 2015). Also, the properties of hydrogen, which included in HHO gas, such as high flame speed resulted with more completed combustion (Thiruselvam et al., 2023). Therefore, further decrement of CO emission was achieved during the experiments. The higher calorific value and zero carbon content of HHO gas essentially ensure the release of lower harmful pollutant gases such as CO (Ijaz Malik et al., 2023).

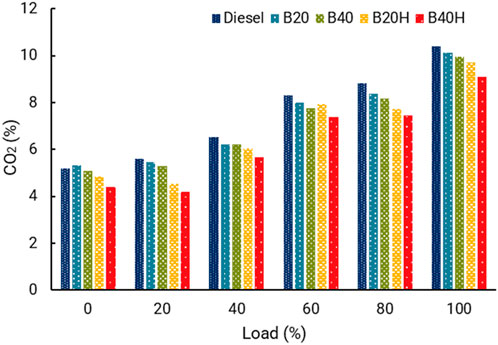

Carbon dioxide emission (CO2)

The percentage values of CO2 emissions versus engine loads are represented in Figure 6. With increasing engine load, the CO2 emission value of all fuel increases (Oguz et al., 2023). B20 and B20H indicated an average of 2.94% and 9.08% lower CO2 emissions, respectively compared to diesel, and B40 showed an average of 5.33% and 14.93% lower CO2 emissions compared to diesel at all loads. Previous studies (Mahmudul et al., 2017); (Akar et al., 2018) have shown that CO2 emissions decrease as the amount of biodiesel added to diesel increases.

When HHO gas was introduced, B20H saw a reduction in CO2 emissions by an average of 6.33% compared to B20, and B40H showed a decrease of 10.13% in CO2 emissions compared to B40. This reduction in CO2 emissions with HHO gas supplementation is credited to an enhanced hydrogen/carbon ratio, the lack of carbon atoms in HHO, improved combustion efficiency, and reduced combustion duration. Moreover, the decline is also due to the diminished availability of carbon in the combustion process when HHO is utilized (Tosun and Özcanlı, 2021).

Nitrogen oxide emission (NOx)

Figure 7 displays the measurement of NOx emissions of the tested fuels. NOx emissions in compression ignition engines are largely related to oxygen concentration, cylinder temperature, and reaction residence time (Baltacioglu et al., 2014). As the engine load increases and in parallel with the increase in exhaust gas temperature, as shown in Figure 3, NOx emissions increase in all tested fuels. B20 fuel indicated average 14.58% more emissions than diesel fuel, and B40 fuel showed average 28.50% more emissions than diesel, averagely. NOx emission largely depends on the in-cylinder temperature, and it is stated that the oxygen atoms in the chemical structure of biodiesel can create more complete combustion, that is, increase the cylinder temperature (Özcanlı et al., 2022).

In diesel engines powered by HHO, the combustion process is characterized by a significantly higher peak pressure, which leads to the formation of a notably slender flame reaction area and reduces the duration of combustion. This phenomenon compresses the gases that are burnt at the commencement of the combustion cycle to a temperature that is higher than what they achieve right after the combustion has occurred, consequently leading to the generation of NOx (Kumar et al., 2015). HHO gas addition increased the NOx values up to 49.80% compared to diesel fuel. Also, HHO gas resulted with 22.06% and 16.58% higher NOx emissions when the engine fueled with B20 and B40, respectively. Previous studies (Mirhashemi and Sadrnia, 2020), (Agarwal et al., 2017) have shown that engines running on hydrogen/HHO-enriched biodiesel emit higher NOx levels than diesel fuel.

Conclusion

In this search, the outputs of HHO-enriched canola biodiesel were examined in the way of performance and emission properties of the diesel engine. The test engine was subjected to HHO induction operation with canola biodiesel at flow rates. In order to achieve optimum results in terms of performance and emissions, tests were carried out with a diesel engine using 5 different fuels, in which HHO flow rates were added to B20 and B40, as well as canola oil biodiesel blends added at 20% and 40% by volume to pure diesel fuel. The outcomes of the study are as follows.

• BSFC was increased by 6.67% and 12.1% with B20 and B40 fuels. However, this increment was restricted with HHO addition.

• Compared to diesel fuel, BTE decreased by an average of 7.39% and 12.33% with B20 and B40, respectively. While, adding HHO was increased BTE as 3.92% and 3.97% when added to B20 and B40 fuels, respectively.

• Exhaust gas temperature increased as the load enhanced. Although the biodiesel decreased the values due to its calorific values and improper fuel mixture, adding HHO increased the end-exhaust temperatures since HHO gas adding a faster-burning component to the fuel, shortening the combustion time and making the process more constant volume.

• The CO values decreased by an average of 7.77%, 15.21%, 29.66%, and 35.43% by using B20, B40, B20H, and B40H fuels, respectively.

• The CO2 levels declined by an average of 2.94%, 5.33%, 9.08%, and 14.93% decrement with B20, B40, B20H, and B40H fuels with respect to diesel fuel.

• NOx emissions increased by an average of 14.58% and 28.50% with the addition of B20 and B40, respectively. Compared to diesel fuel, HHO addition with biodiesel fuel increased the values up to 49.80%.

In future studies, various flow-rate of HHO gas and biodiesels from other resources may be considered to be studied. Also, their affect on other outputs such as combustion characteristic, noise, vibration, etc. of the engine may be considered.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

AÇ: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adebisi, A., Abd-Rasheed, A., Olusegun, T., Sanni, S. E., Oguntade, T., and Oni, B. A. (2023). Effects of hydrogen enrichment on diesel engine fueled with Afzelia Africana biodiesel – TiO2 blends. Egypt. J. Pet. 32 (1), 81–86. doi:10.1016/j.ejpe.2023.02.002

Adewole, D. I., Rogiewicz, A., Dyck, B., and Slominski, B. A. (2016). Chemical and nutritive characteristics of canola meal from Canadian processing facilities. Anim. Feed Sci. Technol. 222, 17–30. doi:10.1016/j.anifeedsci.2016.09.012

Agarwal, A. K., Gupta, J. G., and Dhar, A. (2017). Potential and challenges for large-scale application of biodiesel in automotive sector. Prog. Energy Combust. Sci. 61, 113–149. doi:10.1016/j.pecs.2017.03.002

Akar, M. A., Kekilli, E., Bas, O., Yildizhan, S., Serin, H., and Ozcanli, M. (2018). Hydrogen enriched waste oil biodiesel usage in compression ignition engine. Int. J. Hydrogen Energy 43 (38), 18046–18052. doi:10.1016/j.ijhydene.2018.02.045

Akcay, M., Yilmaz, I. T., and Feyzioglu, A. (2020). Effect of hydrogen addition on performance and emission characteristics of a common-rail CI engine fueled with diesel/waste cooking oil biodiesel blends. Energy 212, 118538. doi:10.1016/j.energy.2020.118538

Baltacioglu, M. K., Ozcanli, M., and Aydin, K., “Effect of pure hydrogen addition on a compression ignition engine performance and exhaust emissions parameters,”, AVTECH '14/II. Automotive and Vehicle Technologies Conference, Istanbul, Turkey, October 2014.

Cecrle, E., Depcik, C., Guo, J., and Peltier, E. (2012). Analysis of the effects of reformate (hydrogen/carbon monoxide) as an assistive fuel on the performance and emissions of used canola-oil biodiesel. Int. J. Hydrogen Energy 37 (4), 3510–3527. doi:10.1016/j.ijhydene.2011.11.026

Chiriac, R., and Apostolescu, N. (2013). Emissions of a diesel engine using B20 and effects of hydrogen addition. Int. J. Hydrogen Energy 38 (30), 13453–13462. doi:10.1016/j.ijhydene.2013.07.095

Demir, U., Çelebi, S., and Özer, S. (2024). Experimental investigation of the effect of fuel oil, graphene and HHO gas addition to diesel fuel on engine performance and exhaust emissions in a diesel engine. Int. J. Hydrogen Energy 52, 1434–1446. doi:10.1016/j.ijhydene.2023.08.007

El-Kassaby, M. M., Eldrainy, Y. A., Khidr, M. E., and Khidr, K. I. (2016). Effect of hydroxy (HHO) gas addition on gasoline engine performance and emissions. Alexandria Eng. J. 55 (1), 243–251. doi:10.1016/j.aej.2015.10.016

Elumalai, R., and Ravi, K. (2023). A hybrid calibration scheme for developing hydrogen enrichment ratio control map using RSM and ANN technique to enhance the characteristics of an ammonia biodiesel RCCI combustion engine. Case Stud. Therm. Eng. 49, 103257. doi:10.1016/j.csite.2023.103257

Forero, J. D. (2021). Energy, exergy and environmental assessment of partial fuel substitution with hydroxy powered by a thermoelectric generator in low displacement diesel engines. Clean. Eng. Technol. 3, 100086. doi:10.1016/j.clet.2021.100086

Geo Varuvel, E. (2023). Effect of premixed hydrogen on the performance and emission of a diesel engine fuelled with prunus amygdalus dulcis oil. Fuel 341, 127576. doi:10.1016/j.fuel.2023.127576

Gowrishankar, S., and Krishnasamy, A. (2023). Emulsification – a promising approach to improve performance and reduce exhaust emissions of a biodiesel fuelled light-duty diesel engine. Energy 263, 125782. doi:10.1016/j.energy.2022.125782

Hasan, M. M., and Rahman, M. M., “Performance and emission characteristics of biodiesel–diesel blend and environmental and economic impacts of biodiesel production: a review,” Renew. Sustain. Energy Rev., 74, 938–948, 2017, doi:10.1016/j.rser.2017.03.045

Hong, I. K., Lee, J. R., and Lee, S. B. (2015). Fuel properties of canola oil and lard biodiesel blends: higher heating value, oxidative stability, and kinematic viscosity. J. Ind. Eng. Chem. 22, 335–340. doi:10.1016/j.jiec.2014.07.027

Ijaz Malik, M. A., Mujtaba, M. A., Kalam, M. A., Silitonga, A. S., and Ikram, A. (2023). Recent advances in hydrogen supplementation to promote biomass fuels for reducing greenhouse gases. Int. J. Hydrogen Energy 49, 463–487. doi:10.1016/j.ijhydene.2023.09.154

Kanth, S., and Debbarma, S. (2021). Comparative performance analysis of diesel engine fuelled with hydrogen enriched edible and non-edible biodiesel. Int. J. Hydrogen Energy 46 (17), 10478–10493. doi:10.1016/j.ijhydene.2020.10.173

Kanth, S., Debbarma, S., and Das, B. (2020). Effect of hydrogen enrichment in the intake air of diesel engine fuelled with honge biodiesel blend and diesel. Int. J. Hydrogen Energy 45 (56), 32521–32533. doi:10.1016/j.ijhydene.2020.08.152

Kanth, S., Debbarma, S., and Das, B. (2022). Experimental investigations on the effect of fuel injection parameters on diesel engine fuelled with biodiesel blend in diesel with hydrogen enrichment. Int. J. Hydrogen Energy 47 (83), 35468–35483. doi:10.1016/j.ijhydene.2022.08.095

Kenanoğlu, R., Baltacıoğlu, M. K., Demir, M. H., and Erkınay Özdemir, M. (2020). Performance and emission analysis of HHO enriched dual-fuelled diesel engine with artificial neural network prediction approaches. Int. J. Hydrogen Energy 45 (49), 26357–26369. doi:10.1016/j.ijhydene.2020.02.108

Kukana, R., and Jakhar, O. P. (2022). Effect of ternary blends diesel/n-propanol/composite biodiesel on diesel engine operating parameters. Energy 260, 124970. doi:10.1016/j.energy.2022.124970

Kumar, R. S., Loganathan, M., and Gunasekaran, E. J. (2015). Performance, emission and combustion characteristics of CI engine fuelled with diesel and hydrogen. Front. Energy 9 (4), 486–494. doi:10.1007/s11708-015-0368-4

Li, Q., Backes, F., and Wachtmeister, G. (2015). Application of canola oil operation in a diesel engine with common rail system. Fuel 159, 141–149. doi:10.1016/j.fuel.2015.06.060

Mahmudul, H. M., Hagos, F. Y., Mamat, R., Adam, A. A., Ishak, W. F. W., and Alenezi, R. (2017). Production, characterization and performance of biodiesel as an alternative fuel in diesel engines – a review. Renew. Sustain. Energy Rev. 72, 497–509. doi:10.1016/j.rser.2017.01.001

Manigandan, S., Praveenkumar, T. R., Ir Ryu, J., Nath Verma, T., and Pugazhendhi, A. (2023). Role of hydrogen on aviation sector: a review on hydrogen storage, fuel flexibility, flame stability, and emissions reduction on gas turbines engines. Fuel 352, 129064. doi:10.1016/j.fuel.2023.129064

Martins, E. H., Ratuchne, A., de Oliveira Machado, G., and Knob, A. (2020). Canola meal as a promising source of fermentable sugars: potential of the Penicillium glabrum crude extract for biomass hydrolysis. Biocatal. Agric. Biotechnol. 27, 101713. doi:10.1016/j.bcab.2020.101713

Masera, K., and Hossain, A. K. (2023). Advancement of biodiesel fuel quality and NOx emission control techniques. Renew. Sustain. Energy Rev. 178, 113235. doi:10.1016/j.rser.2023.113235

Ming, C., Rizwanul Fattah, I., Chan, Q. N., Pham, P. X., Medwell, P. R., Kook, S., et al. (2018). Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 224, 167–177. doi:10.1016/j.fuel.2018.03.053

Mirhashemi, F. S., and Sadrnia, H. (2020). NOX emissions of compression ignition engines fueled with various biodiesel blends: a review. J. Energy Inst. 93 (1), 129–151. doi:10.1016/j.joei.2019.04.003

Oguz, M., Uyumaz, A., Babagiray, M., Solmaz, H., Calam, A., and Aksoy, F. (2023). The effects of metallic fuel addition into canola oil biodiesel on combustion, engine performance and exhaust emissions. J. Energy Inst. 111, 101390. doi:10.1016/j.joei.2023.101390

Ozcanli, M., Akar, M. A., Calik, A., and Serin, H. (2017). Using HHO (Hydroxy) and hydrogen enriched castor oil biodiesel in compression ignition engine. Int. J. Hydrogen Energy 42 (36), 23366–23372. doi:10.1016/j.ijhydene.2017.01.091

Özcanlı, M., Tosun, E., and Çalık, A. (2022). Influences of iron oxide nanomaterial and hydrogen addition into sunflower biodiesel/diesel powered diesel engine performance and emissions. Macromol. Symp. 404 (1), 2–4. doi:10.1002/masy.202100410

Öztürk, E. (2015). Performance, emissions, combustion and injection characteristics of a diesel engine fuelled with canola oil-hazelnut soapstock biodiesel mixture. Fuel Process. Technol. 129, 183–191. doi:10.1016/j.fuproc.2014.09.016

Öztürk, E., and Can, Ö. (2022). Effects of EGR, injection retardation and ethanol addition on combustion, performance and emissions of a DI diesel engine fueled with canola biodiesel/diesel fuel blend. Energy 244 (x), 123129. doi:10.1016/j.energy.2022.123129

Öztürk, E., Can, Ö., Usta, N., and Yücesu, H. S. (2020). Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng. Sci. Technol. Int. J. 23 (6), 1466–1475. doi:10.1016/j.jestch.2020.06.008

Praveenkumar, T. R., Sekar, M., Pasupuleti, R. R., Gavurová, B., Arun Kumar, G., and Vignesh Kumar, M. (2024). Current technologies for plastic waste treatment for energy recovery, it’s effects on poly aromatic hydrocarbons emission and recycling strategies. Fuel 357, 129379. doi:10.1016/j.fuel.2023.129379

Qenawy, M., Khalaf, M., Wang, J., Tian, J., Zuo, L., Mustafa, H. M. M., et al. (2024). Performance and emission of extracted biodiesel from mixed Jatropha-Castor seeds. Fuel 357, 130060. doi:10.1016/j.fuel.2023.130060

Raghavulu, K. V., Uppalapati, S., Kumar, A. N., Jani, S. P., Rajalingam, A., and Rasu, N. G. (2020). Effect on performance and emission of canola oil and snake gourd oil biodiesel blended in fossil Diesel-Biodiesel blend. Mater. Today Proc. 37 (2), 1091–1095. doi:10.1016/j.matpr.2020.06.338

Rami Reddy, S., and Sarangi, S. K. (2023). Optimizing the effect of using novel hydrogen enriched nano particles added emulsified waste mango seed biodiesel in diesel engine. Fuel 342, 127783. doi:10.1016/j.fuel.2023.127783

Riyadi, T. W. B., Spraggon, M., Herawan, S., Idris, M., Paristiawan, P., Putra, N., et al. (2023). Biodiesel for HCCI engine: prospects and challenges of sustainability biodiesel for energy transition. Results Eng. 17, 100916. doi:10.1016/j.rineng.2023.100916

Roy, M. M., Wang, W., and Bujold, J. (2013). Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel-diesel and canola oil-diesel blends at high idling operations. Appl. Energy 106, 198–208. doi:10.1016/j.apenergy.2013.01.057

Şanli, B. G., and Uludamar, E. (2020). Energy and exergy analysis of a diesel engine fuelled with diesel and biodiesel fuels at various engine speeds. Energy Sources, Part A recover. Util. Environ. Eff. 42 (11), 1299–1313. doi:10.1080/15567036.2019.1635229

Sekar, M., Selim, M. Y. E., and Elgendi, M. (2024). Improving the performance of a diesel engine using nanomaterials and chlorella vulgaris microalgae blends assisted with biogas. Int. J. Hydrogen Energy 49, 496–506. doi:10.1016/j.ijhydene.2023.09.171

Simsek, S., and Uslu, S. (2020). Comparative evaluation of the influence of waste vegetable oil and waste animal oil-based biodiesel on diesel engine performance and emissions. Fuel 280, 118613. doi:10.1016/j.fuel.2020.118613

Sorate, K. A., and Bhale, P. V. (2015). Biodiesel properties and automotive system compatibility issues. Renew. Sustain. Energy Rev. 41, 777–798. doi:10.1016/j.rser.2014.08.079

Thiruselvam, K., Murugapoopathi, S., Ramachandran, T., and Amesho, K. T. T. (2023). Hydrogen-enriched palm biodiesel as a potential alternative fuel for diesel engines: investigating performance and emission characteristics and mitigation strategies for air pollutants. Int. J. Hydrogen Energy 48 (79), 30974–30984. doi:10.1016/j.ijhydene.2023.04.256

Tosun, E., and Özcanlı, M. (2021). Hydrogen enrichment effects on performance and emission characteristics of a diesel engine operated with diesel-soybean biodiesel blends with nanoparticle addition. Eng. Sci. Technol. Int. J. 24 (3), 648–654. doi:10.1016/j.jestch.2020.12.022

Varatharajan, K., and Cheralathan, M. (2012). Influence of fuel properties and composition on NO x emissions from biodiesel powered diesel engines: a review. Renew. Sustain. Energy Rev. 16 (6), 3702–3710. doi:10.1016/j.rser.2012.03.056

Wu, Y., Yuan, Y., Xia, C., Alahmadi, T. A., Alharbi, S. A., Sekar, M., et al. (2024). Production of waste tyre pyrolysis oil as the replacement for fossil fuel for diesel engines with constant hydrogen injection via air intake manifold. Fuel 355, 129458. doi:10.1016/j.fuel.2023.129458

Xia, C., Brindhadevi, K., Elfasakhany, A., Alsehli, M., and Tola, S., “Performance, combustion and emission analysis of castor oil biodiesel blends enriched with nanoadditives and hydrogen fuel using CI engine,” Fuel, 306, 121541, 2021, doi:10.1016/j.fuel.2021.121541

Xue, J., Grift, T. E., and Hansen, A. C. (2011). Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 15 (2), 1098–1116. doi:10.1016/j.rser.2010.11.016

Zhao, B., Wang, H., Liao, Y., Nasif, O., Alharbi, S. A., Shanmugam, S., et al. (2022b). Effects of hydrocarbon liquid and HHO as the alternate fuel for unmodified compression ignition engines. Fuel 324, 124726. doi:10.1016/j.fuel.2022.124726

Keywords: diesel engine, canola oil biodiesel, hydroxy addition, engine performance, exhaust emission

Citation: Çalık A (2024) Exploring the efficiency and emission characteristics of hydroxy-boosted canola biodiesel in comparison to traditional diesel fuels. Front. Energy Res. 12:1386440. doi: 10.3389/fenrg.2024.1386440

Received: 15 February 2024; Accepted: 18 March 2024;

Published: 27 March 2024.

Edited by:

Erinç Uludamar, Adana Alparslan Turkes Science and Technology University, TürkiyeReviewed by:

Nitin Shrivastava, Rajeev Gandhi Technical University, IndiaManigandan Sekar, Sathyabama Institute of Science and Technology, India

Ömer Cihan, Sakarya University of Applied Sciences, Türkiye

Copyright © 2024 Çalık. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ahmet Çalık, acalik@mehmetakif.edu.tr

Ahmet Çalık

Ahmet Çalık