- 1China Coal Technology Engineering Group Chongqing Research Institute, Chongqing, China

- 2State Key Laboratory of Coal Mine Disaster Prevention and Control, Chongqing, China

- 3College of Safety and Environment Engineering, Shandong University of Science and Technology, Qingdao, China

To enhance the permeability of coal seam and improve the gas extraction efficiency is an effective measure to ensure the safety of coal mine production, especially, the research of hydraulic fracturing technology has shown better permeability enhancement efficiency of coal seam. However, when the technology is faced with deep and high stress environment, it is easy to cause“Water lock” in the area near the borehole, thus seriously hindering the efficiency of gas extraction. In order to solve the above problems, we deepened the study of more suitable for the upper hole fracturing resistance, hanging sand, anti-swelling, environmental protection and other requirements of cracking fluid: X3 thickening agent + P1 anti-expansion agent + J3 glue breaking agent, etc., and determined the matching S1 fracturing sand,In Songzao Coal Mine, the gas extraction effect is good after sand fracturing, and the average pure amount of gas extraction is 0.0036 m3/min, which is more than 2 times compared with water fracturing hole. The concentration of gas extraction is up to 65%, and it is 26% on average, which is more than 1 times compared with the concentration of water fracturing hole.The results provide parameter support for improving seam permeability and gas production efficiency, and provide important guidance for mine safety production.

1 Introduction

The complex geological conditions of coal occurrence (Fengyun et al., 2020; Song et al., 2021) generally show the characteristics of the coal seam, including low hardness, soft structure, rich high concentration of gas, and poor permeability performance, and in the process of the implementation of gas extraction drilling, often encountered hole collapse, vent, drilling stuck, seriously hindered the effective gas extraction, frequent gas-related safety accidents, become the main obstacle of coal mine safety production and efficient operation (Yang et al., 2018; Qin et al., 2018). Therefore, enhancing the air permeability of coal seams to improve gas extraction efficiency becomes the key to ensuring mining safety, and water and gas control are the most commonly used coal seam penetration technologies (Lou et al., 2025; Lou et al., 2024).

The core of hydraulic fracturing technology implemented in underground coal mines (Ye et al., 2017) is to use high-pressure water flow to create cracks in the coal-rock structure. These cracks extend and redistribute the stress distribution of the surrounding coal rock, forming a pressure relief area and significantly improving the air permeability of the coal seam. Multiple benefits, such as enhanced coal body wetting, strength reduction, and coal dust suppression, accompany this process. It provides innovative strategies for effectively treating coal seams with high gas content and poor permeability, attracting much attention from field engineers. Given this, the academic community has carried out extensive exploration in the field of coal seam hydraulic fracturing, and the research focuses on four aspects, including basic clear water fracturing theory, advanced construction process, development of professional fracturing equipment, and precision monitoring technology of fracturing process (Li et al., 2018; Ni et al., 2019).

In order to study the mechanism of water inhibiting the risk of gas eruption, many scholars have studied the mechanical properties, seepage characteristics, and acoustic emission characteristics of coal samples with different water contents (Chen and Yao, 2017; Perera and Ranjith, 2011) to study the mechanism by which water inhibits the risk of gas eruption. Perera MSA compared the strength and deformation characteristics of saturated and dry coal samples and found that when lignite reached saturation, the strength of lignite decreased while the toughness increased (Huang et al., 2010). Huang Sheng et al. studied the mechanical properties of water-bearing sandstone’s tensile strength under dynamic load. The results show that the increase in loading rate decreases sandstone’s tensile strength and softening coefficient (Krooss et al., 2002). Krooss et al. made a comparative analysis of the adsorption properties of coal samples in the dehydrated state and the state of water balance through experiments, and the results pointed out that compared with the coal samples containing water, the completely dry coal showed a superior adsorption capacity (Crosdale et al., 2008). Crosdale et al. studied the adsorption isotherm at different temperatures and water content. They concluded that the adsorption of coal by water exhibited nonlinear attenuation, indicating that water hindered coal adsorption (Zhang et al., 2018). These experiments prove that increasing coal’s water content effectively reduces the potential for gas explosion. Zhang Qun (Zhang et al., 2023; Sun et al., 2013) proposed the idea of indirectly fracturing coal seams by laying horizontal Wells on the roof of crushed soft coal seams and made significant progress in the Luling Coal Mine in Huaibei, which has a good reference and guiding significance for gas control technology in coal mine areas in China. Sun Dafa (Yi et al., 2015), Lei Yi (Zongfu et al., 2015), Li Zongfu (Dai, 2010), and others took the lead in applying the hydraulic fracturing technology of perforated drilling to the soft and low permeability coal seam in the Songzao mining area of Chongqing. Dai Zhixu (Wang and Guo, 2009) adopted roof perforation drilling and hydraulic fracturing technology on the working face of the 12th mine in the Pingdingshan Mining area, which accelerated the advancement of the working face and reduced the difficulty of gas extraction. Wang Zhilei et al. (Gan and Liu, 2017) applied the perforated drilling hydraulic fracturing technology to the field of Shimen coal uncovering in Shihao Coal Mine and Pingmei 10 Coal Mine, respectively, achieving the purpose of rapid and safe coal uncovering. Gan Lintang (Lei et al., 2015) and Li Lei et al. (Peng, 2017), aiming at the difficulty of gas extraction in deep soft and low permeability coal seams in the Huainan mining area, adopted perforating hydraulic fracturing technology to improve the permeability of coal seams significantly, thus promoting the significant increase in gas extraction efficiency.

Scholars have made positive progress in hydraulic gas control in recent years, primarily hydraulic fracturing technology, showing better coal seam anti-reflection efficiency. However, in the face of a deep and high-stress environment, the fracture of the fractured coal seam is uncomplicated to be re-sealed, especially in the condition of considerable depth and high stress and after the clean water fracturing of the soft coal seam,”water lock” may occur in the near drilling area due to small coal particles and poor permeability, which seriously impeding the efficiency of gas extraction. This problem becomes more and more prominent with the increase of mining depth and pressure. In order to solve the above problems, we deepened the study of more suitable for the upper hole fracturing resistance, hanging sand, anti-swelling, environmental protection and other requirements of cracking fluid. The concentration of gas extraction is up to 65%, and it is 26% on average, which is more than 1 times compared with the concentration of water fracturing hole. The results provide parameter support for improving seam permeability and gas production efficiency, and provide important guidance for mine safety production.

2 Research and development of anti-swelling and anti-resistance fracturing fluid in coal seam

2.1 Samples and materials

2.1.1 Coal sample preparation

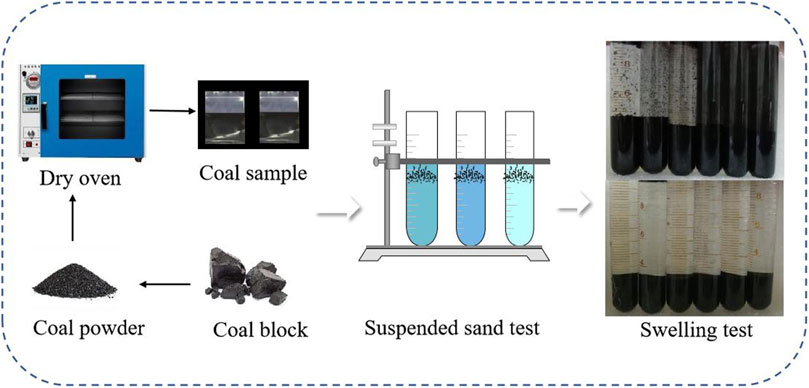

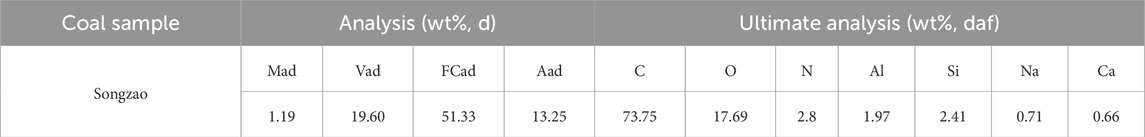

The coal samples used in the experiment are the samples of the Songzao coal mine. The method of coal sample collection is as follows: first, the coal mined on the working face is stored in a sealed bag, transported to the laboratory to peel off the coal sample oxide layer, cored and crushed into coal particles, and screen out the coal with 40–80 grain size. Then dry it in a 60°C vacuum drying tank for 24 h, remove it, and put it in a sealed bag with a label for storage. The experimental flow chart is shown in Figure 1. The approximate analysis of the test coal sample of the coal sample is shown in Table 1.

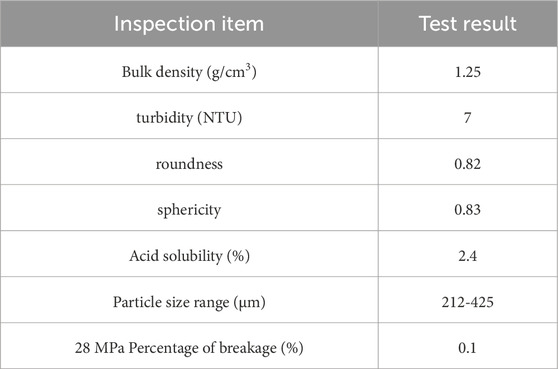

2.1.2 Determination of fracturing sand

Underground hydraulic fracturing in a coal mine is generally upward hole fracturing, which requires the fracturing sand to have the properties of being suspended on the fracturing fluid. At the same time, it is necessary to meet the requirements of strength, roundness, particle size, and other aspects according to the characteristics of the coal seam. According to the field test effect of sand fracturing in the Songzao coal mine, S1 fracturing sand can be fully fused with the fracturing fluid through the sand mixing pump, with small density and excellent suspension performance. It can successfully pass the fracturing pump and meet the requirements of hydraulic fracturing of the upper hole in the coal mine. The performance indexes of S1 fracking sand are shown in Table 2.

2.2 Further study on fracturing fluid and fracturing sand

2.2.1 Selection of fracturing fluid

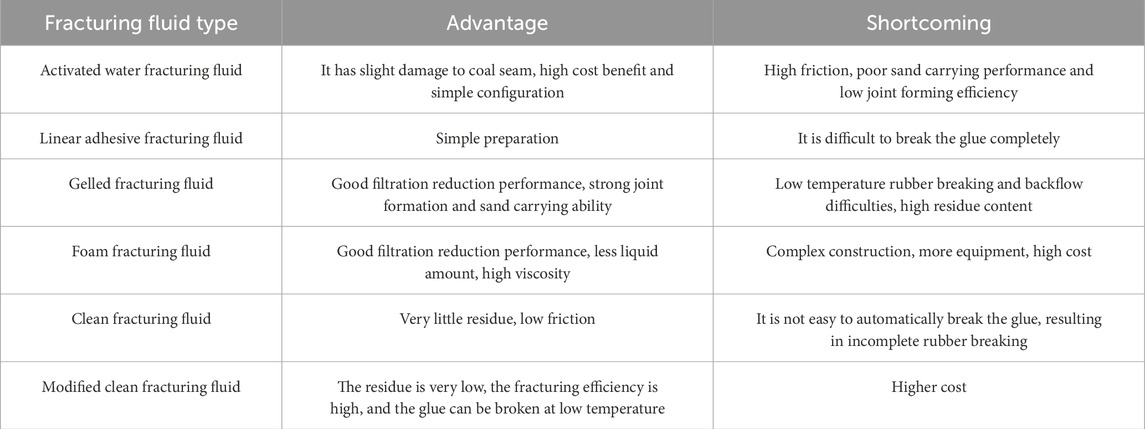

There are many types of fracturing fluids (Lei et al., 2015; Peng, 2017), and the advantages and disadvantages of common fracturing fluids are shown in Table 3. According to the field test results of sand fracturing in Songzao Coal Mine, it can be determined that the modified clean fracturing liquid system with extremely low residue, high fracturing efficiency, and low-temperature rubber breaking is still selected for this test. In order to further meet the needs of downhole fracturing operations, this type of fracturing fluid is constantly optimized. Through experiments and field practice, it is thoroughly evaluated and adjusted to achieve the best performance by taking into account key indicators such as suspended sand ability, formation swelling resistance, and rubber-breaking effect.

2.2.2 Preparation of fracking fluid

In this paper, guar gum was selected as the thickening agent, the mixture composed of ethylenediamine and epochloropropane as the cross-linking agent, magnesium chloride as the anti-expansion agent, and chromium sulfate as the glue-breaking agent as the experimental raw materials. Taking X1 solution as an example, the solution preparation process is as follows: First, a certain mass of guar gum, ethylenediamine and epichlorohydrin mixture, magnesium chloride, and chromium sulfate material is put into a certain amount of water and stirred through a magnetic stirrer for 30 min until it is completely dissolved. Using the same procedure, several other solutions were prepared, as shown in Figure 2. Then, each blocking solution was labeled for subsequent testing.

2.3 Performance evaluation of fracturing fluid

2.3.1 Evaluation of suspended sand performance

The practical method of low displacement sand fracturing is to improve the sand-carrying ability of fracturing fluid. High sand-carrying fracturing fluid generally means high viscosity, but high viscosity will increase the resistance of the fracturing medium and increase the possibility of sand plugging in the fracturing system (Yang et al., 2020; LV, 2022). Therefore, the appropriate viscosity can ensure high-hanging sand and sand carrying and reduce the resistance to achieve the best index for field application.

Add different proportion thickener to set the viscosity of different fracturing solutions, and use S1 fracturing sand to determine the performance of the sand suspension test. Combined with the field test, continue optimizing the suitable proportion for underground coal seam thickener.

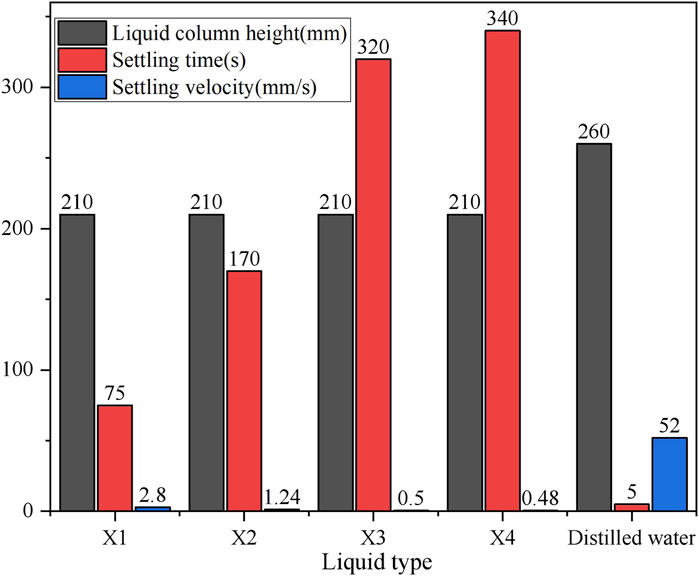

Under normal temperature and pressure conditions, the experiment placed S1 fracturing sand with a particle size of 20–40 in sequence into a measuring cylinder containing pure water, essential fracturing fluid, and glue fluid and recorded the time of sand settling to the bottom of the measuring cylinder. Relevant data are summarized in Table 4.

The experimental data is shown in Figure 3 and Table 5. It is concluded through experiments that when the concentration of fracturing fluid base fluid reaches a certain proportion (bounded by X3 concentration), increasing the concentration cannot significantly improve the suspended sand performance of fracturing sand, increase the settling time and decrease the settling speed. The suspended sand and carrying sand performance of S1 fracturing sand in high concentration X3 fracturing fluid base fluid are up to standard, which aligns with field test standards. At the same time, the combination of X4 concentration base fluid and S1 fracturing sand was used in the field test in the previous stage, which has a better-suspended sand capacity. However, in the actual sand fracturing process, it is found that in the late stage of fracturing fluid configuration, the powder is not easily dissolved in the fracturing fluid, and it is easy to appear flocculent. When mixing with S1 fracturing sand, it is easy to form clumps. I heard fracturing equipment and system load increased, and noise increased. Combined with the laboratory test results, the concentration of fracturing fluid base fluid is reduced to X3 concentration, which not only ensures the sand carrying and suspended sand performance of fracturing fluid but also reduces the fluid resistance, improves the flow capacity of the fracturing system, and reduces the operating burden of the system.

2.3.2 Anti-swelling performance

During fracturing, if the clay minerals in the rock layer encounter water, they may expand, reducing the cracks’ efficiency and the oil and gas mobility. Therefore, the fracturing fluid with good swelling performance can help maintain the open state of the crack, prevent the hydration expansion and dispersed migration of the reservoir during the fracturing process, and increase the oil and gas production.

The main components of anti-swelling agents are potassium chloride, calcium chloride, or magnesium chloride. The linear expansion method is used to analyze the anti-swelling property of a fracturing fluid system. The coal core of the K2b coal seam in Songzao Coal Mine was taken to make 70–100 g mesh coal powder, and 2.0 g was placed in a centrifugal tube. In the test, 0.3% and 0.4% clay anti-swelling agent fracturing fluid, kerosene, and deionized water were added to the coal sample one by one, and each additive was thoroughly mixed with the coal sample and then left for 2 h. Then, the anti-swelling performance of the clay stabilizer was evaluated according to the centrifugal method in SY/T 5971–2016 standard. The anti-swelling rate is calculated according to the following formula:

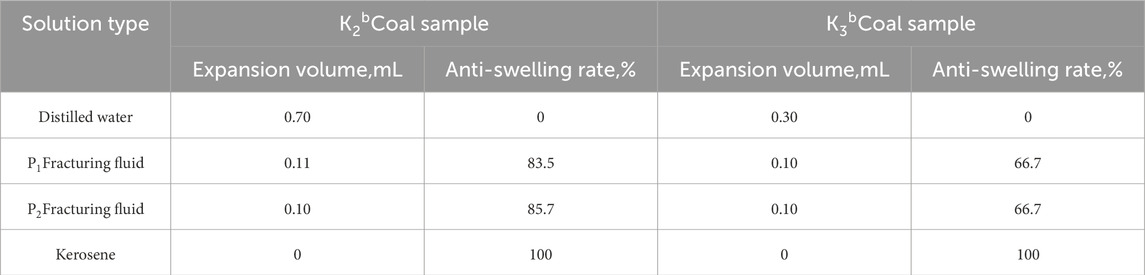

Where: B- anti-swelling rate, %; H2 - Expansion volume of core in clear water, mL; H1 - Expansion volume of core in anti-swelling agent solution, mL; H0 - Expansion volume of core in kerosene solution, mL; The experimental results of coal core expansion are shown in Table 6 below.

Table 6. Statistical table of anti-swelling experimental data of coal samples with different solutions.

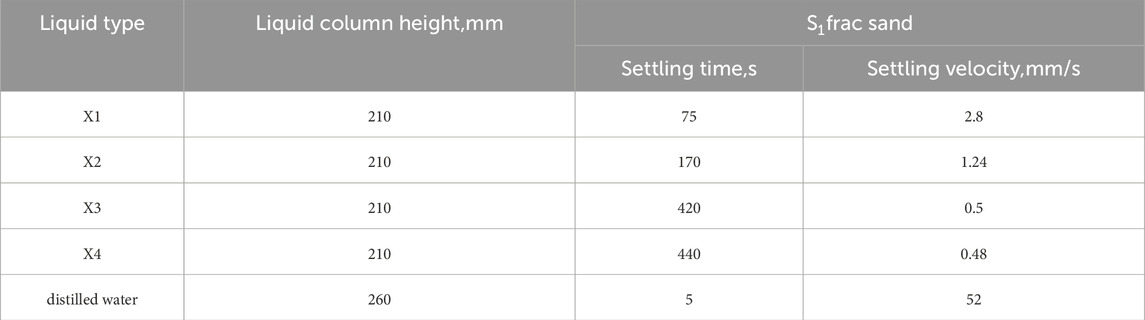

The experimental results are shown in Figure 4. The anti-swelling test of K2b and K3b coal samples shows that the anti-swelling rate of P1 fracturing fluid on the K2b coal core reaches 83.5%, which has a good anti-swelling effect. The expansion volume of the K3b coal sample in clean water is small, indicating that the water sensitivity of the coal sample is weak. Although the anti-expansion rate of P1 fracturing fluid is low, only 66.7%, the expansion volume of the coal sample is small, indicating that P1 fracturing fluid has a good ability to inhibit the expansion of clay, which helps to reduce the damage caused by the expansion of clay in the coal seam and achieve a specific protection effect.

2.3.3 Rubber breaking performance

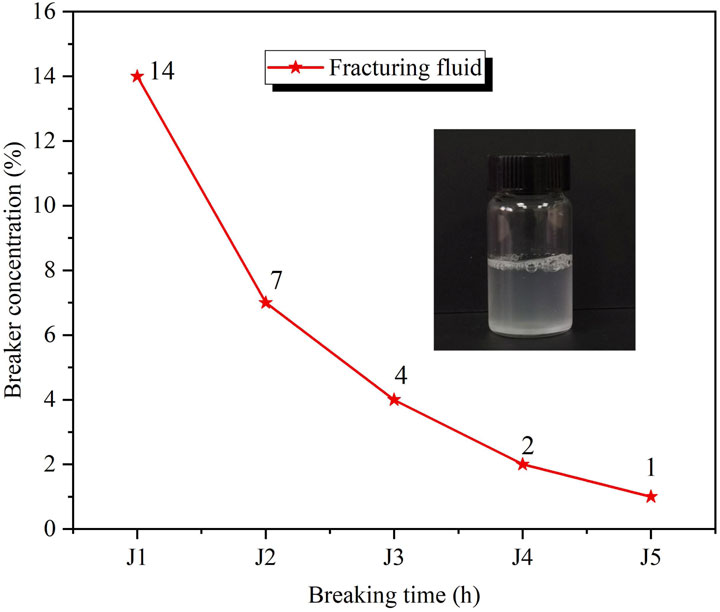

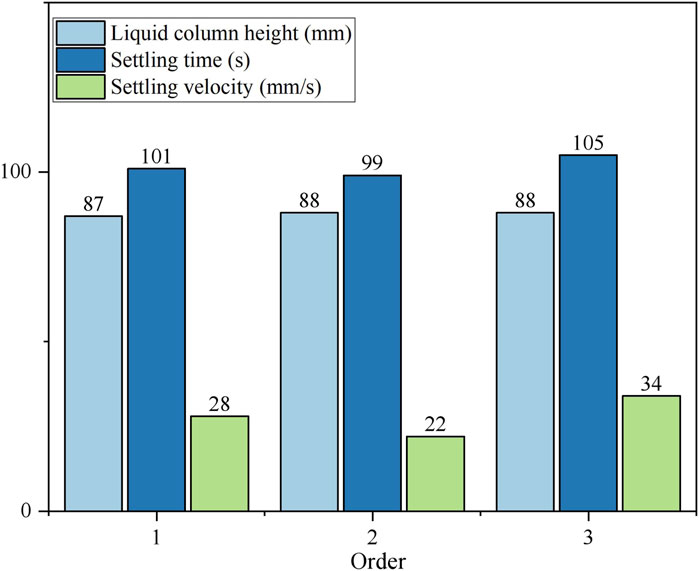

In order to adapt to the low-temperature environment of the coal seam, the effective rubber breaking of the fracturing liquid system at 20°C is realized by carefully adjusting the rubber breaking agent and the low-temperature rubber breaking activator. The main components of the rubber-breaking agent are the mixture of ammonium persulfate and complex amine salts, iron sulfate, or chromium sulfate. Since the construction time of sand fracturing is 1 h, the preparation time is 1 h, and the safety time window is 1 h, the rubber breaking time should be more significant than 3 h. In the field test of the previous stage, the J2 concentration of the glue breaker was used, and the corresponding breaking time of fracturing fluid at 25°C was 7 h. The experimental results are shown in Figure 5.

However, in the field test, it was found that the breaking time of this concentration of glue breaker was too long. The test results are shown in Table 7. Combined with the optimized concentration X3 of fracturing fluid in the previous stage, the concentration of the glue breaker was increased to J3, and the laboratory experiment concluded that the breaking time after adjusting the concentration was 4 h. Theoretically, it can meet the needs of field applications.

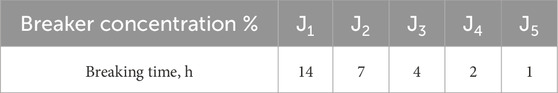

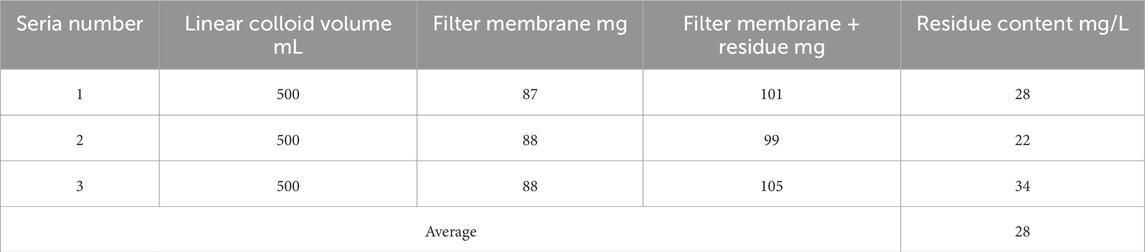

2.3.4 Test of residue content after rubber breaking

The residue generated in the process of fracturing fluid breaking is derived from the insoluble component in the thickener and the water-insoluble substance produced after breaking the glue, which seriously affects the conductivity of the fracture. Therefore, pursuing lower residue content is important in optimizing the fracturing fluid system. Three sets of tests were set at J3 breaking concentration to detect the residue content of the fracturing fluid. According to the determination standard of the residue content, the low-temperature breaking agent combination was added to the fracturing fluid, and the residue content was determined after the breaking under the condition of a 20°C constant temperature water bath.

The test results are shown in Table 8 and Figure 6, and the average residue content obtained by the test is 28 mg/L. Compared with the residue content of conventional guanidine-based fracturing fluid of 300–600 mg/L, the fracturing fluid system shows a significantly reduced residue level, belonging to the very low residue fracturing fluid system, which significantly reduces the barrier of broken rubber residues to the reservoir fracture flow.

In summary, according to the experimental results and the field test in the previous stage, the optimal formula for fracturing fluid is X3 thickener + P1 anti-swelling agent + J3 and other rubber-breaking agents.

3 Research on sand addition technology of hydraulic fracturing fluid in coal seam

3.1 Comprehensive filtration velocity

3.1.1 Dynamic permeability of coal seam

Because coal seam characteristics are usually soft and fragile and there are many natural cracks, its permeability is very sensitive to stress changes. Research shows that the dynamic permeability of coal seam decreases significantly with the change of effective stress according to exponential law (Zhang, 2015; Chen, 2016), that is:

Where: K is the dynamic permeability of coal seam after stress change, 10–12 m2; K0 is the permeability under the initial stress, 10–12 m2; Cf is the compression coefficient of coal seam cleavage, MPa-1;

The test and practical application show that the formula is suitable for calculating the dynamic permeability of coal seam during hydraulic fracturing and subsequent fracturing production. With fracturing fluid injection during the fracturing operation, the pore pressure inside the coal seam rises, resulting in a change in effective stress. At this stage, the newly added effective stress is opposite to the original confining pressure, promoting the increase of the coal seam’s permeability and the acceleration of the liquid filtration rate. The amount of effective stress change

3.1.2 Compressibility coefficient of fluid in coal seam pores

The fluid in the pores of coal seam is composed of formation water, free gas, and adsorbed gas (Wu, 2017). Therefore, its compression coefficient CL can be calculated by the following formula:

Where: Sw is the water saturation in the pore of coal seam; Cw is the compression coefficient of water in the pores of coal seam, MPa-1; Sg is the internal gas saturation of coal seam pores; Cg is the compression coefficient of the fluid in the pores of coal seam, MPa-1; Cd is the compression coefficient of desorption/adsorption caused by pressure change of coal bed methane (MPa-1).

Considering the change in the internal stress of the coal seam, the desorption and adsorption between the coal seam gas and the coal seam are caused, resulting in a change in gas volume. The following formula can calculate the resulting compression coefficient:

Where: Pc is the CBM pressure under the standard state, MPa; PL is Langmiur pressure, MPa; VL is Langmiur volume; T is the formation temperature, °C; Z is the gas volume compression factor in the formation state. φ is the porosity of coal seam; Tc is the temperature under the standard state, °C; Zc is the gas volume compression factor in the standard state.

3.1.3 Comprehensive filtration coefficient of coal seam

In conventional reservoir hydraulic fracturing, the filtration loss of fracturing fluid is mainly controlled by three factors: the viscosity of the fracturing fluid, the compressibility of the formation fluid, and the wall formation of the fracturing fluid itself. However, for coal seams, due to the cleavage system development and stress sensitivity, the filtration loss is significant, so the filtration coefficient needs to be corrected (Chao, 2016). At present, clean water is often used in coal seam fracturing operations, so the influence of fracturing fluid filtration on wall building is ignored. The other two filtration coefficients are calculated as follows:

The filtration coefficient is controlled by the viscosity of fracturing fluid and is sensitive to the permeability of coal seam

Fluid loss coefficient controlled by compressibility of fluid in coal seam and sensitive to permeability of coal seam

Combined fracturing fluid loss coefficient:

3.1.4 Coal seam fracturing fluid filtration rate

When hydraulic fracturing coal seam is carried out, considering that the fracturing fluid filtration channel is a cylinder model, the comprehensive filtration velocity can be calculated by the following formula:

Among them:

In summary, the overall loss of fracturing fluid is affected by the pressure difference at the bottom of the hole, the formation’s porosity, the penetration zone’s size, and the fracturing duration. In short, a more significant pressure difference, higher porosity, and wider percolation range will lead to a more significant filtration rate, and a longer fracturing time will increase total filtration. Therefore, the target fractured coal seam in the test area of Songzao Coal mine needs to be fractured in parallel by the fracturing pump group to meet the demand of 59 m3/h pressing flow rate. The comprehensive filter loss coefficient C of the target fracturing coal seam in the test area of Songzao Coal Mine is about 0.025 m/min1/2, and the comprehensive filter loss rate of the target fracturing coal seam of Songzao Coal Mine is 0.0981 m3/min, namely, 5.9 m3/h. The pressure flow rate in hydraulic fracturing must be much greater than the filter loss speed. According to the field experience, generally 8–10 times, that is, the fracturing rate of the target fracturing coal seam in the test area should be at least 47.2–59 m3/h, and the flow rate of the commonly used fracturing pump group is between 12 and 70.5 m3/h and 35.1 m3/h under 36.5 MPa condition. In 35.1 m3/h at 36.5 MPa condition. Therefore, the target fracturing coal seam in the Songzao coal mine test area needs to use fracturing pump group parallel fracturing to meet the pressure demand into the flow rate of 59 m3/h.

4 Field test of hydraulic fracturing effect

4.1 Implementation plan

4.1.1 Drilling hole arrangement mode

(1) Lane layout and adjacent position relationship in the fracturing area. According to the exposed and drilling conditions nearby, the hydrogeological conditions in this area are relatively simple, and there is no flood influence during the construction process. K2b coal seam is drilled through the construction, and the final hole is 12 m south of the main stone gate.

(2) The gas geology in the fracturing area, normal coal level, and thickness, no structural influence; after sampling test, the original gas content of Shimen K1 coal seam is 14.5 m3/t, the converted gas pressure is 1.21 MPa, the original gas content of K2b coal seam is 10.7 m3/t. The converted gas pressure is 1.865 MPa.

(3) According to the relevant data of the existing water fracturing test radius, the fracturing radius is 60 m, so the distance layout is 120 m;

(4) The primary purpose of underground gas extraction in coal mines is to reduce the danger of the coal seam gas pressure and gas content to below 0.74 MPa and 8 m3/t. According to the coal mine, it is inclined to arrange one borehole.

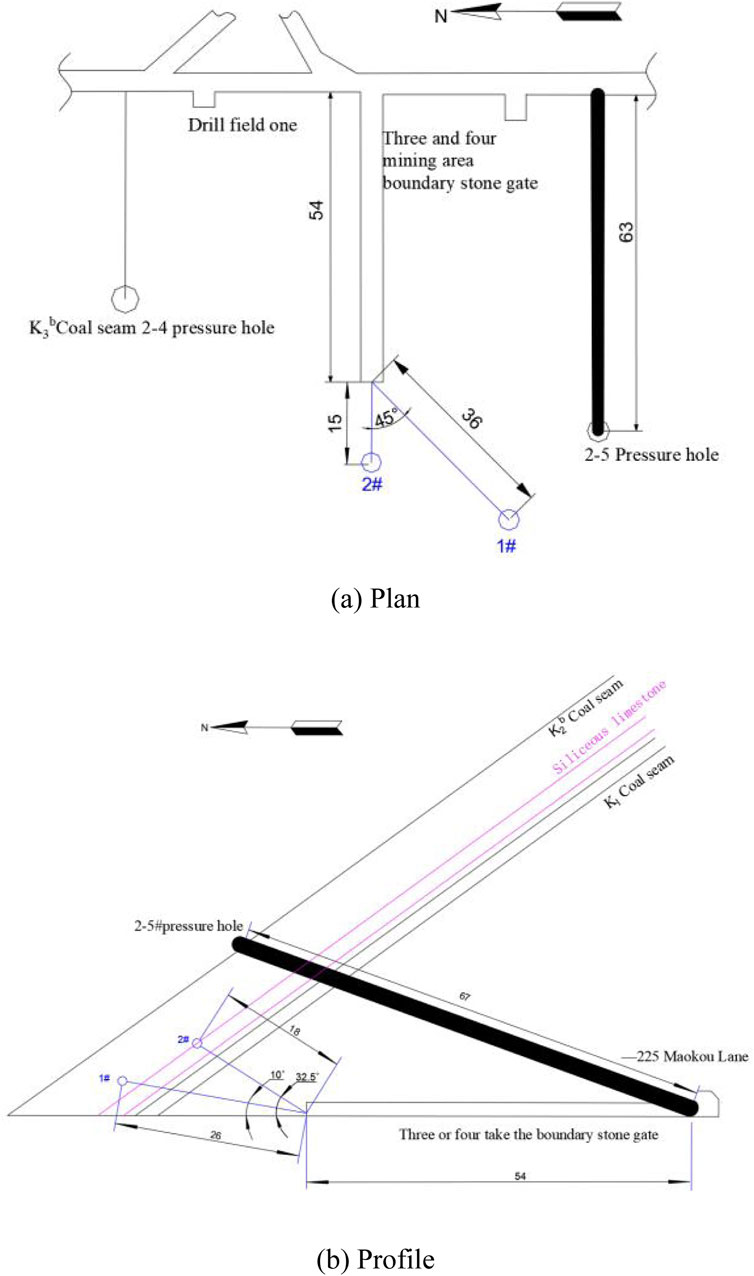

4.1.2 Design drawing of drilling layout

The drilling holes are located at the boundary stone gate of the third and fourth mining areas. A total of two boreholes with a diameter of 130 mm are constructed in the tunnel ahead of the boundary stone gate of the third and fourth mining areas. The Songzao Coal mine provides the drilling rig, and hydraulic slag discharge is used in the drilling process. The hanging height of hole one# is 1.2m, the hole length is 37 m, the azimuth of the hole is 225°, and the inclination is +10°. The hanging height of borehole two# is 2 m, the length of the borehole is 18 m, the azimuth of the borehole is 270°, and the inclination is +32.5°. The drill hole layout is shown in Figure 7.

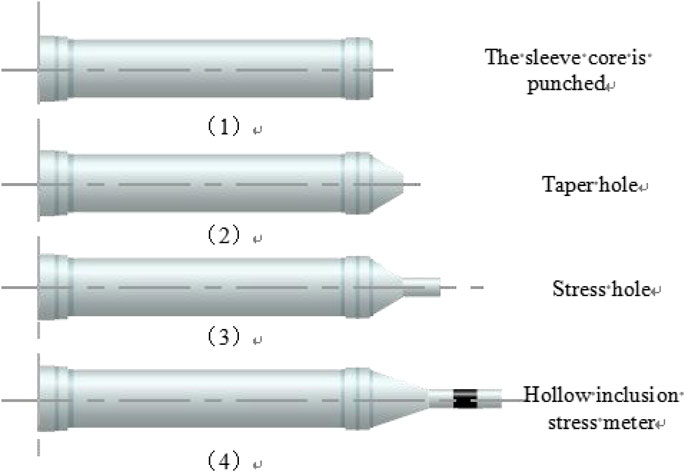

4.1.3 Drilling procedure

At the predetermined location, drill a large hole with Φ130 mm core, immediately stop drilling when drilling through the silicic limestone between K1 coal seam and K2b coal seam, smooth the bottom of the hole, and replace the drill with a unique cone bit for construction, forming a cone hole, the length of the cone hole is 120 mm after the cone hole is finished, the drill is removed and replaced with a special tiny bit. The construction stress gauge is installed in the center of the large hole in the core. The depth of the hole is 310 mm. At this point, the drilling construction process has been completed, and the construction diagram is shown in Figure 8.

4.2 Effect analysis

4.2.1 Analysis of the influence range of sand addition in hydraulic fracturing

Intuitively, after the fracturing operation of the 3# pressure crack hole was completed, it was observed that noticeable sweating and water seepage occurred in the roadway wall of the drilling site along the direction of the coal seam at 60 m away from the drilling hole, which increased the influence radius by 12% compared with that of 50 m when Songzao Coal Mine used clean water fracturing technology. The transient electromagnetic method (TEM) was used in the field to monitor the apparent resistivity of the 3# and 4# pressure holes before and after fracturing to assess their affected areas. The results show that the fracturing area is more than 60 m along the coal seam strike. The large-flow fracturing sand addition technology with double pumps in parallel can significantly increase the fracturing range compared with the single-pump sand addition method. The fracturing range can reach 70 m along the coal seam trend with the dual-pump parallel system. Compared to water fracturing technology, this fracturing method can expand the affected area by 40–60 percent, which is significant. This lift ensures that the strip area is well covered to avoid fracturing gaps.

4.2.2 Analysis of hydraulic fracturing sand pumping effect

(1) Analysis of extraction effect

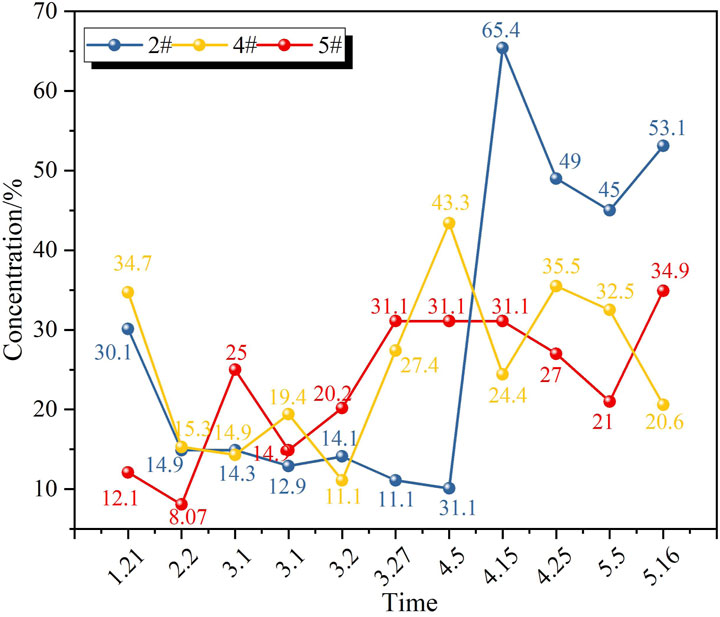

According to the experience of coalbed methane drainage in coal mines, after maintaining pressure for some time, the first to desorb is the free-state coalbed methane, which exists in liquid form, leading to higher gas production during the initial drainage period; as the drainage time increases, the amount of free-state gas decreases, resulting in reduced gas production. Due to the decrease in pressure, the gas-liquid equilibrium redistributes, causing the coalbed methane adsorbed in the coal rock to gradually desorb until complete desorption is achieved.However, the desorption of coalbed methane is a slow process. Generally speaking, it takes one to several months to achieve overall desorption, and the specific desorption time varies under the influence of multiple factors.However, the desorption of coalbed methane is a slow process. Generally speaking, it takes one to several months to achieve overall desorption, and the specific desorption time varies under the influence of multiple factors. The concentration maps of gases 2#, 4# and 5# are shown in Figure 9. The concentration of extracted gas was high before February 2; then it entered the stage of no overall desorption, and the concentration of extracted gas was low; around April 5, it basically reached the stage of overall desorption, and the concentration of extracted gas was basically stable in the region.After basically reaching the overall desorption stage, the gas concentration of hole two is 45–65%, with an average of 53%; the gas concentration of hole four is 21–44%, with an average of 32%; and the gas concentration of hole five is 21–35%, with an average of 29%.

(2) Extraction effect analysis

① Extraction concentration: In addition to the fracturing effect of hole one and hole three due to fractures, the gas extraction concentration of hole two is 10%–65%, with an average of 29%; The 4# holes were 12%–44%, with an average of 26%. The 5# hole was 8%–35%, averaging 23.3%. The average gas concentration of the three holes was 26%.As shown in Figure 8, the gas extraction concentration more than doubled compared to the plain water fracturing borehole without sand, significantly improving extraction efficiency. After the overall desorption stage is basically reached, the concentration of two# pore gas is 45–65%, with an average of 53%. The concentration of four# pore gas was 21%–44%, with an average of 32%. The concentration of five# pore gas is 21%–35%, with an average of 29%.

② Extraction purity

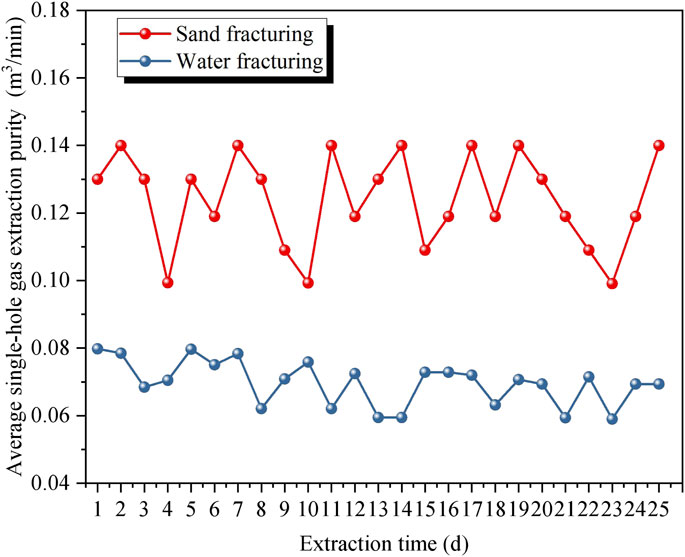

After being pressurized for 10 days, the fracture hole is connected to the pumping system, and data is collected to evaluate the pumping efficiency of sand hydraulic fracturing by comparing it with water fracturing. The extraction parameters of clear water fracturing drilled in Songzaocoal Mine were collected. The extraction concentration of pressure fracture holes after apparent water fracturing ranged from 60% to 66%. A single hole’s average pure gas extraction volume was calculated to be 0.061–0.08 m3/min. By measuring the extraction data of hole 3 # and hole 4#, the pressure fracture hole’s extraction concentration after sand fracturing ranges from 58% to 65%. The calculation results show that the average gas extraction amount per hole is 0.10–0.14 m3/min, which is 20%–30% higher than the water fracturing method. A detailed comparison can be seen in Figure 10.

Figure 10. Comparison of single-hole extraction purity between water fracturing and sand fracturing.

Compared with the clean water fracturing, the concentration of the extraction of the gas has not changed much, and the pure flow of the extraction has increased by 20–30%. Because of the comparison experiment in similar areas, the difference in coal seam geology and gas occurrence is ignored. The difference and heterogeneity of coal seam geology in actual coal mines lead to differences in key parameters such as coal seam permeability and gas content in adjacent sites, and the differences in these key parameters may also directly affect the effect of gas extraction. Therefore, future research on the effect of gas extraction under the joint action of coal seam occurrence, gas parameters, and process is needed.

5 Conclusion

Through further research on fracturing fluid and fracturing sand suitable for underground hydraulic fracturing in coal mine, We have studied the fracturing fluid with better sand resistance, anti-expansion and environmental protection properties suitable for perforated fracturing.The main achievements are as follows:

(1) Further research has been made on fracturing fluids that are more suitable for upward hole fracturing to reduce resistance, suspended sand, anti-swelling and environmental protection in coal mine underground sites: X3 thickening agent + P1 anti-swelling agent + J3 gumming agent, etc., and the matching S1 fracturing sand has been determined;

(2) The successful application of this technology in Songzao Coal mine marks the first breakthrough. In Songzao Coal Mine, the gas extraction effect is good after sand fracturing, and the average pure amount of gas extraction is 0.0036 m3/min, which is more than 2 times compared with water fracturing hole. The concentration of gas extraction is up to 65%, and it is 26% on average, which is more than 1 times compared with the concentration of water fracturing hole.The results provide parameter support for improving seam permeability and gas production efficiency, and provide important guidance for mine safety production.

(3) The changes in stress and strain during hydraulic fracturing: In the initial stage of fracturing, the strain spreads rapidly, and the stress influence on the monitoring point reaches its peak 2 h after fracturing. In the late fracturing stage, the strain gradually stabilized but remained in a stable state higher than the original level, indicating that the stress distribution of coal rock mass changed due to fracturing. After the end of fracturing, the stress growth gradually becomes stable and slowly weakens, and tends to the original stable level but remains higher than the stress value before hydraulic fracturing. In addition, the hydraulic fracturing operation has little effect on the orientation parameters of coal and rock mass, namely, the azimuth Angle and the inclination Angle.

(4) The dredging technology for fracturing boreholes after fracturing has been formed, and the operation specification of drilling dredging has been integrated. After the drainage reform, the average concentration of No. 4 and No. 5 pressure holes increased by more than two times, and the extraction concentration and extraction effect of pressure holes after drainage have been greatly improved.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

JL: Writing – original draft, Writing – review and editing, Data curation, Investigation, Methodology, Resources. QZ: Data curation, Project administration, Conceptualization, Writing – review and editing. CZ: Data curation, Formal Analysis, Methodology, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by the Youth Program of National Natural Science Foundation of China (52204261) and the surface program of Chongqing Natural Science Foundation of China (CSTB2023NSCQ-MSX0577). National Key R&D Program of China (2024YFC3013805), Key Science and Technology Project of Ministry of Emergency Management of the People’s Republic of China (2024EMST070703).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chao, Li (2016). Research and application of fracturing induced stress field in dagang tight oil reservoir. Chengdu: Southwest Petroleum University.

Chen, S. (2016). Optimization of cluster perforation parameters for shale gas horizontal wells based on stratigraphic characteristics. Beijing: China University of Petroleum.

Chen, X., and Yao, G. (2017). An improved model for permeability estimation in low permeable porous media based on fractal geometry and modified Hagen-Poiseuille flow. Fuel 210, 748–757. doi:10.1016/j.fuel.2017.08.101

Crosdale, P. J., Moore, T. A., and Mares, T. E. (2008). Influence of moisture content and temperature on methane adsorption isotherm analysis for coals from a low-rank, biogenically-sourced gas reservoir. J. Coal Geol. 76 (1-2SI), 166–174. doi:10.1016/j.coal.2008.04.004

Dai, Z. (2010). Research and application of high pressure hydraulic fracturing technology in comprehensive gas control. Coal Eng. (12), 82–84.

Fengyun, S., Song, Y., and Gang, W. (2020). The effect of microemulsion on coal wetting characteristics and physicochemical structure. Colloid Interface Sci. Commun. 39, 2215–0382.

Gan, L., and Liu, J. (2017). Application of hydraulic fracturing and permeability enhancement technology in soft and protruding coal seam mining face Coal Mine Safety, 48 (7): 70–73+77.

Huang, S., Xia, K., Yan, F., and Feng, X. (2010). An experimental study of the rate dependence of tensile strength softening of longyou sandstone. Mech. Rock Eng. 43 (6SI), 677–683. doi:10.1007/s00603-010-0083-8

Krooss, B. M., van Bergen, F., Gensterblum, Y., Siemons, N., Pagnier, H., and David, P. (2002). High-pressure methane and carbon dioxide adsorption on dry and moisture-equilibrated Pennsylvanian coals. J. Coal Geol. 51, 69–92. doi:10.1016/s0166-5162(02)00078-2

Lei, L., Zhongjun, L., and Wenbin, W. (2015). Research on hydraulic fracturing technology for soft and low-permeability coal seams underground Mining Safety and Environmental Protection, 42 (6): 5–9.

Li, D., Wang, E., and Song, L, D. (2018). KongSpatio-temporal evolution of apparent resistivity during coal-seam hydraulic flushing. Geophys Eng. 15 (3), 707–717. doi:10.1088/1742-2140/aaa228

Lou, Z., Kai, W., Mary, K., Zhao, W., Wei, G., Yue, J., et al. (2024). Plugging methods for underground gas extraction boreholes in coal seams: a review of processes, challenges and strategies. Gas Sci. Eng. 122, 205225. doi:10.1016/j.jgsce.2024.205225

Lou, Z., Wang, K., Yao, H., Zhao, W., Qin, H., Wu, Z., et al. (2025). A novel dynamic filling material for plugging fractures around underground gas extraction boreholes: experimental and engineering performances. Energy 314, 134202. doi:10.1016/j.energy.2024.134202

Lv, S. (2022). Massive hydraulic fracturing to control gas outbursts in soft coal seams. Rock Mech. Rock Eng. 24 (05), 1–18. doi:10.1007/s00603-021-02734-2

Ni, G., Dong, K., Li, S., and Sun, Q. (2019). Gas desorption characteristics effected by the pulsating hydraulic fracturing in coalFuel, 236 190–200. doi:10.1016/j.fuel.2018.09.005

Peng, Lu (2017). Current status of hydraulic fracturing technology in China. Petrochem. Technol. 24 (05), 280.

Perera, M. S. A., and Ranjith, P. G. (2011). Effects of saturation medium and pressure on strength parameters of Latrobe Valley brown coal: carbon dioxide, water and nitrogen saturations. water nitrogen Satur. Energy 36 (12), 6941–6947. doi:10.1016/j.energy.2011.09.026

Qin, L., Zhai, C., Liu, S., and Xu, J. (2018). Mechanical behavior and fracture spatial propagation of coal injected with liquid nitrogen under triaxial stress applied for coalbed methane recovery. Geol 233, 1–10. doi:10.1016/j.enggeo.2017.11.019

Song, J., Jun, D., Jingyu, Z., Zhang, Y. N., and Shu, C. M. (2021). Comparative analysis of exothermic behaviour of fresh and weathered coal.during low-temperature oxidation. Fuel 289, 119942. doi:10.1016/j.fuel.2020.119942

Sun, D., Chen, J., and Jianming, L. (2013). Experimental study on high pressure hydraulic fracturing technology in shimen coal mining. Coal Sci. Technol. 41 (S2), 163–165.

Wang, Z., and Guo, P. (2009). The application of hydraulic fracturing technology in coal mining. Zhongzhou Coal (5), 20–21+24.

Wu, X. (2017). Study on the propagation law and mechanism of segmented fracturing cracks in horizontal wells of fractured soft and low-permeability coal seam roof. Beijing: Coal Science Research Institute.

Yang, W., Wang, H., Lin, B., Wang, Y., Mao, X., Zhang, J., et al. (2018). Outburst mechanism of tunnelling through coal seams and the safety strategy by using “strong-weak” coupling circle-layers. Undergr. Space Techol 74, 107–118. doi:10.1016/j.tust.2018.01.013

Yang, W., Lu, C., Si, G., Lin, B., and Jiao, X. (2020). Coal and gas outburst control using uniform hydraulic fracturing by destress blasting and water-driven gas release. J. Nat. Gas Sci. Eng. 79 (C), 103360–350. doi:10.1016/j.jngse.2020.103360

Ye, Q., Jia, Z., and Zheng, C. (2017). Study on hydraulic-controlled blasting technology for pressure relief and permeability improvement in a deep hole. Sci. Eng. 159, 433–442. doi:10.1016/j.petrol.2017.09.045

Yi, L., Wu, W., and Chen, J. (2015). Hydraulic fracturing and permeability enhancement technology for soft coal seam underground and its application Coal Mining, 20 (1): 105–107+4.

Zhang, W. (2015). Optimization and application of segmented hydraulic fracturing process parameters for coalbed methane horizontal wells in hebi mining area. Beijing: China University of Mining and Technology.

Zhang, Q., Ge, C., and Li, W. (2018). Efficient extraction mode of coalbed methane through segmented fracturing of horizontal wells in fractured soft and low-permeability coal seam roof Coal. Journal 43 (1), 150–159.

Zhang, Q., Jiang, W., and Jiang, Z. (2023). The current situation and technological research progress of surface development of coalbed g methane in coal mining areas in China. Coalf. Geol. Explor. 51 (1), 139–158.

Keywords: coal seam permeability, gas extraction, hydraulic fracturing, coal, fracturing fluid

Citation: Liu J, Zhang Q and Zhang C (2025) Study of coal mine modified clean fracturing fluid and optimization of hydraulic fracturing sand adding process. Front. Built Environ. 11:1554463. doi: 10.3389/fbuil.2025.1554463

Received: 16 January 2025; Accepted: 25 July 2025;

Published: 21 August 2025.

Edited by:

Sujit Kumar Dash, Indian Institute of Technology Kharagpur, IndiaReviewed by:

Pengfei Shan, Xi’an University of Science and Technology, ChinaHaowei Yao, Zhengzhou University of Light Industry, China

Copyright © 2025 Liu, Zhang and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jun Liu, bGl1anVuaGViZWkyMDA2QDEyNi5jb20=

Jun Liu

Jun Liu Qinghua Zhang1,2

Qinghua Zhang1,2