- 1Guizhou Survey and Design Research Institute for Water Resources and Hydropower, Guiyang, China

- 2School of Civil Engineering, Shaoxing University, Shaoxing, China

- 3Yunnan Phosphating Group Co., LTD., Kunming, China

- 4College of Civil Engineering, Qilu Institute of Technology, Jinan, Shandong, China

- 5School of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou, China

Introduction: Taking Yunnan Phosphate Group Co., Ltd. Kunyang Phosphate Mine No. 2 as the engineering background, this study aims to explore mining methods for deep ore bodies in phosphorus mines. Three mining schemes, namely open-pit mining, open-pit deep concave mining, and underground mining, were carefully selected for optimization. This article thoroughly analyzes the three schemes from various perspectives, including technical, economic, safety, and other aspects.

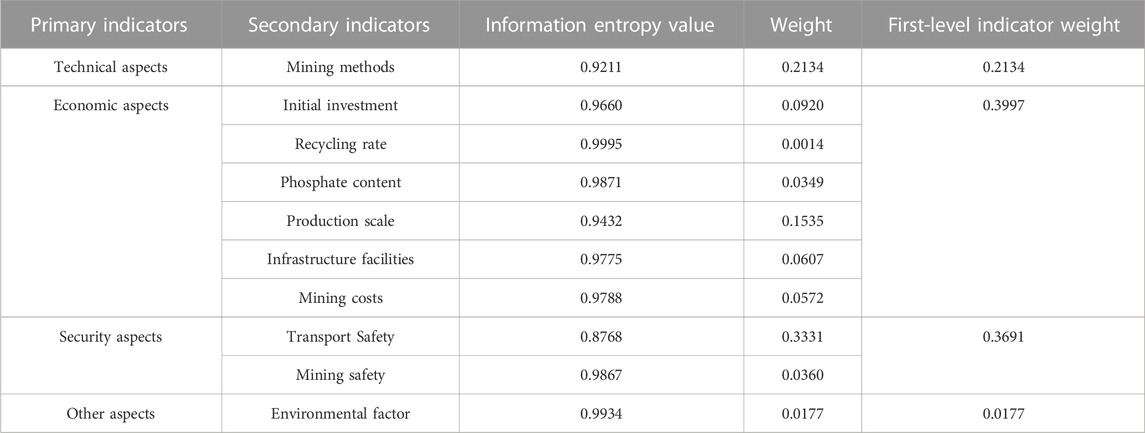

Methods: The assessment of these aspects was conducted using the entropy weighted TOPSIS method. The technical aspects focused on evaluating the mining methods employed in each scheme. The economic aspects considered factors such as initial investment, resource recovery rate, phosphate content, production scale, infrastructure, and mining costs. Safety aspects took into account transportation safety and production safety. Additionally, the analysis considered environmental impact as one of the key factors. In total, 10 indicators were quantified to provide a comprehensive evaluation. To assess the schemes, the positive and negative ideal distances (Di+, Di−) and the relative proximity (Ci) for open-pit mining, open-pit deep concave mining, and open-pit to underground mining were calculated. These calculations helped to determine the relative performance of each scheme.

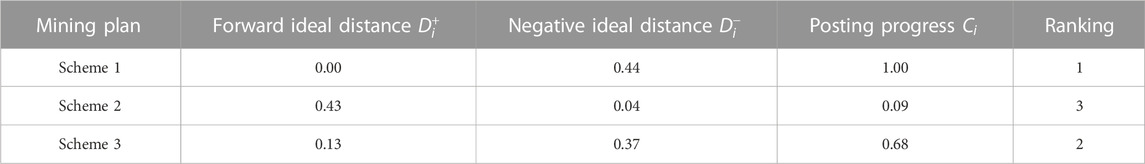

Results: The relative closeness values (Ci) for Scheme 1, Scheme 2, and Scheme 3 are determined as 1.00, 0.09, and 0.68, respectively.The evaluation results indicate that the relative closeness (Ci) for open-pit mining in Scheme 1 is 1.00, for open-pit deep concave mining in Scheme 2 is 0.09, and for underground mining in Scheme 3 is 0.68. Through comparison and analysis of these results, it can be concluded that open-pit mining is the most optimal method. However, considering the fact that the open-pit portion of Kunyang Phosphate Mine No. 2 has already been extensively mined, the study recommends underground mining as the best mining plan for the phosphate mine.

Discussion: By applying the entropy weight TOPSIS method to underground mining, this study overcomes the challenge of transitioning from qualitative to quantitative analysis for selecting mining methods. The mathematical approach enables the presentation of optimal mining techniques in a more precise manner. Through comparison of relative closeness, an optimal solution can be selected. This method holds significant value not only for selecting suitable mining methods for phosphorus mines but also for choosing optimal solutions for underground mining methods, drainage, ventilation, and other relevant considerations.

1 Introduction

Phosphate ore is a crucial chemical mineral raw material with widespread applications in new energy, new materials, grain production, the modern chemical industry, and national defense in China. The Ministry of Land and Resources has listed phosphorus as one of the 20 mineral types that cannot meet the needs of national economic development after 2010. The growth and demand for phosphate mineral resources are currently encountering a challenging situation (Li Y. J. et al., 2015).

China boasts abundant phosphate ore resources, ranking third in the world in terms of proven reserves, following Morocco and the United States. The provinces of Yunnan, Guizhou, Sichuan, Hubei, and Hunan serve as the principal regions for storing phosphate ore resources in China, collectively holding reserves of 9.86 billion tons, which accounts for 74.5% of the country’s total reserves (Wu et al., 2021). However, the average grade is only 16.95%, with only 5.8% of rich ore exceeding 30% and up to 90% of medium-to-low-grade phosphate ore that cannot be directly utilized. At the same time, China is the largest demand country for phosphorus ore globally, consuming 60 million tons of phosphorus ore annually and extracting about 30 million tons of rich ore annually. The remaining rich ore can only sustain mining for over 10 years (Zhao et al., 2021; He, 2022).

There are three primary mining methods for phosphate ore in China: open-pit mining, open-pit deep concave mining, and underground mining. Numerous scholars have conducted comprehensive research on these methods. Wei et al. (2022), considering the current research status of mining in China, discussed the mining technology, mining boundary, stripping process, and safety aspects of open-pit mining operations using a stepped open-pit mining method. They also proposed technical safety measures to enhance open-pit mining practices. Liu et al. (2023) focused on optimizing the mining process and equipment layout for the Huolin Hebei open-pit mine. They determined the mining process, equipment selection, and layout that best met the specific needs of the Huolin Hebei mine, aiming to reduce production costs and improve economic benefits. Sun (2021) specifically targeted deep open-pit mines as their research objective. They addressed challenges such as increased mining difficulty, heightened slope height, intensified environmental pollution, and the prevention and drainage of mining pits. To tackle these issues, they proposed a range of effective countermeasures.

In order to reduce transportation costs in open-pit mining, Chen et al. (2019) conducted an economic comparison and selection of plans based on specific overseas open-pit mining projects. Eventually, they identified the most suitable plan for the mining company Kangshi. Meanwhile, Wang J. et al. (2023) performed an analysis and research on various aspects including mining limits, transitioning from open-pit to underground development, mining methods for hanging wall and deep ore bodies. They determined that the sublevel caving method without bottom pillars is the most suitable for extracting deep ore bodies. Furthermore, Gong (2022) analyzed the common issues in underground mining and highlighted relevant mining problems and countermeasures in line with the safety production requirements of the new era. The objective was to establish a mining environment that is both safe and efficient, fostering the sustainable development of mining enterprises, all while ensuring the preservation of the overall benefits derived from mineral resource extraction. Open pit mining has numerous advantages compared to open pit deep concave mining and underground mining. One major advantage of open pit mining is its high safety index, which reduces the likelihood of mine safety accidents. Furthermore, open pit mining requires lower initial investment and has fewer infrastructure construction costs, thereby maximizing mining efficiency. However, as mining intensity increases, some open-pit ore bodies have already been depleted, leading many mines to transition towards open pit deep mining or even underground mining. As open-pit deep mining advances, some of the advantages traditionally associated with open-pit mining are gradually diminishing. The management and control of high and steep slopes formed during open-pit deep mining are becoming increasingly challenging. Moreover, high and steep open-air slopes are highly susceptible to disasters such as surface cracking, collapse, landslides, mudslides, and ground subsidence (Du et al., 2022; Wu and Tang, 2022). Therefore, the future development trajectory of phosphorus mines largely depends on the choice between continuing open-pit deep mining or making a direct transition to underground mining.

2 Overview of Kunyang Phosphate Mine No. 2 project

2.1 Geographical and traffic location of the mining area

Kunyang Phosphate Mine No. 2 is situated southwest of the Dianchi Phosphate Accumulation Zone, adjacent to Kunyang Phosphate Mine (mining areas 1 to 4) to the east (Chen and Han, 2021). It is also located near Xiaojiaying Phosphate Mine to the west and Haikou Phosphate Mine to the north. The mine is in Erjie Town, Jinning District. The exploration line runs between 56 and 74, with an east-west length of approximately 4.5 km, a north-south width of around 1.7 km, and an area of 7.66 km2. At the northern end of the mining area, there are several major transportation routes, including 320 National Highway, the Kunming, Kunyang, Yuxi Railway and Highway, the Gaohai Expressway, and the Anjin Expressway to the east, as well as the Bajie Erjie Haikou Highway to the south. Within the mining area is an interconnected network of roads, with a total mileage of about 13 km to the urban area of Jinning District and around 62 km to Kunming City. The nearest train station to the mining area is Zhongyi Village Station, which is approximately 10 km away and has highly convenient transportation (Shen and Ning, 2022).

The mining area’s surface extends in a long serpentine shape from southwest to northeast, with an overall terrain higher in the north and lower in the south. The highest elevation is 2,335 m from the edge of the mining boundary in the north of the mining area, while the lowest height is 1938.7 m from the gully near the mining boundary in the southwest of the mining area (which is the lowest erosion benchmark within the mining area), with a relative elevation difference of 396.3 m. The mining area is in a gently sloping zone with deep groundwater burial. There are no surface water bodies inside or near the mining area, and the terrain slope in the mining area is relatively gentle. Moreover, there are no residential villages in the mining area.

3 Discussion on underground mining methods of phosphate ore

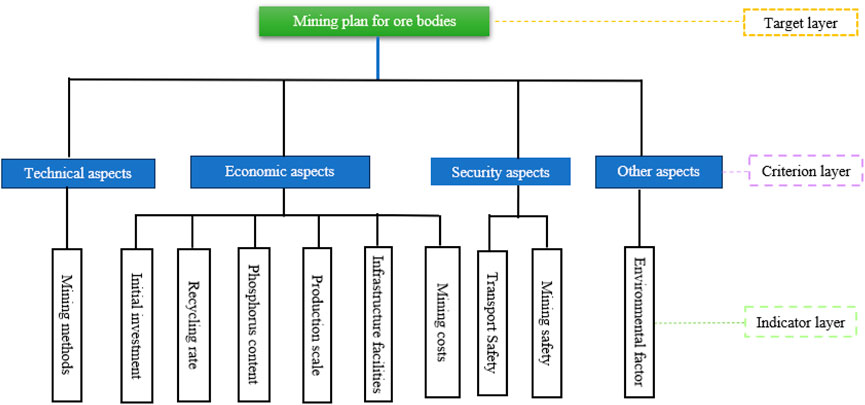

Drawing on the construction method and principles of the evaluation index system for mining plans, a theoretical system evaluation index system is formulated, taking into account factors such as technology, economy, safety, and other relevant aspects. The 10 most influential sub-factors are carefully selected to construct the evaluation index system for Kunyang Phosphate Mine No. 2’s mining plan, visualized in Figure 1. The resulting system provides a thorough and rigorous representation of the relevant influencing factors of the mining plan.

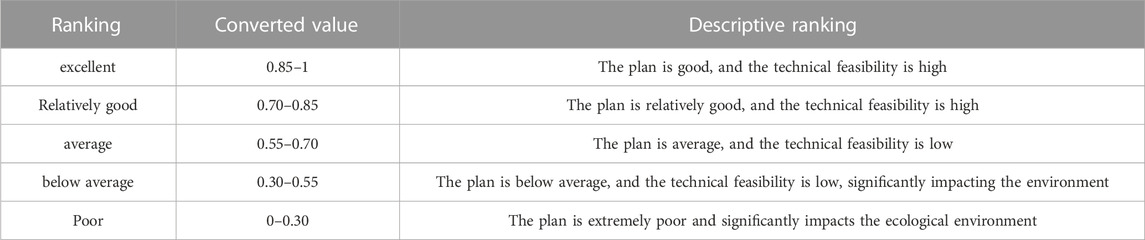

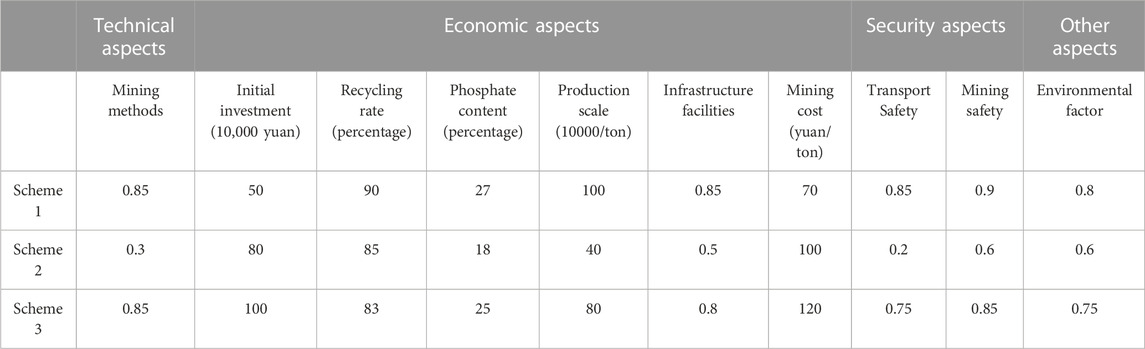

In all the evaluation index systems, certain aspects such as mining method, infrastructure facilities, transportation safety, mining safety, environmental factors, and others cannot be precisely quantified with numerical values. These factors fall under qualitative indicators. To address these concentrated influencing factors, Kunyang Phosphate Mine No. 2 sought the expertise of specialists to classify the specific plans based on the on-site engineering geological conditions and engineering background, as presented in Table 1. The optimal selection levels are categorized as follows: excellent, relatively good, average, below average, and poor.

4 Comprehensive evaluation and analysis method based on entropy weight TOPSIS method

The TOPSIS method ranks a limited number of evaluation objects by measuring their proximity to an idealized goal. It allows for the assessment of relative strengths and weaknesses among existing objects. This sorting method generates solutions that approximate to the ideal, while concurrently ensuring that each utility function exhibits monotonic properties of increase (or decrease). The TOPSIS method is widely employed as an effective approach in multi-objective decision analysis, often referred to as the distance between superior and inferior solutions (Huang et al., 2014).

4.1 Establishment of evaluation indicators for deep ore body mining

Drawing from the investigation of mining methods for deep ore bodies, the primary technical evaluation indicators (mining methods) are established. Additionally, economic evaluation indicators encompass aspects such as initial investment, resource recovery rate, phosphate content, production scale, infrastructure, and mining costs. Safety considerations encompass transportation safety and mining safety. Furthermore, the evaluation encompasses four aspects and ten indicators, including other factors related to the environment.

Step 1. Establishing an Initial Evaluation Index Matrix.

To begin with, we need to create an initial evaluation index matrix. Let’s assume that there are

Step 2. Normalize the initial matrix.

To normalize the indicator matrix, the difference between each indicator value

Positive indicator value: The greater the corresponding indicator parameter, the higher the feasibility of the solution.

Negative indicator value: A higher value of the corresponding indicator parameter indicates greater solution feasibility.

Step 3. Calculate the proportion of initial indicator values.

To obtain the processed indicator

Step 4. Calculate the information entropy

Step 5. Calculate the weights of each indicator

Step 6. Constructing a weighted matrix involves multiplying

Step 7. To find the optimal and worst solutions for each indicator, establish a positive ideal solution vector denoted as

Step 8. : Calculate the distance

In the formula,

Step 9. Calculate the relative proximity

Step 10. Scheme optimization. The greater the relative closeness

5 Optimization of phosphate mining methods

There are three plans for mining the ore body of Kunyang Phosphate Mine No. 2. The first Scheme focuses solely on surface mining. Scheme 2 involves open-pit deep mining, while Scheme 3 involves underground mining. The discussion will address technical aspects, economic aspect, safety aspect, and other relevant aspects.

Scheme 1: From a mining method perspective, surface mining adopts open-pit bench mining. Based on the on-site data, the initial investment in certain mining areas of Kunyang No. 2 Phosphate Mine amounts to 500,000 yuan. The stripping amount in surface mining is significant initially but gradually decreases over time. The recycling rate for surface mining stands at approximately 90%. According to geological exploration results, the phosphate rock content during the surface mining period is 27%, with a production scale of 1 million tons. In terms of infrastructure, a comprehensive production, living, and fire water supply and drainage system, along with the corresponding configuration workshops and various equipment factories, have been established. The cost of surface mining is relatively low in the early stage, but as the mining progresses, the price significantly increases, averaging around 70 yuan/ton. Regarding safety, surface mining poses the least risk compared to open-pit deep mining and underground mining. Due to the thin overburden of open-pit phosphate rock, there is no need for underground mining or open-pit bottom mining, resulting in the lowest mining risk. Additionally, surface mining has the most negligible impact on the surrounding geological environment compared to the other two mining methods.

Scheme 2: Open-pit deep mining is an alternative approach to convert open-pit mining into underground mining. Initially, open-pit deep mining shares many advantages with surface mining. However, as the mining progresses more profoundly into the underground, it leads to high and steep open pit slopes, gradually losing various vital parameters. The open-pit deep concave mining method still employs open-pit bench mining. Considering the current mining situation of Kunyang Phosphate Mine No. 2, the initial investment in certain mining areas for open-pit deep concave mining amounts to 800,000 yuan, and the maintenance cost in the later stages gradually increases compared to underground mining. Nevertheless, on the whole, the initial investment for underground mining is lower. The open-pit deep mining of Kunyang Phosphate Mine No. 2 has formed a 300 m high and steep open-pit slope, yet the recycling rate remains high, reaching around 85%. However, due to the depletion of high-content phosphorus ore beds through surface mining, the deep-buried phosphorus ore content is only 18%. The production scale of certain mining areas is 400,000 tons, which falls short of meeting the demands of both the enterprise’s development and society. Moreover, as the mining depth increases, the mining cost gradually rises, reaching approximately 100 /ton. Regarding safety, Regarding mining poses significant challenges in transportation due to increased distances and narrower working faces. This leads to extremely difficult transportation processes, especially during the rainy season when transportation safety accidents are more likely. Additionally, the high and steep slopes formed in the open pit become increasingly challenging to control (Song et al., 2010; Li B. et al., 2015; Lan, 2023), which also affects the mining factor of safety, gradually increasing the risks involved (Cai and Yang, 2018; Li W. Q. et al., 2023; Wang G. et al., 2023). Furthermore, the environmental impact of open-pit deep mining is primarily observed in aquifers and impermeable layers. It can cause damage to the original aquifer, resulting in the formation of a depression funnel centered around the mine pit (Zhang et al., 2021; Li, 2022; Zou et al., 2022). This phenomenon would accelerate the groundwater flow, deplete groundwater reserves, and cause a subsequent decline in water levels, ultimately resulting in nearby wells and springs drying up. Additionally, the large areas of exposed land that form would have significant adverse impacts on the surrounding geological environment.

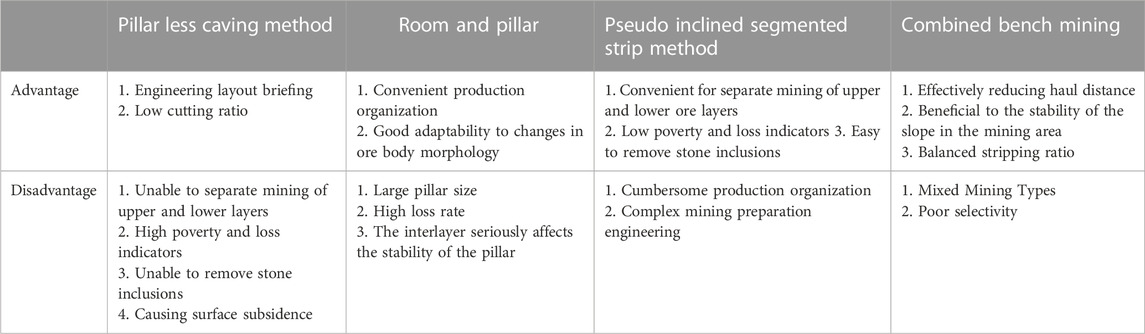

Scheme 3: Undertake underground mining, representing the final approach for transitioning from open-pit to underground mining. Through the optimization of mining methods, three main types of underground mining methods have emerged: bottomless pillar caving method (He et al., 2022; Wu et al., 2023; Yang et al., 2023), room pillar method (Jia et al., 2021; Huang et al., 2022; Wang et al., 2022), and pseudo inclined strip approach with subsequent filling method (Bin, 2016; Jin et al., 2017; Zeng et al., 2022). Following thorough feasibility research, it has been determined that the pseudo-inclined segmented strip mining method boasts numerous advantages and demonstrates a higher level of mining technology maturity. This method suits ore bodies with dip angles ranging from 2° to 31°. A comparison of the advantages and disadvantages of these four mining methods can be found in Table 2.

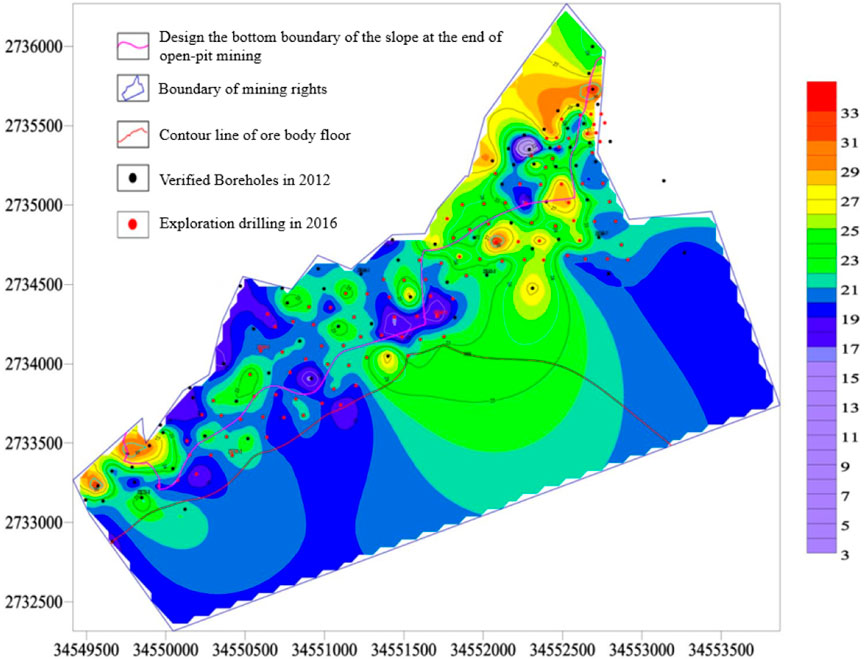

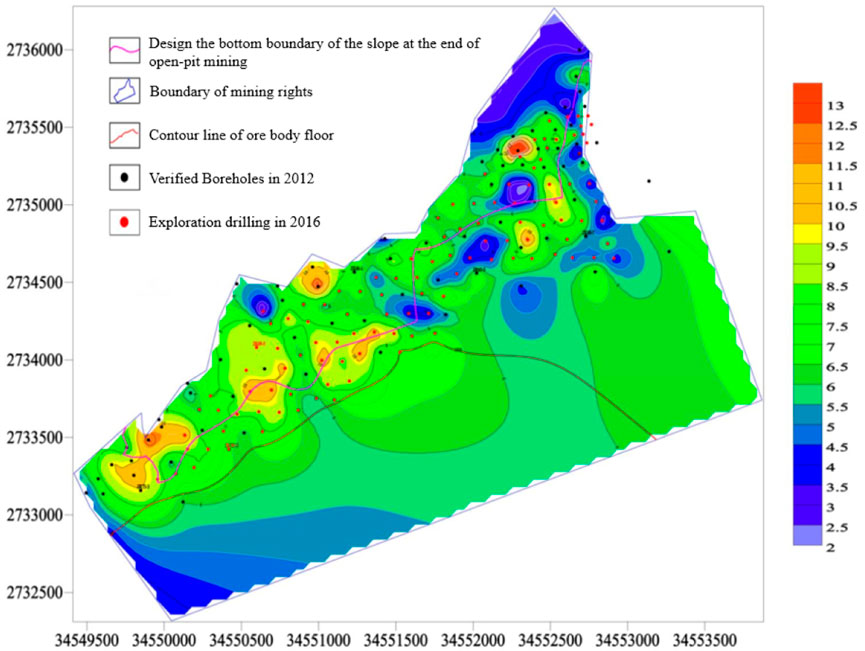

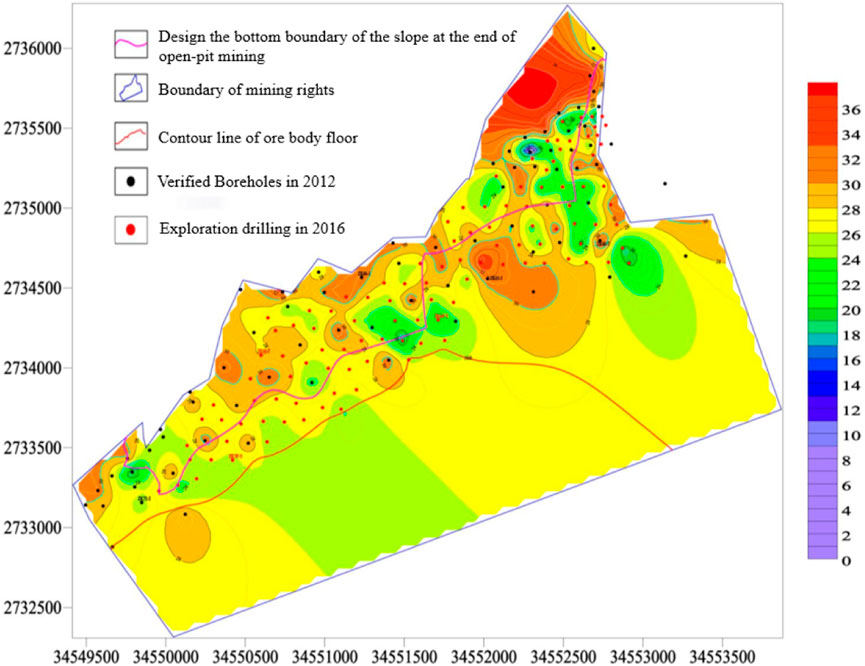

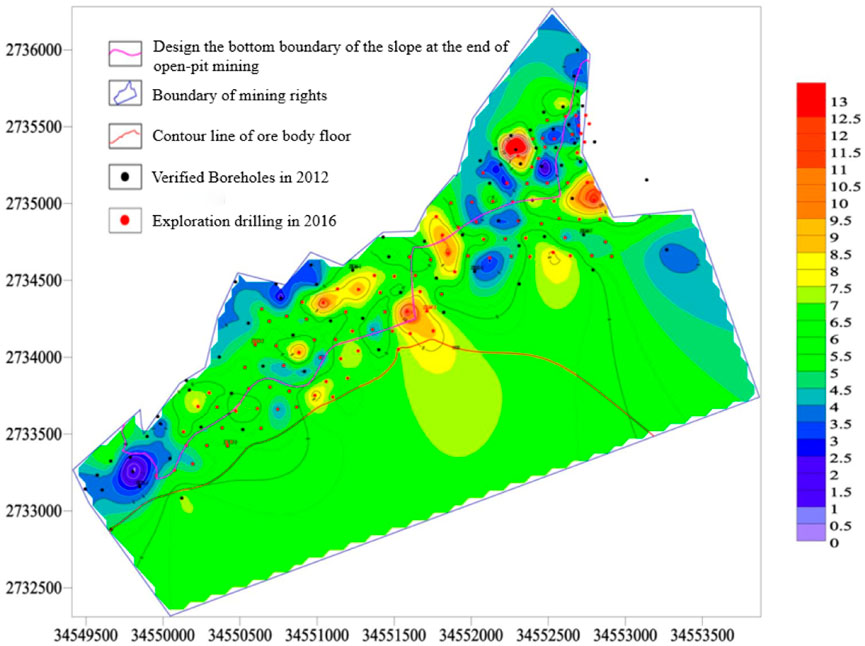

When compared to open-pit mining and open-pit deep concave mining, underground mining presents a higher initial investment cost. In certain mining areas, the initial investment can reach as high as 1 million yuan. However, due to limitations imposed by underground stops, the recycling rate is slightly lower at 83%, with a dilution rate of 6%. Despite this, the phosphorus content in the underground phosphorus ore layer is relatively high, with an average P205 content of approximately 25% in both the upper and lower layers. The phosphorus content contour map and thickness contour map of the upper and lower layers can be seen in Figures 2–5.

The production scale of underground mining in Kunyang Phosphate Mine No. 2 reaches 800,000 tons annually. To facilitate underground mining operations, a comprehensive set of production, living, fire water supply, drainage systems, and power supply infrastructure for production and living was established during the surface mine period. These systems effectively cover the entire mining area, ensuring efficient and reliable support for underground mining activities.

A flotation plant with a yearly capacity of 4.5 million tons has been constructed on the west side of the mine. This plant is approximately 3 km from the mining area and benefits from a relatively short surface transportation distance for the ore. Based on the data obtained from phosphorus mines, underground mining costs are estimated to be 120 yuan per ton. In terms of safety, underground mining at Kunyang Phosphate Mine No. 2 presents several advantages. The shorter transportation distance eliminates the requirement for long-distance transportation, thereby enhancing safety precautions. Additionally, adopting the cantilever-type road header excavation method in underground mining significantly enhances the safety factor and reduces mining risks. Furthermore, the waste rock generated during underground mining is repurposed as solid waste-filling material, thereby minimizing the transportation process.

In addition, underground mining imposes less damage on the environment. Since the entire process takes place underground, there is no need to clear large amounts of vegetation. In contrast to open-pit mining and deep concave mining, underground mining does not necessitate rehabilitation of damaged areas, thus mitigating the harm inflicted upon the ecological environment (Li et al., 2022; Zhang and Xing, 2022; Li X. S. et al., 2023; Feng, 2023).

6 Entropy weighted TOPSIS method evaluation

6.1 Acquisition and processing of indicators

Based on the current mining conditions of the mine, a comprehensive evaluation is conducted, utilizing ten key indicators derived from technical, economic, safety, and other pertinent aspects. The specific details regarding the selected data can be found in Table 3.

Normalize the initial indicators by assigning negative values to the initial investment and mining cost while designating the remaining indicators as positive. The resulting normalized matrix is as follows:

Using Matlab software, the information entropy

According to Table 4, it can be observed that the economic and safety indicators carry the highest weight in deep ore body mining. This signifies that the mining direction is primarily determined by considerations of economic feasibility and safety. Mining is related to the core interests of enterprise development, and it is necessary to ensure the safety of mining while ensuring maximum efficiency. Therefore, these two aspects have high indicator weights.

6.2 Calculating positive and negative ideal distances and relative distances

Construct the weighted matrix

Positive ideal solution vector

Negative ideal solution vector

Calculate the positive ideal distance

Table 5 displays the positive and negative ideal distances as well as the relative proximity derived from equations (8–10).

By utilizing formulas 8, 9, and 10, the positive ideal distances

7 Conclusion

This study focuses on the Kunyang Phosphate Mine No. 2 operated by Yunnan Phosphate Group Co., Ltd. It aims to ascertain the future development direction of the mine, whether it should continue with open-pit deep mining or transition to underground deep ore body mining once the open-pit mining is finished. To explore the most suitable mining method for deep ore bodies in Kunyang Phosphate Mine, the entropy weighted TOPSIS method is employed in this article, leading to the following conclusions.

1) The selection of mining methods, including surface mine mining, open-pit deep mining, and underground mining, for extracting deep ore bodies is closely tied to the overall development prospects of the mine and the interests of the enterprise. The study employs the entropy weight TOPSIS method to evaluate these three mining approaches. A comprehensive set of 10 indicators covers technical, economic, safety, and other aspects. These indicators include the mining method, initial investment, recycling rate, phosphate rock content, production scale, infrastructure facilities, mining cost, transportation safety, and environmental factors.

2) The optimal mining plan is determined by calculating the positive and negative ideal distances

Considering the above factors, it is necessary for Kunyang Phosphate Mine No. 2 to mine deep ore bodies, which can meet society’s current production and living needs and play an important role in environmental protection. Adopting the entropy weight TOPSIS entropy weight method and selecting economic parameters in actual mining production can accurately display the production situation of the mine, and can transform qualitative indicators in mining production into quantitative analysis, using mathematical methods to select the optimal mining method. The use of entropy weighted TOPSIS can analyze various indicators in the mining industry, such as selecting the optimal underground mining method, optimal underground drainage scheme, optimal underground ventilation scheme, and other most reasonable and safe schemes, with a relatively close degree

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

DH: Writing–review and editing. MX: Writing–original draft. XL: Conceptualization, Writing–review and editing. JW: Data curation, Writing–review and editing. MW: Investigation, Writing–review and editing. SL: Supervision, Writing–review and editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. The research work was funded by the Research Fund of National Natural Science Foundation of China (NSFC) (Grant No. 42277154), the project of Slope safety control and disaster prevention technology innovation team of “Youth Innovation Talent Introduction and Education Plan” of Shandong Colleges and universities [Grant No. Lu Jiao Ke Han (2021) No. 51]; Guizhou Province Science and Technology Planning Project [Grant No. Guizhou science and technology cooperation support (2022) common 229], National Natural Science Foundation of Shandong Province of China (NSFC) (Grant No. ZR2022ME188), Jinan City “new university 20” research leader studio project (Grant No. 20228108), The State Key Laboratory of Coal Resources and safe Mining, CUMT (SKLCRSM22KF009), and Open Fund of National Engineering and Technology Research Center for Development and Utilization of Phosphate Resources of China (Grant No. Funded the research work NECP 2022-04) and the Open Fund of Key Laboratory of Geological Hazards on Three Gorges Reservoir Area (China Three Gorges University), Ministry of Education (Grant No. 2022KDZ07).

Conflict of interest

Authors MX, MW, and SL were employed by the Yunnan Phosphating Group Co., LTD.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bin, T. (2016). The application of pseudo-inclined arrangement in mining methods in gently inclined thin ore bodies. Eng. Constr. 48 (03), 33–36+78. doi:10.13402/j.gcjs.2016.03.007

Cai, B. T., and Yang, Y. (2018). Identification and evaluation of disaster Hazards in the waste dump of Kunyang phosphate mine. Nonferrous Metallurgical Des. Res. 39 (06), 8–11. doi:10.16663/j.cnki.lskj.2021.12.069

Chen, F., Yang, Y., and Chen, Y. (2019). The selection of transportation technology scheme for large-scale deep open pit mine development. Min. Metallurgy 28 (05), 27–31.

Chen, R. H., and Han, Z. C. (2021). Analysis of environmental geological problems in Kunyang phosphate mine. Yunnan Green Technol. 23 (12), 196–198.

Du, M., Wang, F. J., Zhang, Z. F., Zhang, X. K., and Fu, S. J. (2022). Prevention and control measures for geological disasters in mining. World Nonferrous Met. 611 (23), 214–216.

Feng, P. (2023). Ecological restoration plan for backfilling to the boundary area of fushun west open pit mine. Open Pit. Min. Technol. 38 (01), 90–92. doi:10.13235/j.cnki.ltcm.2023.01.024

Gong, X. L. (2022). The main problems and countermeasures of deep mining in underground mining. China Metal. Bull. 03, 16–18.

He, H. M. (2022). Comprehensive utilization of phosphate ore resources and exploration of new process technologies. Phosphate Compd. fertilizers 37 (08), 34–36.

He, R. X., Chen, L. Y., and Ren, F. Y. (2022). Research status and development direction of loss and dilution in China's pillarless sublevel caving method. Metal. Mines 577 (11), 1–9. doi:10.19614/j.cnki.jsks.202211001

Huang, J., Li, S. J., Xia, Y. Y., Wang, M. L., Zhang, B., and Liu, Y. H. (2022). Research on underground mining methods for gently inclined medium thick ore bodies in Kunyang Phosphate Mine No. 2. Mod. Min. 38 (07), 45–50+55.

Huang, Y. Y., Wei, X., Su, J. Y., Yang, L. H., and Chen, W. C. (2014). A comprehensive evaluation of groundwater using entropy weight TOPSIS method in Matlab. J. Earth Environ. 5 (04), 261–265.

Jia, J. K., Zhen, L. B., and Cai, Y. (2021). Research on optimization of structural parameters of mining stopes using room and column method. Min. Res. Dev. 41 (11), 5–9. doi:10.13827/j.cnki.kyyk.2021.11.002

Jin, J. R., Zhang, F. G., Tang, M. W., Yang, Z. B., Zheng, Z., Tang, T., et al. (2017). Experimental research and application of panel mechanized pseudo tilt slice mining method. Gold 38 (07), 33–39.

Lan, Y. (2023). Analysis and treatment of high and steep slope stability in open pit dump based on numerical simulation. Min. Res. Dev. 43 (03), 77–82. doi:10.13827/j.cnki.kyyk.2023.03.029

Li, B., Yang, Z. Q., and Gao, Q. (2015b). Numerical analysis of the impact of deep pit open-pit to underground mining on the stability of high and steep slopes. Min. Res. Dev. 35 (02), 65–68. doi:10.13827/j.cnki.kyyk.2015.02.016

Li, C. Z. (2022). Optimization of waterproofing and drainage system for the bottom water pump room of Xiaolongtan open-pit mine. Open Pit. Min. Technol. 37 (02), 37–39+43. doi:10.13235/j.cnki.ltcm.2022.02.010

Li, W. C., Zhang, B., and Li, W. (2022). Ecological restoration technology for Yimin open-pit mine. Open Pit. Min. Technol. 37 (05), 82–85. doi:10.13828/j.cnki.ckjs.2023.01.019

Li, W. Q., Chen, M., and Kou, X. Y. (2023a). Stability analysis and landslide prevention measures for open-pit mine waste dump. Min. Technol. 23 (01), 59–61. doi:10.1016/j.ijmst.2023.07.009

Li, X. S., Li, Q. H., Wang, Y. M., Liu, W., Hou, D., Zheng, W. B., et al. (2023b). Experimental study on instability mechanism and critical intensity of rainfall of high-steep rock slopes under unsaturated conditions. Int. J. Min. Sci. Technol. 2023. doi:10.1016/j.ijmst.2023.07.009

Li, Y. J., Li, X. S., and Wang, M. L. (2015a). Research on filling and mining technology for gently inclined thin to medium thick phosphorus ore bodies with soft interlayers. Nonferrous Met. Min. Part. 67 (01), 11–14.

Liu, J. Y., Shi, J., Liu, Z. H., Wu, J., and Shuang, W. N. (2023). Optimization of mining process and equipment layout in Huolin Hebei open-pit mine. Open Pit. Min. Technol. 38 (01), 72–75+78. doi:10.13235/j.cnki.ltcm.2023.01.019

Shen, D. Y., and Ning, G. J. (2022). Discussion on hydrogeological characteristics and water prevention and control in inclined shaft engineering of Kunyang Phosphate Mine No. 2. China Min. Eng. 51 (01), 86–89. doi:10.19607/j.cnki.cn11-5068/tf.2022.01.008

Song, W. D., Du, J. H., Yang, X. C., and Tennant, D. D. (2010). Deformation and failure patterns of high and steep slopes in deep concave open-pit to underground mining. J. Univ. Sci. Technol. Beijing 32 (02), 145–151. doi:10.13374/j.issn1001-053x.2010.02.002

Sun, G. Y. (2021). Exploration of mining technology for deep open pit mines technology and innovation. Min. Industry Future 02, 155–156. doi:10.15913/j.cnki.kjycx.2021.02.060

Wang, G., Zhang, J., Cao, F. Z., Huang, C., and Wei, Z. Q. (2023b). Research on key technologies for ecological restoration of open pit dumps in the northern region. Energy Energy Conservation 209 (02), 108–111. doi:10.16643/j.cnki.14-1360/td.2023.02.048

Wang, J., Li, M., and Zheng, S. H. (2023a). Research on the conversion of open-pit to underground mining technology for a certain iron mine. Min. Eng. 21 (04), 16–19. doi:10.16672/j.cnki.kygc.2023.04.007

Wang, M. L., Li, X. S., Wang, Y. M., and Li, Q. H. (2022). Study on the stability of the stope under disturbance during open-pit to underground pillar mining. Min. Metallurgical Eng. 42 (02), 32–37.

Wei, G. D., Zhen, D. S., and Liu, Z. Y. (2022). Exploration of mining technology and safety in open pit mining. Inn. Mong. Coal Econ. 345 (04), 97–99. doi:10.13487/j.cnki.imce.021798

Wu, F. F., Wang, J. X., Liu, J. T., Zeng, G. P., Xiang, P., Hu, P., et al. (2021). The distribution, characteristics, and development status of phosphate rock. Geol. China 48 (01), 82–101.

Wu, T., Cao, P., and Lu, Z. X. (2023). The influence of roadway width on the stability of surrounding rock in pillarless sublevel caving method. Metal. Mines 2023, 1–12.

Wu, Y. J., and Tang, S. A. (2022). Analysis and research on geological disasters caused by mining. China Metal. Bull. 1070 (06), 23–25.

Yang, Y., Zhang, Z. Q., Shi, Y. B., and Yang, W. Q. (2023). The influence of different mining sequences on the ore drawing effect of nonpillar sublevel caving method. Min. Res. Dev. 43 (01), 1–7. doi:10.13827/j.cnki.kyyk.2023.01.005

Zeng, J. L., Zhou, Y., Gao, X., He, B. L., Guo, H. Q., Liu, Q., et al. (2022). Stability analysis of the stope using pseudo inclined segmented strip filling mining method. Min. Technol. 22 (04), 107–111. doi:10.13828/j.cnki.ckjs.2022.04.052

Zhang, T., Li, P., and Ye, X. C. (2021). Analysis of water filling factors and prediction of water inflow in the open pit of huayangchuan uranium niobium lead polymetallic mine. Groundwater 43 (05), 40–42. doi:10.19807/j.cnki.DXS.2021-05-013

Zhang, X., and Xing, E. D. (2022). Research on comprehensive management measures for ecological restoration of open pit ash storage yard. Inn. Mong. Water Conserv. 243 (11), 15–17.

Zhao, Y. F., Li, W. C., and Wang, H. J. (2021). Current situation and reflection on the development and utilization of phosphate. Mineral Resour. China Industrial Innovation Res. 69 (16), 62–63+69.

Keywords: engineering background, phosphate mining, scheme optimization, quantification of indicators, mining plan

Citation: Hou D, Xu M, Li X, Wang J, Wang M and Li S (2023) Optimization of mining methods for deep orebody of large phosphate mines. Front. Built Environ. 9:1282684. doi: 10.3389/fbuil.2023.1282684

Received: 24 August 2023; Accepted: 02 October 2023;

Published: 13 October 2023.

Edited by:

Hamid Rajabi, University of Liverpool, United KingdomReviewed by:

Roberto Alonso González-Lezcano, CEU San Pablo University, SpainMohammad Masud Noruzi, University of Liverpool, United Kingdom

Copyright © 2023 Hou, Xu, Li, Wang, Wang and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jiawen Wang, MjYwMTQzNzc0MEBxcS5jb20=; Xiaoshuang Li, eHNsaTIwMTFAMTI2LmNvbQ==

Di Hou1

Di Hou1 Mengchao Xu

Mengchao Xu Xiaoshuang Li

Xiaoshuang Li Jiawen Wang

Jiawen Wang