- 1BASIS.ed Texas, Pflugerville, TX, United States

- 2Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), Lawrence Berkeley National Laboratory, Emeryville, CA, United States

- 3Biological Systems and Engineering Division, Lawrence Berkeley National Laboratory, Berkeley, CA, United States

- 4Deconstruction Division, Joint BioEnergy Institute, Emeryville, CA, United States

- 5Department of Bioresource and Environmental Security, Sandia National Laboratories, Livermore, CA, United States

This article outlines the technical and economic potentials of lignin in unlocking sustainable biorefineries. The benefits of using this highly functionalized biopolymer for the growth of sustainable economy have been highlighted. But practically, the possibility of commercially substituting petroleum oil with lignin is still not very high as the estimated biofuel production cost is 2–3 times higher than the former one. However, with the advancement in technology and more efficient measures by biorefineries such as storing and processing the biomass near the field so as to reduce the transportation cost, it is possible to gain higher profits. Companies like Domtar, Stora Enso, Borregaard’s LignoTech, VITO, and Chemelot InSciTe have been promoting commercial value of lignin. The growth of lignin market after the start-up production at various sites has been discussed in this review. Combining the complete “start-to-finish” analysis with economic evaluation gives a pragmatic overview of the possibilities whether lignin will join petroleum oil as an efficient and cost-effective renewable source.

Introduction

The past decade has been quite interesting in terms of dealing with chemicals, energy and renewable resources—especially lignocellulosic biomass. The major raw materials for transportation, energy and chemicals in the latter half of the 20th century has been mainly the “crude” or “petroleum” oil. Processing crude oil has always been a chief task and technologies have been developing since 1860s for the same. Currently, several refineries/industrial plants have been developed that are highly advanced including hi-tech integrated devices (Babich and Moulijn 2003; Rana et al., 2007). Due to limited technical maturity of lignocellulosic biomass-based processes thus far, the chemical industries were obligated to depend on petroleum, coal, or natural gas feedstocks as the carbon source to produce nearly 90% carbon containing plastics, paints, adhesives, fertilizers, pesticides, among others. The reliance on fossil fuel to accomplish every single need of the modern industrialized society could be attractive until “peak-oil” is reached, as indicated by Hubbert’s in 1956 that the petroleum oil will not last forever (Hubbert 1956; Sorrell et al., 2010; Aleklett et al., 2010; de Almeida and Silva 2009). Studies have anticipated over 60% energy demand by 2030 owing to the increasing world population (Kumarasamy et al., 2017). This raises an alarming question of how are we going to meet this additional energy requirement when we have already been struggling with depleting fossil fuel resources today? In order to meet these huge energy requirements throughout the world, nearly 85 million barrels of crude oil is being processed currently, which are expected to increase to 116 million barrels in the next decade (IEA 2007). It is only after the public awareness about the depletion of crude oil reserves that federal agencies around the globe paid significant attention to find substitutes for fossil fuels (Maggio and Cacciola 2012). This change is highly imperative for the development of sustainable economy. In order to achieve this target, “biorefineries” are envisaged as highly significant since they convert biomass into biodiesel, bioethanol, and value-added chemicals (Sun and Cheng 2002; Kiss et al., 2006). So, is it true that we are shifting gears from petroleum refineries to biorefineries? This move towards biorefineries is “born from necessity” as we did not have many options but to switch to alternative source of energy due to the limited available reserves of non-renewable sources. Worldwide, renewable resources contributed to nearly 19% of the total energy consumption in 2014 (compared to ∼38%, 21%, 20%, and 2% from oil, coal, natural gas, and nuclear, respectively) and is expected to increase dramatically in the coming decades (World Bioenergy Statistics, 2017).

Remarkably, in this revolutionizing world, not only the growth of bio-economy (involving natural feedstocks) has been a great achievement, but also the society’s attitude towards the utilization of renewables such as lignocellulosic biomass as source of energy has changed significantly (UNECE, 2021). For instance, in contrast to the fossil resources, lignocelluloses have lower carbon footprints in addition to its abundance and rapid rate of growth under varied climatic conditions (Therasame, et al., 2022; Awosusi, et al., 2022, Hadj 2021). The holocellulosic component of lignocelluloses have been successfully converted into fuels and commodities, but lignin, on the other hand, has been underutilized (Tuck et al., 2012). In order to attain a sustainable bio-refinery, lignin must be processed and valorized through a biorefining process that is cost-effective and environment friendly (Zakzeski et al., 2010). Typically, bio-economy aims to (a) decrease dependency on fossil fuels that are non-renewable, (b) prevent deprivation of ecosystems, (c) promote economic development of the country, and (d) create new jobs.

Lignin: Emerging petroleum-substitute?

Lignin is an untouched natural gem—at least from the bio-economy point of view, representing about 10-35% of lignocellulose biomass consisting of various phenylpropanoids (aromatic building blocks), thereby a potential source of fuel, energy, and chemicals including pharmaceuticals, paints, and plastics (Dossier, 2017).

Lignin being a highly complex polymer with variable structures (like molecular weight distribution, chemical functionalities, etc. depending upon the biomass source and fractionation process), the valorization of lignin into value-added products is still challenging (Cateto et al., 2008; Sun et al., 2018). It is more reasonable and economical that instead of defunctionalizing lignin completely into fine chemicals, i.e., BTX (benzene, toluene and xylene), we should defunctionalize to alkanes, arenes, and mixture of products that together can be used as feedstocks for the production of chemicals and biofuels (Zmierczak and Miller 2006; Kleinert and Barth 2008). Its high abundance and wide opportunities for defunctionalization has motivated scientists to carry out extensive research into catalytic valorization of lignin and thereby developing economical methods for its use as a feedstock (Chio et al., 2019; Liao et al., 2020; Wener et al., 2020; Abu-Omar et al., 2021).

Valorization or processing of lignin is mainly targeted to obtain a product (either pure or mixture) that fits into a particular purpose, and the by-products obtained are regarded as residue. But this is not in accordance with the “atom economy” principle of Green Chemistry (Anastas and Warner, 1998), as no by-products should be left behind and the matter should be processed completely. Scarce information is available on the complete valorization of lignin and its by-products. Borges da Silva et al., 2009, anticipated that during the valorization of lignin into vanillin, its by-products can be utilized for the production of polyurethanes (de Almedia and Silva, 2009).

An understanding of all of the interconnected stages starting from the extraction of lignocellulose from its source (mainly trees), its transportation to the bio-refineries and finally the conversion of the initial biomass feedstock into intended lignin-derived product (with no by-products) is very important. In spite of the high potential of lignin to be used as an alternative to petroleum or crude oil, it can only be made commercially available if it is easily affordable by the common people. In this article, we aim to present an analysis on the potential of lignin as an emerging petroleum alternative and current efforts/hurdles in commercialization process.

Isolation of lignin

The isolation of lignin from lignocellulosic biomass is targeted from high lignin containing sources such as woody biomass, i.e., hardwoods and softwoods in the bio-refineries producing “biofuel” along with lignin (Strassberger et al., 2014; Abu-Omar et al., 2021). Most of the lignin is obtained as a by-product of the pulp and paper industry. Also, it is separated from linked wood components either by preferentially dissolving lignin or by preferentially dissolving non-lignin components (Glennie and McCarthy 1962). Several methods are employed for the purpose, such as, ball milling, milled wood lignin (MWL), Brauns or Native Lignin, Organosolv processes, etc. Chemical pulping is employed in order to separate native lignins from wood in the form of MWL. In this process, various by-products that possess industrial applications are also formed such as dioxane lignin and enzymically liberated lignin. Kraft, sulfite and soda-AQ pulping of wood yield Kraft lignin, lignosulfonates and soda lignin (or alkali lignin), respectively (Stenius 2000); the first two being the major lignin types available commercially. During the isolation of lignin from black liquor, carbon dioxide is used to reduce the pH of the liquor while precipitating lignin from the black liquor, followed by the addition of sulfuric acid (Tamminen at al., 1995). A brown amorphous lignin powder is obtained from such processes where the lignin structure, molecular weight, and color is process severity dependent. Low grade lignin production in 2010 by pulp and paper industry was estimated to be 50 MT (metric tons). Out of this, just 2% was pure enough for further commercial use, rest of the amount was employed to generate energy through combustion (Higson and Smith, 2011). The conversion of such lignin to value-added chemicals have been an Achilles’s heel but success stories utilizing lignin in the production of specialty or performance materials in terms of heat and water resistance, lower weight, higher durability and toughness and fire retardancy have been demonstrated by various ventures (Graichen et al., 2017).

Storage and transportation

The production of biofuels in biorefineries are economically unfeasible unless a maximum yield of fermentable sugars followed by maximum bioconversion is achieved (Periyasamy et al., 2018). Also, for the economic operation of a biorefinery, it is essential that it is located within 50 miles from the feedstock location. This is because the bulk density of biomass is very low and should not be stored at centers with high moisture content as the feedstock decomposes on exposure to the microbes present in the moisture (Audsley and Annetts 2003; Annetts and Audsley 2003; Baral et al., 2019). Keeping in view the continuous feedstock supply throughout the year, it becomes more reasonable if we store and process the biomass near the field (You and Wang 2011; Kurian et al., 2013). Transportation of the feedstock to the biorefinery becomes easier in this case since the field is very near and thus uninterrupted supply is possible. Such centers or facilities operated by farmers for processing the biomass are named as “regional biomass processing depots (RBPDs).” This concept was first given by the researchers at Michigan State University (Carolan et al., 2007) and then studied by the University of Tennessee Biofuel Initiative and benefited Dupont Cellulosic Ethanol (DCE) and the Idaho National Laboratory (INL) (Sharma et al., 2013). These RBPDs are not only storage centers for the feedstock, but also helps in creating new job opportunities and improvement of infrastructure in the rural areas. Biomass is mainly transported via trucks to the biorefinery located nearby. But this adds on to the overall production cost of the biofuel as nearly 88 trips per day will be required to achieve the target of 2,000 tons. Furthermore, transportation cost will increase with the increase in distance from the field (Sultana et al., 2010).

Cost reduction strategies

To gain market access, several developments have been carried out to cut short the processing cost and prove its credentials to compete with petroleum-based counterparts. One of the best strategies to gain wide-ranging economic benefits is by carrying out “genetic engineering.” It aims at reducing the energy intake for breaking down the biomass and thereby, making the whole process more cost-effective. Scientists at Scion, New Zealand, in collaboration with the University of Wisconsin, have successfully engendered pine trees genetically containing syringyl units (mostly occurring in hardwoods). These genetically engineered species now comprise more labile linkages in the lignin backbone, thus, making its processing far easier (Wagner et al., 2015). It has been reported that genetic reduction of lignin content successfully overcame the resistance of cell wall for bioconversion. The current prototype for the production of ethanol involves costly pretreatment of the biomass for making the cell walls easily accessible to enzymes. Whereas, the untreated genetically modified plants such as HCT and C3H alfalfa lines produced much higher amounts of sugar than those obtained from the natural plants after the pretreatment process (Hiroshi et al., 2009). Hence, such genetic manipulations in plants can be helpful in reducing the overall cost of biofuel production. Voelker et al., 2010 demonstrated the positive effects of lignin reduction practically by conducting field trials (Voelker et al., 2010). The authors synthesized a hybrid with lower lignin content in cell walls and high growth rate, thus, proving to be a worthy feedstock for pulp and paper industries. In view of this, it can be concluded that “genetic engineering” can be considered as a game changer in the way tress are cultivated for cost and energy reductions.

Commercial development

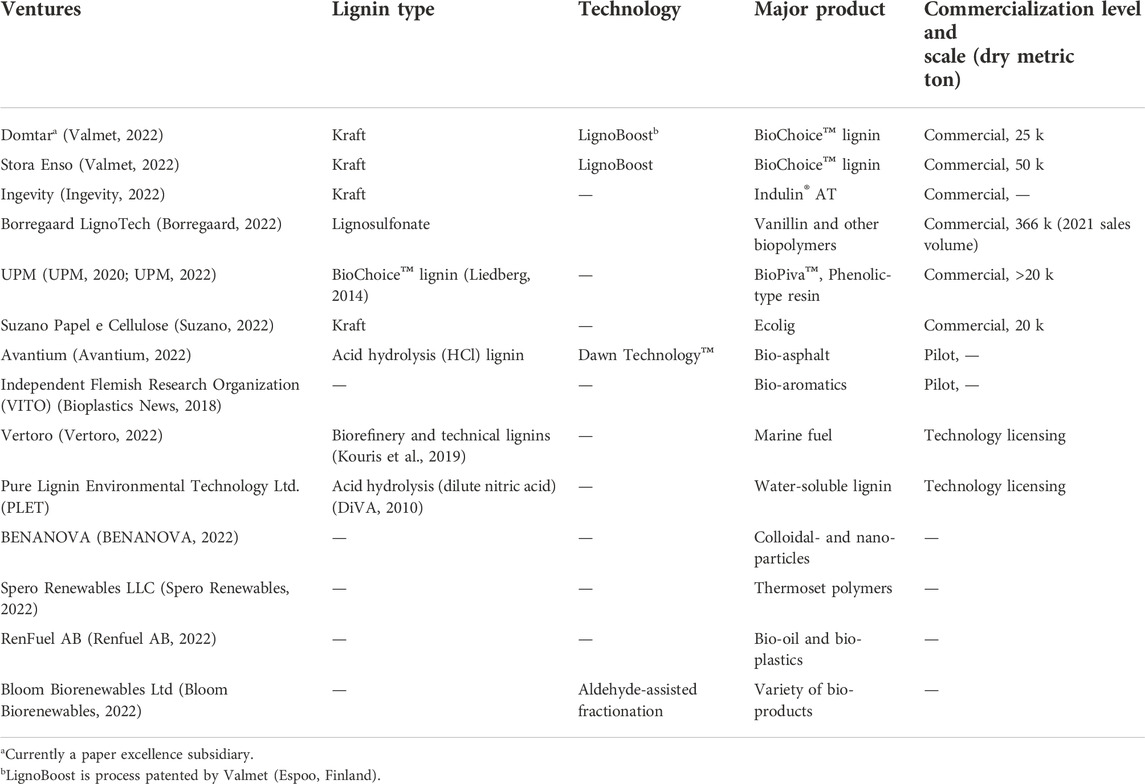

World’s first investigations into commercial development and application of lignin were performed in 1934 at Rothschild, Wisconsin, USA. After 1971, there was a significant increase in the sale of lignin, hence, new grades of purified lignin products started fabricating. Over the recent 10 years, the industry has observed several successful attempts in developing and expanding commercially relevant lignin processes. The world’s first large-scale lignin manufacturing plant started at Domtar’s Plymouth mill (NC, United States) in 2013, where LignoBoost®, a patented lignin extraction process, was employed in a kraft pulp mill is employed to produce high-quality lignin. This plant has an annual capacity of 25,000 MT of lignin along with 466,000 ADMT (Air Dry Metric Ton) of softwood kraft pulp from South Pinewood and now markets the lignin as BioChoice™ lignin (Björk et al., 2015). In 2015, the second LignoBoost® plant was deployed at Stora Enso’s Sunila mill (Kotka, Finland). Sunila plant has an annual capacity of 50,000 MT of lignin and produces 370,000 ADMT of bleached softwood Kraft pulp from pine and spruce. The existing lignin market has grown significantly since the start-up of lignin production at these sites. For example, UPM signed an agreement with Domtar to acquire all BioChoice™ lignin from Domtar’s Plymouth Mill (UPM, 2020). Most supply will be used for manufacturing UPM BioPiva™ products, which are substitutes to fossil-based phenol in phenolic-type resins (UPM, 2022). Borregaard’s LignoTech, a biorefinery operated in Norway for over 70 years, is an exclusive company where 90% of the woody biomass input exits as marketable products (Martin Lersch, 2009). It reported an annual sales of lignin-based products 366,000 metric tons in 2021 (Borregaard, 2022) including its flagship wood/lignin-based vanillin. Recently, Avantium (2022) demonstrated the use of its lignin product as asphalt, which is normally derived from crude oil, for road pavement. Vertoro, a spin-off of Chemelot InSciTe (Chemelot Institute for Science and Technology), developed a technology platform where lignin is processed into the form of “oil” (Kouris et al., 2019). Through partnering with companies such as Shell and Maersk, the oil will be hydro-processed and used as a fuel for boats and ships (InSciTe, 2017a; Vertoro, 2022). Pure Lignin Environmental Technology Ltd. (Kelowna, British Columbia, Canada) aims at producing superior grade lignin and cellulose from any biomass following a cost-effective strategy. The company produces a unique “water-soluble lignin,” which is now attracting customers worldwide (PLET 2012). A Belgium based company named VITO (Independent Flemish Research Organization) co-financed by the European Regional Development Fund (ERDF) aims to convert lignin and wood into bio-aromatics in close collaboration with Scion, a Crown Research Institute in New Zealand (Bioplastics News, 2018). It is worthwhile mentioning that more and more lignin is now available in the market with continuously improving technologies; some other start-up companies are not discussed here but listed in Table 1.

Large quantities of lignin are expected to be produced from paper and pulp industries in the coming years. According to the international lignin institute (ILI), about 40–50 million MT of lignin is being produced worldwide, currently (www.ili-lignin.com). But, in order to meet the ambitious goal of replacing 30% of fossil fuels with biofuel by 2030, this production should shoot up to 225 million MT (Sahoo et al., 2011). This is only possible if the biorefineries are able to successfully utilize the complete feedstock and convert all its components into value-added bioproducts (Gowen and Fong, 2011; Rabinovitch-Deere et al., 2013). The US Department of Agriculture (USDA) and the US Department of Energy (DOE) have made mandatory that by 2022, 20% of liquid transportation fuel, 5% of heat and power energy, and 25% of chemicals and materials should come from biomass (Perlack et al., 2005). However, achieving this target is highly challenging, as it is evident from the recent estimates of biofuel production cost which is 2–3 times higher than its petroleum/crude oil counterparts on an energy equivalent basis (Carriquiry et al., 2011). Yet, with the advancement in technology the total production cost is expected to decrease. Few measures must be followed by biorefineries in order to gain high profits. This includes producing high value products such as chemical precursors, human food or medicinal materials in low volume, managing their own needs and finally producing high volumes of low value products like animal feed and fuels (Balan 2014).

Conclusion

This review highlighted the need, potential, and emergence of underutilized biopolymer, i.e., lignin, since it is the nature’s prime reserve of functional groups and aromatics. Owing to its high abundance and functionalization, lignin can be considered as the best substituent in tomorrow’s energy, fuel and chemical sectors. Lignin can be used in diverse applications, depending on its original source and method of extraction. However, commercialization of the biofuel production for the economic development is still a challenge mainly because of its complex nature and scarce information on extraction protocols. Moreover, the bio-refining processes for the extracted of lignin are economically infeasible. In order to compete with the cost of petrol or diesel, energy efficient technologies must be employed to reduce the biofuel processing cost. Biorefineries should focus on the complete conversion of feedstock into valuable products. Based on public awareness and extraordinary efforts by companies like Borregaard LignoTech, VITO and Chemelot (InSciTe, 2017b), it looks like lignin-derived biofuel the market soon, though, some delay is also expected due to the challenges discussed in this paper.

Present and future scope

Inspite of the high natural abundance and polyaromatic nature, lignocellulosic biomass is still not a commercially available feedstock for biofuel production. Methods for the extraction and purification of lignin are complex and expensive, consequently, cannot be employed at large-scales. The advancement in technology along with intensive collaboration among teams of different disciplines such as catalysis, chemical engineering and processing, analytics, etc. and boundaries is the key to solving problem. Big companies should establish commercial grade biorefineries that could produce several million gallons of fuel per year. The location of the biorefinery is very important for the economic transportation of the feedstock. In the coming years, biorefineries can be designed to utilize energy from renewable resources like solar, wind and geothermal, or we can even collocate them near thermal plants (coal or nuclear). This will help in preserving other non-renewable sources of energy such as natural gas. In view of above discussion about the pros and cons of using a sustainable biofuel, should not lignin be given the same chance as petroleum or crude oil?

Licenses and permission statement

The United States Government and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. Sandia National Laboratories is a multi-mission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy's National Nuclear Security Administration under contract DE-NA0003525 (SAND No. SAND2022-15460 J).

Author contributions

HC and BAS conceptualized; VJ wrote the original draft; All authors edited the manuscript.

Funding

This work was part of the DOE Joint BioEnergy Institute (https://www.jbei.org) supported by the U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research, through contract DE-AC02-05CH11231 between Lawrence Berkeley National Laboratory and the U.S. Department of Energy.

Author Disclaimer

The views expressed in the article do not necessarily represent the views of the DOE or the U.S. Government.

Acknowledgments

ABPDU would also like to thank the support from The Bioenergy Technologies Office (BETO) within the US DOE's Office of Energy Efficiency and Renewable Energy. Authors also thank Xiao Jiang of North Carolina State University in scouting the lignin technologies.

Conflict of interest

Author SS and HC were employed by company Sandia National Laboratories.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abu-Omar, M. M., Bara, K., Beackham, G. T., Luterbacher, J. S., Ralph, J., Rinaldi, R., et al. (2021). Guidelines for performing lignin-first biorefining. Energy Environ. Sci. 14, 262–292. doi:10.1039/d0ee02870c

Aleklett, K., Jakobsson, K., Lardelli, M., Snowden, S., and Soderbergh, B. (2010). The peak of the oil age – analyzing the world oil production reference scenario in world energy outlook. Energy Policy 38, 1398–1414. doi:10.1016/j.enpol.2009.11.021

Anastas, P. T., and Warner, C. J. (1998). Green Chemistry: Theory and practice. Oxford University Press.

Annetts, J. E., and Audsley, E. (2003). Modelling the value of a rural biorefinery—part II: Analysis and implications. Agric. Syst. 76, 61–76. doi:10.1016/s0308-521x(02)00039-2

Audsley, E., and Annetts, J. E. (2003). Modelling the value of a rural biorefinery—part I: The model description. Agric. Syst. 76, 39–59. doi:10.1016/s0308-521x(02)00038-0

Avantium, (2022). Dawn technology. Available at: https://www.avantium.com/technologies/dawn/(Accessed: October 28, 2022).

Awosusi, A. A., Adebayo, A. A., Altuntas, M., Agyekum, E. B., Zawbaa, H. M., and Kamel, S. (2022). The dynamic impact of biomass and natural resources on ecological footprint in brics economies: A quantile regression evidence. Energy Rep. 8, 1979–1994. doi:10.1016/j.egyr.2022.01.022

Babich, I. V., and Moulijn, J. A. (2003). Science and technology of novel processes for deep desulfurization of oil refinery streams: A review. Fuel 82, 607–631. doi:10.1016/s0016-2361(02)00324-1

Balan, V. (2014). Current challenges in commercially producing biofuels from lignocellulosic biomass. ISRN Biotechnol., 463074. doi:10.1155/2014/463074

Baral, N. R., Sundstrom, E. R., Das, L., Gladden, J. M., Eudes, A., Mortimer, J. C., et al. (2019). Approaches for more efficient biological conversion of lignocellulosic feedstocks to biofuels and bioproducts. ACS Sustain. Chem. Eng. 7 (10), 9062–9079. doi:10.1021/acssuschemeng.9b01229

Bioplastics News (2018). Belgium will build plant to convert lignin and wood into bio-aromatics. Available at: https://bioplasticsnews.com/2018/07/29/belgium-pilot-plant-convert-lignin-wood-bio-aromatics/(Accessed October 28, 2022).

BENANOVA (2022). BENANOVA - Benign innovations. Available at: https://benanova.com/ (Accessed October 28, 2022)

Björk, M., Rinne, J., Nikunen, K., Kotilainen, A., Korhonen, V., Christiansen, G., et al. (2015). “Valmet, Important lessons learned during the commercialization of the LignoBoost process,” in International Bioenergy and Bioproducts Conference, Atlanta, GA, October 28–30. Available at: https://www.valmet.com/media/articles/up-and-running/new technology/PEERS1stLignoBoostPlants/.

Borges da Silva, E. A., Zabkova, M., Araújo, J. D., Cateto, C. A., Barreiro, M. F., an Belgacem, M. N., et al. (2009). An integrated process to produce vanillin and lignin-based polyurethanes from Kraft lignin. Chem. Eng. Res. Des. 87, 1276–1292. doi:10.1016/j.cherd.2009.05.008

Borregaard, (2022). 2nd quarter 2022 results - borregaard. Available at: https://www.borregaard.com/investors/ir-news/2nd-quarter-2022-results/(Accessed: October 28, 2022).

Carolan, J. E., Joshi, S. V., and Dale, B. E. (2007). Technical and financial feasibility analysis of distributed bioprocessing using regional biomass pre-processing centers. J. Agric. Food Ind. Organ. 5 (2), 1–29. doi:10.2202/1542-0485.1203

Carriquiry, M. A., Du, X., and Timilsina, G. R. (2011). Second generation biofuels: Economics and policies. Energy Policy 39, 4222–4234. doi:10.1016/j.enpol.2011.04.036

Cateto, C. A., Barreiro, M. F., Rodrigues, A. E., Brochier-Salon, M. C., Thielemans, W., and Belgacem, M. N. (2008). Lignins as macromonomers for polyurethane synthesis: A comparative study on hydroxyl group determination. J. Appl. Polym. Sci. 109, 3008–3017. doi:10.1002/app.28393

Chio, C., Sain, M., and Qin, W. (2019). Lignin utilization: A review of lignin depolymerization from various aspects. Renew. Sustain. Energy Rev. 107, 232–249. doi:10.1016/j.rser.2019.03.008

de Almeida, P., and Silva, P. D. (2009). The peak of oil production--Timings and market recognition. Energy Policy 37, 1267–1276. doi:10.1016/j.enpol.2008.11.016

DiVA (2010). Available at: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1308186&dswid=5491 (Accessed: October 28, 2022).

Dossier, (2017). Juliette irmer, BIOPRO baden-württemberg GmbH lignin- a natural resource with huge potential. available at: https://www.biooekonomie-bw.de/en/articles/dossiers/lignin-a-natural-resource-with-huge-potential/.15

Glennie, D. W., and McCarthy, J. L. (1962). “Chemistry of lignin,” in Pulp and paper science and technology. Editor C. E. Libby (New York: McGraw-Hill Book Company, Inc), 82–107.

Gowen, C. M., and Fong, S. S. (2011). Applications of systems biology towards microbial fuel production. Trends Microbiol. 19 (10), 516–524. doi:10.1016/j.tim.2011.07.005

Graichen, F. H. M., Grigsby, W. J., Hill, S. J., Raymond, L. G., Sanglard, M., Smith, D. A., et al. (2017). Y es, we can make money out of lignin and other bio-based resources. Ind. Crops Prod. 106, 74–85. doi:10.1016/j.indcrop.2016.10.036

Higson, A., and Smith, C. (2011). Lignin. Fact sheet. NNFCC. Available at http://www.nnfcc.co.uk/publications/nnfcc-renewable-chemicals-factsheet-lignin.A.

Hubbert, M. K. (1956). Nuclear energy and the fossil fuels. San Antonio: American Petroleum InstituteProceedings of Spring Meeting, 7–25.

Ingevity, (2022). Indulin® at - ingevity. Available at: https://www.ingevity.com/products/indulin-at-agricultural-chemicals/(Accessed: October 28, 2022).

InSciTe (2017a). InSciTe. https://medium.com/@BrightlandsIF/inscite-comes-with-the-worlds-first-lignin-refinery-for-marine-fuel-3da8b0e89186 (Accessed October 28, 2022).

InSciTe (2017b). InSciTe. Available at: https://medium.com/@BrightlandsIF/inscite-comes-with-the-worlds-first-lignin-refinery-for-marine-fuel-3da8b0e89186.

International Energy Agency (IEA) (2007). World energy outlook world energy outlook. Paris, France: International Energy Agency.

Kiss, A. A., Omota, F., Dimian, A. C., and Rothenberg, G. (2006). The heterogeneous advantage: Biodiesel by catalytic reactive distillation. Top. Catal. 40, 141–150. doi:10.1007/s11244-006-0116-4

Kleinert, M., and Barth, T. (2008). Towards a lignincellulosic biorefinery: Direct one-step conversion of lignin to hydrogen-enriched biofuel. Energy fuels. 22, 1371–1379. doi:10.1021/ef700631w

Kouris, P., Boot, M. D., Hensen, E. J. M., and Oevering, H. (2019). A method for obtaining a stable lignin: Polar organic solvent composition via mild solvolytic modifications. WO 2019/053287 A1.

Kumarasamy, R., Uthandi, S., and Thangappan, S. (2017). Lignin depolymerization route derived commodities towards tangible bio-economy. Madras Agric. J. 104 (7-9), 207–217. doi:10.29321/maj.2017.000046

Kurian, J. K., Nair, G. R., Hussain, A., and Raghavan, G. S. V. (2013). Feedstocks, logistics and pre-treatment processes for sustainable lignocellulosic biorefineries: A comprehensive review. Renew. Sustain. Energy Rev. 25, 205–219. doi:10.1016/j.rser.2013.04.019

Lersch, Martin (2009). ‘Creating value from wood-The Borregaard Biorefinery’, bioref-integ.eu. Solihull, UK. Available at: https://www.bioref-integ.eu/fileadmin/bioref-integ/user/documents/Martin_Lersch__Borregaard_-_Creating_value_from_wood_-_The_Borregaard_biorefinery.pdf (Accessed October 28, 2022).

Liao, Y., Koelewijn, S. F., Van den Bossche, G., Van Aelst, J., Van den Bosch, S., Renders, T., et al. (2020). A sustainable wood biorefinery for low–carbon footprint chemicals production. Science 367 (6484), 1385–1390. doi:10.1126/science.aau1567

Liedberg, A. (2014). Valmet’s new LignoBoost technology gaining foothold. Available at: https://valmetsites.secure.force.com/solutionfinderweb/sfc/servlet.shepherd/version/download/06858000000qgfXAAQ (Accessed October 28, 2022).15

Maggio, G., and Cacciola, G. (2012). When will oil, natural gas, and coal peak? Fuel 98, 111–123. doi:10.1016/j.fuel.2012.03.021

Periyasamy, K., Santhalembi, L., Mortha, G., Aurousseau, M., Boyer, A., and Subramanian, S. (2018). Bioconversion of lignocellulosic biomass to fermentable sugars by immobilized magnetic cellulolytic enzyme cocktails. Langmuir 34 (22), 6546–6555. doi:10.1021/acs.langmuir.8b00976

Perlack, R. D., Wright, L. L., Turhollow, A. F., Graham, R. L., Stokes, B. J., and Erbach, D. C. (2005). Biomass as feedstock for a Bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply. Oak Ridge, Tenn, USA: U.S. Department of Energy & U.S. Department of Agriculture.

PLET (2012). Pure lignin environmental technology. Available at: http://purelignin.com/ (Accessed October 28, 2022).

Rabinovitch-Deere, C. A., Oliver, J. W. K., Rodriguez, G. M., and Atsumi, S. (2013). Synthetic biology and metabolic engineering approaches to produce biofuels. Chem. Rev. 113 (7), 4611–4632. doi:10.1021/cr300361t

Rana, M. S., S`amano, V., Ancheyta, J., and Diaz, J. A. I. (2007). A review of recent advances on process technologies for upgrading of heavy oils and residua. Fuel 86, 1216–1231. doi:10.1016/j.fuel.2006.08.004

Renfuel, A. B. (2022). RenFuel. Available at: https://renfuel.se/(Accessed: October 28, 2022).

Sahoo, S., Seydibeyoglu, M. O., Mohanty, A. K., and Misra, M. (2011). Characterization of industrial lignins for their utilization in future value added applications. Biomass Bioenergy 35, 4230–4237. doi:10.1016/j.biombioe.2011.07.009

Sharma, B., Ingalls, R. G., Jones, C. L., and Khanchi, A. (2013). Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 24, 608–627. doi:10.1016/j.rser.2013.03.049

Sorrell, S., Speirs, J., Bentley, R., Brandt, A., and Miller, R. (2010). Global oil depletion: A review of the evidence. Energy Policy 38, 5290–5295. doi:10.1016/j.enpol.2010.04.046

Spero Renewables, L. L. C. (2022). SperoSETTMrecyclable. Available at: https://www.sperorenewables.com/(Accessed October 28, 2022).

Strassberger, Z., Tanase, S., and Rothenberg, G. (2014). The pros and cons of lignin valorisation in an integrated biorefinery. RSC Adv. 4, 25310–25318. doi:10.1039/c4ra04747h

Sultana, A., Kumar, A., and Harfield, D. (2010). Development of agri-pellet production cost and optimum size. Bioresour. Technol. 101 (14), 5609–5621. doi:10.1016/j.biortech.2010.02.011

Sun, Y., and Cheng, J. (2002). Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 83, 1–11. doi:10.1016/s0960-8524(01)00212-7

Sun, Z., Fridrich, B., De Santi, A., Elangovan, S., and Barta, K. (2018). Bright side of lignin depolymerization: Toward new platform chemicals. Chem. Rev. 118, 614–678. doi:10.1021/acs.chemrev.7b00588

Suzano, (2022). Suzano ecolig: A universe of biopossibilities. Available at: https://www.suzanoecolig.com.br/en-home/(Accessed: October 28, 2022).

Tamminen, T., Vuorinen, T., Tenkanen, M., Hausalo, T., and Hortling, B. (1995). “Analysis of lignin and lignin- carbohydrate complexes isolated from black liquor,” in The 8th International Symposium on Wood and Pulping Chemistry: Poster presentations vol. 2, Gummerus, , and Jyväskylä (Helsinki, Finland: 8th International Symposium on Wood and Pulping Chemistry), 297–302.

Thersasme, O., Volk, T. A., Fortier, M. O., Kim, Y., Wood, C. D., Ha, H., et al. (2022). Carbon footprint of biofuels production from forest biomass using hot water extraction and biochemical conversion in the Northeast United States. Energy 241, 122853. doi:10.1016/j.energy.2021.122853

Tuck, C. O., Pérez, E., Horváth, I. T., Sheldon, R. A., and Poliakoff, M. (2012). Valorization of bio- mass: Deriving more value from waste. Science 337, 695–699. doi:10.1126/science.1218930

UNECE (2021). “Circularity concepts in forest-based industries,” in United nations economic commission for europe (UNECE) or the food and agriculture organization of the united nations (Geneva: FAO).

UPM (2022). About UPM biochemicals | UPM biochemicals. Available at: https://www.upmbiochemicals.com/lignin-solutions/products/(Accessed: October 28, 2022).

UPM (2020) UPM Biochemicals grows lignin business with new Domtar supply agreement | Available at: https://www.upm.com/about-us/for-media/releases/2020/12/upm-biochemicals-grows-lignin-business-with-new-domtar-supply-agreement/(Accessed: 28 October 2022).

Valmet, (2022). Valmet LignoBoost - lignin extraction. Available at: https://www.valmet.com/pulp/other-value-adding-processes/lignin-extraction/(Accessed: October 28, 2022).

Vertoro, (2022). Projects & partners. Available at: https://vertoro.com/projectspartners/(Accessed: October 28, 2022).

Voelker, S. L., Lachenbruch, B., Meinzer, F. C., Jourdes, M., Ki, C., Patten, A. M., et al. (2010). Antisense down-regulation of 4CL expression alters lignification, tree growth, and saccharification potential of field-grown poplar. Plant Physiol. 154, 874–886. doi:10.1104/pp.110.159269

Wagner, A., Tobimatsu, Y., Phillips, L., Flint, H., Geddes, B., Lu, F., et al. (2015). Syringyl lignin production in conifers: Proof of concept in a pine tracheary element system. Proc. Natl. Acad. Sci. U. S. A. 112, 6218–6223. doi:10.1073/pnas.1411926112

Wener, J., Haas, V., and Stern, T. (2020). Why can we make anything from lignin except money? Towards a broader economic perspective in lignin research. Curr. For. Rep. 6, 294–308. doi:10.1007/s40725-020-00126-3

World Bioenergy Statistics (2017). Available at: https://worldbioenergy.org/uploads/WBA%20GBS%202017_lq.pdf.

You, F., and Wang, B. (2011). Life cycle optimization of biomass-to- liquid supply chains with distributed-centralized processing networks. Ind. Eng. Chem. Res. 50, 10102–10127. doi:10.1021/ie200850t

Zakzeski, J., Bruijnincx, P. C. A., Jongerius, A. L., and Weckhuysen, B. M. (2010). The catalytic va- lorization of lignin for the production of renewable chemicals. Chem. Rev. 110, 3552–3599. doi:10.1021/cr900354u

Keywords: ligno cellulose, valorization, commercial and industrial, biorefinery and bioeconomy, material and process optimization, biofuel, bioproduct

Citation: Jassal V, Dou C, Sun N, Singh S, Simmons BA and Choudhary H (2022) Finding values in lignin: A promising yet under-utilized component of the lignocellulosic biomass. Front. Chem. Eng. 4:1059305. doi: 10.3389/fceng.2022.1059305

Received: 01 October 2022; Accepted: 31 October 2022;

Published: 29 November 2022.

Edited by:

Rafael Luque, University of Cordoba, SpainReviewed by:

Guoyong Song, Beijing Forestry University, ChinaCopyright © 2022 Jassal, Dou, Sun, Singh, Simmons and Choudhary. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hemant Choudhary, hchoudhary@lbl.gov

Vidhisha Jassal

Vidhisha Jassal Chang Dou2,3

Chang Dou2,3 Ning Sun

Ning Sun Seema Singh

Seema Singh Blake A. Simmons

Blake A. Simmons Hemant Choudhary

Hemant Choudhary