- 1Plastic Pollution Coalition, Washington, DC, United States

- 2Public Health Institute, Oakland, CA, United States

- 3Kasokwa-Kityedo Forest Project, Masindi, Uganda

- 4California Academy of Sciences, San Francisco, CA, United States

- 5Around the World in 80 Fabrics 501c3, Santa Fe, NM, United States

- 6Center for Sustainable Macromolecular Materials and Manufacturing, The Biodesign Institute, Arizona State University, Tempe, AZ, United States

- 7Shaw Institute, Blue Hill, ME, United States

- 85 Gyres Institute, Los Angeles, CA, United States

Plastic pollution and climate change are serious and interconnected threats to public and planetary health, as well as major drivers of global social injustice. Prolific use of plastics in the construction industry is likely a key contributor, resulting in burgeoning efforts to promote the recycling or downcycling of used plastics. Businesses, materials scientists, institutions, and other interested stakeholders are currently exploring the incorporation of plastic waste into building materials and infrastructure at an accelerated rate. Examples include composite asphalt-plastic roads, plastic adhesives, plastic-concrete, plastic/crumb rubber turf, plastic lumber, plastic acoustic/thermal insulation, plastic-fiber rammed earth, and plastic soil reinforcement/stabilizers. While some believe this to be a reasonable end-of-life scenario for plastic waste, research shows such efforts may cause further problems. These uses of plastic waste represent an ongoing effort at “greenwashing,” which both delays and distracts from finding real solutions to the plastic pollution crisis. Hypothesized effects of incorporating plastic waste in construction materials, including economic, environmental, human health, performance, and social impacts, are evaluated in this mini review. We compare known impacts of these treatments for plastic waste and provide recommendations for future research. Evidence shows that such practices exacerbate the negative ecological, health, and social impacts of plastic waste and increase demand for continued production of new (virgin) plastics by creating new markets for plastic wastes. We urge caution—and more research—before widely adopting these practices.

Introduction

The modern petrochemical industry’s development during World Wars I and II led to mass production of fossil fuel–based plastics. Plastics facilitated widespread advancements in medicine, science, and technology, resulting in industrial and governmental economic gain (Tickner et al., 2021). However, mass production of plastics and its copious waste streams is harming the environment and living beings, including humans (Landrigan et al., 2023).

By 2015, more than 8.3 billion metric tons of plastic had been produced. If plastics production continues to increase at historic and projected rates, humanity is expected to produce 32 billion metric tons of plastics along with 2 billion metric tons of plastic chemical additives, by the end of 2050 (Geyer et al., 2017). Most plastic is not and has not been historically recycled (9%), but instead is primarily put in landfills, discharged into the environment (79%), or incinerated (12%) (Geyer et al., 2017) in energy-intensive and polluting processes (Eriksson and Finnveden, 2009). A significant reduction, if not cessation, of new plastics production is recommended to seriously address the numerous impacts of plastic pollution and its consequent chemical pollution and contributions to the climate crisis (Lavers et al., 2022). Even if addressed promptly, plastics and their related pollutants will inevitably remain a problem well into the future (Borrelle et al., 2020; Persson et al., 2022).

Life cycle analyses (LCAs) find reuse and recycling of plastics show greater environmental benefits compared to composting, landfilling, or incinerating with or without energy recovery (Mannheim, 2021; Gómez and Escobar, 2022). LCAs also find that, from a circular economy perspective, the energy produced during plastics incineration cannot substitute (in terms of energy output) fossil fuel energy sources (Horodytska, 2020). Primary plastics recycling (Kutz, 2011) has been identified as a method of addressing plastic pollution with a goal of eliminating or minimizing waste (Uekert et al., 2023). However, major challenges remain. Plastic waste is not comprised of a single material, but includes hundreds of polymers and thousands of chemical additives in different combinations (Rosato et al., 1991). Many plastic products are not designed for easy recycling (Burrows et al., 2022), limiting their potential for circularity in desirable closed loop systems. Moreover, industries have favored the historically low cost and high economic gain of new (virgin) polymers, reducing the overall demand for recycled plastics (Merrington, 2017).

Secondary recycling involves downgrading or downcycling (Hopewell et al., 2009; Helbig et al., 2022). Of growing interest is the use of homogenous and mixed plastic wastes in construction materials such as asphalt-plastic roads, plastic adhesives, plastic-concrete, plastic/crumb rubber turf, plastic lumber, plastic acoustic/thermal insulation, plastic-fiber rammed earth, and plastic soil reinforcement/stabilizers (Safinia and Alkalbani, 2016; Kassa et al., 2020; Ma et al., 2021; Rahman et al., 2022). Many of these uses have been promoted as strategies to reduce metal and other materials in construction, thereby reducing water and energy use (Yina et al., 2016) and construction costs (Rebeiz and Craft, 1995).

Focus on this topic has increased as plastic pollution, along with the social pressures of a growing human population (e.g., a lack of housing) increases (Awoyera and Adesina, 2020). The Global South may be particularly vulnerable, as many areas lack formal primary recycling systems and instead depend on informal recycling to manage wastes (Velis, 2017). Huge volumes of plastic pollution have accumulated in the Global South as a result of the global plastics waste trade (Zhao et al., 2021).

Given the rise in downcycling plastics for use in construction, the goal of the present review was to document use of plastic waste in construction and determine what is known and to evaluate the hypothesized effects—including economic, environmental, health, performance, and social impacts. Our specific objectives are to 1) identify the frequency of plastic waste used in construction reported in the literature, including the source material (i.e., product and polymer types) and end application (i.e., types of building materials and infrastructure), 2) evaluate what is known about the effects, 3) identify whether the practice is portrayed as a net positive or negative, and 4) recommend areas for future research.

Assessing the full impacts of incorporating plastic waste into construction materials

This mini review focused on studies documenting the feasibility and impacts of secondary recycling of plastic waste in construction materials published online from 1992 through 2022. Using ScienceDirect and Google Scholar, our search included the terms: “plastic waste in construction materials,” “plastic waste building materials,” and “plastic waste in built environment.” We included studies presenting original research published in peer-reviewed journals, government reports, and academic theses. Primary recycling of plastic waste was not included.

In total, we reviewed 100 studies (Figure 1). Most of these were published primarily between 2012 and 2022 (n = 92). Across studies reviewed, both homogenous and mixed plastic wastes were used in construction materials, and included:

• acrylonitrile butadiene styrene

• coffee-cup waste

• cross-linked polyethylene

• crumb rubber

• e-waste (mixed and hazardous)

• expanded polystyrene

• high-density polyethylene

• industrial waste (mixed)

• low-density polyethylene

• mixed synthetic textile fibers

• nylon

• personal protective equipment

• polyester

• polyethylene terephthalate (including plastic bottles)

• polypropylene

• polystyrene

• polyvinyl chloride

• polyurethane foam

• urban plastic waste (mixed)

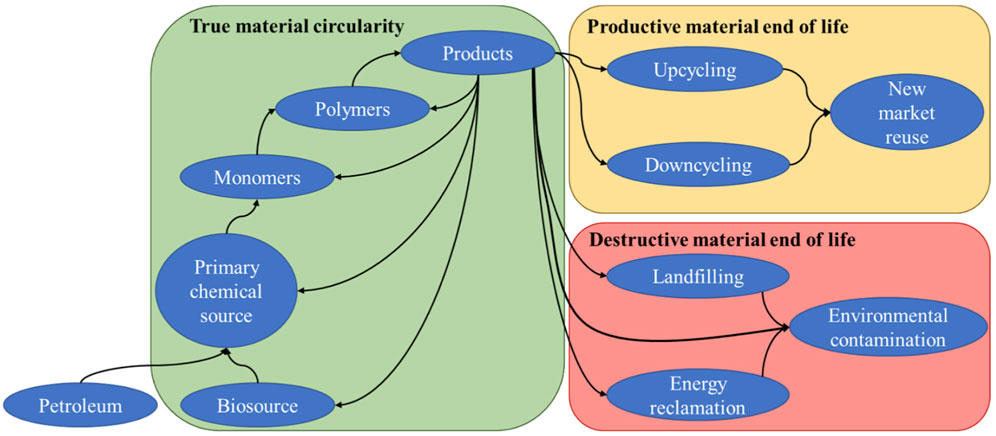

FIGURE 1. Summary of studies evaluating plastic waste in construction materials. Applications and assessed impacts (economic, environmental, health, performance, and social) were summed across a total of 100 articles from the literature, with some articles assessing multiple construction materials.

Some of the plastic waste also required chemical additives for processing. Several studies examined use of more than one type of plastic waste, and/or assessed the production of more than one type of construction material. (Supplementary Datasheet S1)

Sixty-one studies examined plastic composites. Composite mixtures incorporated plastic waste with:

• banana fiber (n = 1)

• concrete (n = 45)

• gypsum (n = 2)

• particle board (n = 1)

• rubber (n = 1)

• sand or clay bricks (n = 9)

• wood (n = 4)

Other studies examined incorporation of plastic waste into:

• acoustic and thermal insulation (n = 1)

• adhesives (n = 1)

• plastic lumber (n = 4)

• rammed earth (n = 1)

• roads (n = 34)

• reinforcement and stabilizers (n = 3)

• synthetic turf (n = 8)

Of the 100 studies, incorporation of plastic waste into construction materials was portrayed as a net positive (64%); net neutral (26%); or net negative (10%) sentiment, determined by each study’s final recommendations on researched materials. Primary benefits and risks spanned economic, environmental, human health, performance, and social impacts. Few studies addressed aesthetic impacts. Some applications of plastic waste in construction materials are in early test phases and less feasible to produce at scale, such as producing wood adhesives by chemically recycling polyurethane foams (Beran et al., 2021), so less was known about their impacts.

Several of the studies used LCAs (Muralikrishna and Manickam, 2017) to evaluate use of plastic waste in construction materials. LCAs are designed to capture economic, environmental, health, social, and other important factors. However, we note LCAs of emerging technologies are challenging to compare due to a lack of existing data, which can present uncertainty (Thonemann et al., 2020). Furthermore, LCAs can lack quality data and employ unclear boundary choices that may exclude a complete assessment of key parts of the full plastic life cycle (Miller, 2022). An important factor missing from the literature is the impact on human health, which is adversely affected by contact with plastic waste, and intersects all pillars of a triple bottom line approach to sustainability (Omer and Noguchi, 2020).

Figure 1 illustrates a summary of studies evaluating plastic waste in construction materials. Here, we outline where studies have evaluated or discussed the economic, environmental, health, performance, and social implications of these practices, and whether those impacts were described as costs or benefits for each material category.

Economic effects

The economic cost of utilizing plastic waste as a secondary or primary component in construction materials appears competitive compared to traditional construction materials. However, indirect costs may be underrepresented in these studies. Research on other waste materials, such as fly ash waste, which has been used in some construction materials since the 1970s, indicates costs increase when wastes are transported to processing sites (Sandanayake et al., 2020). In a few cases, elevated production costs resulted in an economic downside, particularly when additional processing or complex technologies were used. Further, economic benefits were dependent on numerous factors, including: cost-effectiveness of collecting, sorting, and preparing plastic wastes for downcycling; costs of producing the materials; establishment of markets for these materials; and construction, maintenance, operation, and end-of-life costs (Alqahtani et al., 2021). Many of the costs unaccounted for in plastic production (Tejaswini et al., 2022) are addressed in this mini review.

While studies emphasized the longevity of plastics, they lacked discussions of the fate of plastic-laced construction materials at their end of life. It is unclear whether downcycled materials can themselves be effectively reused. For example, a majority of road pavement is recycled in situ and can be recycled multiple times (Turk et al., 2016), but cannot be recycled indefinitely. Construction and demolition waste accounts for an estimated 30 percent of all wastes generated globally. Ultimately, materials will be incinerated or sent to landfills at the end of their useful lives. Moving the construction sector toward circularity in the future involves deconstructing and evaluating the quality of different materials, handling hazardous waste, developing advanced processing for recovery, as well as incentivizing material recovery and reuse (Purchase et al., 2022).

Environmental effects

Most studies highlighting environmental benefits focused on diversion of discarded plastic waste from landfills and the environment. However, studies frequently overlooked production of microplastics and nanoplastics, a key effect of processing and using plastic waste (Hartmann et al., 2019; Rahman et al., 2022). Shredding or pelletizing homogenized or mixed plastic wastes for incorporation into asphalts, composites, lumbers, and synthetic turfs generates microplastics and nanoplastics. These particles, along with chemical additives and sorbed contaminants (e.g., heavy metals and legacy POPs), travel widely through ecological compartments—including but not limited to the air (Amato-Lourenço et al., 2020), the ocean (Eriksen et al., 2023), and soils (Cramer et al., 2022)—and into living bodies including humans (Amobonye et al., 2021). An identified environmental risk is the need to incorporate additive chemicals and/or new materials to plastic waste to maintain structural and performance integrity, which diminishes a material’s circularity and safety (Parece et al., 2022).

The reviewed literature was most critical of the environmental impacts of synthetic turfs, which are typically composed of many layers of plastics including micro-sized crumb rubber from synthetic automobile tires. Crumb rubber particles and their leachates are easily transported from the material into surrounding environments where they threaten ecosystem and human health (Armada et al., 2022; Murphy and Warner, 2022). These and other plastics are known to contain a wide range of toxic additives that contribute to environmental and human health burdens, exacerbating barriers to their safe recycling and reprocessing in a circular economy (Wagner et al., 2020).

Health effects

Studies occasionally cited benefits to people via employment (e.g., informal waste sorting, recycling, production of construction materials) in the Global South (Estil, 2019; Kumi-Larbi, Jr. et al., 2022). However, no studies identified potential health costs of plastics, microplastics, or chemical exposures in this informal sector. Research documents serious health hazards linked to work in informal waste picking (Alfers, 2022; Zolnikov et al., 2021), especially in poor communities of color who work unprotected and lack access to reliable healthcare (Morais, 2022).

While the full human health impacts of microplastics and associated chemicals are still emerging, microplastics damage human cells in vitro (Danopolous et al., 2022) and cause serious illness in wildlife, such as seabirds (Charlton-Howard et al., 2023). Presence of plastic particles have been reported in blood (Leslie et al., 2022), breastmilk (Ragusa et al., 2022), feces (Zhang et al., 2021), human lungs (Jenner et al., 2022), placenta (Ragusa et al., 2021), testes and semen (Zhao et al., 2023), and venous tissue (Rotchell et al., 2023). Although all people living in a built environment made from plastic waste are at risk of absorbing, ingesting, and inhaling hazardous plastic particles and chemicals (Domenech and Marcos, 2021), those involved in producing construction materials from plastic fragments and items may be at an even greater risk through occupational exposure (Murashov et al., 2021).

Beyond the particles themselves, plastics are associated with over 10,000 chemical substances, very few of which have undergone rigorous toxicity testing and assessment (Wiesinger et al., 2021). Synthetic turf fields and plastic-asphalt roads offgas hazardous chemicals (including hydrogen chloride) known to originate from plastics, especially under hot climatic conditions or during melting in production (Pavilonis et al., 2013; Sabradra, 2017). The human health impacts of chemical offgassing from plastics is largely unknown.

Performance effects

Performance benefits varied across construction materials. For structural materials, including composites and bricks, performance benefits include: cohesive strength, compressibility, flexural strength, seismic performance, shear strength, and thermal insulation. For roadways, performance benefits include ability to withstand cracking, rutting, and other effects of weathering; perform well on fatigue tests; and show limited stiffness with high tensile strength. Across the studies, synthetic turf had the fewest performance benefits, and was limited to providing additional cushioning for athletes who use fields for sport (Pavilonis et al., 2013). Some of the applications of plastic waste in construction materials are still in early development, such as with producing wood adhesives by chemically recycling polyurethane foams (Beran et al., 2021), so their performance is not yet well understood.

Further, in some construction materials, while the addition of plastic waste may show no risks to performance or may even slightly enhance performance (e.g., Rahman et al., 2022), several studies showed clear performance risks across various uses of plastic waste in construction materials, particularly when increased amounts of plastics were used. For example, when producing asphalt from plastic waste, the smallest quantities of plastics incorporated (e.g., less than 5% of total asphalt mixture) were most beneficial to performance (Santos et al., 2021). The quantity of plastic waste that can potentially be sequestered in construction materials is inherently limited and should not be oversold.

Social effects

We found construction materials made from plastic waste were often recommended for application in the Global South. Across studies, these materials were generally not recommended for large or multi-story structures due to strength- and/or integrity-related performance risks. Flammability was identified as a major concern (Gulhane and Gulhane, 2017). Research shows constructions made of synthetic materials, chiefly plastics, burn more intensely and quickly than constructions made of natural materials like wood (Kerber, 2012).

A net positive asset of plastic waste was its flexibility and heat-insulating characteristics when incorporated into construction materials, potentially making it well suited for temporary housing applications in refugee camps and slums (Estil, 2019; Haque and Islam, 2021; Zuraida et al., 2023). However, the propensity for heavy rains and natural disasters in the Global South can threaten infrastructure, and infrastructure made from plastic waste, including roadways, may be more vulnerable (Sabrada, 2017).

Incorporation of plastic waste into construction materials is still in its infancy and its focus has centered on the potential environmental and social benefits (e.g., cleanup and housing). The exposure and subsequent harm these practices may cause to humans however remains unquantified. Specific research gaps include investigations into potentially hazardous employment (e.g., from creating plastic bricks) and unsafe housing/infrastructure, as well as the short- and long-term health consequences.

Discussion

Before broad recommendations to incorporate plastic waste into construction materials are made, we urge researchers to further investigate human health and social consequences to avoid exacerbating injustices to communities in which the most vulnerable people are exposed to more environmental hazards and potential long-term health implications.

Our mini review documents varied benefits and costs (Figure 1) to downcycling homogenous and mixed plastic wastes in construction materials across categories such as economic, environmental, health, performance, and social impacts.

A key finding was that while this may extend the useful life of plastics that would otherwise be discarded as waste, such applications rely on continued generation of plastic waste. Adding plastic waste to construction materials ultimately does not address the core cause of continued plastic pollution, which is the still rapidly escalating increase in global plastic production. Current patterns of plastic production, use, and disposal have been identified as unsustainable and responsible for significantly harming human health and driving serious societal injustices (Landrigan et al., 2023). To prevent the worst-case scenario of future plastic pollution, many have called for capping plastic production and ceasing new (virgin) plastic production. With a Global Plastics Treaty currently being negotiated, such possibilities now exist via legally binding policy (Bergmann et al., 2022).

Upstream approaches to addressing plastic pollution (e.g., prevention through regulation curbing plastics production) are clearly favorable to midstream and downstream approaches like downcycling plastic waste into construction materials. Upstream approaches involve eliminating wastefulness wherever possible by tapping into strategies of refill and reuse (Moss et al., 2022), repair (Tellier, 2022), and share (Wieser, 2019), along with reducing reliance on single-use items that require recycling or composting. Eliminating single-use plastic items avoids landfilling, incineration, pollution, and continued resource use/waste creation. These systems that enable refill, reuse, repair, and sharing already exist and were more prevalent before mass production of plastics (Lucas, 2002).

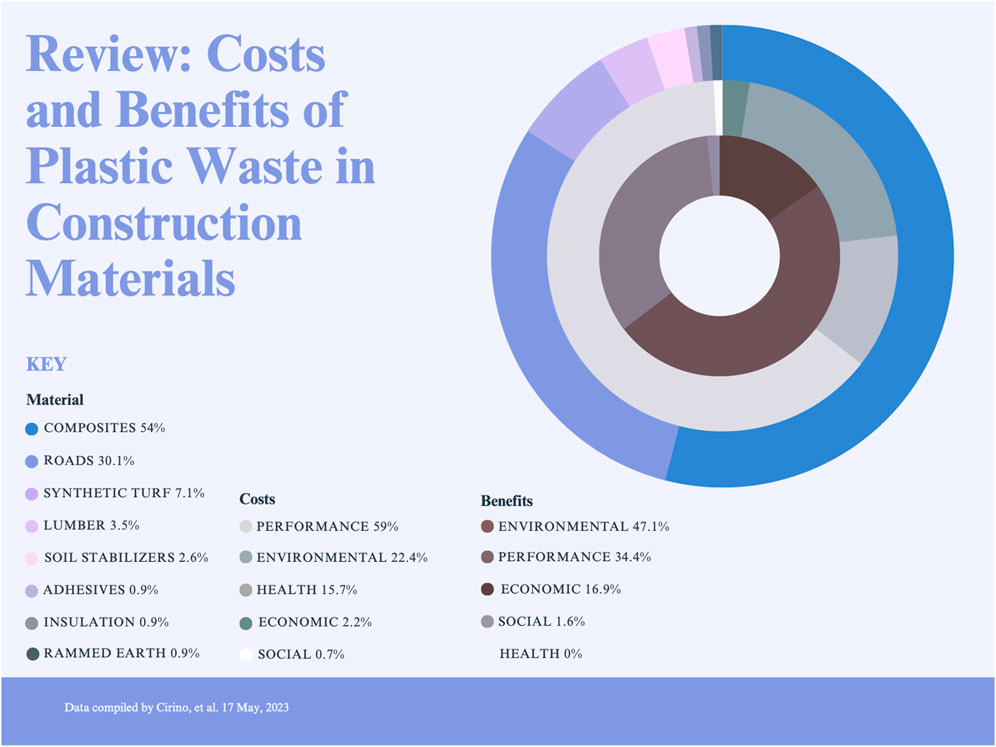

Various iterations of a waste hierarchy have been proposed by scientists and policy makers—particularly those in the European Union—to facilitate reduction or cessation of new plastics production. This hierarchy prioritizes prevention of material pollution, including plastics. (Figure 2). These measures emphasize products designed for perpetual use and avoidance of using wasteful throwaway materials before taking the following actions (Egüez, 2021; European Union, 2022; Zhang et al., 2022):

• preparing used products for reuse

• recycling of products that cannot be reused

• downcycling of products that cannot be reused, or recovery (such as waste-to-energy incineration or chemical/“advanced” recycling) of products that cannot be reused or recycled

• disposal (landfilling or incineration without energy capture) of products that cannot be reused, recycled, downcycled, or recovered

Ultimately downcycling plastic waste into construction materials is not circular and does not address the core problem of plastic pollution. While LCAs may deem this to be a next-best approach to addressing plastic waste, current research does not fully assess and weigh potential consequences. To reduce risks and enhance benefits of downcycled materials in the immediate term, we recommend that safeguards are implemented to promote better health and labor conditions for people working in the informal waste sector, mandatory material end-of-life plans, and standardized material toxicity tests (preferably audited by a third party). However, without also prioritizing measures to curb wasteful plastics production, downcycling effectively greenlights continued manufacturing of plastic material items (Borrelle et al., 2020; Lau et al., 2020). This perpetuates the cycle of increased pollution and injustice.

To reduce the generation of plastic waste, we recommend future research on proposed solutions such as expanded reuse models, new business models to promote reuse, nontoxic material and green chemical development, increased precision of green building standards, and new product development and design to eliminate single-use plastics and toxic chemicals. Education and the creation of models for the purchase of affordable, safe alternatives are critical. Government incentives such as tax breaks, subsidies, and grants can help shift business practices (Zhao et al., 2021). But even if we are to succeed at stopping plastic pollution upstream, the urgent question remains of what to do with the plastics and toxic additives produced to date. If LCAs are used to justify use of plastic waste as a resource, they must take into account the full cost of toxic impacts from plastic wastes’ effects on the environment, to social injustices, and harmful effects on human health—including the little-known effects of chemical offgassing of plastics. Along with implementing upstream approaches to curb the growth of plastic pollution, we recommend urgent research on remediation of landfills, the environment, and communities impacted by plastics and their numerous forms of toxic pollution.

Author contributions

EC wrote the first draft of the manuscript. SC, JW, TT, JB, CR-S, and LE edited the manuscript. EC created Figure 1. JB created Figure 2. All authors contributed to the article and approved the submitted version.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fbuil.2023.1206474/full#supplementary-material

References

Alqahtani, F. K., Abotaleb, I. S., and ElMenshawy, M. (2021). Life cycle cost analysis of lightweight green concrete utilizing recycled plastic aggregates. J. Build. Eng. 40, 102670. doi:10.1016/j.jobe.2021.102670

Amato-Lourenço, L. F., dos Santos Galvão, L., de Weger, L. A., Hiemstra, P. S., Vijver, M. G., and Mauad, T. (2020). An emerging class of air pollutants: Potential effects of microplastics to respiratory human health? Sci. Total Environ. 749, 141676. doi:10.1016/j.scitotenv.2020.141676

Amobonye, A., Bhagwat, P., Raveendran, S., Singh, S., and Pillai, S. (2021). Environmental impacts of microplastics and nanoplastics: A current overview. Front. Microbiol. 12, 768297. doi:10.3389/fmicb.2021.768297

Armada, D., Llompart, M., Celeiro, M., Garcia-Castro, P., Ratola, N., Dagnac, T., et al. (2022). Global evaluation of the chemical hazard of recycled tire crumb rubber employed on worldwide synthetic turf football pitches. Sci. Total Environ. 812, 152542. doi:10.1016/j.scitotenv.2021.152542

Awoyera, P. O., and Adesina, A. (2020). Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 12, e00330. doi:10.1016/j.cscm.2020.e00330

Beran, R., Zárybnická, L., Machová, D., Večeřa, M., and Kalenda, P. (2021). Wood adhesives from waste-free recycling depolymerisation of flexible polyurethane foams. J. Clean. Prod. 305, 127142. doi:10.1016/j.jclepro.2021.127142

Bergmann, M., Almroth, B. C., Brander, S. M., Dey, T., Green, D. S., Gundogdu, S., et al. (2022). A global plastic treaty must cap production. Am. Assoc. Adv. Sci. 376, 469–470. doi:10.1126/science.abq0082

Borrelle, S., Ringma, J., Lavender Law, K., Monnahan, C., Lebreton, L., McGivern, A., et al. (2020). Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 369 (6509), 1515–1518. doi:10.1126/SCIENCE.ABA3656

Burrows, S. D., Ribeiro, F., O’Brien, S., Okoffo, E., Toapanta, T., Charlton, N., et al. (2022). The message on the bottle: Rethinking plastic labelling to better encourage sustainable use. Environ. Sci. Policy 132, 109–118. doi:10.1016/j.envsci.2022.02.015

Charlton-Howard, H. S., Bond, A. L., Rivers-Auty, J., and Lavers, J. L. (2023). ‘Plasticosis’: Characterising macro- and microplastic-associated fibrosis in seabird tissues. J. Hazard. Mater. 450, 131090. doi:10.1016/j.jhazmat.2023.131090

Cramer, A., Benard, P., Zarebanadkouki, M., Kaestner, A., and Carminati, A. (2023). Microplastic induces soil water repellency and limits capillary flow. Vadose Zone J. 22 (1). doi:10.1002/vzj2.20215

Danopoulos, E., Twiddy, M., West, R., and Rotchell, J. M. (2022). A rapid review and meta-regression analyses of the toxicological impacts of microplastic exposure in human cells. J. Hazard. Mater. 427, 127861. doi:10.1016/j.jhazmat.2021.127861

Domenech, J., and Marcos, R. (2021). Pathways of human exposure to microplastics, and estimation of the total burden. Curr. Opin. Food Sci. 39, 144–151. doi:10.1016/j.cofs.2021.01.004

Egüez, A. (2021). Compliance with the eu waste hierarchy: A matter of stringency, enforcement, and time. J. Environ. Manag. 280, 111672. doi:10.1016/j.jenvman.2020.111672

Eriksen, M., Cowger, W., Erdle, L. M., Coffin, S., Villarrubia-Gómez, P., Moore, C. J., et al. (2023). A growing plastic smog, now estimated to be over 170 trillion plastic particles afloat in the world’s oceans—urgent solutions required. PLoS ONE 18 (3), e0281596. doi:10.1371/journal.pone.0281596

Eriksson, O., and Finnveden, G. (2009). Plastic waste as a fuel - CO2-neutral or not? Energy Environ. Sci. 2 (9), 907–914. doi:10.1039/b908135f

Estil, K. (2019). From waste to housing: Using plastic waste to build sustainable housing in Haiti. Boca Raton, Florida: Florida Atlantic University. https://fau.digital.flvc.org/islandora/object/fau%3A42168/datastream/OBJ/view/FROM_WASTE_TO_HOUSING__USING_PLASTIC_WASTE_TO_BUILD_SUSTAINABLE_HOUSING_IN_HAITI.pdf.

Geyer, R., Jambeck, J., and Lavender Law, K. (2017). Production, use, and fate of all plastics ever made. Sci. Adv. 3 (7), 19–24. doi:10.1126/sciadv.1700782

Gómez, I. D. L., and Escobar, A. S. (2022). The dilemma of plastic bags and their substitutes: A review on lca studies. Sustain. Prod. Consum. 30, 107–116. doi:10.1016/j.spc.2021.11.021

Gulhane, S., and Gulhane, S. (2017). Analysis of housing structures made from recycled plastic. IRA-International J. Technol. Eng., 7(2), 45. doi:10.21013/jte.icsesd201705

Haque, M. S., and Islam, S. (2021). Effectiveness of waste plastic bottles as construction material in Rohingya displacement camps. Clean. Eng. Technol. 3, 100110. doi:10.1016/j.clet.2021.100110

Hartmann, N. B., Hüffer, T., Thompson, R. C., Hassellöv, M., Verschoor, A., Daugaard, A. E., et al. (2019). Environ. Sci. Technol. 53 (3), 1039–1047. doi:10.1021/acs.est.8b05297

Helbig, C., Huether, J., Joachimsthaler, C., Lehmann, C., Raatz, S., Thorenz, A., et al. (2022). A terminology for downcycling. J. Industrial Ecol. 26 (4), 1164–1174. doi:10.1111/jiec.13289

Hopewell, J., Dvorak, R., and Kosior, E. (2009). Plastics recycling: Challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences. 364, 1526, 2115-2126. doi:10.1098/rstb.2008.0311

Horodytska, O., Kiritsis, D., and Fullana, A. (2020). Upcycling of printed plastic films: LCA analysis and effects on the circular economy. J. Clean. Prod. 268 (20), 122138. doi:10.1016/j.jclepro.2020.122138

Jenner, L. C., Rotchell, J. M., Bennett, R. T., Cowen, M., Tentzeris, V., and Sadofsky, L. R. (2022). Detection of microplastics in human lung tissue using μFTIR spectroscopy. Sci. Total Environ. 831, 154907. doi:10.1016/j.scitotenv.2022.154907

Kassa, R. B., Workie, T., Abdela, A., Fekade, M., Saleh, M., and Dejene, Y. (2020). Soil stabilization using waste plastic materials. Open J. Civ. Eng. 10 (01), 55–68. doi:10.4236/ojce.2020.101006

Kerber, S. (2012). Analysis of changing residential fire dynamics and its implications on firefighter operational timeframes. Fire Technol. 48 (4), 865–891. doi:10.1007/s10694-011-0249-2

Kumi-Larbi Jnr, A., Galpin, R., Manjula, S., Lenkiewicz, Z., and Cheeseman, C. (2022). Reuse of waste plastics in developing countries: Properties of waste plastic-sand composites. Waste Biomass Valorization 13, 3821–3834. doi:10.1007/s12649-022-01708-x

Kutz, M. (2011). Applied plastics engineering handbook. William Andrew, Norwich, NY, USA. doi:10.1016/C2010-0-67336-6

Landrigan, P. J., Raps, H., Cropper, M., Bald, C., Brunner, M., Canonizado, E. M., et al. (2023). The minderoo-Monaco commission on plastics and human health. Ann. Glob. Health 89 (1), 23. doi:10.5334/aogh.4056

Lau, W., Shiran, Y., Bailey, R. M., Cook, E., Stutchey, M. R., Koskella, J., et al. (2020). Evaluating scenarios toward zero plastic pollution. Science 369, 1455–1461. doi:10.1126/science.aba9475

Lavers, J. L., Bond, A. L., and Rolsky, C. (2022). Far from a distraction: Plastic pollution and the planetary emergency. Biol. Conserv. 272, 109655. doi:10.1016/j.biocon.2022.109655

Leslie, H. A., van Velzen, M. J. M., Brandsma, S. H., Vethaak, A. D., Garcia-Vallejo, J. J., and Lamoree, M. H. (2022). Discovery and quantification of plastic particle pollution in human blood. Environ. Int. 163, 107199. doi:10.1016/j.envint.2022.107199

Lucas, G. (2002). Disposability and dispossession in the twentieth century. J. Material Cult. 7 (1), 5–22. doi:10.1177/1359183502007001303

Ma, Y., Zhou, H., Jiang, X., Polaczyk, P., Xiao, R., Zhang, M., et al. (2021). The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2, 100031. doi:10.1016/j.clema.2021.100031

Mannheim, V. (2021). Life cycle assessment model of plastic products: Comparing environmental impacts for different scenarios in the production stage. Polymers 13 (5), 777. doi:10.3390/polym13050777

Merrington, A. (2017). “Recycling of plastics,” in Applied plastics engineering handbook: Processing, materials, and applications. 2nd, 167–189. Elsevier, Amsterdam, Netherlands, doi:10.1016/B978-0-323-39040-8.00009-2

Miller, S. A. (2022). The capabilities and deficiencies of life cycle assessment to address the plastic problem. Front. Sustain. 3. doi:10.3389/frsus.2022.1007060

Morais, J., Corder, G., Golev, A., Lawson, L., and Ali, S. (2022). Global review of human waste-picking and its contribution to poverty alleviation and a circular economy. Environ. Res. Lett. 17, 63002. doi:10.1088/1748-9326/ac6b49

Moss, E., Gerken, K., Youngblood, K., and Jambeck, J. R. (2022). Global landscape analysis of reuse and refill solutions. Front. Sustain. 3. doi:10.3389/frsus.2022.1006702

Muralikrishna, I. V., and Manickam, V. (2017). Chapter five - life cycle assessment. Environmental management. Butterworth-Heinemann, Oxford, United Kingdom.

Murashov, V., Geraci, C. L., Schulte, P. A., and Howard, J. (2021). Nano- and microplastics in the workplace. J. Occup. Environ. Hyg. 18, 489–494. doi:10.1080/15459624.2021.1976413

Murphy, M., and Warner, G. R. (2022). Health impacts of artificial turf: Toxicity studies, challenges, and future directions. Environ. Pollut. 310, 119841. doi:10.1016/j.envpol.2022.119841

Omer, M. A. B., and Noguchi, T. (2020). A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 52, 101869. doi:10.1016/j.scs.2019.101869

Parece, S., Rato, V., Resende, R., Pinto, P., and Stellacci, S. (2022). A methodology to qualitatively select upcycled building materials from urban and industrial waste. Sustainability 14 (6), 3430. doi:10.3390/su14063430

Pavilonis, B. T., Weisel, C. P., Buckley, B., and Lioy, P. J. (2014). Bioaccessibility and risk of exposure to metals and SVOCs in artificial turf field fill materials and fibers. Risk Anal. 34 (1), 44–55. doi:10.1111/risa.12081

Persson, L., Carney Almroth, B. M., Collins, C. D., Cornell, S., de Wit, C. A., Diamond, M. L., et al. (2022). Outside the safe operating space of the planetary boundary for novel entities. Environ. Sci. Technol. 56 (3), 1510–1521. doi:10.1021/acs.est.1c04158

Purchase, C. K., Al Zulayq, D. M., O’brien, B. T., Kowalewski, M. J., Berenjian, A., Tarighaleslami, A. H., et al. (2022). Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 15, 76. doi:10.3390/ma15010076

Ragusa, A., Notarstefano, V., Svelato, A., Belloni, A., Gioacchini, G., Blondeel, C., et al. (2022). Raman microspectroscopy detection and characterisation of microplastics in human breastmilk. Polymers 14 (13), 2700. doi:10.3390/polym14132700

Ragusa, A., Svelato, A., Santacroce, C., Catalano, P., Notarstefano, V., Carnevali, O., et al. (2021). Plasticenta: First evidence of microplastics in human placenta. Environ. Int. 146, 106274. doi:10.1016/j.envint.2020.106274

Rebeiz, K. S., and Craft, A. P. (1995). Plastic waste management in construction: Technological and institutional issues. Resour. Conservation Recycl. 15, 245–257. doi:10.1016/0921-3449(95)00034-8

Rosato, D. V., Di Mattia, D. P., and Rosato, D. V. (1991). Designing with plastics and composites: A handbook. Springer US. Berlin, Germany.

Rotchell, J. M., Jenner, L. C., Chapman, E., Bennett, R. T., Bolanle, I. O., Loubani, M., et al. (2023). Detection of microplastics in human saphenous vein tissue using μFTIR: A pilot study. PLoS ONE 18, e0280594. doi:10.1371/journal.pone.0280594

Sabrada, V. (2017). Use of polymer modified bitumen in road construction. Int. Res. J. Eng. Technol. 4 (12), 799–801.

Safinia, S., and Alkalbani, A. (2016). Use of recycled plastic water bottles in concrete blocks. Procedia Eng. 164, 214–221. doi:10.1016/j.proeng.2016.11.612

Sandanayake, M., Gunasekara, C., Law, D., Zhang, G., Setunge, S., and Wanijuru, D. (2020). Sustainable criterion selection framework for green building materials – an optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 25, e00178. doi:10.1016/j.susmat.2020.e00178

Santos, J., Pham, A., Stasinopoulos, P., and Giustozzi, F. (2021). Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total Environ. 751, 141842. doi:10.1016/j.scitotenv.2020.141842

Tejaswini, M. S. S. R., Pathak, P., Ramkrishna, S., and Ganesh, P. S. (2022). A comprehensive review on integrative approach for sustainable management of plastic waste and its associated externalities. Sci. Total Environ. 825, 153973. doi:10.1016/j.scitotenv.2022.153973

Tellier, J. P. (2022). https://dial.uclouvain.be/memoire/ucl/fr/object/thesis%3A35225.How to extend the product lifetime: Citizens' initiatives as an alternative or a complement to professional repair services. A case study about Repair Cafés

Thonemann, N., Schulte, A., and Maga, D. (2020). How to conduct prospective life cycle assessment for emerging technologies? A systematic review and methodological guidance. Sustainability 12, 1192. doi:10.3390/su12031192

Tickner, J., Geiser, K., and Baima, I. (2021). Transitioning the chemical industry: The case for addressing the climate, toxics, and plastics crises. Environment 63 (6), 4–15. doi:10.1080/00139157.2021.1979857

Turk, J., Mauko Pranjić, A., Mladenovič, A., Cotič, Z., and Jurjavčič, P. (2016). Environmental comparison of two alternative road pavement rehabilitation techniques: Cold-in-place-recycling versus traditional reconstruction. J. Clean. Prod. 121, 45–55. doi:10.1016/j.jclepro.2016.02.040

Uekert, T., Singh, A., DesVeaux, J. S., Ghosh, T., Bhatt, A., Yadav, G., et al. (2023). Technical, economic, and environmental comparison of closed-loop recycling technologies for common plastics. ACS Sustain. Chem. Eng. 11 (3), 965–978. doi:10.1021/acssuschemeng.2c05497

Union, European (2022). Waste prevention and management. https://ec.europa.eu/environment/green-growth/waste-prevention-and-management/index_en.htm.

Velis, C. (2017). Waste pickers in Global South: Informal recycling sector in a circular economy era. Waste Manag. Res. 35, 329–331. doi:10.1177/0734242X17702024

Wagner, S., and Schlummer, M. (2020). Legacy additives in a circular economy of plastics: Current dilemma, policy analysis, and emerging countermeasures. Resour. Conservation Recycl. 158, 104800. doi:10.1016/j.resconrec.2020.104800

Wieser, H. (2019). Consumption work in the circular and sharing economy: A literature review. Problems and Perspectives in Management, 19, 1, 198-208.

Wiesinger, H., Wang, Z., and Hellweg, S. (2021). Deep dive into plastic monomers, additives, and processing aids. Environ. Sci. Technol. 55 (13), 9339–9351. doi:10.1021/acs.est.1c00976

Yina, S., Tuladhar, R., Sheehan, M., Combe, M., and Collister, T. (2016). A life cycle assessment of recycled polypropylene fibre in concrete footpaths. J. Clean. Prod. 112, 2231–2242. doi:10.1016/j.jclepro.2015.09.073

Zhang, C., Hu, M., Di Maio, F., Sprecher, B., Yang, X., and Tukker, A. (2022). An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 803, 149892. doi:10.1016/j.scitotenv.2021.149892

Zhang, J., Wang, L., Trasande, L., and Kannan, K. (2021). Occurrence of polyethylene terephthalate and polycarbonate microplastics in infant and adult feces. Environ. Sci. Technol. Lett. 8 (11), 989–994. doi:10.1021/acs.estlett.1c00559

Zhao, C., Liu, M., Du, H., and Gong, Y. (2021). The evolutionary trend and impact of global plastic waste trade network. Sustainability 13 (7), 3662. doi:10.3390/su13073662

Zhao, L., Zhang, Y. Q., Sadiq, M., Hieu, V. M., and Ngo, T. Q. (2021). Testing green fiscal policies for green investment, innovation and green productivity amid the COVID-19 era. Econ. Change Restruct. doi:10.1007/s10644-021-09367-z

Zhao, Q., Zhu, L., Weng, J., Jin, Z., Cao, Y., Jiang, H., et al. (2023). Detection and characterization of microplastics in the human testis and semen. Sci. Total Environ. 877, 162713. doi:10.1016/j.scitotenv.2023.162713

Zolnikov, T. R., Furio, F., Cruvinel, V., and Richards, J. (2021). A systematic review on informal waste picking: Occupational hazards and health outcomes. Waste Manag. 126, 291–308. doi:10.1016/j.wasman.2021.03.006

Keywords: plastic pollution, plastics, waste, construction materials, built environment, microplastics

Citation: Cirino E, Curtis S, Wallis J, Thys T, Brown J, Rolsky C and Erdle LM (2023) Assessing benefits and risks of incorporating plastic waste in construction materials. Front. Built Environ. 9:1206474. doi: 10.3389/fbuil.2023.1206474

Received: 15 April 2023; Accepted: 12 June 2023;

Published: 05 July 2023.

Edited by:

Zora Vrcelj, Victoria University, AustraliaReviewed by:

Viktoria Mannheim, University of Miskolc, HungaryCopyright © 2023 Cirino, Curtis, Wallis, Thys, Brown, Rolsky and Erdle. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Erica Cirino, ZXJpY2EuY2lyaW5vQHBsYXN0aWNwb2xsdXRpb25jb2FsaXRpb24ub3Jn

Erica Cirino

Erica Cirino Sandra Curtis2

Sandra Curtis2 Tierney Thys

Tierney Thys Charles Rolsky

Charles Rolsky