- Assistant Professor of Architectural Engineering, Architectural Engineering Department, Faculty of Engineering and Technology, Future University in Egypt, Cairo, Egypt

This research investigates the feasibility of using desert sand as a sustainable substitute for traditional construction materials in Egypt. Utilizing local sand resources in Egypt’s extensive desert landscape could substantially decrease dependence on energy-intensive materials like Portland cement and clay bricks, thereby reducing environmental impact and promoting decarbonization initiatives. This research takes a hierarchical approach to analyzing the geological distribution of distinct Egyptian sand kinds, assessing important national initiatives and legislation, in addition to laboratory findings and concluded mechanical qualities in recent publications. It exposes flaws in Egyptian adopted decarbonization and sustainability programs in concrete and masonry industries. It also investigates construction techniques, including autoclaved aerated concrete (AAC) blocks, which provide environmental and economic advantages compared to traditional clay bricks. Therefore, optimizing the use of sand in the concrete and masonry industries is very suitable for Egypt’s urban growth, as it will enhance decarbonization initiatives, improve thermal insulation, and decrease energy consumption. In accordance to this, the study highlights the necessity for additional experimental validation to incorporate sand-based materials into Egypt’s construction sector, which needs to be supported by policy interventions to standardize and generalize sand-based materials. It concludes with an indicative approach for the integration of the abundant desert sand into the production of Portland Pozzolana Cement (PPC) and the enforcement of AAC block usage for modular based construction through national standards and supply chain optimization.

1 Introduction

Products with great resource intensity, such as Portland cement and clay bricks, damage the surroundings and are currently dominant in the building sector of Egypt. With 96% of Egypt’s land covered in deserts, this underused resource should be considered as a cement replacement is desert sand. This research investigates the physical characteristics and mechanical qualities of desert sand to see if it may lessen the impact of building on the surroundings. By lowering clinker content (basically because of cement material) and raising energy efficient masonry production, sand substitution may help to lower carbon dioxide emissions. Egypt’s building practices and rules on technology must change if we are to exploit desert sand as a building resource. Research findings provide guidance for further steps to be taken in order to promote the usage of Egyptian desert sand.

1.1 Problem statement

The construction sector in Egypt plays a crucial role in the country’s economic growth, contributing considerably to its Gross Domestic Product (GDP) and enabling rapid urbanization. However, industry faces numerous major challenges that hamper its sustainability and efficiency. These challenges are:

⁃ The sandy soils, covering more than 96% of Egypt’s area, are not fully used.

⁃ Recent rules have addressed cement industry environmental problems, but little is known about renewable resources like desert sand.

⁃ Egypt’s masonry industry still depends on conventional clay bricks, which are energy-intensive to manufacture and harm the surroundings. Although autoclaved aerated concrete (AAC) blocks have financial and environmental advantages, their acceptance is still restricted.

⁃ Urbanization and fast population rise in Egypt have raised demand for reasonably priced, environmentally friendly construction materials.

1.2 Research objectives

⁃ Assess the possibility of using desert sand as an alternative material in concrete and masonry applications.

⁃ Explore policy gaps and technical barriers hindering the implementation of sand-based materials in Egypt.

⁃ Introducing an indicative approach to launch different Egyptian sand types in replacing cement and reducing energy consumption.

2 Literature review

2.1 Challenges in accessing technical information on concrete and masonry materials in Egypt

Reliable technical information is crucial for the sustainable development of concrete and masonry materials in construction. However, in Egypt, access to comprehensive and well-documented sources on these materials remains limited. This study examined the technical information of concrete and masonry materials in Egypt based on the existing sources which are:

⁃ National market data collection based on reliable property and construction consultancy companies.

⁃ National established guidelines.

⁃ National and International published lab tests.

⁃ Websites.

2.2 Potential of sand as core construction material

Egypt’s geography consists of four regions: the Nile River Valley and Delta, the Western Desert, the Eastern Desert, and the Sinai Peninsula, Figure 1. The Nile Valley and Delta are the most heavily populated regions, while the majority of Egypt relies on rainfall and deep aquifers for water. The Western Desert covers 66% and is known for its large tracts of parched plains and sand dunes, and includes coastal basins like Matruh, Shushan, Alamein, and Natrun. The Eastern Desert covers 22% of Egypt’s land, with rocky plateaus and large valleys. The Sinai Peninsula, covering 61,000 km2, is another significant geographical area with a limestone plateau and hilly topography. The southeastern part of the Western Desert includes the Toshka area. Nearly 96% of Egypt is undeveloped desert territory, and rapid population growth has made metropolitan centers denser. This highlights the need for prioritizing sand as a locally accessible sustainable resource for future urban development (Younes, 2012; Balderer et al., 2014; Hereher, 2014; nasa, 2018).

Figure 1. Geological area in Egypt (nasa, 2018).

2.2.1 Egyptian soil types

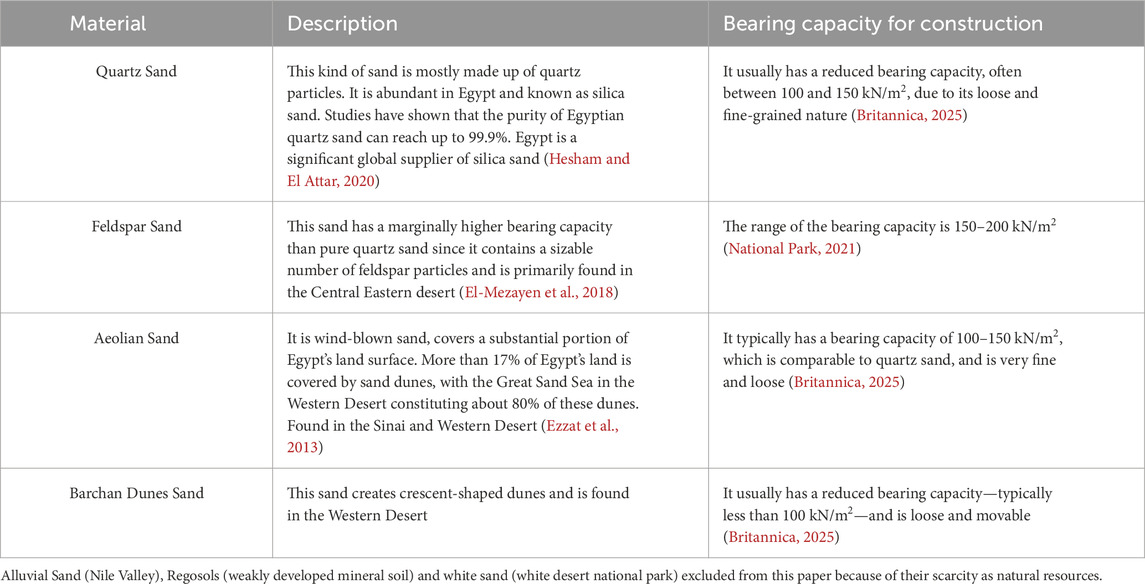

Egypt’s diversified soil composition, impacted by distinct geological formations, has a significant impact on the country’s economic potential and land use trends. After excluding, black soil from the Nile Valley and white sand because of their scarcity as natural resources, sandy soils in Egypt exhibit a diverse range of types which can be summarized as follows:

(1) Soils developed mainly from limestones include: stoney and loamy sand lithosols (5.95%), shallow loamy sands (16.01%), and gravelly sands (1.92%), covering significant areas such as peneplains and desert plains. Additionally, sandy soils with stoney hill remnants (2.99%) and arid brown loamy soils with rocky ridges (0.57%) are also present.

(2) Sandstone-based soils, especially in the Nubia sandstone plains (18.04%) and desert regions (5.99%), have sandy and gravelly lithosols. These include stoney sand lithosols on difficult terrain.

(3) Alluvial fans and Nile terraces have gravelly sand soil (1.05%) and loamy sand to sandy loam soils with lithosols (1.56%).

(4) Desert oases have reddish brown calcareous clayey soils made from shales (0.19%).

(5) Solonchaks and salt-affected soils are found in the lower Nile delta (0.51%) and coastal plains (0.71% and 0.70%).

(6) Soil with saltwater marshes (0.57%) and lagoons-coastal limestone ridges (0.20%) (Elbasioumy and Elbehiry, 2018). Egypt’s unique soil composition reflects its complicated geological and climatic history, affecting agriculture and land usage.

2.2.2 Sand soil types in Egypt: suitability for construction

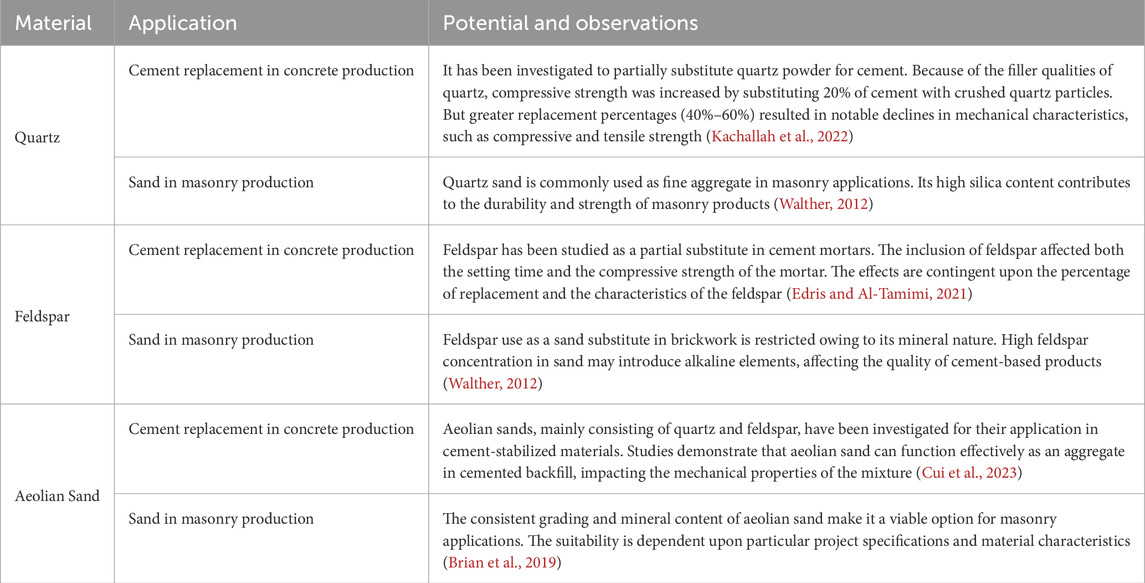

The previous section revealed that sandy soils in Egypt exhibit diverse mineralogical compositions, primarily influenced by their parent materials and formation processes. The engineering properties of desert sands in Egypt are generally similar, but they are still different. Here’s an overview of the main sand types: quartz, feldspar, and aeolian sands.

⁃ Most of Egypt’s Western Desert’s sandy soils representing 66% of Egypt area, particularly those derived from sandstones and limestones, consist of quartz sands (El-Sayed and Youssef, 2018).

⁃ Feldspar sands can be found in sedimentary rocks including sandstones and shales as well as in soils derived from igneous and metamorphic rocks (Abu Seif, 2015).

⁃ Important component of Egypt’s desert soils are Aeolian sands, delivered by the wind. Their great impact on the formation of sandy soils in dry environments helps to explain why they are well-sorted and abundant of quartz (Embabi, 2018).

Sand types found in Egyptian deserts, each with unique properties and bearing capacity. Compaction and stabilizing procedures can increase the bearing capacity of these sands and therefore increase their suitability for construction. The acceptable bearing capacity of desert sand can vary, although for loose, dry sand, it typically falls between 100 and 150 kN/m2. Using the right compaction and stabilizing methods can greatly raise this value. Compacted sand, for instance, has a bearing capacity of 250–450 kN/m2. The sand types in Egypt can be categorized as follows in Table 1.

2.2.3 The status of concrete production in egyptian industry

Among the Middle East and Africa’s (MEA) biggest cement and concrete manufacturers is Egypt. The construction sector is a main driver of concrete demand supported by infrastructure projects and urban growth. Egypt is a major participant in the worldwide market as its cement industry has yearly capacity of more than 80 million tons. Among the big enterprises are Suez Cement, Titan Cement, Arabian Cement Company, and Lafarge Egypt (OHLA, 2022; Cement, 2023).

The first environmentally friendly substitute for site-mixed concrete (SMC) was ready-mixed concrete (RMC). Among the many long-term benefits it offered over SMC are quality, convenience, less waste, site storage, longer building lifespan, smaller structural element size, and less on-site personnel and equipment used (Varghese and Pillai, 2007; Anderson et al., 1992; Varghese and Pillai, 2007; Anderson et al., 1992). RMC is more costly than SMC, although the advantages described typically help to offset this. RMC has been the worldwide norm and only source of recently produced concrete during the last three decades.

With around 6% of Egypt’s GDP, construction makes almost half of all the country’s GDP and has been a major factor in its economic development throughout the last 20 years. Although concrete is the most regularly used building material in Egypt, well-documented research on methods, quality, and consumption rates in the building industry is somewhat lacking and sometimes inadequate (GAFI, 2013; GAFI, 2014; Mobarak, 2001; Crosthwaite, 2000).

- In 2000, there were nine major Portland cement companies in Egypt, which increased to 14, with eight producing two million metric tons annually. Monopolies in cement production control supply and prices, impacting the construction market. Cement is a major contributor to pollution in Egypt, with an estimated 7% annual growth rate in local consumption (Daily News Egypt, 2015).

- RMC entered the Egyptian market 35 years ago in Cairo, accounting for only 10% of local cement manufacturing (Lafarge, 2009). The Egyptian Code of Practice does not require or encourage RMC use in construction (ECP, 2007). The World Bank ranked Egypt 128, 149, and 156 out of 189 nations in terms of ease of doing business, efficacy in dealing with construction permits, and contract enforcement. Egypt’s construction sector appears to be challenged by the current economic situation and political direction (TheWorldBank, 2014).

Numerous material advancements took place, such as: admixtures and supplementary cementitious materials (SCM). These include fly ash, ground granulated blast furnace slag, silica fume, and natural pozzolans, such as calcined shale, clay, or metakaolin (Kosmatka et al., 2017). They are siliceous-based cementitious substitutes/alternatives (SCMs) which can be combined with Portland cement during manufacture or added into the concrete mix at the batch plant, to produce high-performance concrete that meets sustainability criteria (Cement and Concrete Association, British Cement Association, 2002). These alternatives to Portland cement offer high durability with compressive, split tensile, flexural, and elastic modulus, while reducing porosity. The pozzolanic reaction targets the concrete microstructure (Dilip and Amitava, 2012), making it ideal for mass constructions. Additionally, substituting Portland cement with SCM reduces clinker production’s carbon footprint (Kosmatka et al., 2017; EPA and U.S. Environmental Protection Agency, 2012).

Knowing that clinker production is the main source of CO2 emissions in the cement industry, researchers are focusing on finding the best ratio of natural substitutes for solid waste materials without sacrificing technical qualities. Nevertheless, the application of substitutes like fly-ash, a coal-byproduct, or pozzolana; a volcanic material; in Egypt is expected to be difficult as most of these materials, are close to non-existent in Egypt. Therefore, due to the limited availability of good-quality clinker substituting materials such as granulated slag, fly ash and pozzolana in Egypt, the significance of substituting clinker with domestic materials, such as abundant sand, is emphasized.

2.2.4 The status of masonry production in egyptian industry

The construction industry in Egypt, including masonry production, is experiencing significant growth (Globenewswire, 2024). This growth is driven by both residential and commercial construction, supported by government initiatives and foreign investments (Gleeds, 2025). The industry primarily relies on traditional materials like clay bricks, concrete blocks, and cement-based products, which contributes significantly to greenhouse gas emissions, accounting for about 17% of Egypt’s total greenhouse gas (GHG) emissions (Sakr, 2023). Traditional brick production in Egypt is energy-intensive, often relying on fossil fuels like coal and natural gas. This contributes to high carbon emissions and environmental degradation. The lack of widespread adoption of energy-efficient technologies and renewable energy sources in masonry production has hindered progress toward sustainability goals. In Egypt, some initiatives are emerging to adopt energy-efficient practices, such as using alternative fuels (e.g., agricultural waste) and optimizing production processes, but progress is slow due to economic constraints and limited awareness (Justindargin, 2014).

Egypt has implemented several energy-efficient building codes and standards to enhance energy performance in the construction sector, including masonry manufacturing. Between 2005 and 2010, mandatory energy performance requirements were introduced for residential, commercial, and governmental buildings. These codes aim to improve energy efficiency across various building types (Hanna, 2015). Regarding masonry manufacturing, the Egyptian Organization for Standardization and Quality (EOS, 2006; Quality, 2015) has established specific standards:

• ES 1292–1: This standard specifies requirements for loadbearing concrete masonry units (Quality).

• ES 4763: This standard outlines specifications for building brick masonry units made from clay (EOS).

Despite attempts to apply energy-efficient rules, Egypt’s building sector still mostly depends on conventional, non-renewable materials such as clay and cement, with limited incorporation of renewable resources such as plentiful sand.

3 Identified gaps in concrete and masonry manufacturing processes and potentials of sand as core construction material in Egypt

3.1 Validity of decarbonization policies in concrete manufacturing sector

Egypt adopted strict regulatory standards for dust emissions and harmful pollutants from cement plants relatively late, with significant updates only implemented in 2010 by the Egyptian Environmental Affairs Agency (EEAA). These updates amended the 1994 Egyptian environment protection law to align with international standards and included online monitoring for cement plants. However, they do not address CO2 emissions (Askar et al., 2010).

In 2015, Egypt’s cement industry faced scrutiny due to new regulations allowing the use of coal and petcoke instead of natural gas, which was either unavailable or not economically viable. This shift caused increasing CO2 emissions by up to 15%, noting that the cement industry in Egypt is responsible for up to 14% of the country’s CO2 emissions, which is double the global average. The industry predominantly uses a fuel mix of 95% coal and petcoke, both high carbon-emitting fuels, with only 5% coming from waste and refuse-derived fuels (RDFs) (EBRD, 2016). The aforementioned was despite Egypt ratifying the Paris Agreement in 2016 and committing to reduce CO2 emissions.

At the end of 2016, the “Low-Carbon Roadmap for the Egyptian Cement Industry” was published, funded by the European Bank for Reconstruction and Development (EBRD) and supported by various Egyptian authorities and the World Business Council for Sustainable Development (WBCSD). This publication came a year after the Paris Agreement and nearly 2 years after Egypt allowed the use of coal and high-carbon fuels in cement production. The EBRD report recommended balancing the licensing of new cement plants with long-term domestic market needs. The cement market was currently operating at 70% capacity, which was economically unsustainable due to oversupply and decreased demand over the past decade.

Since 2020, Egyptian market made significant changes in concrete manufacturing to meet international standards and adhere to sustainable practices. The adopted sustainable practices to align with global environmental standards were as follows:

⁃ Waste-to-Energy co-processing of waste materials not only reduces landfill use but also provides a sustainable energy source for cement production (Association, 2021). Ministry of Trade and Industry in Egypt, is promoting policies to encourage cleaner production methods and renewable energy adoption (Industry, Ministry of Trade, 2023).

⁃ Heidelberg Materials Egypt inaugurated an 18 MW waste heat recovery unit at its Helwan Cement plant in 2024, showcasing efforts to cut energy costs and improve efficiency (Perilli, 2024).

⁃ The Global Cement and Concrete Association (GCCA) launched a series of net-zero accelerator initiatives in Egypt to help the industry decarbonize in line with the 2050 Net-Zero Global Industry Roadmap (Daily news, 2022).

⁃ Alternative Fuel Investments:

⁃ The European Bank for Reconstruction and Development (EBRD) and A3&Co. (World Cement Association, 2025) supported energy efficiency in Egypt’s cement industry. They have provided financing to Arabian Cement Company (ACC) to reduce CO2 emissions by 130,000 tons annually using alternative fuels and energy-efficient technologies to produce low-carbon cement with lower cost (Development and European Bank for Reconstruction and, 2025; Cement and World, 2023). ACC implemented the ISO 50001 energy management standard, leading to a 2% reduction in energy consumption (UNIDO, 2019).

⁃ Cemex Egypt invested in decarbonization equipment and technology, achieving the highest alternative fuels substitution rate in Egypt’s cement industry. This investment is part of Cemex’s “Future in Action” strategy, which focuses on reducing CO2 emissions, increasing the use of alternative fuels, and enhancing energy efficiency across all operations (CEMEX, 2024).

The latest efforts in Egypt concrete sector addressed lowering the carbon footprint of fuel consumption during manufacture with a significant emphasis on alternative fuels and emission reduction. Although these developments support sustainability, they do address the integration of renewable materials (such as desert sand) in the clinker process.

3.2 Validity of sustainable initiatives in the masonry manufacturing sector

3.2.1 The sand lego blocks in Egypt

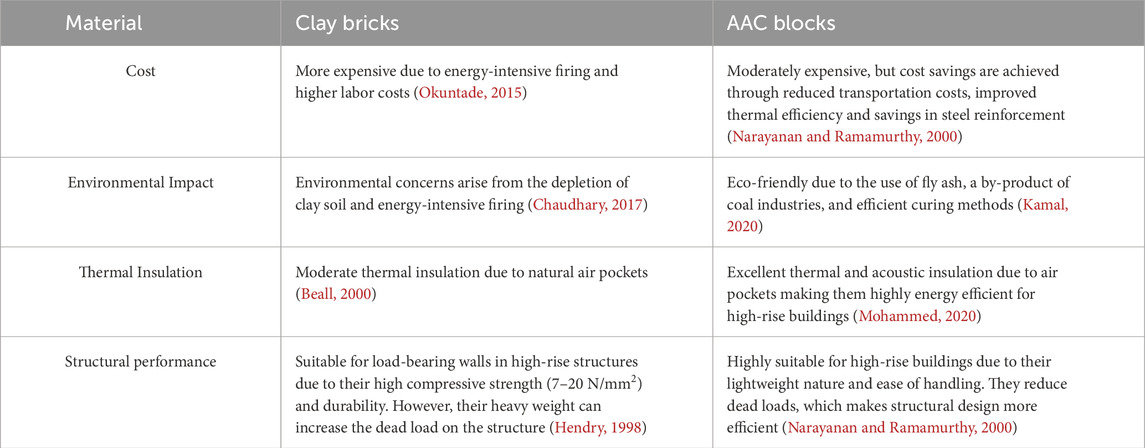

Using sand soil, researchers from October University for Modern Sciences and Arts in Egypt have created an original interlocking hollow brick, Figure 2. Later given a patent by the Egyptian Academy of Scientific Research, the team constructed a one-story trial building out of these bricks in December 2020. Although an Egyptian building code for this type of brick has been in place since 2010, Figure 3 (ES, 2008), lack of understanding among brick producers and builders limits their commercial use. Among the several advantages the bricks bring are financial economy, structural strength, and visual appeal. They are functional in acoustic and thermal isolation and roughly half building expenses. The bricks are produced using a pressing machine and there is no burning involved in manufacturing. The National Housing and Building Research Center handed the study team a structural safety certificate and the successful completion of this experimental building is expected to raise awareness and promote commercial use of sandy soil bricks in Egypt (SciDevNet, 2021).

Figure 2. One-story trial building by interlocking sand blocks in Egypt MSA University (ES, 2008).

Figure 3. Researchers while working on interlocking hollow brick in Egypt MSA University (ES, 2008).

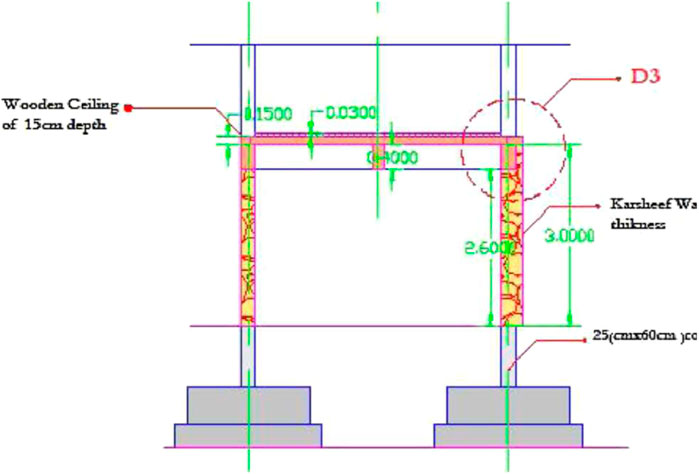

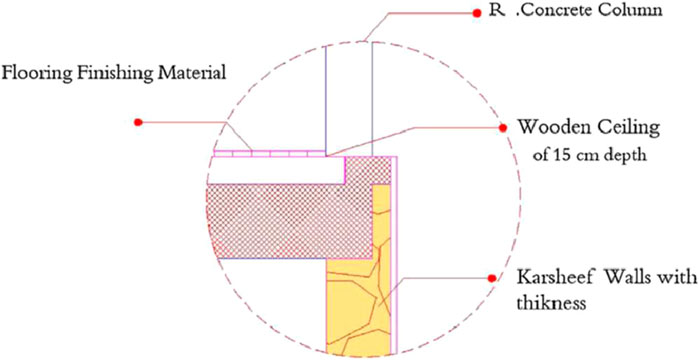

3.2.2 New karshif: a hybrid structural technique between old kashif and reinforced concrete

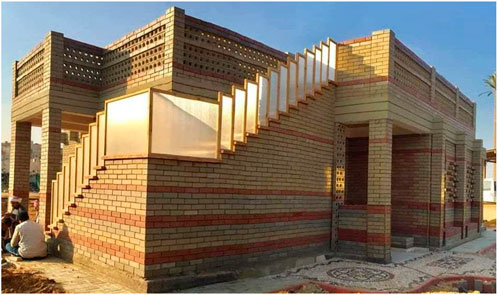

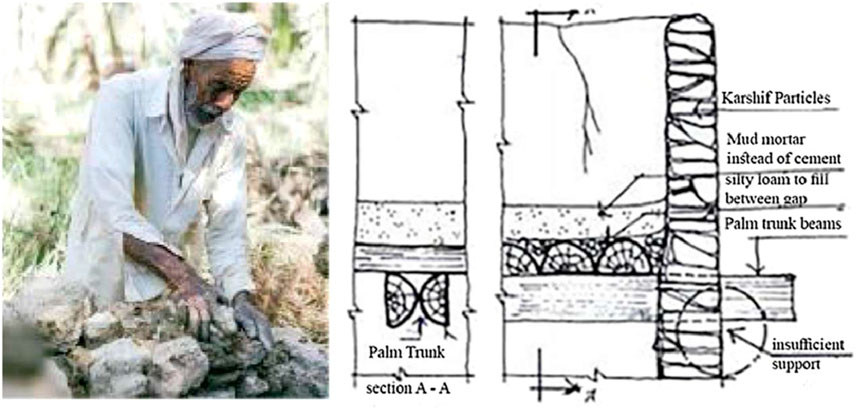

The inhabitants of this oasis in Egypt’s Western Desert constructed their homes from materials found in their immediate vicinity. Over several epochs, oasis architectural architecture has reflected the maturation of various building methods and materials in response to climatic challenges. Karshif is one of the stones found on the shores of the Salt Lake. Figure 4 shows that the stone’s particles typically range from 50 mm to 200 mm in size, and that its irregular shapes and varying diameters are caused by its composition of salt, clay, and fine sand.

Figure 4. Construction with palm trees and Karshif particles (Farrag and Elalfy, 2016)

Previous research in Siwa compared architectural design options for an inexpensive dwelling in Siwa Oasis. These architecture design options depend on local materials and the best construction system. In Siwa oasis, traditional building materials were upgraded to resist rain and other environmental issues. Karshif particles are cut into 30–50-cm-long, 15–25-cm-wide, and 10–15-cm-thick pieces. Figure 4 shows Siwan mortar being prepared for Karshif particle bonding. This building uses “Silt L” which comes from nearby lakes and “Silt M” brought in from nearby mountains (Hussein, 2005; Shafik and Adel, 1997).

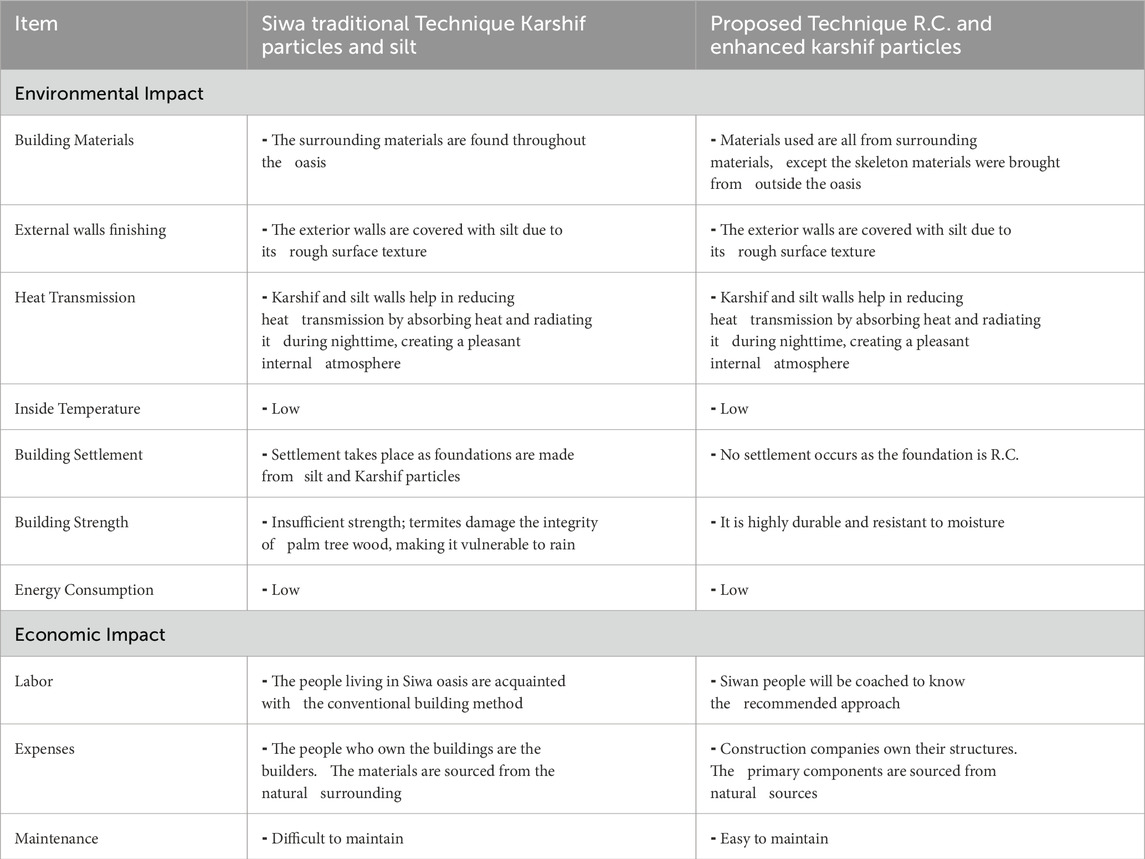

These elements are abundant in Siwa oasis, including Karshif, silt, palm wood, and natural stone. These environmentally friendly materials create strong, rain-resistant construction, as shown in Figures 5, 6, with detailed architectural elements. Traditional and recommended building methods according to the research are compared in Table 2.

Table 2. Comparison between traditional and proposed building techniques (Abdelaziz, 2020).

4 Enablers of sand as a sustainable earth construction material

4.1 The suitability of sustainable desert sand for concrete manufacturing

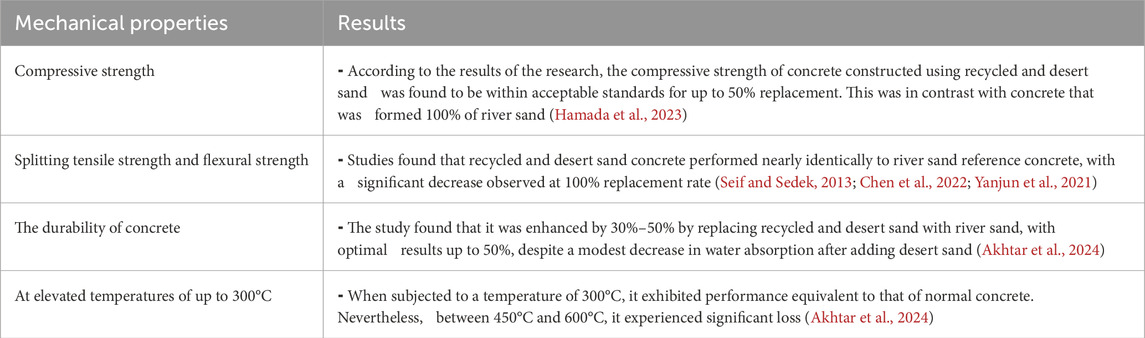

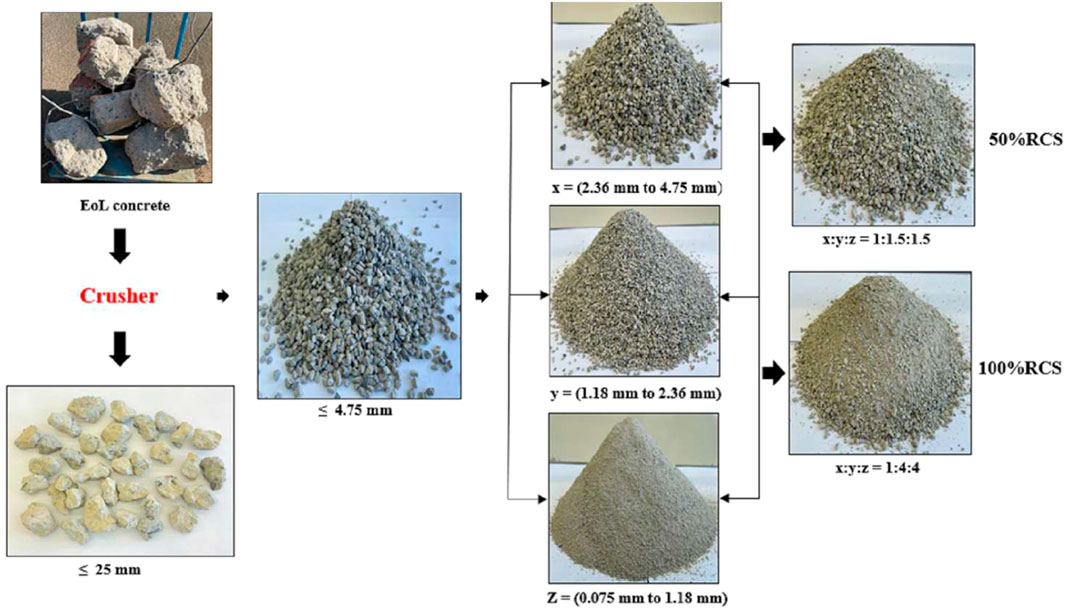

According to previous publications based on Standard Specification for Concrete Aggregates according to American Concrete Institute, sand grains require rough edges to adhere when used in construction. These studies have shown that the strength and durability of concrete decrease when more desert sand is added, and that compressive strength significantly decreases when desert sand replaces more than half of river sand. The chemical and physical properties of cement-aggregate mixtures are influenced by the effects of the desert sand, necessitating the processing and purification of this material, (Figure 7) (Haifeng et al., 2017; Institute, 2018).

Figure 7. Technique of optimization for modified sand (Akhtar et al., 2024).

In other publications performed using desert sand of Egypt and Saudi Arabia, mixing recycled crushed sand (RCS) with leftover concrete might enhance the qualities of desert sand and therefore increase its utility in the manufacturing of concrete. Recent studies by Akhtar et al., according to which varying proportions of recycled sand enhanced the physical characteristics of desert sand. The best results came from combining 40% desert sand with 60% recycled crushed sand (Akhtar et al., 2023; Seif and Sedek, 2013; Kachouh et al., 2019; Noui et al., 2020; El-Mir et al., 2022; Kog, 2020; Khalid et al., 2021). These studies used British Standard methods (BSI, 1988; British Standards Institution, 1990).

Past studies did not recommend the 100% separate utilization of recycled and desert sand in concrete (Ju et al., 2020; Bourguiba et al., 2017; Surendar et al., 2021; Levy and Hel`ene, 2020; Tamanna et al., 2020; Le et al., 2019). The main reason is that replacing more recycled sand in concrete requires longer curing time to reach the prepared concrete’s design and target strengths (Akhtar et al., 2021).

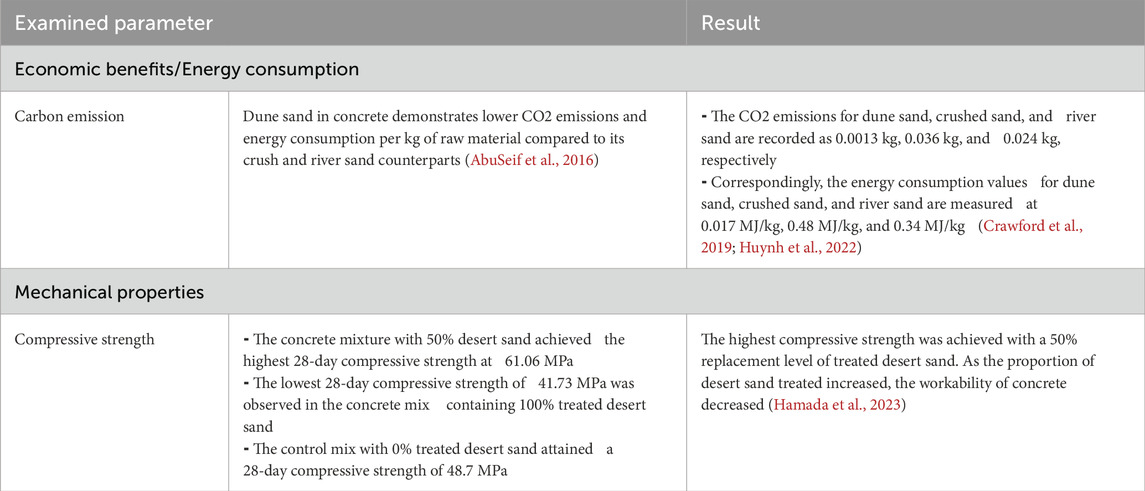

In a previous study, the conclusions of the data extraction process results from 109 peer-reviewed papers about the suitability of sustainable sand for concrete manufacturing by substitution with recycled and desert sand, were introduced, Table 3. The following table introduces past studies results which introduced desert sand for concrete manufacturing.

4.1.1 Lowering the clinker content and carbon emission reduction in concrete production

Including desert sand into concrete mixtures lowers the clinker content which improves environmental sustainability (Cao et al., 2025). Adding waste products with strong calcium and silicon-based oxides will help one to create ecologically friendly concrete using less cement (Hamada et al., 2023).

Recent studies have examined the possibility of using desert sand to produce ecological concrete, which would reduce the clinker content, i.e., natural materials (limestone and clay). Algerian researchers investigated the possibility of adding 10% powdered dune sand to eco-friendly self-compacting concrete. Their low water-to-cement ratio of 0.40 resulted in a 55 MPa compressive strength, significantly enhancing the concrete’s structural integrity (Radcliffe).

Research conducted in Saudi Arabia showed that combined with 10% silica fume, replacing natural sand with a mix of 50% desert sand and 50% recycled crushed sand produced best results. Along with increasing concrete strength and durability, this combination let cement usage be dropped by 10%. The study found that the suggested concrete design mix may save 10% of cement and 100% of natural sand, so encouraging sustainability in concrete building (Akhtar et al., 2025).

These findings suggest that incorporating desert sand into concrete mixtures can effectively reduce cement consumption and enhance environmental sustainability. Table 4 was developed by the researcher to introduce the results of the above-mentioned studies.

Table 4. Examination of desert sand as a primary source in concrete manufacturing (developed by researcher).

4.1.2 Silica sand as cement replacement in Portland Pozzolana Cement (PPC) concrete manufacturing in Egypt

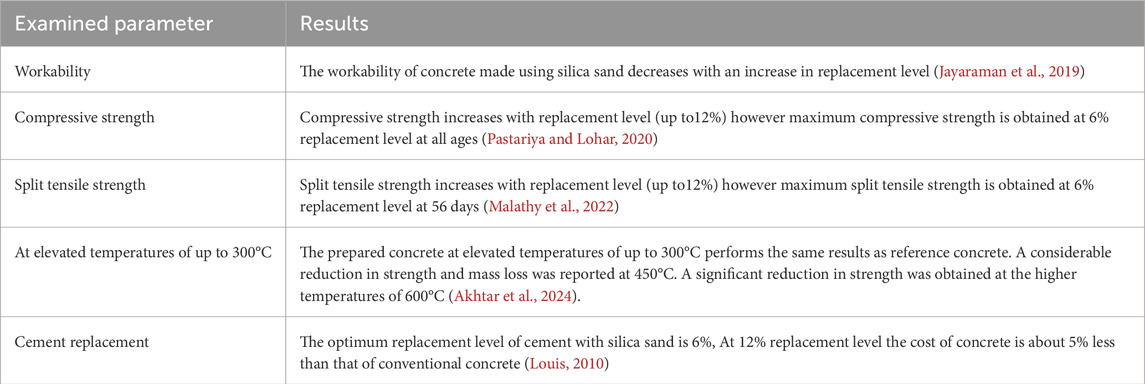

Silica sand is a cost-effective material that is predominantly composed of quartz. It is comprised of silicon and oxygen or SiO2, typically containing up to 99% SiO2. It is found in significant quantities within sand, rock, and mineral ore. Silica sand can be used in making concrete mix as partial replacement of fine aggregate. It is very durable material resistant to heat and chemical attack. Silica sand was tested as a cement substitute in an earlier study conducted in 2015, its purpose was to determine how silica sand affected the strength of Portland Pozzolana cement concrete (Chaudhary et al., 2015). Results of different parameters were concluded and illustrated in Table 5.

Table 5. The effect of silica sand on strength of Portland Pozzolana cement concrete (developed by researcher).

Numerous studies have shown the advantages of including silica-based elements in concrete. According to Louis (2010), at 28 days the usage of reactive silica sand considerably improved the compressive strength of concrete (Ahmed and Mamat, 2011). Likewise, Ahmed and Mamat (2011) noted that adding nano-silica sand enhanced tensile strength and hardness (Ahmed and Mamat, 2011). Adding micro and nano-silica strengthened concrete and enhance abrasion resistance and compressive strength, according to research by Rahmari et al. (2012). Abdelbaky et al. (2013); Egyptian researchers at Housing and Building National Research Centre of Egypt; investigated what happened when nano-silica sand was used instead of some cement and discovered that it considerably raised the compressive and bending strengths though it made the concrete tougher to work with (Abdelbaky et al., 2013). A similar study by Jiang et al. (2014) indicated that substituting silica sand powder and slag powder for some Portland cement would help to reduce the environmental damage caused by concrete manufacture (Feng et al., 2014).

Generally, these findings reveal that silica-based components strengthen concrete mixes and extend their lifetime. They are an indicative approach to decrease the overuse of cement. Thus, it will lead to less expensive buildings which is a typical economic benefit coupled with carbon emission reduction.

4.2 Sand blocks, an environmentally friendly bricks for construction in Egypt

This type of bricks depends on a technology known worldwide as AAC blocks (autoclaved aerated concrete), known in the Egyptian market as “Light White Block” due to its physical characteristics. The production process includes the usage of the following raw materials: sand, cement, lime, gypsum, and water. The process starts with sand grinding with water in large grinding mills. All the raw materials are added with an expansion agent to become a homogenized slurry, which is then cast into large metal molds. The molds are then transferred to increase in volume “swells”, creating the compound structure that creates the brick’s specifications. Once the mixture is hardened sufficiently, it is then cut into different sizes. The blocks are then exposed to high heat and pressure to generate the block’s strength. According to the manufacturing sources provided by the manufacturer, the production cycle is automated and depends on electricity as the energy source (El-Hamawy, 2020).

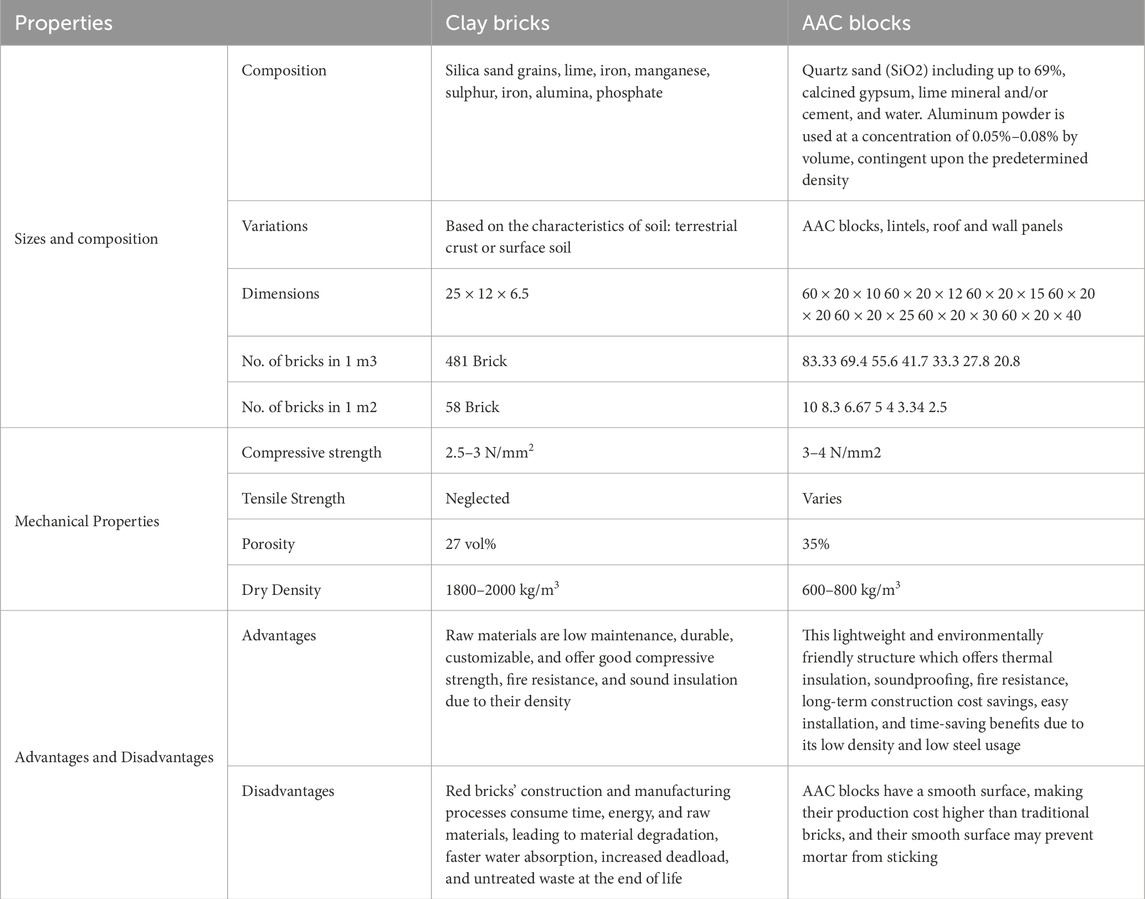

According to EOS standard 1401/2021 (Egyptian Organizationfor Standards & Quality, 2021), the following Table 6 summarizes the comparison between traditional clay bricks and AAC blocks for masonry construction in terms of sizes, mechanical properties, advantages and disadvantages.

Prior research has been conducted to evaluate the impact of traditional clay bricks and AAC blocks on wall systems and fenestrations concerning indoor environmental quality, energy efficiency, and economic performance. A summary of the findings and conclusions can be articulated as follows (Khalil, 2019):

⁃ AAC blocks are more environmentally friendly than clay bricks in terms of cost and environmental impact. They save 37.9% and 34.1% in residential and commercial structures, respectively. The most effective option is double AAC blocks with air gaps and double reflecting glass, which can reduce energy usage by 23.6% for residential buildings and 24.6% for commercial buildings. Although the initial cost is higher, the cost of operating the business is lower. AAC blocks also have superior thermal performance due to their low thermal conductivity and high thermal resistance, resulting in lower energy consumption.

5 An indicative approach for a future national direction

5.1 Incorporating desert sand in PPC production to mitigate the negative impacts of the clinker process

The discussion in this paper has have shown the appropriateness of reconsidering sand as earth material to replace cement in PPC production and attain decarbonization correspondingly. Clinker production is still a major source of CO2 emissions in Egypt. Not having enough fly ash, granulated blast furnace slag, or pozzolana as alternatives, makes desert sand a good choice for lowering carbon emissions.

The researcher suggests that the following approach to ensure the proposed approach to incorporate desert sand in PPC production:

⁃ Studies have shown how well recycled crushed sand (RCS) and desert sand work together to improve the qualities of concrete. Concrete strength and durability are best enhanced by a 40% desert sand and 60% RCS combination, according to studies done in Saudi Arabia and Egypt using British Standard techniques. Additional research conducted in Saudi Arabia revealed that adding 10% silica fume to a 50/50 mixture of recycled and desert sand resulted in high-performance concrete with a 10% reduction in cement use. The research on nano-silica sand in Housing & Building National Research Centre of Egypt found that it significantly increased compressive and bending strength.

⁃ Given the sandy soils in Egypt which exhibit diverse mineralogical compositions and similar engineering properties, it should be taken under consideration making additional lab tests for Egyptian sand types (quartz, feldspar and aeolian) to validate a complete life cycle analysis and economic feasibility of replacing cement in PPC manufacturing by desert sand. The suggested lab tests are to be designed to particularly examine the engineering characteristics of the Egyptian sand for this aim and produce validated data compatible with both local and international standards. The following are some considerations that validate the proposed approach and for future research, Table 7:

5.2 Applying established guidelines to enforce the use of sand blocks in egyptian construction

When evaluating the suitability of traditional clay bricks versus autoclaved aerated concrete (AAC) Blocks for construction, several factors such as structural performance, environmental benefits, thermal properties, and construction cost efficiency must be considered. Table 8 introduces a short analysis between the two types in terms of cost, environmental/energy efficiency and structural performance.

AAC blocks are governed by specific national standards set by EOS, ensuring their quality and performance. These standards cover aspects such as dimensions, strength, thermal insulation, and fire resistance. They have several advantages over traditional clay bricks, making them a superior choice for modern construction. AAC blocks are significantly lighter, reducing the overall dead load on structures, which can lead to cost savings in foundation and structural support. Their excellent thermal insulation properties help maintain indoor temperatures, reducing the need for additional heating or cooling and thus lowering energy (Praveen, 2024).

The researcher suggests that the following approach in order to ensure that AAC blocks are enforced:

⁃ Supply Chains: Manufacturers are required to obtain certification and conduct regular testing to verify the properties of AAC blocks.

⁃ Jointing mortar or adhesive: It is preferred for laying AAC blocks than conventional cement mortar (like a 1:3 ratio) for high bond strength, no shrinkage cracks, flexible and shock resistant (magicrete, 2024).

⁃ Reducing AAC production cost: High demand of AAC can help reduce production costs through economies of scale, where producing larger quantities lowers the cost per unit by spreading fixed costs over more units. It can also justify investments in efficient production technologies, which improve efficiency, reduce waste, and speed up production, further lowering costs. Additionally, increased demand can attract more competitors, driving innovation and efficiency as companies strive to maintain or grow their market share.

5.3 Lego principle in sand construction for egyptian urban expansion

In the Architecture, Engineering, and Construction (AEC) sector, LEGO principle has become a valuable tool, offering a flexible and interactive approach to various project development aspects. Architects and engineers use LEGO principle to create tangible models during conceptual design and prototyping, aiding in visualizing layouts and structures and enhancing idea communication. These models allow for rapid testing of different configurations before committing to detailed designs. The modular nature of LEGO facilitates easy adjustments and experimentation, enabling designers to explore various solutions without complex tools or software. The growth in Egyptian urban expansion driven by both residential and commercial construction, supported by government initiatives and foreign investments (section 2.2.4) makes prototyping with LEGO a cost-effective option, allowing for quick iteration and testing without expensive materials or equipment, especially in the early stages of design.

Low-rise buildings with AAC blocks using the modular nature of Lego principle offer numerous benefits making them an ideal choice for Egyptian sustainable development:

- being locally sourced, reduce transportation costs and environmental impact, in addition to fostering community interaction through the creation of communal spaces, such as: housing projects, educational facilities, and touristic villages.

High-rise buildings with AAC blocks using modular nature of Lego principle offer numerous benefits making them an ideal choice for Egypisn sustainable development:

- This accelerated construction timeline is essential for Egypt’s expanding cities, such as Cairo and New Administrative Capital, which require quick project delivery (Smith, 2010).

- Setting up modular factories and acquiring advanced machinery requires significant upfront investment. However, this cost is offset in the long term by faster project delivery and reduced labor costs (Jaillon and Poon, 2008).

6 Conclusion

The study indicates that incorporating desert sand into Egypt’s construction industry is beneficial from technical, economical, and environmental perspectives. It presents sand as a renewable resource which reduce CO2 emissions by substituting cement-based materials locally widespread, hence enhancing energy efficiency. Regarding thermal insulation and sustainability, blocks made of autoclaved aerated concrete (AAC) offer clear benefits. Still, industry inexperience, legal uncertainty, and technical restrictions prevent broad use. To standardize locally recognized criteria, the researcher underlines the necessity of further experimental investigations especially including Egyptian sand and regulatory actions that help to integrate masonry and sand-based concrete. The research supports the adoption of LEGO-inspired building methods, modular and sustainable sand-based building materials, to enable quick and environmentally friendly urban growth.

Author contributions

DK: Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

The author wishes to acknowledge Paul Awoyera (Editor-in-Chief) and the two reviewers for insightful comments and criticism that improved this manuscript.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

GDP, gross domestic product; MEA, Middle East and Africa; RMC, Ready-mixed concrete; SMC, site-mixed concrete; GAFI, General Authority for Investment in Egypt; SCM, supplementary cementitious materials; GHG, greenhouse gas; EOS, Egyptian Organization for Standardization and Quality; RCS, Recycled Crushed Sand; EEAA, Egyptian Environmental Affairs Agency; EBRD, European Bank for Reconstruction and Development; WBCSD, World Business Council for Sustainable Development; A3&Co., A3&Co. is a Dubai-based consultancy company specializing in the cement and concrete industry.; GCCA, Global Cement and Concrete Association; PPC, Portland Pozzolana Cement; AAC, autoclaved aerated concrete; AEC, Architecture, Engineering, and Construction.

References

Abdelaziz, F. A. M. (2020). Comparative study of traditional and modern building techniques in Siwa Oasis, Egypt. Case study: affordable residential building using appropriate building technique. Case Stud. Constr. Mater. 12, E00311. doi:10.1016/j.cscm.2019.e00311

Abdelbaky, S., Yehia, S., and Khalil, S. I. (2013). Influence of nano silica addition on properties of fresh and hardened cement mortar. Egypt: Housing and Building National Research Center.

Abu Seif, E. S. (2015). Geotechnical and mineralogical Characteristics of the Nubia sandstone Formation in Egypt. s.l. Arabian J. Geosciences 8 (6), 3709–3721.

AbuSeif, E. S. S., Sonbul, A. R., Hakami, B. A. H., and El-Sawy, E. K. (2016). Experimental study on the utilization of dune sands as a construction material in the area between Jeddah and Mecca, Western Saudi Arabia. Bull. Eng. Geol. Environ. 75, 1007–1022. doi:10.1007/s10064-016-0855-9

Ahmed, T., and Mamat, O. (2011). Characterization and properties of aluminium–silica nano particle compositie. Solid State Sci. Technol.

Akhtar, M. N., Ibrahim, Z., Bunnori, N. M., Jameel, M., Tarannum, N., and Akhtar, J. (2021). Performance of sustainable sand concrete at ambient and elevated temperature. Constr. Build. Mater. 280, 122404. doi:10.1016/j.conbuildmat.2021.122404

Akhtar, M. N., Ibrahim, Z., Bunnori, N., and Bani-Hani, K. (2023). Development of sustainable modified sand concrete: an experimental study. Ain Shams Eng. J.

Akhtar, M. N., Bani-Hani, K. A., Malkawi, D. A., and Albatayneh, O. (2024). Suitability of sustainable sand for concrete manufacturing - a complete review of recycled and desert sand substitution. s.l. Results Eng. 23, 102478. doi:10.1016/j.rineng.2024.102478

Akhtar, M. N., Alotaibi, A., and Shbeeb, N. I. (2025). River sand replacement with sustainable sand in design mix concrete for the construction industry. Civ. Eng. J. 11 (1), 201–214. doi:10.28991/cej-2025-011-01-012

Anderson, R., Dewar, J., Heather, M., and Ian, T. (1992). Manual od ready-mixed concrete. United Kingdom: Taylor&Francis Group.

Askar, Y., Jago, P., Mourad, M. M., and Huisingh, D. (2010). The cement industry in Egypt: challenges and innovative cleaner production solutions. Knowledge collaboration and learning for sustainable innovation ERSCP-EMSU.

Association (2021). World cement. Available online at: https://www.worldcementassociation.org/wca-annual-conference-2021.

Balderer, W., Porowski, A., Idris, H., and LaMoreaux, J. W. (2014). “Thermal and Mineral Waters: Origin, Properties and Applications (Environmental Earth Sciences). Heidelberg: Springer, 2223–2224.

Bourguiba, A., Ghorbel, E., Cristofol, L., and Dhaoui, W. (2017). Effects of recycled sand on the properties and durability of polymer and cement based mortars. Constr. Build. Mater. 153, 44–54. doi:10.1016/j.conbuildmat.2017.07.029

Brian, N., Liqun, L., Pengfei, Z., Christophe, N., and Xu, T. (2019). Mineralogical characterization of aeolian sands from inner Mongolia, China. J. Minerals Mater. Charact. Eng. 7, 81–102.

Britannica (2025). Egypt - Soils, Deserts, Agriculture Available online at: https://www.britannica.com/place/Egypt/Soils.

British Standards Institution.(1990). British Standard Methods of test for soils for civil engineering purposes.

BSI (1988). BS 812–117: Testing Aggregates. Method for determination of watersoluble chloride salts. Milton Keynes: BSI.

Cao, A., Ma, Y., Li, Z., Du, X., Li, G., and Wang, A. (2025). Study of the influence of desert sand-mineral admixture on the abrasion resistance of concrete. Materials 18 (2), 446. doi:10.3390/ma18020446

Cement and Concrete Association, British Cement Association. (2002). BCA concrete practice. Britain. 3rd Edition.

Cement and World (2023). World cement. United Kingdom: World Cement. Available online at: https://www.worldcement.com/africa-middle-east/21112023/ebrd-and-aco-join-forces-to-drive-decarbonisation-at-arabian-cement-company-in-egypt/.

Cement (2023). Egyptian chamber of. Available online at: https://www.amcham.org.eg/publications/industry-insight/issue/87.

CEMEX (2024). Cemex Egypt invests in Decarbonization Equipment and Technology making it the highest Alternative Fuels substitution rate cement company in Egypt. Available online at: https://www.cemex.com.eg/press-releases-full-view/-/asset_publisher/CBG7DkTcJQMD/content/cemex-egypt-invests-in-decarbonization-equipment-and-technology-making-it-the-highest-alternative-fuels-substitution-rate-cement-company-in-egypt.

Chaudhary, J. L., Harison, A., and Srivastava, V. (2015). Use of silica sand as cement replacement in PPC concrete. J. Res. Eng. Technol. 04, 55–58. doi:10.15623/ijret.2015.0411010

Chaudhary, S. e. (2017). Environmental impact of traditional brick manufacturing. Environ. Manag. J.

Chen, Q., Liu, H., Han, L., and Wang, Y. (2022). Comparative studies of dynamic mechanical properties of desert sand concrete and ordinary concrete. Shock Vib. 2022, 1–13. doi:10.1155/2022/8680750

Crawford, R., Stephan, A., and Prideaux, F. (2019). Environmental performance in construction. Australian Research Council.

Crosthwaite, D. (2000). The global construction market: a cross-sectional analysis. Constr. Manag. Econ. 18, 619–627. doi:10.1080/014461900407428

Cui, Q., Liu, G., Zhang, Z., Fang, Y., and Gu, X. (2023). Experimental investigation on the strength and microscopic properties of cement-stabilized aeolian sand. Buildings 13, 395. doi:10.3390/buildings13020395

Daily News Egypt (2015). Egyptian cement executives found guilty of price-fixing. Available online at: https://www.dailynewsegypt.com/2008/08/25/20-egyptian-cement-executives-found-guilty-of-price-fixing/.

Daily news. (2022). Cement, concrete industry launches net-zero accelerators across the world. Available online at: https://www.dailynewsegypt.com/2022/03/31/cement-concrete-industry-launches-net-zero-accelerators-across-the-world/.

Development, European Bank for Reconstruction and (2025). European Bank for reconstruction and development. Eur. Bank Reconstr. Dev. Available online at: https://www.ebrd.com/news/2025/ebrd-and-eu-foster-energy-efficiency-in-egypts-cement-industry.html.

Dilip, K. S., and Amitava, S. (2012). Effect of partial replacement of cement by silica fume on hardened concrete. Int. J. Emerg. Technol. Adv. Eng. 2 (8), 472–475.

ECP (2007). The Egyptian code of practice for design and construction for reinforced concrete structures, ECP 203-2007. Ministry of Building Construction. Cairo, Egypt: Research Center for Housing, Building and Physical Planning.

Edris, W., and Al-Tamimi, M. (2021). Implementation of Feldspar as a partial replacement material in cement mortar (exploration and application). J. Appl. Eng. Sci. 20, 1–9. doi:10.5937/jaes0-31694

Egyptian Organization for Standards and Quality (2021) Standard specification for autoclaved aerated concrete (AAC). Egpt.

Elbasioumy, H., and Elbehiry, F. (2018). Geology, the soils of Egypt. World soils Book series. Springer, 93–109.

El-Hamawy, M. A. (2020). “An evaluation of the usage of environmentally friendly bricks for housing in Egypt, MSc,” in Integrated urbanism and sustainable design 2020 (Egypt: Ain Shams University, Egypt and University of Stuttgart).

El-Mezayen, A. M., El-Desoky, H. M., Abayazed, S. D., and El-Bery, A. M. (2018). Suitability of Feldspar sand deposits as raw material for the production of ceramic tiles WADI El-Yatima, Wadi El-Tuleia district, Central Eastern Desert, Egypt. Al Azhar Bull. Sci. 29 (2), 19–31.

El-Mir, A., El-Hassan, H., El-Dieb, A., and Alsallamin, A. (2022). Development and optimization of geopolymers made with desert dune sand and blast furnace slag. Sustainability 14, 7845. doi:10.3390/su14137845

El-Sayed, M. I., and Youssef, M. M. (2018). Mineralogical and geochemical characteristics of sandy soils in the Western Desert of Egypt. J. Afr. Earth Sci. 145, 1–12.

Embabi, N. S. (2018). The geomorphology of Egypt: landforms and evolution, 1. Egypt: The Nile Valley and the Western Desert.

EPA and U.S. Environmental Protection Agency (2012). Available and emerging technologies for reducing greenhouse gas emissions from the portland cement industry. s.l. USA: United States Environmental Protection Agency EPA.

Ezzat, K., Kamal, A. E., and Mamdoh, H. (2013). Factor analysis of meteorological and granulometrical data of aeolian sands in arid area as a geo-environmental clue: a case study from western bank of lake nasser, Egypt. Int. J. Civ. and Environ. Eng. IJCEE-IJENS 13 (03), 21–37.

Farrag, N., and Elalfy, M. (2016). Harmonization between architectural development and heritage in Siwa oasis, Egypt. J. Eng. Appl. Sci., 2005–2015.

Feng, J., Chang, D., Wang, Z., Shen, B., Yang, J., Jiang, Y., et al. (2014). A FITC-doped silica coated gold nanocomposite for both in vivo X-ray CT and fluorescence dual modal imaging. RSC Adv. 4, 51950–51959. doi:10.1039/c4ra09392e

GAFI (2013). A Snapshot of the Egyptian economy. s.l. General Authority for Investment, Egypt, 2013.

Gleeds (2025). Egypt construction market report 4Q 2024. Available online at: https://www.gleeds.com/en/insights-and-reports/market-reports/egypt-construction-market-report-4q-2024/.

Globenewswire (2024). Egypt Construction Industry Databook 2023 - Construction Output Expected to Reach EGP 714.8 billion by 2027, Recording a CAGR of 7.5% During 2023-2027. Available online at: https://www.globenewswire.com/news-release/2024/01/22/2813396/28124/en/Egypt-Construction-Industry-Databook-2023-Construction-Output-Expected-to-Reach-EGP-714-8-billion-by-2027-Recording-a-CAGR-of-7-5-During-2023-2027.html.

Haifeng, L., Jurong, Ma., Yiying, W., and Jianguo, N. (2017). Influence of desert sand on the mechanical properties of concrete subjected to impact loading. Acta Mech. Solida Sin. 30, 583–595. doi:10.1016/j.camss.2017.10.007

Hamada, H. M., Abed, F., Al-Sadoon, Z. A., Elnassar, Z., and Hassan, A. (2023). The use of treated desert sand in sustainable concrete: a mechanical and microstructure study. J. Build. Eng. 79, 107843. doi:10.1016/j.jobe.2023.107843

Hanna, G. B. (2015). “Energy efficiency building codes and green pyramid rating system,” in Renewable Energy in the Service of Mankind Vol I. Springer Nature, 2015, 597–608.

Hereher, M. (2014). Assessment of sand drift potential along the Nile Valley and Delta using climatic and satellite data. Appl. Geogr. 55, 39–47. doi:10.1016/j.apgeog.2014.09.004

Hussein, N. (2005). “An approach to develop ecolodges in Siwa oasis using natural building materials: theoretical and experimental study. Alexandria, Egypt: thesis at construction and building department, college of engineering and technology, arab Academy for science, technology and maritime transport. 2005.

Huynh, T. P., Ho, S., and Ho, V. (2022). Experimental investigation on the performance of concrete incorporating fine dune sand and ground granulated blast-furnace slag. Constr. Build. Mater.

Jaillon, L., and Poon, C. S. (2008). Sustainable construction aspects of using prefabrication in dense urban environment.

Jayaraman, A., Prasath, S. B., and Senthilkumar, V. (2019). Effect of using different types of sand on workability, mechanical and durability performance of high strength concrete. Int. J. ChemTech Res. 12 (02), 37–50. doi:10.20902/IJCTR.2019.120206

Ju, M., Jeong, J. G., Palou, M., and Park, K. (2020). Mechanical behavior of fine recycled concrete aggregate concrete with the Mineral admixtures. Materials 13, 2264. doi:10.3390/ma13102264

Justindargin (2014). Overview of Egypt’s energy efficiency regulations. Available online at: http://www.justindargin.com/uploads/5/1/5/3/5153441/split_ee.pdf.

Kachallah, B. G., Muhammad, M. I., and Olubajo, O. O. (2022). Effect of quartz particle size and cement replacement on Portland limestone cement properties. J. Build. Material Sci. 04, 02.

Kachouh, N., El-Hassan, H., and El-Maaddawy, T. (2019). Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 213, 348–359. doi:10.1016/j.conbuildmat.2019.04.087

Kamal, M. A. (2020). Analysis of autoclaved aerated concrete (AAC) blocks with reference to its potential and sustainability. J. Build. Mater. Struct. 7, 76–86. doi:10.34118/jbms.v7i1.707

Khalid, M. Y., Al Rashid, A., Arif, Z. U., Ahmed, W., Arshad, H., and Zaidi, A. A. (2021). Natural fiber reinforced composites: sustainable materials for emerging applications. Results Eng. 11, 100263. doi:10.1016/j.rineng.2021.100263

Khalil, E. A. S. (2019). Impact of autoclaved aerated concrete (AAC) on modern constructions: a case study in the new Egyptian administrative capital, MSc., school of Sciences and engineering. Cairo, Egypt: The American University.

Kog, Y. C. (2020). High-performance concrete made with dune sand. Mag. Concr. Res. 72, 1036–1046. doi:10.1680/jmacr.18.00073

Kosmatka, S. H., Kerkhoff, B., and Panarese, W. C. (2017). Design and control of concrete mixtures. 2017. Open J. Civ. Eng. 7 (1).

Lafarge (2009). Lafrage in Egypt and the United Arab Emirates: a platform for sustainable growth. Available online at: https://www.lafarge.com.eg/en/6_3_5-Sustainable_Construction.

Le, M. T., Tribout, C., and Escadeillas, G. (2019). Durability of mortars with leftover recycled sand. Constr. Build. Mater. 215, 391–400. doi:10.1016/j.conbuildmat.2019.04.179

Levy, S., and Hel`ene, P. (2020). Durability of concrete mixed with fine recycled aggregates. Sustainable Construction Materials and Technologies. USA, Florida: CRC Press, 45–51.

Louis, M. A. (2010). Strength of reactive silica sand powder concrete made of local powders. J. Eng. Sci.

magicrete (2024). Block jointing mortar. Available online at: https://www.magicrete.in/walling-solutions/dry-mix-products/block-jointing-mortar#TechnicalSpecification.

Malathy, R., Sentilkumar, S. R. R., Rangasamy Prakash, A., Das, B. B., Chung, I.-M., Kim, S.-H., et al. (2022). Use of industrial silica sand as a fine aggregate in concrete—an explorative study. Build. (Basel). 12, 1273. doi:10.3390/buildings12081273

Mobarak, A. (2001). The challenges of sustainable industrial development in Egypt. United Nations Industrial Development organization UNIDO. World Summit on Sustainable Development WSSD.

Narayanan, N., and Ramamurthy, K. (2000). Structure and properties of aerated concrete: a review. Cem. and Concr. Compos. 22, 321–329. doi:10.1016/s0958-9465(00)00016-0

nasa (2018). The lower Nile Valley. Available online at: https://visibleearth.nasa.gov/images/68269/the-lower-nile-valley.

National Park (2021). White Desert National Park. Available online at: https://national-parks.org/egypt/white-desert.

Noui, A., Bouglada, M., Belagraa, L., Achour, Y., and Abderazak, B. (2020). Study of the mechanical behavior and durability of mortars based on prepared sand. Min. Sci., 47–59.

OHLA (2022). Global cement report. Available online at: https://www.cfic.dz/images/telechargements/eGCJan2022ns.pdf.

Okuntade, T. F. (2015). Review of shortage of skilled craftsmen in small and medium construction firms in Nigeria. J. Environ. Earth Sci. 5, 98–111.

Pastariya, S., and Lohar, G. (2020). Effect of silica fume on mechanical properties of hardened concrete as partial replacement of cement for M-35 concrete. Int. Res. J. Eng. Technol. (IRJET).

Perilli, D. (2024). Global cement. Glob. Cem. Available online at: https://www.globalcement.com/news/item/17933-update-on-egypt-october-2024.

Praveen, D. J. (2024). Comparative study of clay bricks and AAC blocks. Int. J. Struct. Des. Eng. 5 (1), 10–14.

Quality (2015). Egyptian Organization for Standards and. Concrete masonry units Part 1: Loadbearing concrete masonry units. Available online at: https://www.eos.org.eg/en/standard/3177.

Radcliffe, I. 2025 Algerian researchers turn desert sand into eco-friendly concrete for energy sector. Sustain. Constr. Rev. Available online at: https://sustainableconstructionreview.com/2025/02/01/algerian-researchers-turn-desert-sand-into-eco-friendly-concrete-for-energy-sector/#google_vignette.

Rahmari, K., Shamsai, A., Saghafian, B., and Peroti, S. (2012). Effect of water and cement ratio on compressive strength and abrasion of micro silica cement. Middle- East J. Sci. Res.

Sakr, D. (2023). Status of energy efficiency in the Egyptian building sector, march 2023, Egypt green building Council. Available online at: https://www.buildings-mena.com/files/EgyptGBC_StatusofEnergyEfficiencyintheEgyptianBuildingSector.pdf.

SciDevNet (2021). A building on a university campus promotes. sand-based 'LEGO' bricks in Egypt. Available online at: https://www.scidev.net/mena/news/a-building-on-the-campus-promotes-the-sandy-bricks-in-egypt/.

Seif, E. A., and Sedek, E. (2013). Performance of cement mortar made with fine aggregates of dune sand, Kharga Oasis, Western Desert, Egypt: an experimental study. Jordan J. Civ. Eng. 7, 270–284.

Shafik, K., and Adel, K. (1997). “Silica fume improves concrete strength; is that true?,” in Third international conference on structural and geotechnical engineering (ACSGE3). Alexandria, Egypt: Faculty of Engineering, Alexandria University.

Smith, R. E. (2010). Prefab architecture: a Guide to modular Design and construction. John Wiley and Sons, Inc.

Surendar, M., Ananthi, G. B. G., Sharaniya, M., Deepak, M., and Soundarya, T. (2021). Mechanical properties of concrete with recycled aggregate and M−sand. Mater. Proc. 44, 1723–1730. doi:10.1016/j.matpr.2020.11.896

Tamanna, N., Tuladhar, R., and Sivakugan, N. (2020). Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 239, 117804. doi:10.1016/j.conbuildmat.2019.117804

TheWorldBank (2014). Doing business 2014: understanding regulations for small and medium-size enterprises. USA, Washington: World Bank Group.

UNIDO (2019). “How Arabian Cement Company responded to Egypt’s energy crisis with innovation and efficiency. Available online at: https://www.industrialenergyaccelerator.org/egypt/how-arabian-cement-company-responded-to-egypts-energy-crisis-with-innovation-and-efficiency/.

Varghese, R., and Pillai, A. K. (2007). “Global competition and competitiveness of Indian corporate. India: s.n,” in Ready mix concrete business: operational vs strategic choices.

Walther, H. B. (2012). Quality requirements of quartz sand in the building industry. Springer Nature Link, 53–70.

World Cement Association (2025). Dubai-based consultancy company specializing in the cement and concrete industry

Yanjun, J., Chuang, L., and Zhichao, D. (2021). Research and analysis on present situation of desert sand concrete. E3S Web Conf. 271, 02004. doi:10.1051/e3sconf/202127102004

Keywords: desert sand, earth material, sustainable construction, concrete manufacturing, masonry production, urban expansion

Citation: Khater D (2025) Rethinking sand as earth material for a sustainable construction in Egypt. Front. Built Environ. 11:1566515. doi: 10.3389/fbuil.2025.1566515

Received: 25 January 2025; Accepted: 24 April 2025;

Published: 16 May 2025.

Edited by:

Paul Awoyera, Prince Mohammad bin Fahd University, Saudi ArabiaReviewed by:

Valentina Tomei, University of Cassino, ItalyParthiban Devarajan, Aarupadai Veedu Institute of Technology, India

Copyright © 2025 Khater. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dina Khater, ZGluYS5raGF0ZXJAZnVlLmVkdS5lZw==

Dina Khater

Dina Khater