Exploration of the impact of green supply chain management practices on manufacturing firms’ performance through a mediated-moderated model

- 1School of Economics and Management, Chang’an University, Chang’an, China

- 2Faculty of Management Sciences, University of Kotli, Kotli, Pakistan

- 3Department of Economics, University of Kotli, Kotli, Pakistan

This study aimed to examine the impact of green supply chain management (GSCM) practices on the performance of manufacturing firms. It explored the mediating role of green innovation (GI) and the moderating role of information sharing (IS) and information technology innovation (ITI) on the relationship between GSCM practices and manufacturing firms’ performance. Data were collected through a structured questionnaire from employees working in manufacturing firms in Pakistan. Random sampling was used to select the participants. The hypotheses were tested using partial least squares (PLS) analysis. The study revealed that GSCM practices significantly positively impacted manufacturing firms’ performance. It highlighted the mediating role of green innovation, suggesting that GSCM practices fostered innovation and improved firm performance. The study also uncovered the moderating role of information sharing and IT innovation, indicating that the effectiveness of GSCM practices in driving performance varied based on the extent of information sharing and IT innovation within the industry. The findings of this study had practical implications for industry practitioners and policymakers. Implementing effective GSCM practices and promoting green innovation could enhance firm performance in the manufacturing sector. Recognizing the importance of information sharing and IT innovation was crucial, as they significantly enhanced the effectiveness and efficiency of GSCM practices. This study contributed to the existing literature by examining the relationships among GSCM practices, green innovation, information sharing, IT innovation, and manufacturing firm performance. It provided insights into the mechanisms through which GSCM practices impacted firm performance, offering a comprehensive understanding of the role of green innovation and the moderating effects of information sharing and IT innovation.

1 Introduction

Resource depletion and environmental degradation have put businesses in a more difficult situation. The massive use of resources and energy has made the manufacturing sector a significant contributor to global environmental changes. It is Pakistan’s biggest and most vibrant economic sector. While certain green supply chain methods are employed in South East Asian countries such as the Philippines, Malaysia, Thailand, Indonesia, and Singapore (Wang et al., 2020), there is little research on GSCM in developing countries. According to (Zhang, 2023), China and India have just begun implementing environmental policies. GSCM is “the integration of environmental, sociological, and economic considerations in a supply chain that functions as connected activities starting from sourcing raw materials to post-consumption activities of products or services by the consumers” (Ali et al., 2017). Developing hardware or software innovations that support environmentally friendly goods and procedures, such as improvements in energy efficiency, pollution avoidance, trash recycling, environmentally friendly product designs and corporate environmental management, is the emphasis of green innovation (Sheng et al., 2023). Sharing information with supply chain partners involves exchanging important and private information. It enhances the durability and dependability of connections, which is important for supply chain management (Soda and Aggarwal, 2022).

Prior research has delved into the impact of GSCM on diverse domains, encompassing organizational performance (Abdallah and Al-Ghwayeen, 2020), firm performance (Agyabeng-Mensah et al., 2020), environmental efficacy (Le, 2020), environmental consciousness (Sheng et al., 2023), as well as the challenges related to closed-loop and reverse supply chain processes (Piprani et al., 2023) and sustainable outcome (Alhamali, 2019). Recent scholarly literature has also examined the changing trends and forthcoming challenges in the domain of GSCM (Alhamali, 2019). Moreover, many studies in this field have focused on the challenges hindering GSCM adoption across different industries and within developed nations (Yu et al., 2021). It is worth noting that although there has been a surge in recent research on GSCM conducted in several countries like China, Vietnam, Uganda, Europe, and America, there’s a noticeable scarcity of studies about the South-Asian context. The previous study demonstrates that GSCM is frequently applied to enhance an organization’s environmental performance and competitive advantage. In the past, studies by (Soda and Aggarwal, 2022) and others have looked at how GSCM affects business performance, firm performance, environmental performance, environmental awareness, closed-loop and reverse supply chain issues, and sustainable performance (Foo et al., 2018). There are not enough in-depth studies examining how green supply chain management practices encourage green innovation within the manufacturing industry and how this mediates the relationship between GSCM and industry performance (Khan et al., 2023). Information sharing and IT innovation’s moderating effects on GSCM and industry performance in the manufacturing industry are not well explored. More investigation is required to comprehend the effects of green innovation, knowledge sharing, and IT innovation on the efficacy of GSCM methods and what motivates performance enhancements. Insights and recommendations surrounding GSCM, green innovation, information exchange, and IT innovation will need further research to be industry-specific.

This study aimed to investigate the influence of GSCM practices on the performance of manufacturing firms. Additionally, the study sought to analyze the mediating effect of GI and the moderating effects of IS and ITI in the relationship between GSCM practices and the performance of manufacturing firms.

Resource-based View (RBV) highlights that GSCM is a valuable resource that can enhance environmental sustainability and supply chain efficiency, leading to superior performance for manufacturing firms (Chatterjee et al., 2023). Innovation Diffusion Theory suggests that green innovation mediates the relationship between GSCM and firm performance. Green innovation involving eco-friendly products and processes is expected to reduce environmental impacts and attract environmentally conscious customers, enhancing manufacturing firms’ performance (Qader et al., 2023). Contingency theory emphasizes that management practices’ effectiveness depends on external and internal factors. Effective IT innovation and information sharing can amplify the positive impact of GSCM on performance by improving communication, coordination, and decision-making processes (Zhou et al., 2023).

Implementing GSCM innovations poses challenges in seamlessly integrating new technologies and sustainable practices throughout the supply chain. The initial significant investment required for these innovations may challenge short-term ROI justification. Keeping up with rapid technological advancements and ensuring alignment with sustainability objectives is crucial. Bridging the skill and knowledge gap through training is essential for successful GSCM implementation. Additionally, complying with evolving global environmental regulations is a continual challenge, necessitating ongoing process monitoring and adjustment (Zhang, 2023). GSCM innovations drive sustainable competitive advantage by highlighting a company’s commitment to environmental responsibility, appealing to consumers and investors. Despite the initial high investment, GSCM innovations yield long-term cost savings through reduced waste, optimized resource usage, and streamlined processes. Embracing sustainability fosters market expansion by attracting a broader customer base valuing Eco-conscious products. GSCM encourages collaborative partnerships within the supply chain for joint development and implementation of sustainable solutions. Furthermore, GSCM cultivates a culture of innovation, enhancing brand image and corporate reputation as a sustainability pioneer (Zhang, 2023).

Environmental impact assessments are crucial for studying the knowledge gap in GSCM’s impact on the performance of manufacturing enterprises for several reasons. First, we may better comprehend the connection between GSCM and the success of manufacturing organizations by studying in this area. Through examining the mediating and moderating roles of green innovation, information sharing, and IT innovation, it is possible to fill the research gap and add new knowledge and insights to existing literature. Second, looking into the research gap may have applications for businesses that make products. Companies may embrace and apply sustainable practices in their supply chains with more knowledge of how GSCM methods affect performance, possibly improving overall business results and environmental performance. Third, research in this field may educate regulators and policymakers about how well GSCM techniques work to achieve environmental objectives. It can offer fact-based information to help create laws and policies that motivate and incentive manufacturers to adopt sustainable practices. Fourth, recognizing the research gap in the performance of the manufacturing industry and GSCM enables the area to progress further. It offers a chance to investigate fresh theories, approaches, and models for measuring and assessing how GSCM activities affect environmental performance. This may help the establishment of industry benchmarks and best practices.

2 Literature review and supportive theories

Adopting green practices, including supply chain planning activities, had a favorable impact on operational performance, resulting in increased effectiveness and environmental sustainability. According to (Gao et al., 2022), green supply chain strategies assess the electronics industry’s sustainable performance. According to their research, green supply chain planning and other green practices favorably impact sustainability, especially in the environmental, financial, and social spheres. Studies show that GSCP activities have a beneficial effect on the productivity of manufacturing companies. They illustrate possible advantages of incorporating environmentally friendly methods into supply chain planning procedures, such as improved operational performance, firm performance, and higher sustainability. The link between GSCP and environmental performance in the manufacturing business was investigated by (Asghar, 2023). According to the study, businesses that adopted GSCP practices saw a considerable improvement in environmental performance measures, such as lower energy use, waste creation, and emissions (C.-C. Lee et al., 2016), study looked at the effects of GSCP on operational effectiveness and cost-cutting in the electronics sector. Luthra et al. (2017) concentrated on the contribution of GSCP to improving stakeholder integration and collaboration in the manufacturing sector. Chen et al. (2022) investigated how the GSCP affected regulatory compliance and risk management in the manufacturing industry. Therefore, we develop the following hypothesis:

H1a. Green supply chain planning positively influences manufacturing firms’ performance.

Adomako and Tran. (2022) environmental or green purchasing refers to incorporating environmental considerations into purchasing policies, initiatives, and practices. Others have put forth more purchasing-focused definitions, contending that the term “green supply activities” refers to the purchasing process’s role in facilitating internally driven environmental activities like recycling, reuse, and source reduction (Thahir et al., 2022). To improve supply chain performance, research into shifting production objectives from customers to suppliers has grown over the past 15 years. Supply chain managers may find “green supply” useful for improving their company’s record on corporate social responsibility, lowering reputational risks, cutting waste, and enhancing flexibility in response to changing environmental legislation. Green et al. (2012), investigating the effects of green procurement practices on corporate competitiveness in the manufacturing industry in China, the study found that green procurement positively influenced corporate. These studies show that Green Procurement (GP) procedures improve the efficiency of the electronic manufacturing sector. Mollenkopf et al. (2022) examined the connection between general practitioners’ practices and environmental performance in the electronics sector. According to the survey, businesses implementing GP activities, such as employing environmentally friendly suppliers and sustainable products, saw a noticeable increase in their environmental performance. Klassen and Vereecke. (2012) examined how GP affected supplier cooperation and innovation in the electronics sector. The function of GP in risk management and resilience in the electronics manufacturing industry was the main topic of study (Luthra et al., 2015). According to the survey, GP procedures like supplier selection based on environmental performance and sustainability activities benefit businesses. Therefore, we develop the following hypothesis:

H1b. Green procurement positively influences manufacturing firms’ performance.

Integrating a green supply chain into manufacturing operations is necessary to link internal environmental management practices with suppliers and customers. This will ensure inter-firm cooperation, encourage mutual GSCM, and affect the company’s sustainable success (Zhou et al., 2023). According to Kim and Chai (2017), businesses participate in green supply chain activities to benefit from cheaper costs, greater revenues, and retained stakeholder values, which offer a sustainable competitive advantage. Shevchenko et al. (2023), examined how operational efficiency in the electronics sector relates to green supply chain strategies. According to their research, green supply chain execution (GSCE) methods, such as waste management and energy conservation, favor operational performance, including cost savings, quality enhancements, and lead time reduction. These studies prove that GSCE procedures have an advantageous effect on the performance of the industrial sector. Shevchenko et al. (2022) examined the connection between GSCE and operational success in the industrial sector. Mathivathanan et al. (2018), focused on how GSCE may improve supply chain integration and collaboration in the manufacturing sector. The effect of the GSCE on environmental performance in the electronics manufacturing sector was examined by (Shang et al., 2019). According to the survey, businesses adopting GSCE procedures saw a considerable increase in environmental performance. Shaharudin et al. (2019) investigated how the GSCE affected consumer happiness and brand reputation in electronics. Based on these, we develop the following hypothesis:

H1c. Green supply chain execution positively influences manufacturing firms’ performance.

Fahim and Mahadi. (2022), suggests using a strategic decision-making framework to manage a green supply chain. He says more companies are considering incorporating environmental practices into their short- and long-term objectives. Businesses have been encouraged to use more environmentally friendly practices through many initiatives. Organizations also carry out an increasing number of optional environmental activities and certain required programs governed by regulations. Reverse distribution network design principles and methods were reviewed (Sant, 2022). Additionally, it has been said that companies must possess and use specific abilities to undertake green projects (Ali et al., 2022). Zhou et al. (2023) reviewed green supply chain management techniques in the high-tech industry, including manufacturing. They emphasized the importance of ecologically friendly methods, including green manufacturing, packaging, and design. Luthra and Mangla. (2018) looked at the variables affecting the adoption of green supply chain strategies in the electronics manufacturing sector. In their research, they discovered several factors that influence the adoption of green practices in the supply chain, including stakeholder pressure, environmental rules, and supplier engagement. The link between GSCM procedures and organizational performance in the manufacturing business was explored (Parkhomenko et al., 2023). They concluded that green efforts, such as converting the supply chain to greener procedures, can enhance organizational performance. Pagell et al. (2010) explore the effects of green supply chain migration on the financial performance of businesses in the manufacturing sector. The study’s findings show a link between green supply chain practices and improved financial performance for businesses, proving the benefits of sustainable sourcing. Therefore, we develop following hypothesis:

H1d. Green supply chain migration positively influences manufacturing firms’ performance.

Zhu et al. (2008) proposed several measures to assess GSCM regarding benchmarking, implementation, and ongoing progress. Greening a company’s supply chain may have several benefits, from cost savings to including suppliers in participatory decision-making and encouraging environmental innovation (Awatara et al., 2020). Creating corporate-wide environmental initiatives and purchasing eco-friendly products from international markets are common business practices (Fahim and Mahadi, 2022). According to research, industries do not think environmental protection is their duty. There was not enough information on environmental regulations and standards and the benefits of making things more environmentally friendly. Changing present investments, information systems, and attitudes would be too expensive (Soda and Aggarwal, 2022). According to Walker et al. (2008), there are more external barriers than internal restraints. In addition, Chen et al. (2022) assert that GSCM attempts to improve environmental management through environmental collaboration or by resolving common concerns that reduce the environmental hazards in supply chains. Sajan et al. (2017) investigated the function of ongoing development in green supply chain management in the industrial sector. Their study underscored the need to include green practices in current continuous improvement programs. A study on green supply chain management strategies was carried out by (Govindan et al., 2016a). They emphasized the value of ongoing endeavors to improve environmental sustainability and operational excellence in electronic manufacturing. According to research, teamwork and information sharing are key elements in encouraging creativity (Li et al., 2018). Companies may foster a climate that supports green innovation by embracing GSCCI principles that promote open communication and cooperation. Therefore, we develop the following hypothesis:

H1e. Green supply chain continuous improvement positively influences manufacturing firms’ performance.

According to D. Li et al. (2018), “green innovation” refers to hardware or software advancements in technology that are connected to environmentally friendly goods or procedures. Such advancements include energy-saving techniques, trash recycling, environmentally friendly product designs, and corporate environmental management. In green supply chain management, the growing significance of green innovation is emerging as a potential area where businesses may minimize the direct and indirect environmental effects of an organization’s final product (Lee and Kim, 2011). To help manufacturers create new goods, the green innovation concept may assist the implementation of GSCM by supplying them with fresh concepts, methods, or technologies. According to Zailani et al. (2011), green innovation entails continuously looking for methods to innovate at every level of the supply chain to obtain a competitive edge and lessen environmental issues in business. As a result, it can be said that the notion of green innovation underpins the GSCM processes. Lee et al. (2012), who asserted that the core innovation underpinning supplier commitment to green product development to boost competitive advantage and environmental performance, corroborate this argument. Sustainable supply chain methods in several industries were examined by (Pagell and Wu, 2009). According to the report, efficient green supply chain planning is significant in driving green innovation, including incorporating environmental factors into product design, purchasing, and logistics choices. According to Zhu and Wu. (2022), they have examined manufacturing companies’ green supply chain collaboration and sustainability performance. The study stressed that green supply chain planning, as a team effort, promotes the interchange of information, tools, and ideas required for developing novel solutions. The effect of GSCM procedures on supplier selection was examined (Saturnino Neto et al., 2014). According to the report, green supply chain planning fosters green innovation, including environmental considerations in supplier selection decisions. Companies might promote green innovation across the supply chain by partnering with suppliers committed to the environment and providing eco-friendly goods or services. Therefore, we develop following hypothesis:

H2a. Green supply chain planning positively influences green innovation.

Environmentally conscious organizational citizenship behaviors (OCBs) were compared to green procurement practices (Boiral, 2009). Employees’ voluntary efforts that enhance organizational effectiveness are included in OCBs. The study discovered that green procurement methods were favorably related to environmental OCBs, such as the invention of fresh concepts and procedures. Sant (2022), looked at how green buying strategies affected environmental performance in the industrial sector. The study discovered that businesses with green procurement policies had greater rates of green innovation. Businesses are more likely to provide creative solutions and products with low environmental effects when they use environmentally friendly purchasing methods, such as choosing suppliers based on their environmental performance or buying eco-friendly materials (Karim et al., 2023). According to J. Liu et al. (2018), green procurement positively impacts innovation performance, showing that businesses are more inclined to pursue green innovation if they prioritize environmentally friendly buying strategies. The study also emphasized the mediating function of environmental management systems, suggesting that these systems aid in converting environmentally friendly purchasing patterns into creative results. Calza et al. (2021), investigated the link between manufacturing companies’ green product creation and environmental policies, such as green buying. According to the study, green procurement businesses were more likely to finance and create ecologically friendly products. Therefore, we develop following hypothesis:

H2b. Green procurement positively influences on green innovation.

According to Shevchenko et al. (2023), green supply chain execution, which entails putting green policies and procedures in place throughout the supply chain, fosters an innovative culture. Rexhepi et al. (2023) provided empirical data to encourage firms to adopt green innovation to enhance environmental performance and boost their market competitiveness. This study discovered that GSCM methods favorably impact green managerial, green process, and green product innovation. To investigate the impact of green innovation in more depth, this research also recommended extending to additional GSCM techniques. An investigation of the incorporation of green innovation into logistic services as GSCM practice was done in Malaysia (Zailani et al., 2011). Studies have examined the connection between innovation and GSCM (Y. Chen et al., 2022; Sarkis et al., 2011). The study stressed how Green Supply Chain Execution, a crucial element of GSCM, fosters innovation by facilitating the adoption of green technology, procedures, and behaviors. The relationship between green supply chain practices, innovation dissemination, and organizational improvement was examined (Negri et al., 2021). According to the report, using green supply chains helps green practices spread throughout firms, spurring creativity and better environmental performance. An investigation was conducted on the effects of supply chain integration on environmental performance (Hajmohammad et al., 2023). The study underlined how integrating suppliers and customers into an efficient green supply chain might lead to innovations in environmental practices. Therefore, we develop following hypothesis:

H2c. Green supply chain execution positively influences green innovation.

Innovation can be aided by “green supply chain migration,” which entails moving environmentally friendly industrial processes and supply chain activities (Hajmohammad et al., 2023). Businesses may foster innovation and better environmental performance by shifting to greener suppliers, implementing sustainable practices, and embracing cleaner technology. The study examined the connection between the sustainable performance of manufacturing companies and green supply chain integration (Vachon and Klassen, 2008; Pinto, 2020). As a component of green supply chain integration, green supply chain migration entails rearranging supply chain operations to improve environmental performance (Y. Chen et al., 2022). The link between environmental collaboration and innovation performance was studied (Bals and Tate, 2018). According to the research, green supply chain migration can promote green innovation by allowing supply chain participants to work together on environmental issues. Even though little research has directly examined the connection between green supply chain migration and green innovation, these findings show that green supply chain migration may favor promoting innovation. The acceptance and innovation of green supply chain management were the subjects of research (Tung and Baird, 2023). The researchers discovered that businesses were more likely to participate in green innovation activities when they embraced green supply chain management methods. Studies in several industries in China concluded that companies with more environmentally friendly supply chain processes are more likely to engage in environmental innovation (Feng et al., 2022. Zhu et al., 2007). Therefore, we develop the following hypothesis:

H2d. Green supply chain migration positively influences green innovation.

A study compared manufacturing businesses’ performance (Sant, 2022) to see how GSCM procedures affected performance. The study discovered that GSCCI fostered creativity. The application of green buying methods in the electrical and electronic industries were found effective (Yalcin et al., 2020). According to the study, green procurement’s ongoing development has a favorable impact on creating novel procedures and goods. The development of greener goods and processes within the sector was sparked by enterprises actively searching out more environmentally friendly materials, suppliers, and methods. According to Kannan et al. (2014), businesses were more likely to engage in green innovation if they integrated GSCCI methods into their supplier selection process. According to Sarkis and Zhu. (2018), green innovation is favorably impacted by GSCM practices that are continuously improved, such as the use of greener technology, waste reduction efforts, and the installation of environmental management systems. Businesses encouraged the creation of novel solutions in line with sustainability objectives by continuously improving environmental performance and looking for chances for improvement across the supply chain. M. Wang et al. (2020) examined the connection between environmentally friendly supply chain management techniques and green innovation in the electronics sector. Researchers discovered that businesses were more likely to create and apply green innovations if they continuously developed their green supply chain strategies. Linton et al. (2007) indicated that continuous improvement programs in sustainable supply chains foster innovation by enticing businesses to investigate novel technologies, procedures, and collaborations that lessen their negative effects on the environment. Therefore, we develop the following hypothesis:

H2e. Green supply chain continuous improvement positively influences green innovation.

Green innovation has a beneficial impact on cost-effectiveness as found by Shin and Cho. (2022), they indicated that manufacturers could save money by using less energy, creating less trash, and using fewer raw materials. Zheng et al. (2018), demonstrated that green innovation significantly promoted product innovation, creating environmentally friendly electronic equipment. Stakeholder perception and financial performance are enhanced through green innovation provided evidence that stakeholders, such as clients, shareholders, and workers, viewed businesses that adopted sustainable practices more favorably (Yu et al., 2017; Sarkis and Zhu, 2018). This favorable view may increase client loyalty, sales, and superior financial performance. Collaboration in the supply chain and efficiency improvements are encouraged through green innovation. According to Mehta et al. (2019), cooperative ties between manufacturers and their suppliers made sharing environmental best practices, resources, and information easier. These partnerships promoted innovation, efficiency improvements and competitive advantage. Therefore, we develop following hypothesis:

H3. Green innovation positively influences manufacturing firms’ performance.

Green innovation in the industrial sector aids businesses in adhering to environmental standards and reducing related risks. According to (Cao et al., 2018), companies that actively implemented green practices had a lower chance of environmental breaches and the resulting fines. (Fiorini et al., 2022), The study examined the connection between green innovation, GSCM practices, and manufacturing company performance. According to this study, green innovation is positively influenced by GSCM methods, which improve firm performance. From the resource-based view (RBV) standpoint (Luthra et al., 2017), the research looked at the mediating influence of green innovation in another study. According to the RBV, businesses with distinctive assets and skills have an edge over rivals. A crucial tool for enabling the conversion of GSCM practices into improved performance results was identified as green innovation. Within the environmental collaboration framework (Zhu et al., 2017), research concentrated on the mediating role of green innovation in the link between GSCM and business performance. According to the study, GSCM positively impacted environmental cooperation, encouraging green innovation. In their investigation of the link between GSCM and company performance (Bai et al., 2017), they looked at the mediating function of environmental technological innovation. The results showed that GSCM had a favorable impact on environmental technology innovation, which benefited company performance. Therefore, we develop following hypothesis:

H4. Green innovation mediates the relationship between green supply chain management practices and manufacturing firms’ performance.

Tian et al. (2014), investigated the connection between GSCM, information sharing, and manufacturing business performance. The findings showed that the association between GSCM and company performance was mitigated by information sharing. Specifically, the beneficial effect of GSCM on business performance was amplified when information sharing was substantial (Shaharudin et al., 2019). This shows that efficient information exchange improves GSCM procedures’ performance results, research concentrated on the moderating role of supply chain integration in the link between GSCM and business performance, including information sharing (Thahir et al., 2022). The research discovered that this link was positively reduced by supply chain integration. The beneficial effect of GSCM on company performance was bolstered when information exchange and collaboration among supply chain partners were strong (Chatterjee et al., 2023). This emphasizes how crucial information exchange is to the whole supply chain integration process. Govindan et al. (2015) examined the moderating impact of information sharing in the link between GSCM and green product innovation, a crucial component of sustainable company performance. The moderating role of information sharing in the link between GSCM and environmental collaboration (Seuring et al., 2022). The study discovered that this association was positively controlled by knowledge sharing. The benefits of GSCM on environmental collaboration were boosted when businesses adopted efficient information-sharing procedures. These studies show that the link between GSCM and the performance of manufacturing organizations is moderated by information sharing. Therefore, we develop the following hypothesis:

H5. Information sharing moderates the relationship between green supply chain management practices and manufacturing firms’ performance.

IT innovation increases businesses’ productivity and market share by introducing new goods and services, client orientation, response to market changes, and innovation for enhanced company performance (Almehairbi et al., 2022). However, Brynjolfsson and Saunders. (2010) argue that organizational structures and work processes must also be improved to successfully implement IT innovation. According to Misuraca et al. (2017), IT innovation is the development of new methods, theories, or products for the IT industry while considering social, political or ecological settings. By offering new goods, services, solutions, and working methods, IT innovation is essential for improving a company’s value chain (Revilla et al., 2020). Furthermore, research has demonstrated that IT innovation moderates the link between GSCM and business performance, demonstrating that higher levels of IT innovation led to increased performance from GSCM practices (Kuo and Smith, 2018). According to research on the importance of IT in GSCM practices, IT is essential for integrating and coordinating different green supply chain activities, improving both environmental and overall business performance (Montabon et al., 2016). According to Y. Liu et al. (2019) investigated the link between IT, GSCM, and business performance. According to the findings, GSCM practices supported by IT benefit business performance, and IT skills play a moderating role in this connection. Innovation in IT improves the efficiency of GSCM procedures and boosts the productivity of manufacturing companies. The research results, which highlight the significance of IT innovation in fostering the advantages of green supply chain practices, show that IT competence greatly improves the favorable impact of GSCM on company performance (Hu et al., 2019). Therefore, we develop the following hypothesis:

H6. Information technology innovation moderate the relationship between green supply chain management practices and manufacturing firms’ performance.

2.1 Supportive theories

The Resource-Based View (RBV) theory underscores the strategic utilization of organizational resources and capabilities to gain a competitive edge by identifying strengths and weaknesses through resource and skill analysis. In the context of this study, embracing eco-friendly practices and innovations expands the resource base within the framework of GSCM, ultimately augmenting performance and competitiveness within the manufacturing sector (S. S. Ali et al., 2021). The Diffusion of Innovation Theory delves into the dissemination of novel concepts or technologies within a social system, providing critical insights into the integration of ideas like green and IT technologies in businesses and diverse sectors (Menzli et al., 2022). Understanding and adopting this theory is essential for implementing and diffusing such innovations in supply chain activities and GSCM. Transaction Cost Economics (TCE) theory explores the impacts of internal and external transactions on governance. In this study, they recognize the significance of collaborative efforts and knowledge sharing among stakeholder’s aids in analyzing how information sharing and IT innovation moderate the relationship between GSCM practices and cost reduction, thereby optimizing green supply chain practices and boosting productivity (Ali and Kaur, 2021). The Social Exchange Theory underscores the importance of balanced partnerships, considering costs and rewards. This aligns with the study’s exploration of how information sharing among supply chain partners facilitates knowledge exchange and cooperative partnerships, portraying green innovation as a means to enhance organizational performance and gain a competitive advantage (Davis-Sramek et al., 2022). Resource Dependence Theory accentuates the necessity of effectively managing ties with resource suppliers for organizational survival and success. In this study, the theory aids in comprehending the dynamics and effects of implementing green and IT innovations into GSCM, shedding light on how manufacturing businesses strive to reduce their dependency on non-renewable resources and manage associated risks linked to environmental legislation (Ali et al., 2022). Lastly, Institutional Theory explores organizational responses to external environmental pressures and challenges. This study can be employed to examine how manufacturing companies respond to institutional pressure to implement green supply chain practices. Information sharing and IT innovation are pivotal in ensuring compliance with institutional standards and improving environmental performance (Nureen et al., 2022).

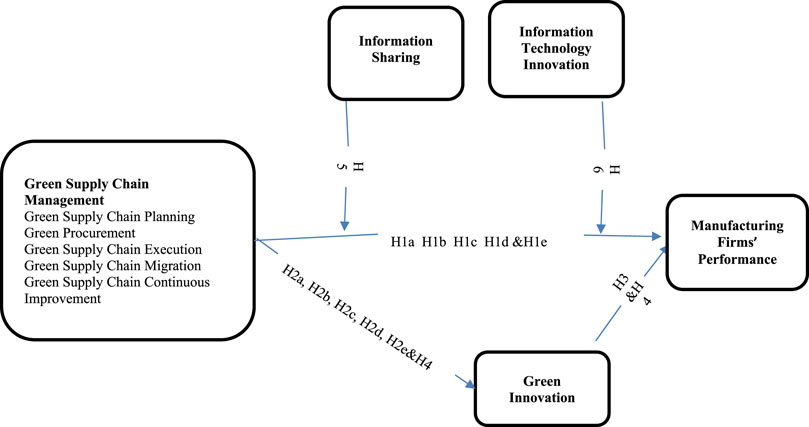

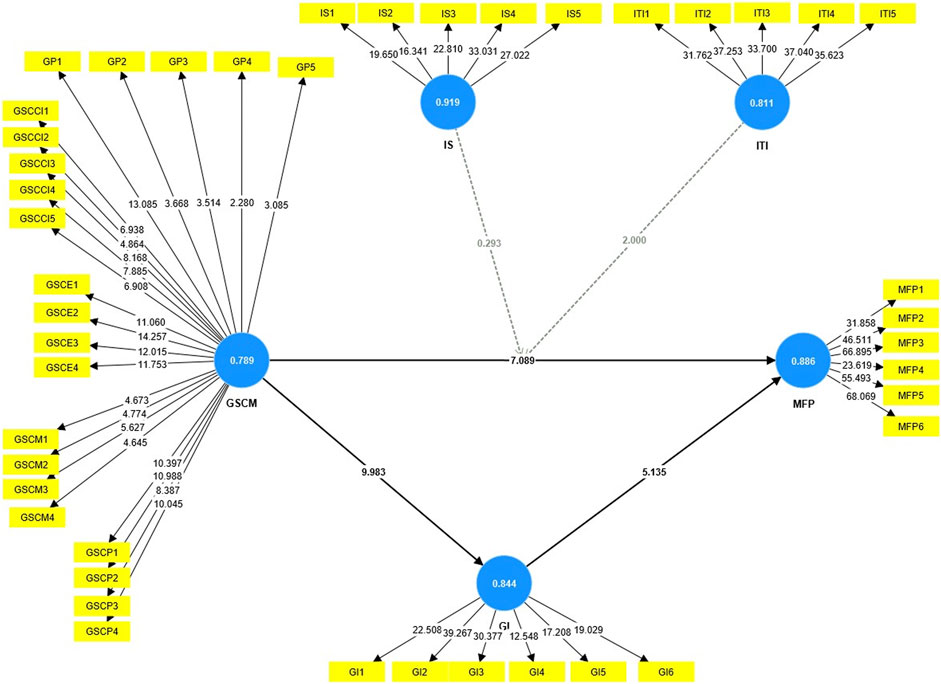

Based on study hypotheses and literature analysis, researchers developed a theoretical framework given below in Figure 1.

3 Methodology

A systematic collection of questions focusing on GSCM practices and their effect on the performance of manufacturing organizations are created for questionnaire research, with the mediating and moderating roles of green innovation, information sharing, and information technology innovation. In a research study, applying a questionnaire involves defining objectives, identifying the target audience, designing the questionnaire, addressing ethical considerations, distributing and administering it, verifying data completeness and accuracy, analyzing the data statistically, reporting findings, and gathering feedback for future refinement. Questionnaires are issued to gather opinions, attitudes, and impressions from the appropriate participants, such as supply chain managers, business experts, and other stakeholders. A web link to the survey questionnaire is distributed to participating companies. Data were collected between January to May 2023.

The researcher contacted the HR departments of manufacturing companies to learn about interesting participants, using online platforms dedicated to the manufacturing sector for data collection. In this study, random sampling was employed to select participants from the target population, which comprised employees working in manufacturing firms in Pakistan, by distributing questionnaires to 300 manufacturing companies. 267 questionnaires from the intended audience were received, which indicates a remarkable degree of involvement in these surveys. Out of these, 18 were deemed incomplete and thus excluded, leaving us with 248 valid questionnaires; nine contained outlier responses among the 18 excluded questionnaires. These outliers were specifically found within the incomplete or improperly filled questionnaires and were excluded because these incomplete questionnaires constituted more than 5% of the missing data.

Consequently, our final dataset consists of 248 questionnaires that were fully completed and deemed accurate. After the initial invitation to complete the survey, the researcher sends two additional email reminders to encourage participation. Respondents are assured of the confidentiality and anonymity of their responses. They are not required to disclose any personal information.

Using random sampling in the study enhances representativeness, reduces bias, ensures statistical validity, and enhances external validity. It enables researchers to make reliable inferences about the association between GSCM practices and manufacturing industry performance, allowing for broader applicability of the findings.

An analysis using a t-test revealed no statistically significant difference (p < 0.05) in the responses based on industry, indicating that industry type did not have a notable impact. Additionally, employing the methodology outlined by (Shaharudin et al., 2019), we found no significant difference between early and late respondents, suggesting the absence of systematic non-response bias. To mitigate social desirability response bias, we ensured anonymity in the questionnaires to encourage candid responses. The questions were impartial and non-leading, and confidentiality was guaranteed. The study refrained from discussing socially desirable answers and conducted pilot testing to address potential bias issues. We utilized the Harman single-factor test that Podsakoff and Organ (1986) outlined to evaluate the potential common method variance. The results of this test demonstrated that no single factor was the predominant source of variance in the variables. This finding suggests that substantial bias of this nature was not a notable concern.

Furthermore, we conducted assessments to address multicollinearity, adhering to the criteria outlined (Sheng et al., 2023). The results demonstrated that the model was free from multicollinearity, as all variance inflation factor (VIF) values were below the threshold of 3.3, as shown in Table 9.

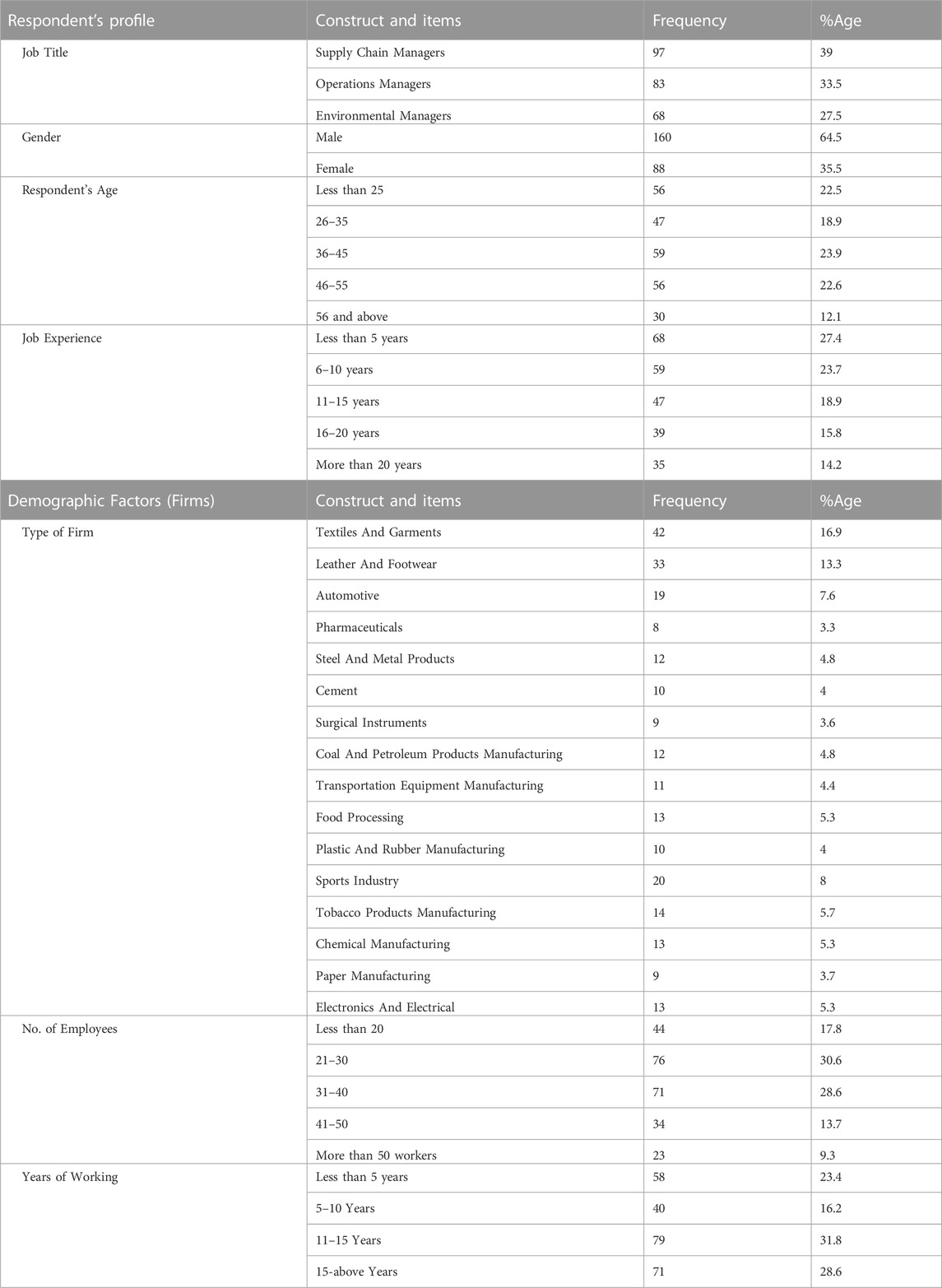

When the entire response rate in manufacturing companies is considered, it is 83%. Within the context of the manufacturing business, this response rate is comparatively high, demonstrating a high level of interest in participating and contributing their perspectives among the targeted participants. Table 1 provides the demographic responses from the respondents and companies.

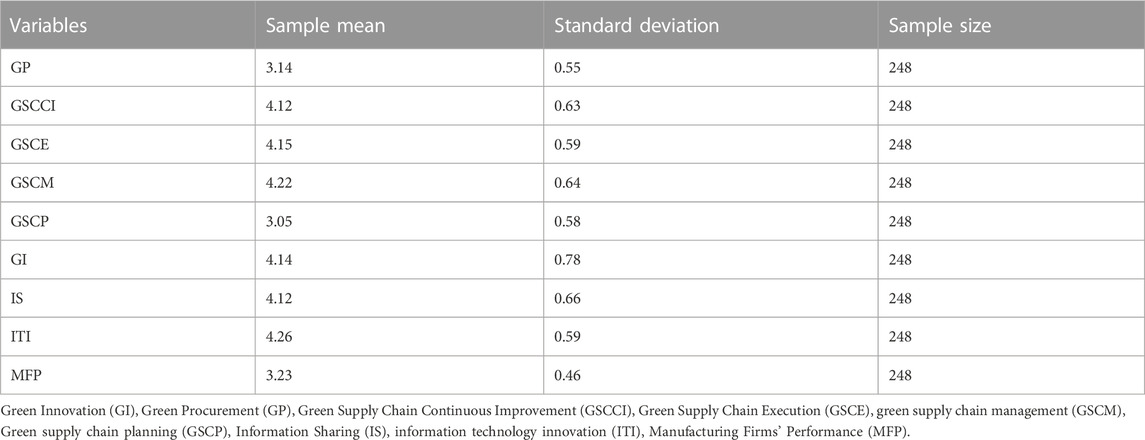

Before doing more complicated statistical analysis, descriptive statistics give a foundational understanding of the variables. They support the selection of statistical tests and models by researchers and the calculation of the necessary sample sizes for upcoming investigations. Descriptive statistics give baseline information, examine data features, make it easier to compare variables, evaluate data quality, and assist data-driven decision-making. Table 2 displays the descriptive statistics of the variables.

For this investigation, the survey tool was a regular questionnaire. There were three sections in the questionnaire. While the second half sought to obtain demographic information about the participants’ jobs, the first piece concentrated on learning more about the participants’ backgrounds. The final portion evaluated ideas concerning GSCM practices, green innovation, information sharing IT innovation and the performance of manufacturing companies. A five-point Likert scale, from strongly disagreeing to strongly agreeing, was used to rate each item on the survey. Partial least squares (PLS) analysis was used to evaluate the gathered data. Table 3 contains information on the sources of the measurement devices.

4 Results interpretations

With a focus primarily on prediction, partial least squares structural equation modeling (PLS-SEM) enables the simultaneous study of several correlations between variables. In this method, measurement and structural models are created and analyzed to assess the model’s goodness of fit. PLS-SEM investigates the alignment between the model obtained from population data and the presumed theoretical model through a series of studies (Sarstedt et al., 2022b). Using the Smart PLS 4 program, PLS-SEM was carried out in the current investigation (Sarstedt et al., 2022a). The study was carried out in two separate processes, the first of which included analyzing the measurement model and the second of which involved testing the structural model.

4.1 Measurement model (outer model)

For researchers, the measuring model is crucial because it directs the choice and assessment of measures, assures the reliability and validity of the constructs, and facilitates hypothesis testing. To evaluate the trustworthiness of the results, we use statistical tests.

4.1.1 Composite reliability, Cronbach’s alpha and AVE

It is considered reliable if an indicator’s loading factor exceeds 0.7 and its average variance extracted (AVE) exceeds 0.5. Cronbach’s alpha, which must be greater than 0.7, and composite reliability (CR), which must also be greater than 0.7, are used to assess reliability. According to the PLS analysis results, all indicators are within the permissible range of values, verifying the whole inquiry. Table 4 presents the outcomes.

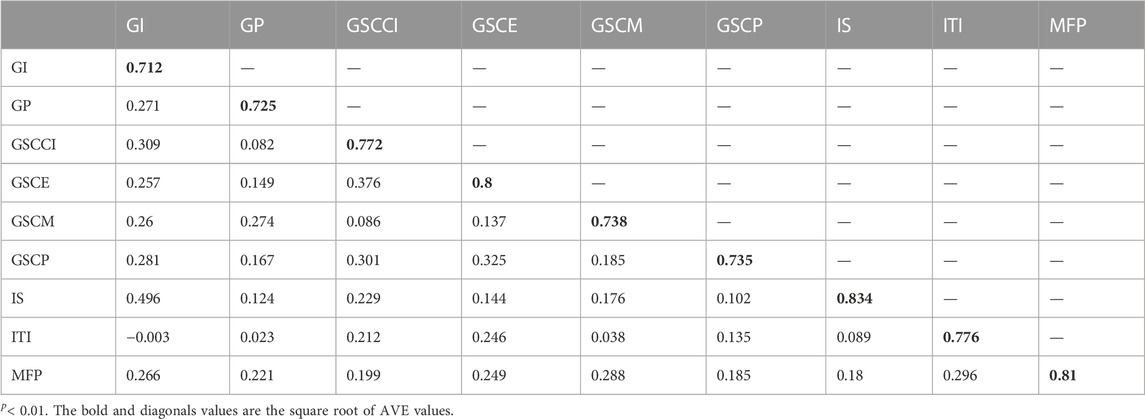

4.1.2 Discriminate validity

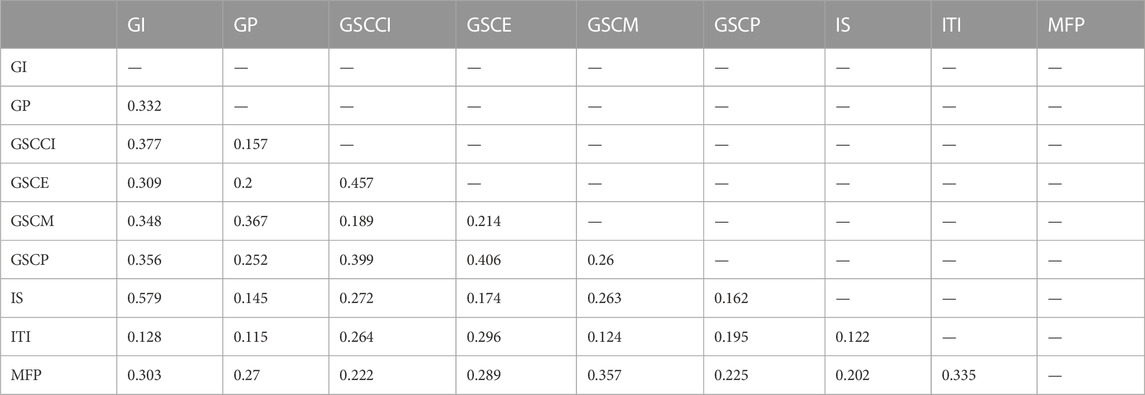

Using the Fornell-Larcker and the HTMT criterion, discriminant validity was examined, which assesses the validity of components related to other constructs within the model. Examining the correlations between the constructs, these criteria help determine if they are distinct. The square roots of the average variance extracted for each construct are compared to the correlations across constructs using the Fornell-Larcker criteria. Table 5 shows that every value in each associated column is less than the square roots of the AVE values in that column. These results suggest that the Fornell-Larcker criteria are completely met.

We assumed that the correlation criteria accurately measured the HTMT coefficients. If a construct’s HTMT value is less than 0.90, its discriminant validity is deemed good (Henseler et al., 2015). It is clear from Table 6 that the HTMT criteria values are below the suggested cutoff point of 0.90. We also did a bootstrap analysis to evaluate the confidence intervals for HTMT. The findings showed that the value of 1 was not included in the confidence intervals. These findings support the constructs’ discriminant validity.

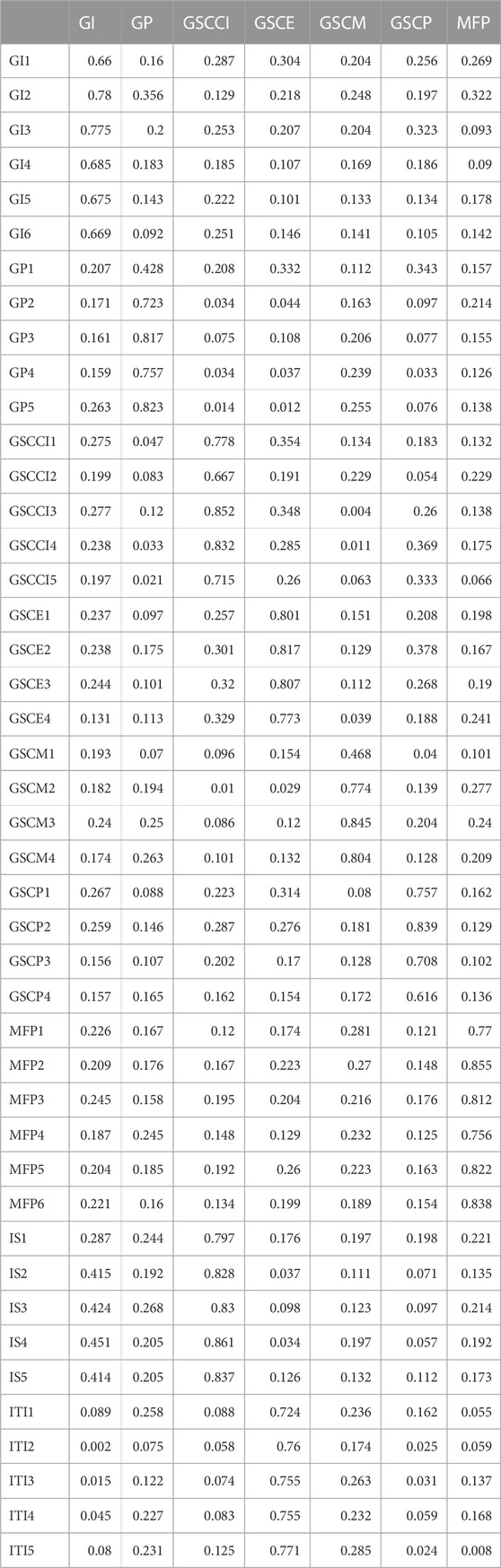

4.1.3 Cross-loading

Cross-loading occurs when an item loads significantly on multiple factors, causing interpretation complexity in the underlying factor structure. The assessment involves checking if observed variables load notably on more than one latent factor. Items with substantial loadings on multiple factors are deemed to have cross-loading. Analyzing cross-loading entails reviewing the factor loading matrix from factor analysis or SEM. Table 7 displays cross-loading between observed variables (items) and their intended latent factors.

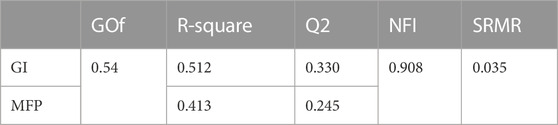

4.1.4 Model fit results

The evaluated model fit indices demonstrate a robust fit. According to (Henseler and Sarstedt, 2013), the Goodness-of-Fit (GoF) value of 0.54 significantly exceeds the recommended threshold of 0.36, confirming a solid fit. Moreover, the R2 values for MFP and GI, measuring 0.413 and 0.512, respectively, surpass the suggested lower limit of 0.1, as proposed by (Akossou and Palm, 2013). Additionally, the Q2 values for the mentioned parameters are all greater than 0, aligning with established criteria. Specifically, the Q2 values for MFP and GI are 0.245 and 0.330, respectively. The Normed Fit Index (NFI) score of 0.908 exceeds the recommended threshold 0.9 specified by (Kenny, 2015), indicating a good fit. Furthermore, the Standardized Root Mean Residual (SRMR) value of 0.035 is notably below the 0.08 cutoff set by (Ramayah et al., 2017). These comprehensive results affirm that the model adheres to the existing literature’s high standards, underlining its strong predictive power. The results of the Model fit are shown in table 8.

4.2 Structural model

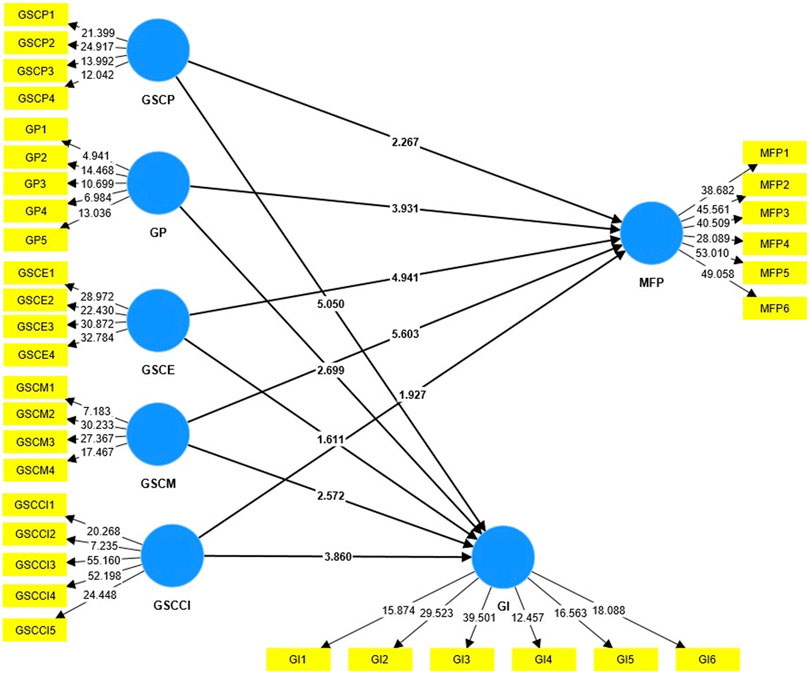

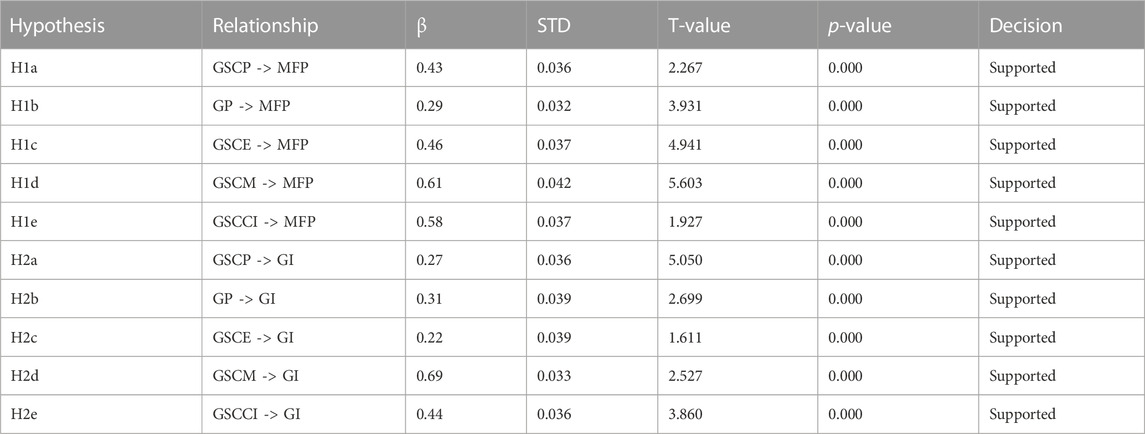

The relationships between the model’s constructs are shown in the structural model. These links align with the theoretical model’s hypotheses (Figures 2, 3). Using the PLS technique and bootstrapping, the structural model was evaluated. Initial evaluation of the VIF values for the structural model’s collinearity revealed no issues with collinearity. The VIF values for each indicator in the model are shown in Table 9. The VIF values in the table often stay below 5, indicating that multicollinearity between the variables is not very prevalent. It is important to remember that a VIF score of 5 or higher is a regularly used threshold for recognizing considerable multicollinearity. In this instance, the highest VIF value in the table is 2.505, which is connected to the variable IS2 and denotes reasonably low multicollinearity.

The study model and the analysis results based on Smart PLS software of direct relation are shown in Figure 2.

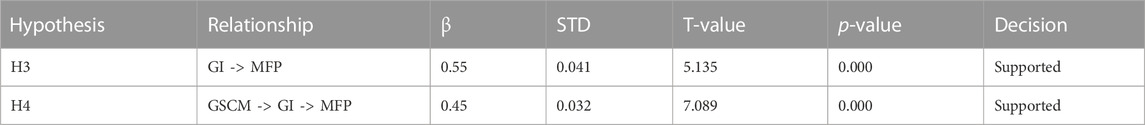

The hypotheses in the structural model were evaluated using path analysis, as presented in Tables 10, 11. The analysis confirmed that all the direct effects examined in the model were statistically significant. Table 10 revealed significant relation among GSCP and MFP (β = 0.43, t = 2.267 p < 0.001), GP and MFP (β = 0.29, t = 2.3.931, p < 0.001), GSCE and MFP (β = 0.46, t = 4.941, p < 0.001), GSCM and MFP (β = 0.61, t = 5.603, p < 0.001), GSCCI and MFP (β = 0.58,t = 1.927, p < 0.001), GSCP and GI (β = 0.27, t = 5.050 p < 0.001), GP and GI (β = 0.31, t = 2.699, p < 0.001), GSCE and GI (β = 0.31, t = 1.611 p < 0.001), GSCM and GI (β = 0.69, t = 2.527 p < 0.001), GSCCI and GI (β = 0.44, t = 3.860, p < 0.001) hence H1a, H1b, H1c H1d, H1e and H2a, H2b, H2c H2d, H2e are accepted.

The study model and the analysis results based on Smart PLS software of mediation and moderation relation are shown in Figure 3.

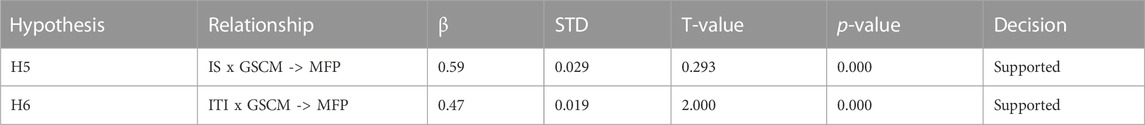

The findings reveal a direct effect of GI and MFP (β = 0.55, t = 5.135 p < 0.001) proved to be a significant and statistically significant indirect effect of green supply chain management practices on manufacturing firms’ performance through the mediating role of green innovation (β = 0.45, t = 7.089, p < 0.001). Thus, H3 and H4 are accepted. The mediation and moderation analysis results can be found in Tables 11, 12 below.

The findings reveal a moderating effect of information sharing and information technology innovation on the relationship between green supply chain management practices and manufacturing firms (β = 0.59, t = 0.293 p < 0.001) and (β = 0.47, t = 2.267, t = 2.000 p < 0.001) respectively, thus H5 and H6 are accepted.

5 Discussions and results

This study investigates how GSCM practices affect manufacturing companies’ performance. It examines the link between GSCM practices and manufacturing businesses’ performance, the mediating function of GI, and the moderating impact of information exchange and information technology innovation. The findings of this study are divided into two groups according to two different hypotheses: direct impacts and mediation and moderation effects.

Through increased productivity, cost reductions, and resource efficiency, GSCP has a favorable impact on MFP. Significant association exists between GSCP and MFP (β = 0.43, p < 0.001). Adoption of the GSCP enhances long-term sustainability, stakeholder perception, and financial performance. To gain a competitive edge, RBV uses special resources to boost GSCP’s beneficial effect on MFP (Sodiq et al., 2022). The institutional theory further supports this link, as organizations adopt sustainability standards to be accepted and legitimated, enhancing performance.

With a statistically significant association of (β = 0.29, p < 0.001), GP favorably increases MFP. The institutional theory supports this connection, as businesses follow evolving sustainability norms to obtain acceptability and legitimacy. Manufacturing companies may improve their reputation and performance by using GP practices (Negri et al., 2021).

GSCE significantly correlates with MFP in a good direction (β = 0.46, p < 0.001). According to the RBV hypothesis, organizations with distinctive and priceless resources, like GSCE practices, obtain a competitive edge. Manufacturing firms may increase resource efficiency, save costs, and create capacities for higher performance by integrating eco-friendly processes and technology (Shevchenko et al., 2022; Rexhepi et al., 2023).

GSCM positively impacts MFP (β = 0.61, p < 0.001). The institutional theory supports this connection, as businesses adhere to sustainability standards to achieve recognition and legitimacy. Manufacturing companies improve their reputation by switching to a green supply chain, which benefits performance. The adoption of GSCM boosts productivity, cost savings, and market competitiveness by enhancing efficiency, supplier relationships, and brand reputation (Sarkis and Zhu, 2018).

GSCCI favorably impacts GI (β = 0.58, p < 0.001). This connection is supported by the RBV, which shows that organizations with a continuous improvement culture centered on sustainability have a competitive edge. Companies may boost their resources and capacities, which increases their potential for green innovation and improves overall performance by investing in GSCCI programs (Yalcin et al., 2020; Chatterjee et al., 2023).

GSCP significantly affects GI favorably (β = 0.27, p < 0.001). The GSCP encourages cooperation and information sharing among supply chain participants, creating a knowledge-sharing culture that supports GI. According to the Institutional Theory, businesses must adhere to sustainability standards to be accepted as legitimate (Shevchenko et al., 2023).

GP significantly correlates with GI in a good direction (β = 0.31, p < 0.001). Through supply chain coordination, the desire for green solutions, and a focus on resource efficiency, GP promotes innovation, which enhances the creation of environmentally friendly products and operational performance. Green innovation, market competitiveness, and environmental performance are expected to improve for businesses prioritizing green buying (Sant, 2022; Sheng et al., 2023).

GSCE significantly correlates with GI in a good direction (β = 0.22, p < 0.001). Collaboration, continuous improvement, and tracking of environmental performance are encouraged by GSCE, which results in the creation of environmentally friendly products and operational enhancements. Improved Green Innovation, market competitiveness, and overall environmental performance result from placing a higher priority on GSCE (Y.-S. Chen, 2008).

GSCM significantly affects GI favorably (β = 0.69, p < 0.001). The institutional hypothesis supports this connection, as businesses adhere to sustainability standards to achieve recognition and legitimacy. Adopting GSCM encourages an innovative culture that supports green innovation and improves performance (Hao et al., 2022).

GGSCC significantly affects GI favorably (β = 0.44, p < 0.001). GSCCI promotes a learning and environmental awareness culture by exchanging best practices and knowledge across the supply chain. This results in more GI projects and ideas, enhancing sustainability and competitive advantage (Awan et al., 2019). The GSCCI improves firms’ resources and capacities for better GI and overall performance, which is supported by the RBV theory.

GI significantly impacts MFP in a good way (β = 0.55, p < 0.001). Businesses get a competitive edge and draw eco-aware clients by providing environmentally friendly goods and services, which boosts productivity in the manufacturing sector (Chiou et al., 2011; Sarkis and Zhu, 2018).

GSCM and MFP are related, and GI partially mediates this link with a significant mediation effect (β = 0.45, p < 0.001). By supporting GI, GSCM indirectly has a good impact on MFP. Businesses that implement sustainable practices across the whole supply chain develop cutting-edge concepts and technology that enhance overall performance in the manufacturing sector (Zailani et al., 2012).

IS and GSCM have a statistically significant interaction impact (β = 0.59, p < 0.001). Data-driven decisions with a positive performance impact are made possible by timely and accurate information. As a result, GSCM efficiency, manufacturing processes, and overall performance are improved. SI on environmental performance, supply chain operations, and consumer preferences help connect plans with sustainability objectives (Green et al., 2012).

IITI and GSCM have a statistically significant interaction impact (β = 0.47, p < 0.001). Data about green practices and supply chains may be processed and analyzed thanks to IT developments like data analytics and sophisticated software. Utilizing IT to get insights enhances GSCM implementation, which results in improved MFP (Zhu et al., 2005; Wang and Sarkis, 2017; Revilla et al., 2020).

Integrating environmentally friendly production procedures and sustainable purchasing policies into GSCM processes is essential. This approach helps in reducing waste, emissions, and environmental degradation. Proper disposal and recycling procedures further contribute to the eco-friendly approach, aligning with sustainability objectives. Moreover, fostering a culture of GI within the organization is crucial (Tian et al., 2014). Establishing cross-functional green innovation teams enhances cooperation, information sharing, and the development of creative sustainability solutions, placing sustainability at the core of the company’s ethos. Technologies not only optimize supply chain processes but also support sustainability efforts. Investing in research and development (R&D) for eco-friendly solutions in electronic manufacturing showcases a commitment to innovation and environmentally responsible practices (Wang et al., 2020). Furthermore, transparency, information exchange, and joint problem-solving are essential to such collaborations. Leveraging information-sharing platforms and technology facilitates real-time communication and cooperation, enhancing supply chain visibility and efficiency (Zhang, 2023).

Efficient green supply chain planning leads to cost savings, resource optimization, and improved performance for manufacturing firms (Govindan et al., 2016b). Green procurement practices enhance company performance by reducing costs, enhancing reputation, and meeting regulatory requirements (Pagell et al., 2010). Effective execution of a green supply chain, including sustainable production processes and logistics, results in enhanced performance through reduced waste and increased efficiency (Do et al., 2020). Transitioning to a green supply chain, involving eco-friendly processes and technologies, is associated with improved performance due to reduced environmental impact and cost savings (Lee et al., 2014). Continuous improvement in the green supply chain enhances performance by promoting innovation, reducing waste, and increasing efficiency, contributing to a competitive advantage (Zaid et al., 2018). Green supply chain planning, integrating environmental considerations, stimulates green innovation by fostering creativity and sustainable practices (Govindan et al., 2016b). Green procurement practices encourage innovation by fostering collaboration and knowledge sharing with suppliers to develop environmentally friendly products and processes (Pagell et al., 2010). Implementing a green supply chain involves deploying innovative technologies and practices that encourage green innovation, improving a firm’s environmental performance (Zaid et al., 2018). Transitioning to a green supply chain often necessitates innovation in processes, products, and technologies, fostering an environment conducive to further green innovation (Pagell et al., 2010). Continuous improvement in the green supply chain supports a culture of innovation, driving the development of new sustainable solutions and practices (Do et al., 2020). Green innovation positively impacts a firm’s performance by creating market differentiation, reducing costs through sustainable practices, and meeting consumer demand for environmentally friendly products (Govindan et al., 2016b). Green innovation acts as a mediator between green supply chain practices and firm performance, enabling effective implementation and integration of sustainable strategies (Zaid et al., 2018). Information technology innovation can moderate the relationship between green supply chain practices and firm performance by enhancing data analytics, supply chain visibility, and decision-making for better sustainability outcomes (Do et al., 2020).

5.1 Conclusion

The favorable effect of GSCM on the performance of manufacturing businesses implies that incorporating ecologically sound supply chain strategies might enhance performance results for manufacturing enterprises. This result is consistent with the rising awareness of the significance of sustainability in corporate operations (Sarkis et al., 2011). According to the mediated function of GI, GSCM favorably affects the performance of manufacturing enterprises through GI This shows enhancing the benefits of GSCM on performance outcomes through developing and adopting novel green practices and technology (Zhu et al., 2008). Additionally, the regulated influence of information sharing and IT innovation implies that when there is efficient information exchange and the adoption of IT innovations, the favorable impact of GSCM on manufacturing sector performance is reinforced. Considering this, it is clear how crucial information management and technology development are to enabling and optimizing the advantages of GSCM deployment.

5.2 Theoretical implications

The study adds to the knowledge about how GI mediates the relationship between GSCM and MIP. Study underlines the need to integrate sustainable practices and eco-friendly technologies throughout the supply chain by demonstrating the beneficial effects of green innovation (Ali and Kaur, 2021) This integration explains the processes through which GSCM practices can result in better performance results. By illuminating the moderating roles of information exchange and IT innovation in the link between GSCM and MIP, the study also adds to the theoretical body of research. To maximize the influence of GSCM practices on performance outcomes, it emphasizes the significance of efficient information exchange systems (Ali et al., 2022). This finding emphasizes the importance of collaboration, openness, and knowledge sharing among supply chain partners and stakeholders to maximize GSCM initiatives’ benefits. Moreover, incorporating IT innovations can improve the efficacy and efficiency of GSCM implementation, ultimately resulting in better performance outcomes (Ali et al., 2023). By including GSCM, GI, IS, and IT innovation in the context of MIP, the study contributes to the theoretical creation of a comprehensive framework. This paradigm thoroughly explains how various components interact with one another and how they all affect performance results. From a theoretical standpoint, sustainable practices are influenced by institutional pressures: coercive/regulative forces from formal regulations, normative forces from prevailing norms and international standards, and mimetic/cognitive forces in response to competitive and stakeholder uncertainties (Nezakati et al., 2016). These pressures, including governmental regulations, institutional norms, global environmental standards, and stakeholder expectations, drive the adoption and implementation of sustainable practices (Ali and Kaur, 2021).

5.3 Practical implications

Companies may increase their overall performance and operational efficiency by applying sustainable practices across the supply chain, such as cutting waste, maximizing energy use, and introducing eco-friendly technology. Businesses are more likely to produce better performance outcomes if they actively pursue environmentally friendly activities and concentrate on creating sustainable goods, processes, and technology. Manufacturing companies may gain a competitive edge and fulfill the rising demand for sustainable solutions by encouraging and supporting green innovation. According to the report, GSCM and the success of manufacturing enterprises are related to information sharing and IT innovation. The impact of GSCM practices on performance outcomes may be increased through exchanging environmental data, best practices, and expertise relevant to sustainable supply chain management. Supply chain partners, industry stakeholders, and appropriate authorities should collaborate and communicate openly to increase performance and sustainability across the manufacturing sector. Adopting modern IT technologies, such as data analytics, cloud computing, and digital platforms, can facilitate the integration and administration of sustainable practices in the supply chain. Utilizing IT innovation may boost green supply chain operations’ efficiency, transparency, and traceability, improving overall performance and sustainability results.

5.4 Limitations and future research

The study’s conclusions are context-specific due to unique qualities that can impact the relationships between GSCM, green innovation, and performance. Caution should be exercised when applying the findings to different areas, nations, or sectors. The study identifies various moderators and a mediator in the link between GSCM practices and performance, but the precise causal directions have not been extensively studied. To advance understanding, industry-specific best practices and strategies can be established through cross-sector data comparison. Long-term research can be conducted to capture the dynamic nature of these interactions over time and understand causation better. Additionally, investigating how GSCM practices, green innovation, and performance in the electronic manufacturing industry relate to external factors like legislative frameworks, market conditions, and customer preferences can provide valuable insights. Comparative studies across nations or regions can also inform policy recommendations at the national or regional level, considering cultural, legal, and institutional influences.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

LZ: Conceptualization, Funding acquisition, Supervision, Writing–review and editing. SN: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Software, Writing–original draft. IH: Supervision, Visualization, Writing–review and editing. SM: Data curation, Formal Analysis, Software, Writing–review and editing. ZN: Data curation, Formal Analysis, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdallah, A. B., and Al-Ghwayeen, W. S. (2020). Green supply chain management and business performance: the mediating roles of environmental and operational performances. Bus. Process Manag. J. 26 (2), 489–512. doi:10.1108/bpmj-03-2018-0091

Adomako, S., and Tran, M. D. (2022). Environmental collaboration, responsible innovation, and firm performance: the moderating role of stakeholder pressure. Bus. Strategy Environ. 31 (4), 1695–1704. doi:10.1002/bse.2977

Agyabeng-Mensah, Y., Ahenkorah, E., Afum, E., Agyemang, A. N., Agnikpe, C., and Rogers, F. (2020). Examining the influence of internal green supply chain practices, green human resource management and supply chain environmental cooperation on firm performance. Supply Chain Manag. Int. J. 25 (5), 585–599. doi:10.1108/scm-11-2019-0405

Akossou, A., and Palm, R. (2013). Impact of data structure on the estimators R-square and adjusted R-square in linear regression. Int. J. Math. Comput. 20 (3), 84–93.

Alhamali, R. M. (2019). Critical success factors for green supply chain management practices: an empirical study on data collected from food processing companies in Saudi Arabia. Afr. J. Bus. Manag. 13 (5), 160–167. doi:10.5897/ajbm2018.8709

Ali, A., Bentley, Y., Cao, G., and Habib, F. (2017). Green supply chain management–food for thought? Int. J. Logist. Res. Appl. 20 (1), 22–38. doi:10.1080/13675567.2016.1226788

Ali, S., Amjad, H., Nisar, Q. A., Tariq, I., and Haq, A. U. (2022a). Impact of Green Supply Chain Management practices and environmental management system on corporate performances and the Moderating role of institutional pressures. J. Public Value Adm. Insight 5 (1), 12–23. doi:10.31580/jpvai.v5i1.2421

Ali, S. S., and Kaur, R. (2021). Effectiveness of corporate social responsibility (CSR) in implementation of social sustainability in warehousing of developing countries: a hybrid approach. J. Clean. Prod. 324, 129154. doi:10.1016/j.jclepro.2021.129154

Ali, S. S., Kaur, R., and Khan, S. (2022b). Evaluating sustainability initiatives in warehouse for measuring sustainability performance: an emerging economy perspective. Ann. Operations Res. 324, 461–500. doi:10.1007/s10479-021-04454-w

Ali, S. S., Kaur, R., and Khan, S. (2023). Identification of innovative technology enablers and drone technology determinants adoption: a graph theory matrix analysis framework. Operations Manag. Res. 16, 830–852. doi:10.1007/s12063-023-00346-3

Almehairbi, K. M. S. S., Jano, Z., and Mosali, N. A. (2022). Structural relationship of technology adoption and performance factors in UAE manufacturing industry. Int. J. Sustain. Constr. Eng. Technol. 13 (4), 320–337. doi:10.30880/ijscet.2022.13.04.028

Asghar, M. M. (2023). Green supply chain management and organizational performance in automotive industry: a case study from Pakistan. South Asian J. Operations Logist. 2 (2), 18–40. doi:10.57044/sajol.2023.2.2.2308

Awan, U., Sroufe, R., and Kraslawski, A. (2019). Creativity enables sustainable development: supplier engagement as a boundary condition for the positive effect on green innovation. J. Clean. Prod. 226, 172–185. doi:10.1016/j.jclepro.2019.03.308

Awatara, I. G. P. D., Hamdani, A., Susila, L. N., and Saryanti, E. (2020). The role of marketing capability, operations capability, management practices and environmental investment on agro-industrial environmental performance. Int. J. Appl. Bus. Int. Manag. (IJABIM) 5 (3), 30–34. doi:10.32535/ijabim.v5i3.978

Bai, C., Kusi-Sarpong, S., and Sarkis, J. (2017). An implementation path for green information technology systems in the Ghanaian mining industry. J. Clean. Prod. 164, 1105–1123. doi:10.1016/j.jclepro.2017.05.151

Bals, L., and Tate, W. L. (2018). Sustainable supply chain design in social businesses: advancing the theory of supply chain. J. Bus. Logist. 39 (1), 57–79. doi:10.1111/jbl.12172

Boiral, O. (2009). Greening the corporation through organizational citizenship behaviors. J. Bus. Ethics 87, 221–236. doi:10.1007/s10551-008-9881-2

Brynjolfsson, E., and Saunders, A. (2010). Wired for innovation. How Information technology in reshaping the economy. USA: Massachusetts Institute of Technology.

Calza, F., Parmentola, A., and Tutore, I. (2021). For green or not for green? The effect of cooperation goals and type on environmental performance. Bus. Strategy Environ. 30 (1), 267–281. doi:10.1002/bse.2620

Cao, J., Zhang, X., Hu, L., Xu, J., Zhao, Y., Zhou, G., et al. (2018). EPR regulation and reverse supply chain strategy on remanufacturing. Comput. Industrial Eng. 125, 279–297. doi:10.1016/j.cie.2018.08.034

Carter, C. R., and Rogers, D. S. (2008). A framework of sustainable supply chain management: moving toward new theory. Int. J. Phys. Distribution Logist. Manag. 38 (5), 360–387. doi:10.1108/09600030810882816

Chatterjee, S., Chaudhuri, R., Vrontis, D., and Thrassou, A. (2023). Revisiting the resource-based view (RBV) theory: from cross-functional capabilities perspective in post COVID-19 period. J. Strategic Mark. 1–16. doi:10.1080/0965254x.2023.2182447

Chen, Y., Zhu, Q., and Sarkis, J. (2022). Green supply chain management practice adoption sequence: a cumulative capability perspective. Int. J. Prod. Res. 61, 5918–5933. doi:10.1080/00207543.2022.2118891

Chen, Y.-S. (2008). The driver of green innovation and green image–green core competence. J. Bus. Ethics 81, 531–543. doi:10.1007/s10551-007-9522-1

Chiou, T.-Y., Chan, H. K., Lettice, F., and Chung, S. H. (2011). The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 47 (6), 822–836. doi:10.1016/j.tre.2011.05.016

Davis-Sramek, B., Hopkins, C. D., Richey, R. G., and Morgan, T. R. (2022). Leveraging supplier relationships for sustainable supply chain management: insights from social exchange theory. Int. J. Logist. Res. Appl. 25 (1), 101–118. doi:10.1080/13675567.2020.1797654

Do, A., Nguyen, Q., Nguyen, D., Le, Q., and Trinh, D. (2020). Green supply chain management practices and destination image: evidence from Vietnam tourism industry. Uncertain. Supply Chain Manag. 8 (2), 371–378. doi:10.5267/j.uscm.2019.11.003

Fahim, F., and Mahadi, B. (2022). Green supply chain management/green finance: a bibliometric analysis of the last twenty years by using the Scopus database. Environ. Sci. Pollut. Res. 29 (56), 84714–84740. doi:10.1007/s11356-022-21764-z

Fiorini, P. C., Jabbour, C. J. C., Latan, H., de Sousa Jabbour, A. B. L., and Mariano, E. B. (2022). Green emerging digital technologies, green supply chains, and the performance of environmentally friendly firms: the underpinning role of human resources. IEEE Transactions on Engineering Management.

Foo, P.-Y., Lee, V.-H., Tan, G. W.-H., and Ooi, K.-B. (2018). A gateway to realising sustainability performance via green supply chain management practices: a PLS–ANN approach. Expert Syst. Appl. 107, 1–14. doi:10.1016/j.eswa.2018.04.013

Gao, S., Lim, M. K., Qiao, R., Shen, C., Li, C., and Xia, L. (2022). Identifying critical failure factors of green supply chain management in China’s SMEs with a hierarchical cause–effect model. Environ. Dev. Sustain. 24, 5641–5666. doi:10.1007/s10668-021-01675-8

Govindan, K., Muduli, K., Devika, K., and Barve, A. (2016a). Investigation of the influential strength of factors on adoption of green supply chain management practices: an Indian mining scenario. Resour. Conservation Recycl. 107, 185–194. doi:10.1016/j.resconrec.2015.05.022

Govindan, K., Rajendran, S., Sarkis, J., and Murugesan, P. (2015). Multi criteria decision making approaches for green supplier evaluation and selection: a literature review. J. Clean. Prod. 98, 66–83. doi:10.1016/j.jclepro.2013.06.046

Govindan, K., Seuring, S., Zhu, Q., and Azevedo, S. G. (2016b). Accelerating the transition towards sustainability dynamics into supply chain relationship management and governance structures. J. Clean. Prod. 112, 1813–1823. doi:10.1016/j.jclepro.2015.11.084

Green, K. W., Zelbst, P. J., Meacham, J., and Bhadauria, V. S. (2012). Green supply chain management practices: impact on performance. Supply Chain Manag. An Int. J. 17 (3), 290–305. doi:10.1108/13598541211227126

Gunasekaran, A., Papadopoulos, T., Dubey, R., Wamba, S. F., Childe, S. J., Hazen, B., et al. (2017). Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 70, 308–317. doi:10.1016/j.jbusres.2016.08.004

Hajmohammad, S., Klassen, R. D., and Vachon, S. (2023). Managing supplier sustainability risk: an experimental study. Supply Chain Manag. An Int. J. doi:10.1108/scm-02-2023-0106

Hao, X., Chen, F., and Chen, Z. (2022). Does green innovation increase enterprise value? Bus. Strategy Environ. 31 (3), 1232–1247. doi:10.1002/bse.2952

Henseler, J., Ringle, C. M., and Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 43, 115–135. doi:10.1007/s11747-014-0403-8

Henseler, J., and Sarstedt, M. (2013). Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 28, 565–580. doi:10.1007/s00180-012-0317-1

Hu, J., Liu, Y.-L., Yuen, T. W. W., Lim, M. K., and Hu, J. (2019). Do green practices really attract customers? The sharing economy from the sustainable supply chain management perspective. Resour. Conservation Recycl. 149, 177–187. doi:10.1016/j.resconrec.2019.05.042

Kannan, D., de Sousa Jabbour, A. B. L., and Jabbour, C. J. C. (2014). Selecting green suppliers based on GSCM practices: using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Operational Res. 233 (2), 432–447. doi:10.1016/j.ejor.2013.07.023

Karim, R. A., Rabiul, M. K., and Kawser, S. (2023). Linking green supply chain management practices and behavioural intentions: the mediating role of customer satisfaction. J. Hosp. Tour. Insights. doi:10.1108/jhti-04-2023-0241

Khan, M., Ajmal, M. M., Jabeen, F., Talwar, S., and Dhir, A. (2023). Green supply chain management in manufacturing firms: a resource-based viewpoint. Bus. Strategy Environ. 32 (4), 1603–1618. doi:10.1002/bse.3207

Kim, M., and Chai, S. (2017). The impact of supplier innovativeness, information sharing and strategic sourcing on improving supply chain agility: global supply chain perspective. Int. J. Prod. Econ. 187, 42–52. doi:10.1016/j.ijpe.2017.02.007

Klassen, R. D., and Vereecke, A. (2012). Social issues in supply chains: capabilities link responsibility, risk (opportunity), and performance. Int. J. Prod. Econ. 140 (1), 103–115. doi:10.1016/j.ijpe.2012.01.021

Kuo, T.-C., and Smith, S. (2018). A systematic review of technologies involving eco-innovation for enterprises moving towards sustainability. J. Clean. Prod. 192, 207–220. doi:10.1016/j.jclepro.2018.04.212

Le, T. (2020). The effect of green supply chain management practices on sustainability performance in Vietnamese construction materials manufacturing enterprises. Uncertain. Supply Chain Manag. 8 (1), 43–54. doi:10.5267/j.uscm.2019.8.007