- Department of Architecture and Building Science, Graduate School of Engineering, Tohoku University, Sendai, Miyagi, Japan

The Precast Prestressed Concrete (PCaPC) frame is characterized by minimal inelastic damage and self-centering behavior under seismic loading. It offers a viable alternative to conventional reinforced concrete construction, particularly in high seismic hazard regions. By employing unbonded prestressing tendons to connect precast beams and columns, PCaPC systems enhance structural resilience and reduce residual deformations. However, their widespread adoption has been hindered by high material and labor costs, as well as complex assembly processes. To address these limitations, this study proposes a cost-effective Mortise-Tenon (MT) connection. This connection eliminates the need for grouting and other labor-intensive procedures, simplifying construction and reducing total costs by 13%. A Matlab-based nonlinear time history analysis was conducted to evaluate the structural response and expected repair costs under different seismic hazard levels. A case study on a four-story office building in Sendai, Japan, showed that PCaPC frames with MT connections have lower expected seismic losses and better economic performance than traditional cast-in-situ PC frames. These findings highlight the potential of MT-connected PCaPC systems for enhancing cost efficiency and seismic resilience, supporting their widespread adoption in prefabricated construction in earthquake-prone regions.

1 Introduction

Precast concrete (PCa) frame structures are widely regarded as a cost-efficient alternative to cast-in-situ concrete structures because of their standardized design, shorter on-site construction time, reduced production cost, lower labor requirements, and better-controlled construction quality (Lv et al., 2025; Ge et al., 2025; Ghayeb et al., 2017; Yan et al., 2018). In addition to these advantages, PCa construction is recognized for its sustainability and environmental friendliness, especially in reducing greenhouse gas emissions (Ahn and Kim, 2014; Mao et al., 2013; Yu et al., 2025). As a result, PCa construction has become widely adopted worldwide. In the early 21st century, countries such as the United States, the United Kingdom, and Australia explored how prefabricated components could improve construction efficiency and transform the industry (Wang et al., 2022). In Singapore, the Building and Construction Authority developed the “Prefabricated Prefinished Volumetric Construction (PPVC)” and “Prefabricated Bathroom Unit (PBU)” systems (Dou et al., 2025). These systems have reduced physical work by about 40% and construction time by 20%. In Sweden, over 80% of residential buildings now use prefabricated methods. By 2024, the cumulative construction area of prefabricated buildings in China had reached 2.4 billion square meters, with a market size of 300 billion US dollars.

However, in some emerging economies and smaller markets, PCa development faces challenges such as cost overruns and construction delays (Mai et al., 2025). Problems arise in various stages, including precast design, component production, stockyard layout, transportation, and assembly. In China, the prefabricated building sector has grown rapidly in recent years due to government incentives. Still, traditional cast-in-situ technology remains dominant. As assembly rates increase, incremental costs also rise significantly, slowing the growth of prefabricated buildings. Even developed countries like New Zealand face challenges such as shortages of skilled labor, limited economies of scale, and geographic isolation (Li et al., 2014).

Beyond these broader challenges, constructing connections in prefabricated buildings presents significant technical and economic difficulties. Design inconsistencies often result in precast components that lack modular repetition, directly increasing production costs. Additionally, the complex details of connection joints complicate on-site assembly. Currently, beam-to-column connections typically rely on cast-in-situ techniques that require skilled labor and prolong construction time, further driving up labor costs.

Beyond construction challenges, the seismic behavior of PCa frames depends heavily on the stiffness, strength, and deformation capacity of the connections (Kurama et al., 2018). In past earthquakes (Nadeem et al., 2021; Campbell et al., 1996; Mohammed et al., 2021), poor performance of PCa buildings was often due to deficiencies in connection design and construction (Dal Lago et al., 2018; Guerrero et al., 2019; Ding et al., 2021; Cavaco et al., 2018). Recognition of these issues dates back to the 1980s, leading to the development of seismic design codes for precast buildings in countries such as the U.S., Japan, and New Zealand. One significant effort was the U.S.-Japan joint research program, PREcast Seismic Structural Systems (PRESSS), which began in the early 1990s and included many individual research projects (Baghdadi et al., 2020). In 1993, the idea of using beam prestressing tendons debonded through the joint in PCaPC frame elements was proposed (Song et al., 2014). This idea led to experimental tests at the National Institute of Standards and Technology in 1999, confirming that PCaPC frames could achieve low damage and residual drift under seismic loading (Song et al., 2015). In 2002, this connection was used in a 39-story apartment complex in San Francisco, marking a milestone in real-world applications (Yu et al., 2020). Following the PRESSS program, Japan developed the PC Mild-Press-Joint method to control earthquake damage in precast buildings (Tanabe, 2009). Full-scale tests at the Tokyo Institute of Technology in 2002 and 2003 showed that these systems could withstand seismic intensities up to JMA level 7 (Sakata et al., 2006). These developments show that PCaPC connection systems can reduce damage and residual deformation, which is critical for post-earthquake functionality.

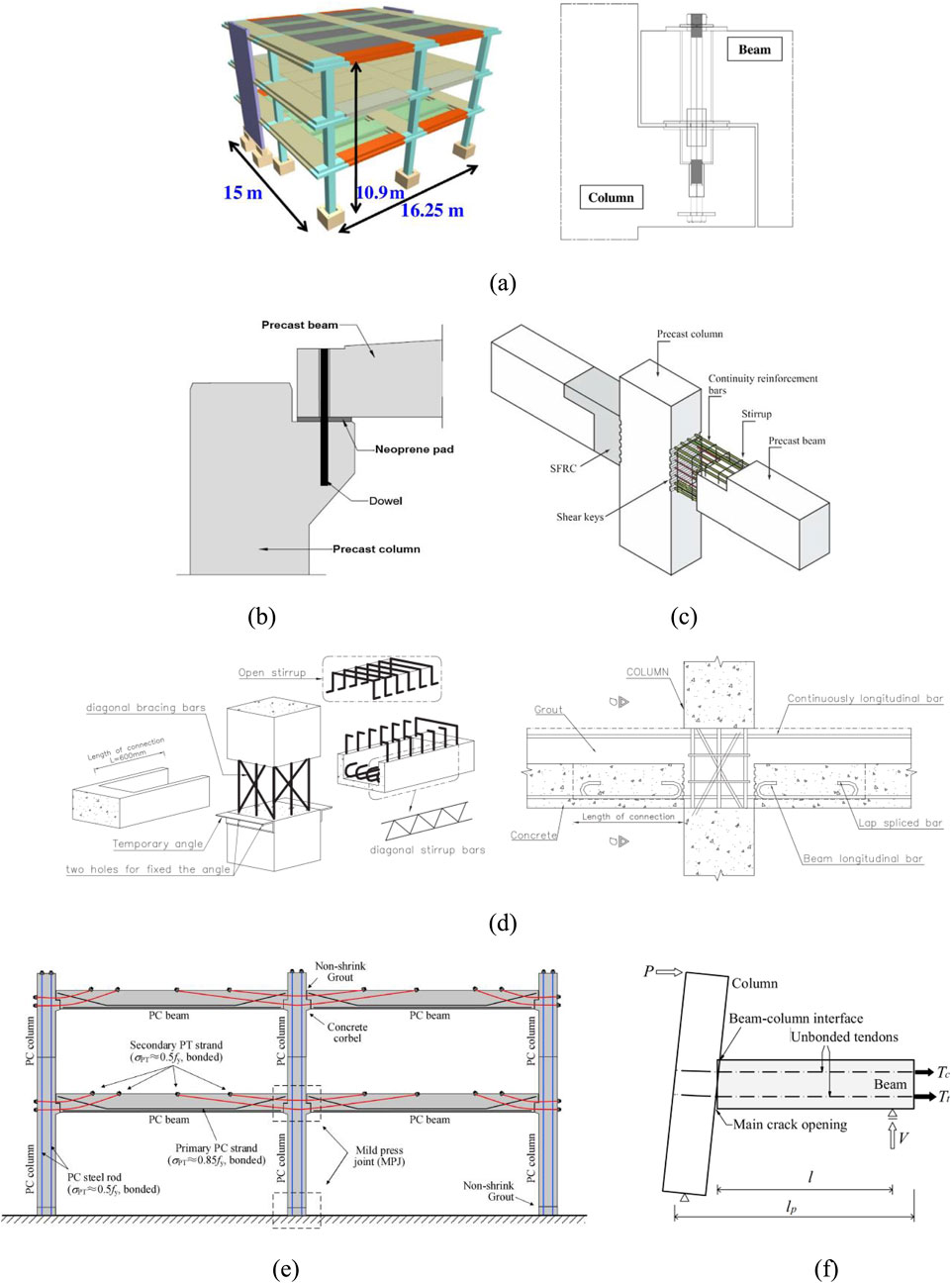

Looking back at recent earthquake damage cases, although many buildings are designed to meet seismic safety standards, they are often demolished after major earthquakes due to large residual displacements. Even when structural repairs are feasible, the associated business interruption costs can be substantial. These issues have led to growing recognition among researchers and engineers of the importance of developing structural systems that are both sustainable and resilient, capable of minimizing damage while facilitating rapid recovery (Shams and Ghobadi, 2021). In this context, the unbonded PCaPC frame structure, with its proven self-centering capacity and minimal residual drift, presents an efficient and economical solution for enhancing post-earthquake reparability and long-term functionality. Building on this direction, many researchers have proposed improved beam-column connection systems for precast concrete frames in recent years. In 2013, a collaborative three-year research project called SAFECAST was undertaken by the European Laboratory for Structural Assessment (ELSA) (Negro et al., 2013; Bournas et al., 2013). A full-scale three-story precast building was subjected to pseudodynamic (PsD) tests (Figure 1a), and the results showed that the proposed mechanical connection system had good seismic performance. Sousa et al. (2020) proposed fiber-based frame models to validate the resisting mechanisms of dowel beam-to-column connections (Figure 1b). Their experimental tests and parametric studies explored frictional behavior, dowel responses, and the effect of neoprene components. de Lima Araújo et al. (2018) presented a connection involving a U-profile steel corbel embedded in the column, supporting a cantilevered steel tube at the beam end (Figure 1c). Test results demonstrated adequate torsional resistance up to 60% of the theoretical steel corbel strength. Parastesh et al. (2014) developed a new ductile moment-resisting beam-column connection, which exhibited significantly higher ductility and energy dissipation under cyclic loading compared to similar monolithic specimens (Figure 1d). Kurosawa et al. (2019) proposed a precast prestressed frame with Mild Press Joints (Figure 1e), which showed minimal residual deformation in hysteresis tests. Jin et al. (2017); Jin and Kitayama (2019); Jin et al. (2021) developed a macro model for beam-column sub-assemblages of unbonded PCaPC frames (Figure 1f), revealing deformation concentration such as crack opening at the interface when subjected to horizontal seismic forces.

Figure 1. Connection devices: (a) mechanical connection system, (b) dowel connection, (c) temporary beam-to-column connection, (d) ductile moment-resisting connection, (e) mild press joint, (f) macro model for beam–column subassemblages.

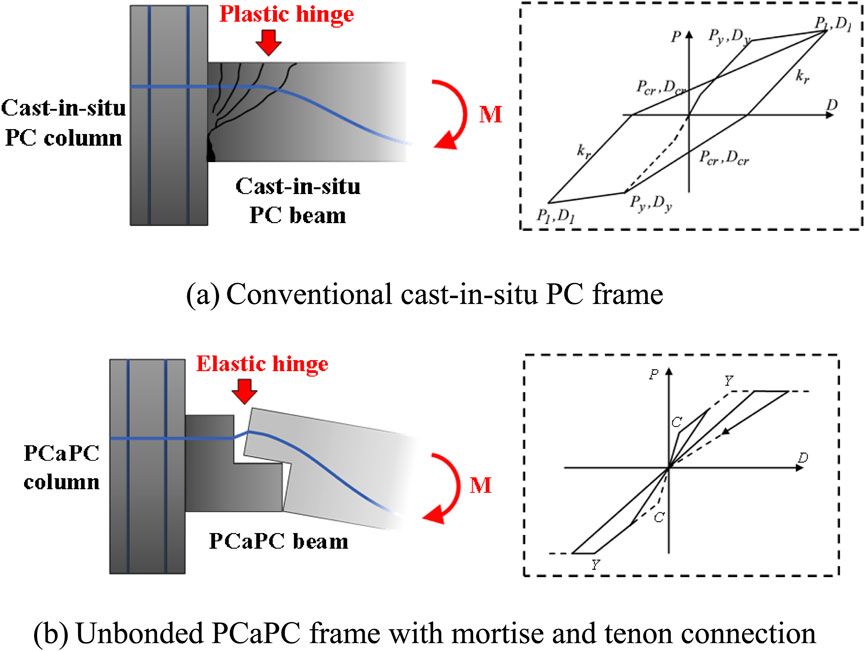

Previous research has shown that self-centering or low-damage connections can effectively reduce inelastic damage. However, most of these connections still require cast-in-situ construction at the beam-column joints, leading to complex assembly processes and a reliance on highly skilled labor (Wasim et al., 2022; Almusallam et al., 2018). To overcome these limitations, this paper proposes a mortise-tenon (MT) connection that eliminates the need for cast-in-situ construction at both beam-column and column-to-column joints. The MT joint offers improvements over conventional PCaPC frame joints in three key aspects: structural design, construction procedure, and kinematic behavior, as illustrated in Figure 2.

Figure 2. Unique behavior of PCaPC joint with MT connection. (a) Conventional cast-in-situ PC frame. (b) Unbonded PCaPC frame with mortise and tenon connection.

1.1 Structural design

In this proposed configuration, the MT connections are strategically placed at locations with minimal bending moments. This placement enables the structure to reduce lateral stiffness through elastic deformation before reaching high stress levels. It also supports the hinge-relocation mechanism, shifting inelastic deformation away from critical joint regions. Furthermore, the MT joint features a clearly defined force-resisting mechanism: longitudinal unbonded prestressing tendons mainly resist bending moments, while the embedded concrete shear keys (tenons) transfer shear forces. This clear separation of force paths improves the predictability of structural behavior and facilitates performance-based design.

1.2 Construction method

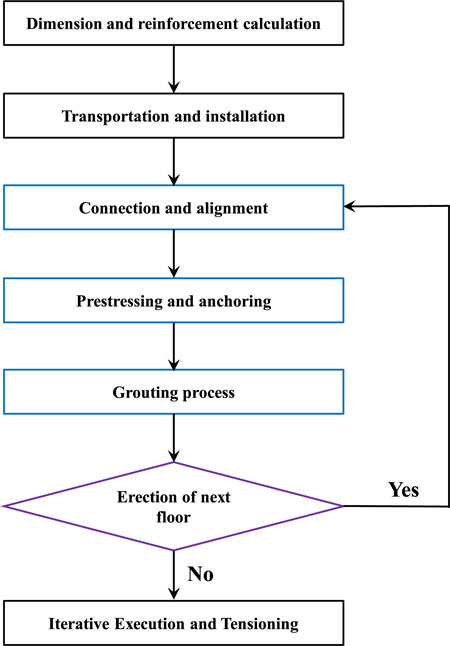

Unlike conventional precast frame systems, which typically require cast-in-situ concrete at beam ends or joint regions for continuity, the MT joint configuration eliminates the need for on-site concreting operations at these locations. This method minimizes the use of formwork and reinforcement placement on site. Prefabricated beam and column members are designed with embedded voids to accommodate tenons from adjacent members, which are assembled using lifting equipment. Due to the geometry of the mortise and tenon interface, the on-site alignment of components during erection is simplified, enhancing construction efficiency. The precise fit between the protruding tenons and their receiving sockets (mortises) facilitates quick and accurate positioning during hoisting, reducing the dependency on skilled labor and minimizing construction time. Final structural integration is achieved through post-tensioning and anchorage, without requiring mechanical fasteners or supplemental damping devices. This dry-assembly technique not only simplifies the construction process but also enables modular, repeatable installation. Furthermore, the prefabricated beams and columns feature high repetitiveness, reducing cost and complexity during production (Zhou et al., 2019; Zhou et al., 2020; Wu et al., 2019). As a result, it achieves a 13% reduction in construction cost relative to cast-in-situ PC frames.

1.3 Kinematic state

The MT connection exhibits distinct kinematic behavior under seismic excitation, which can be characterized in three sequential phases:

• Initial Engagement Phase: At the onset of seismic loading, the beam-column interfaces remain fully engaged, with negligible hinge rotation, resulting in high structural stiffness.

• Hinge Formation Phase: As seismic intensity increases, controlled opening and closing motions occur at the connections, forming transient elastic hinges. These localized rotations enable redistribution of lateral displacement and induce a reduction in lateral stiffness. This mechanism helps to limit stress concentrations at critical regions and modulate the structural response under seismic demand. The progressive development of multiple hinge points causes a dynamic evolution of the frame’s stiffness characteristics.

• Self-Centering Phase: As seismic input diminishes, prestressing force and gravitational restoring force promote the re-closure of the joints. This process realigns the structural members to their original positions, contributing to the self-centering capacity of the system.

This study aims to evaluate the performance of the proposed MT-connected PCaPC system under seismic loading through a comparative seismic loss assessment against a conventional cast-in-situ PC frame. A performance-based evaluation methodology is adopted to compare the expected repair costs of the three prototype buildings under various earthquake scenarios. The comparison results are used to quantify the relative economic and resilience performance of the two systems.

2 Outline of the configuration of proposed MT connection

Previous research has demonstrated that PCaPC frames can achieve adequate ductility and strength, accommodating large inelastic displacements while maintaining excellent self-centering capacity (Zhao and Yin, 2022a; Zhao and Yin, 2022b; Zhao et al., 2023). However, a primary concern with PCaPC frames is their potential for excessive lateral displacements when subjected to strong earthquake ground motions. This is primarily due to their low lateral stiffness and limited energy dissipation.

To maximize the restoring force of post-tensioning (PT) strands, PCaPC frames typically reduce the introduced prestress to about 50% to minimize secondary hyperstatic stresses. However, this reduction in prestress inevitably decreases the beam stiffness, making the beam-to-column connection more susceptible to deformation under lateral loads, which can lead to excessive structural displacement. To address this challenge, optimizing the number of PT strands and adjusting the connection locations can ensure seismic performance while reducing costs. Achieving structural cost reductions without compromising seismic performance is expected to enhance the system’s economic competitiveness.

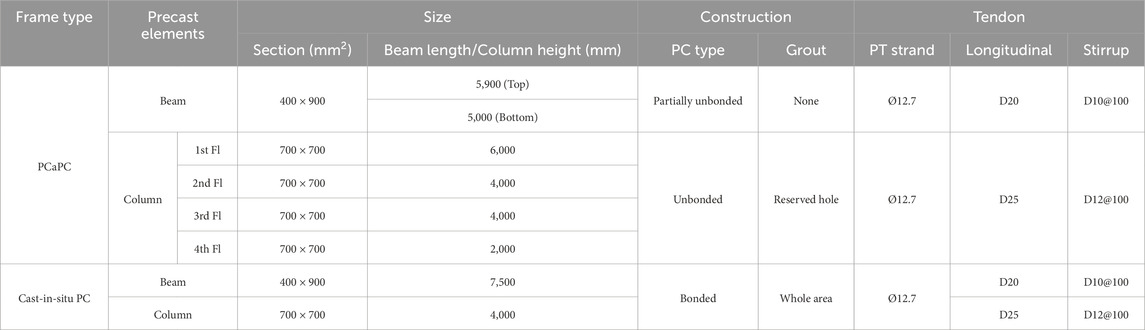

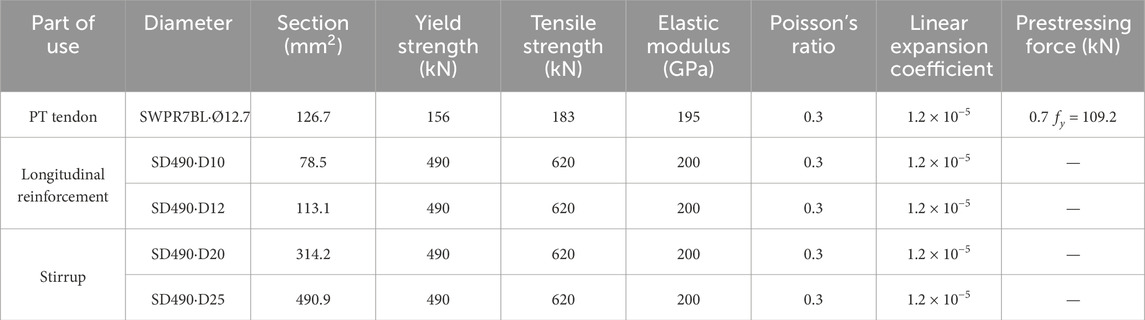

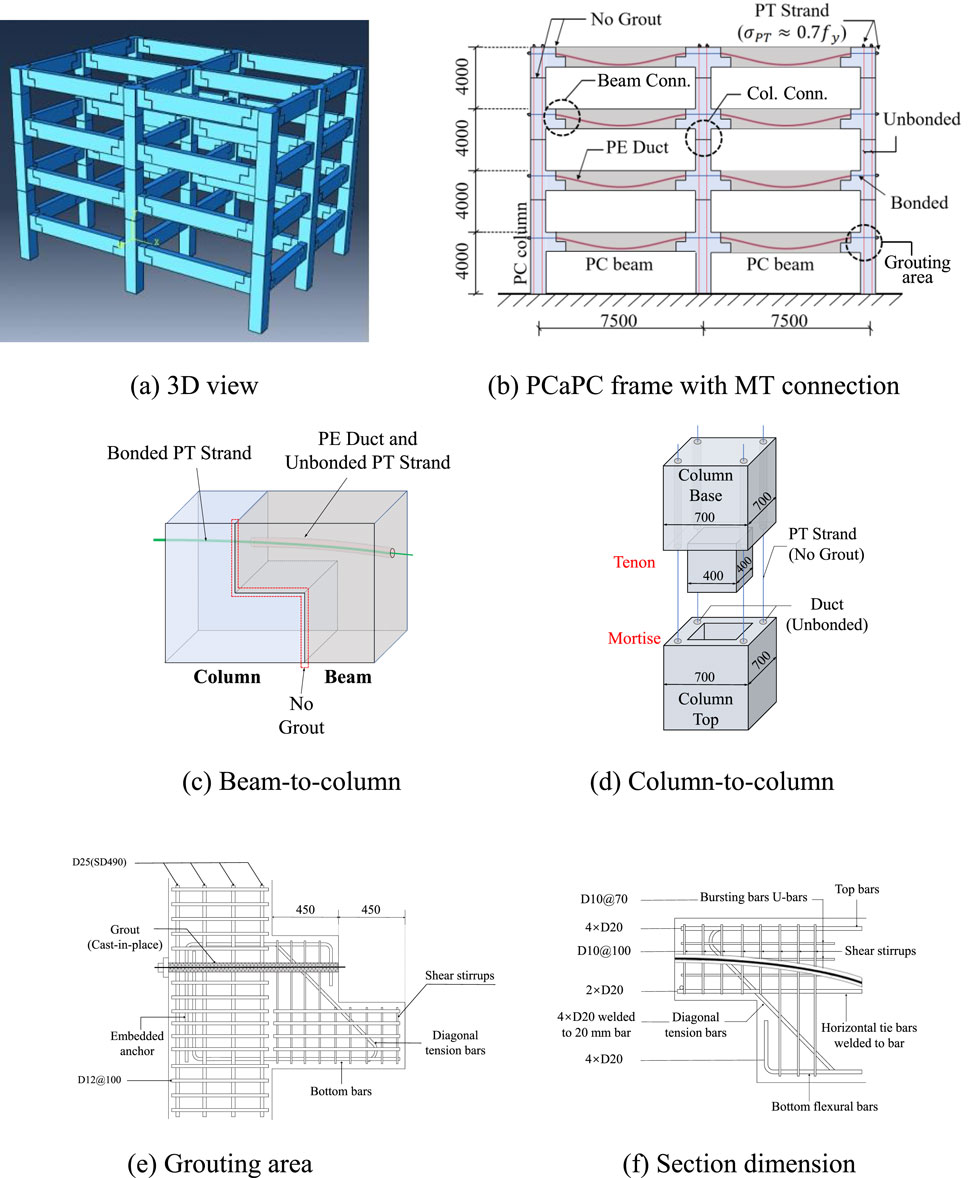

Figure 3 shows the proposed PCaPC frame with MT connections and its components. It consists of precast columns, precast beams, and high-strength PT strands that pass through reserved holes in the beams and columns. These strands post-tension the components into a monolithic system. The precast beam-column joint, partial column segments, and cantilevered beam stumps are prefabricated together to form a PCa column element. The connection locations of these column elements are assigned at points of zero or minimal bending moments at each floor. The other portion of the beam is designed as the PCa beam element, which connects to the PCa column element at the end of the cantilevered beam stump. The dimensions of the PCa elements and reinforcement details are provided in Table 1. Detailed material properties of the concrete and reinforcement are listed in Tables 2, 3. To simplify construction, the ends of the PCa beam and column elements adopt a mortise-and-tenon configuration. The joint interface does not require grout casting before tensioning and can be separated during assembly.

Figure 3. Beam-column assembly form of the PCaPC structure (Unit: mm). (a) 3D view. (b) PCaPC frame with MT connection. (c) Beam-to-column. (d) Column-to-column. (e) Grouting area. (f) Section dimension.

During seismic loading, the PCaPC joints develop opening gaps at both MT connections of each PCa beam element after entering the plastic phase. Slight rotations occur in the PCa beam and column sections, creating effects similar to an elastic hinge system when the joint interface exceeds its linear limit state. The deformation capacity of frame structures varies with different hinge locations, leading to changes in stiffness and strength. To control frame deformations, the connection locations within the PCa assembly pattern have been optimized. The cantilevered beam stumps are set to a length of 1–1.5 times the beam height, while the column segments are approximately half of the floor height. The connection locations are chosen at points of minimal bending moment and away from regions with the largest shear forces under earthquake loading.

The impact of improper reinforcement layout on connection strength can be significant. In particular, distinct brittle failure occurs in the concrete of the nib area when reinforcing bars are omitted (Tambusay et al., 2024; Desnerck et al., 2016). Previous test results have highlighted the importance of diagonal tension bars in controlling crack widths at the re-entrant corner and the need to provide sufficient bursting bars (U-bars) (Menichini et al., 2024). The main reinforcement layout, as shown in Figures 3c,d, includes diagonal reinforcement to transfer most of the applied load from the nib to the full-depth section of the beam. It also incorporates a substantial amount of bursting bars (U-bars) in the nib, which extend sufficiently into the full-depth section to ensure proper end anchorage.

3 Initial cost analysis of PC and PCaPC structures

3.1 The influence of construction method on initial cost

Although prefabrication technologies have advanced, the high initial investment required for factory production, transportation, and specialized equipment often outweighs the short-term savings in labor and construction time. The Ministry of Housing and Urban-Rural Development (Ministry of Housing and Urban-Rural Development, 2023) reported that while prefabrication improves construction quality and reduces environmental impact, its higher initial costs continue to hinder market acceptance, especially in less developed regions. Moreover, China Construction Industry Association (CCIA) (2022) that “a lack of standardization and lower economies of scale further limit cost reductions in small- and medium-sized prefabrication projects.

In recent years, China has introduced a series of land supply policies to promote prefabricated buildings (PBs) by incorporating PB rate requirements into land transfer conditions. In Singapore, mandatory prefabrication requirements are enforced indirectly through statutory compliance with “buildability” provisions in the building control system (Chiang et al., 2006). However, this reliance on administrative measures to drive PB adoption risks distorting the market and creating a dependency on government subsidies, rather than fostering organic growth driven by cost-effectiveness and efficiency improvements. Achieving cost efficiency in prefabrication requires greater standardization of PCa elements and improved connection techniques, with a focus on reducing on-site complexity and material waste.

Figure 4 illustrates the construction method of the PCaPC frame with MT connections. Compared with conventional precast frames, the major difference in the construction of PCaPC frames with MT connections lies in the installation methods and the areas requiring grouting. To minimize on-site erection workload and ensure reliable connection performance, lifting equipment is used to insert the tenons of adjacent columns into the mortises of corresponding elements, assembling the PCa column components. This is followed by the tensioning and anchoring of PT strands. The upper PT strands are continuous across multiple spans by inserting them through the reserved square holes, which significantly accelerates the assembly process. This connection method offers superior quality control and enhanced construction efficiency. Moreover, in large projects, quality is assured through controlled casting conditions and reduced on-site supervision during the concreting process, achieving cost savings. The MT connection design minimizes wet operations, such as formwork fabrication and rebar tying. In contrast, cast-in-situ technology remains the typical construction method for other precast frame structures, resulting in increased costs and extended construction time, while offering limited economic incentives for local contractors.

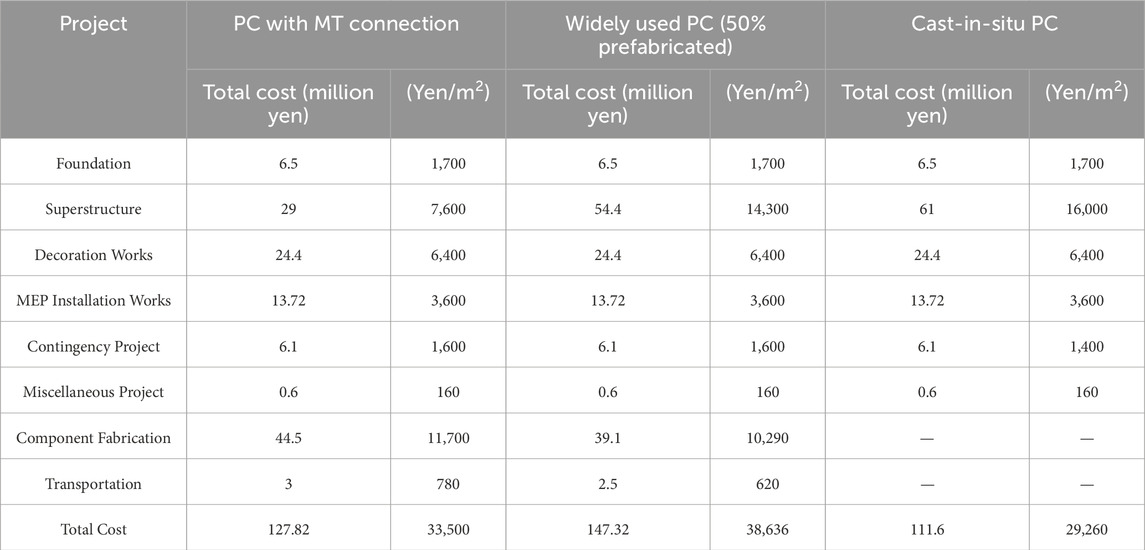

3.2 Case study for PC and PCaPC initial cost

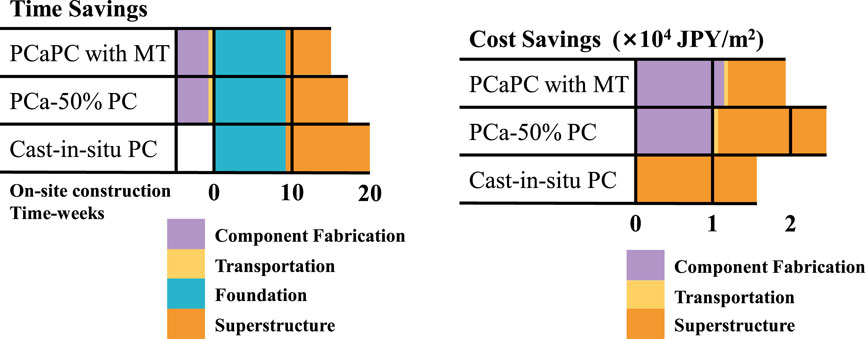

This section presents a comparative cost analysis (mainly based on the Chinese market) of a residential building project in Harbin, China, as shown in Table 4 (Li et al., 2021; Luo et al., 2021). The analysis compares a PCa project with a 50% assembly rate to a cast-in-situ project, using cost data from an actual project published by the China State Construction Engineering Corporation. For the PCa project, the cost variables for PCa with MT connections were recalculated according to different construction methods. Each project’s cost variables consider factors such as construction time, labor efficiency, unit installation cost, and the volume of labor and materials consumed. Relevant data were sourced from the SCP-PCP (Standardized Consumption Quotas for Prefabricated Construction Projects).

For the PCa with MT connections, the cost variables include three components: component fabrication, transportation, and superstructure, as illustrated in Figure 5. The calculation of component fabrication and transportation costs is based on the volume of prefabricated elements, specifically accounting for incremental costs. Due to the different construction methods, the incremental areas for PCa with MT connections are primarily located at the joints and beam ends. As no specific calculation standard exists for this configuration, the calculation does not consider the potential cost reduction from component repeatability. The difference in the superstructure cost primarily arises from the reduction of on-site activities such as concrete production, rebar tying, grouting, and mechanical installation tasks like bolting. The incremental cost is determined using the labor and material consumption data provided by SCP-PCP, along with the unit prices of the construction project.

Comparing the cost structures of cast-in-situ and various PC construction schemes shows that the construction cost of PC buildings with MT connections is 13% lower than that of traditional PC frames. This cost reduction is mainly due to the elimination of several on-site activities, including rebar tying, formwork support, and concrete pouring, which typically increase the cost of PCa construction. Additionally, the high repeatability of prefabricated components can further reduce both production and labor costs. With the expansion of the PCa industry and improvements in standardization, fully assembled buildings are expected to replace cast-in-situ buildings in the future.

4 Loss estimation based on FEMA P-58

4.1 Methodology of seismic loss estimation

Many loss estimation methods have been proposed in decades. In the research on loss estimation, the damage of members should be assessed prior to loss estimation by damage indexes (Park and Ang, 1985) or models such as maximum drift ratio (Ghobarah et al., 1999; Negro and Mola, 2017), residual drift ratio (Ruiz-García and Miranda, 2006), crack characteristics (Takimoto et al., 2004; Takahashi and Nakano, 2009; Takahashi et al., 2010; Wang and Takahashi, 2021; Miao et al., 2021; Chida et al., 2022; Takahashi and Tsuka, 2024), and so on. In recent years, loss estimation methods have been expanded for unique buildings and purposes. As an example, Takahashi et al. (2020) proposed an economic performance evaluation scheme of historic buildings that consider the effect of structural renovation to provide information facilitating to the selection of reasonable renovation methods for preserving historic buildings. In this paper, evaluation analysis of PC buildings, which have not been so much discussed as an evaluation target for loss estimation, is performed.

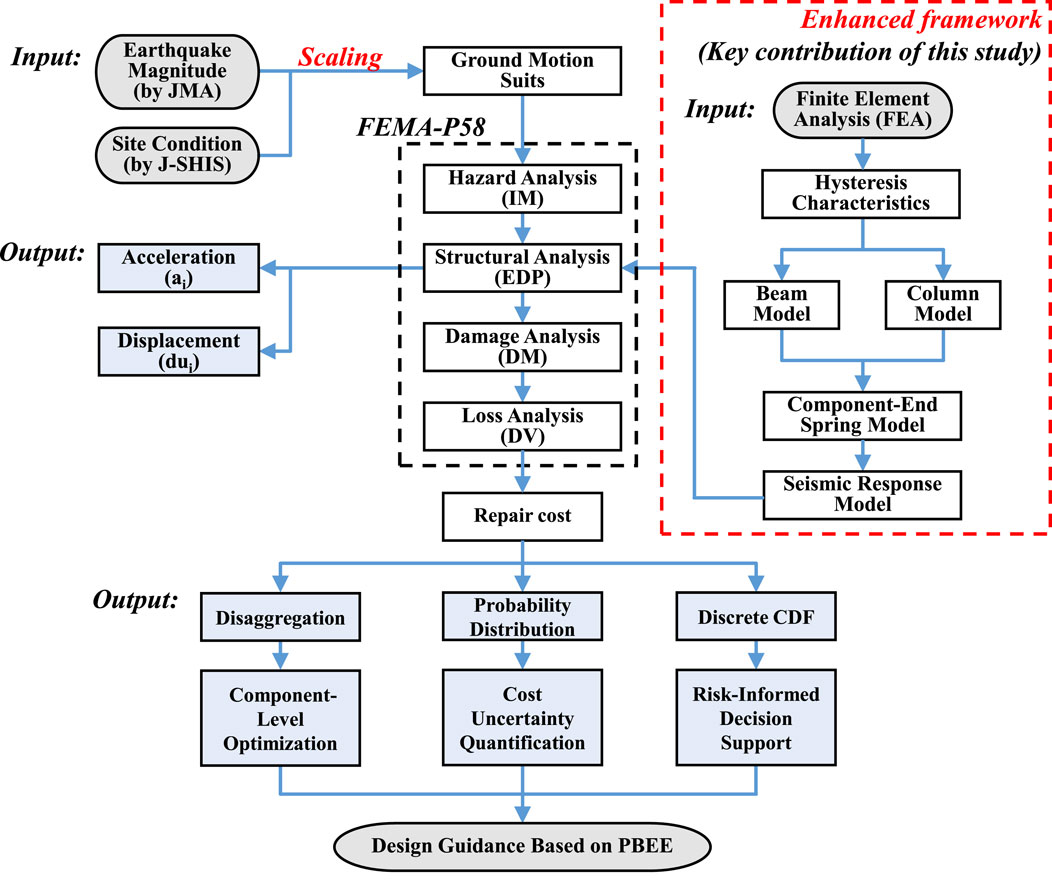

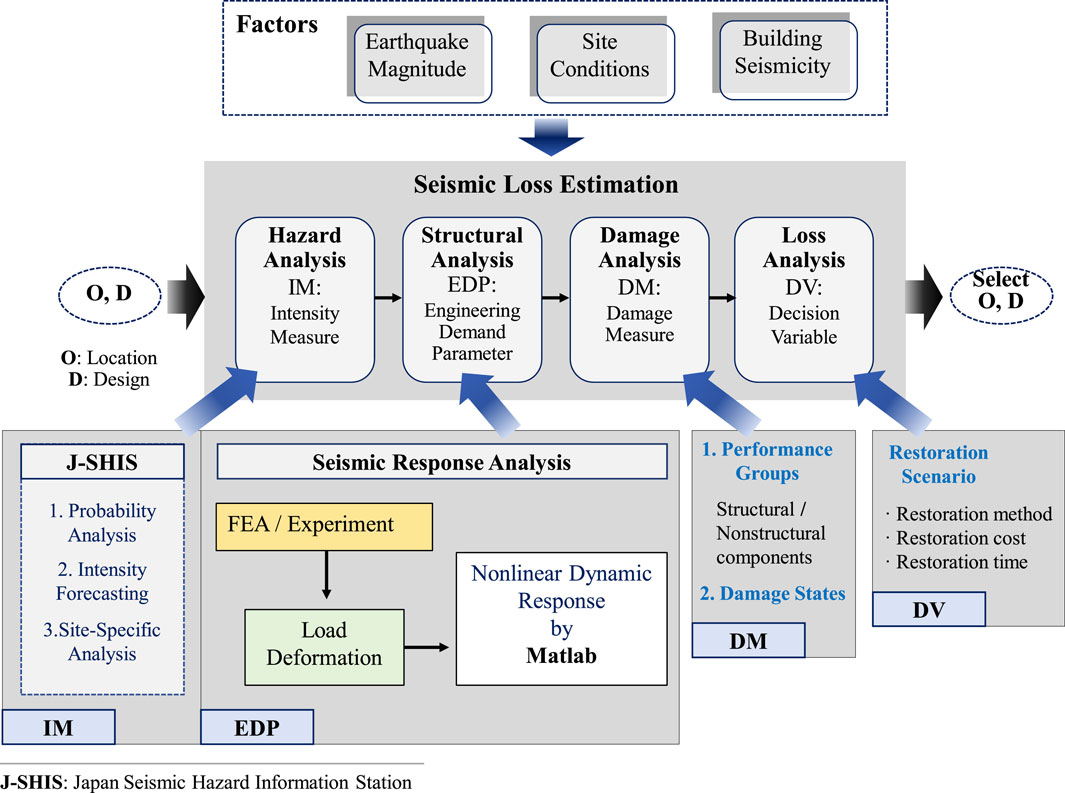

The general seismic loss estimation framework is provided by the Pacific Earthquake Engineering Research Center (PEER), where the practical methodology is described in detail in the FEMA-P58 documentation (FEMA, 2003). The framework is divided into four steps: seismic hazard analysis, facility response analysis, damage analysis, and loss analysis as shown in the upper side of Figure 6. With the available vulnerability function, the outcome of each analysis is then integrated as shown in Equation 1.

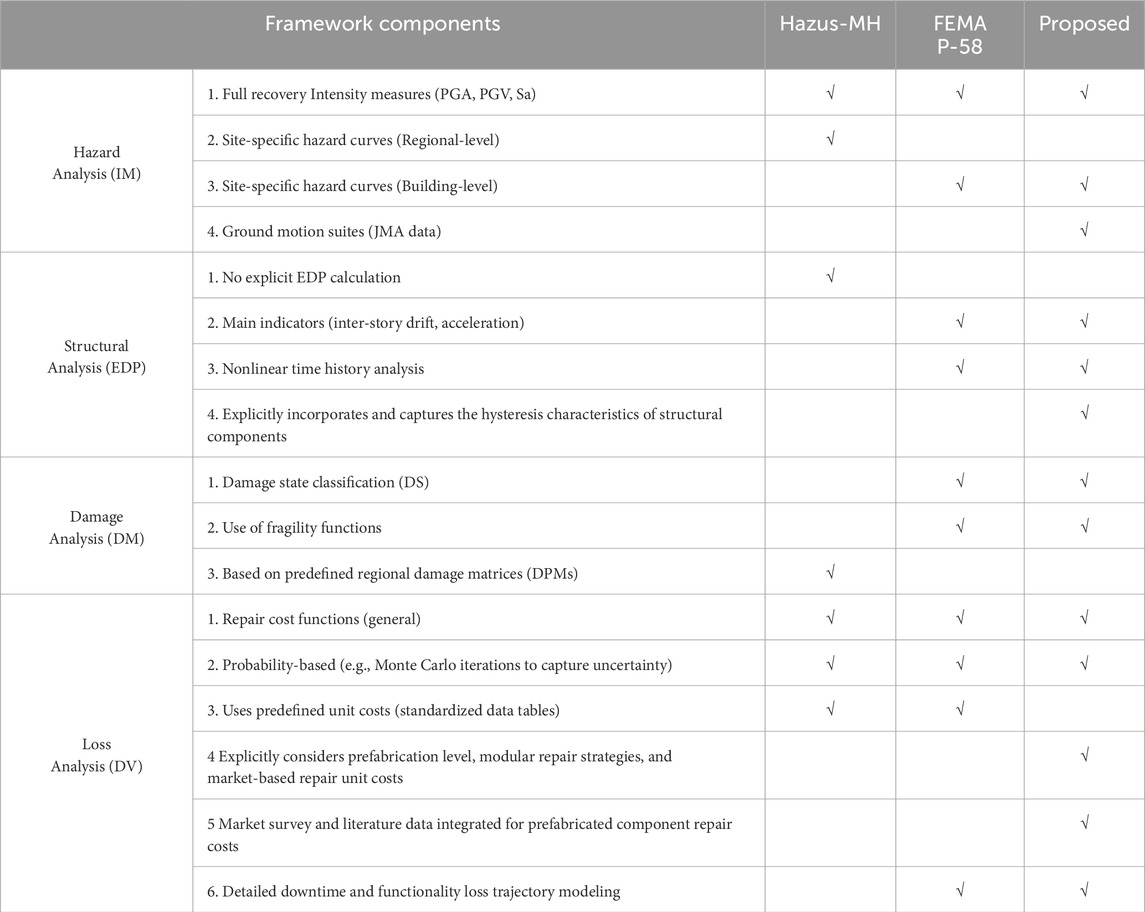

where IM refers to the seismic hazard characteristics at a site, typically including ground motion parameters like peak ground acceleration or spectral acceleration. EDP represents the response of structures under seismic loads, indicating potential deformations or stresses. These parameters are crucial for understanding how a building or structure will likely behave during an earthquake. DM is employed to assess the extent of damage in a structure post-earthquake, typically categorized into various damage states. DV encompasses the economic and functional consequences of earthquake-induced damages, including repair costs, downtime, and loss of functionality. To highlight the differences between existing frameworks (e.g., Hazus-MH, FEMA P-58) and the enhanced approach for loss estimation of PCaPC frames with MT connections, Table 5 summarizes the key features of each method. Moreover, to illustrate the step-by-step implementation of the economic loss estimation methodology in this study, a flowchart is provided, as shown in Figure 6.

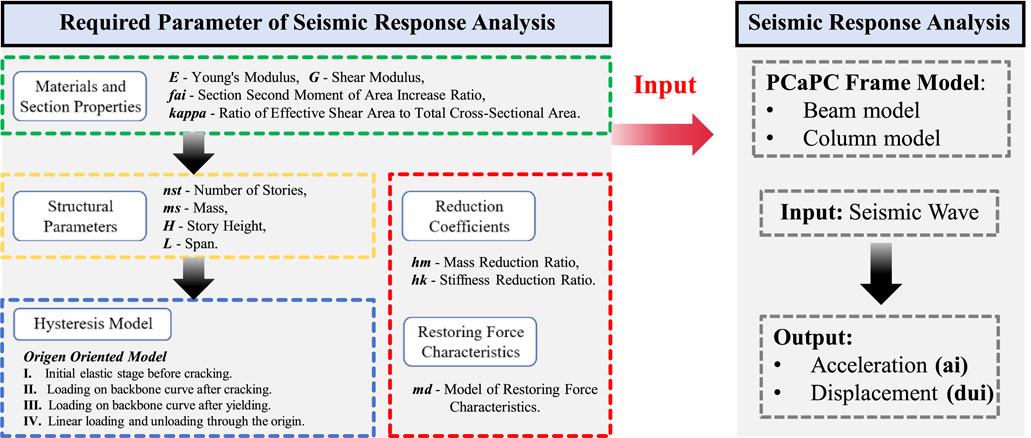

The following four steps (as briefly summarized in Figure 7) are taken for seismic loss estimation:

Step 1. Quantification of the seismic hazard

The initial phase of our framework rigorously quantifies the seismic hazard at the designated site, employing extensive data from the Japan Seismic Hazard Information Station (J-SHIS). This approach, integrating seismic hazard maps and the latest earthquake occurrence data, enables the precise calibration of our IM parameters, including peak ground acceleration, spectral acceleration, and peak ground velocity. These parameters are crucial for assessing the potential seismic impact on structures, ensuring our methodology aligns with cutting-edge earthquake engineering practices.

Step 2. Seismic response analysis

With ground motion records selected in Japan Meteorological Agency (JMA), nonlinear dynamic response analyses are used to quantify the statistical distribution of the structural response (such as interstory drift ratios, dui, and peak floor accelerations, ai) at different levels of earthquake shaking intensities. This study establishes independent seismic response models for a cast-in-situ PC frame and a PCaPC frame with MT connection, facilitating whole frame numerical simulation analysis. Abaqus-based finite element analysis (FEA) is employed to obtain load-deformation relationships, which are then used to simulate the hysteretic behavior of PCa structural elements. Finally, these characteristics are integrated into seismic response models to enhance the accuracy of analysis. Utilizing Matlab to conduct nonlinear dynamic response simulations, we obtain the distributions of EDP at varying levels of IM. Each set of simulations yields a collection of pertinent EDP meticulously compiled from the results of individual analyses.

Step 3. Define the performance groups, damage states, and corresponding repair actions

In the DV section, we categorize key building components into Performance Groups (PG), assessing them against specific Engineering Demand Parameters. Each group’s range of Damage States is defined to depict component damage under different structural responses accurately. This is coupled with estimating repair actions and costs for each state. Our method utilizes inter-story drift ratios and floor accelerations obtained from nonlinear dynamic analyses as principal indicators for assessing building damage states. This approach allows us to determine necessary repairs and systematically estimate their costs.

Step 4. Loss analysis

In the DM section, we focus on two methods: constructing vulnerability functions for intensity-based loss estimation and calculating Mean Annual Frequency (MAF) for time-based assessment. The vulnerability functions link seismic intensities, such as peak ground acceleration, to probabilities of various damage states using a mix of historical seismic data and structural performance analysis. For time-based loss estimation, we determine MAF using probabilistic seismic hazard analysis, integrating it with our vulnerability functions to estimate the annual likelihood of different damage levels. This approach provides a comprehensive view of seismic risk, combining intensity and time-based perspectives for a more accurate assessment of potential losses.

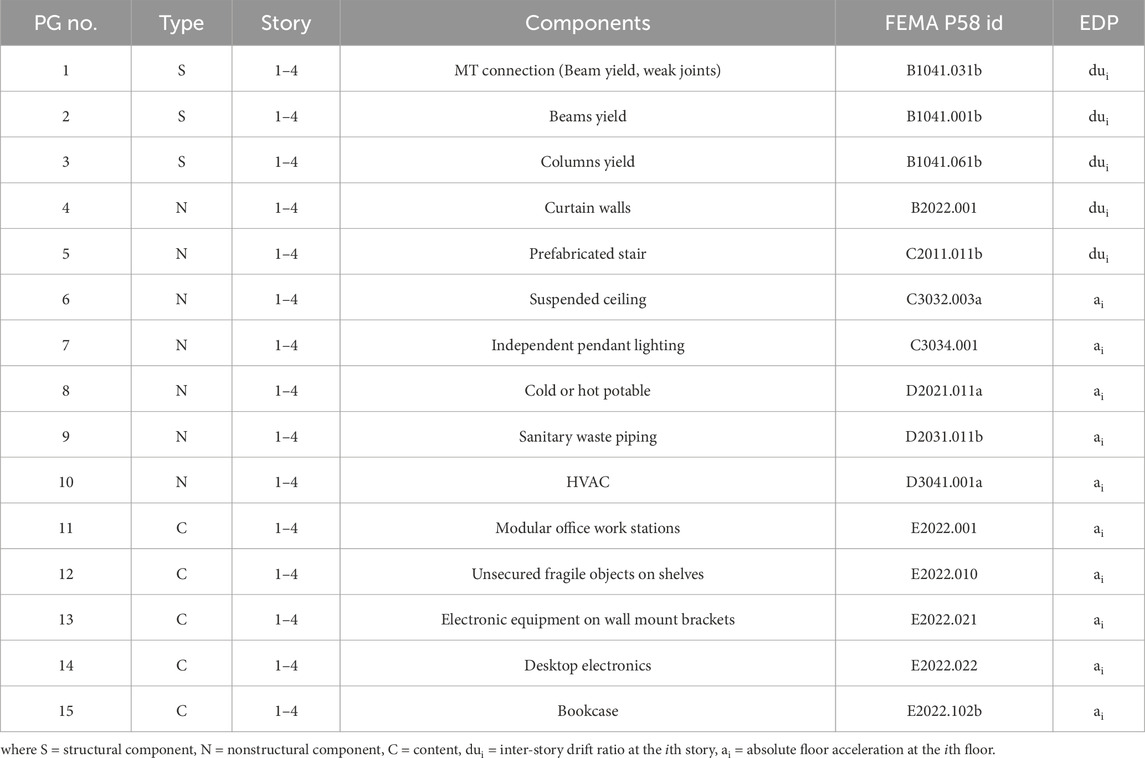

4.2 Target structural and nonstructural component

This analysis scrutinized a cast-in-situ PC frame with bonded tendons and a modular frame structure utilizing MT connection with unbonded PCaPC, as described in Chapter 2. The FEMA-P58 methodology includes three component categories, namely, structural components (e.g., MT connection), nonstructural components (e.g., prefabricated stair), and building contents. Each category consists of a collection of performance groups whose performance is similarly affected by a particular EDP, such as the inter-story drift ratio and the absolute floor acceleration. For the purpose of calculating building performance and repair costs, major components of the prototype building were identified and assigned to 15 performance groups, as shown in Table 6.

The selection of medians was based on the frequency distribution of observed damage thresholds in these studies, reflecting the typical scenarios where specific damage levels begin to manifest at certain acceleration levels or drift ratios. In particular, for drift-sensitive components, each damage state threshold was associated with corresponding physical phenomena observed in unbonded precast PC components with MT connections. For example, a drift of approximately 1% (DS2) typically corresponds to a crack width of 0.2–0.3 mm and the onset of prestressing tendon yielding, while a drift exceeding 2% (DS3) reflects residual crack widths over 0.3 mm and indicates irreparability due to loss of self-centering capacity and local crushing at the joint interface (Matsunaga and Tani, 2025). These relationships are summarized in Table 7.

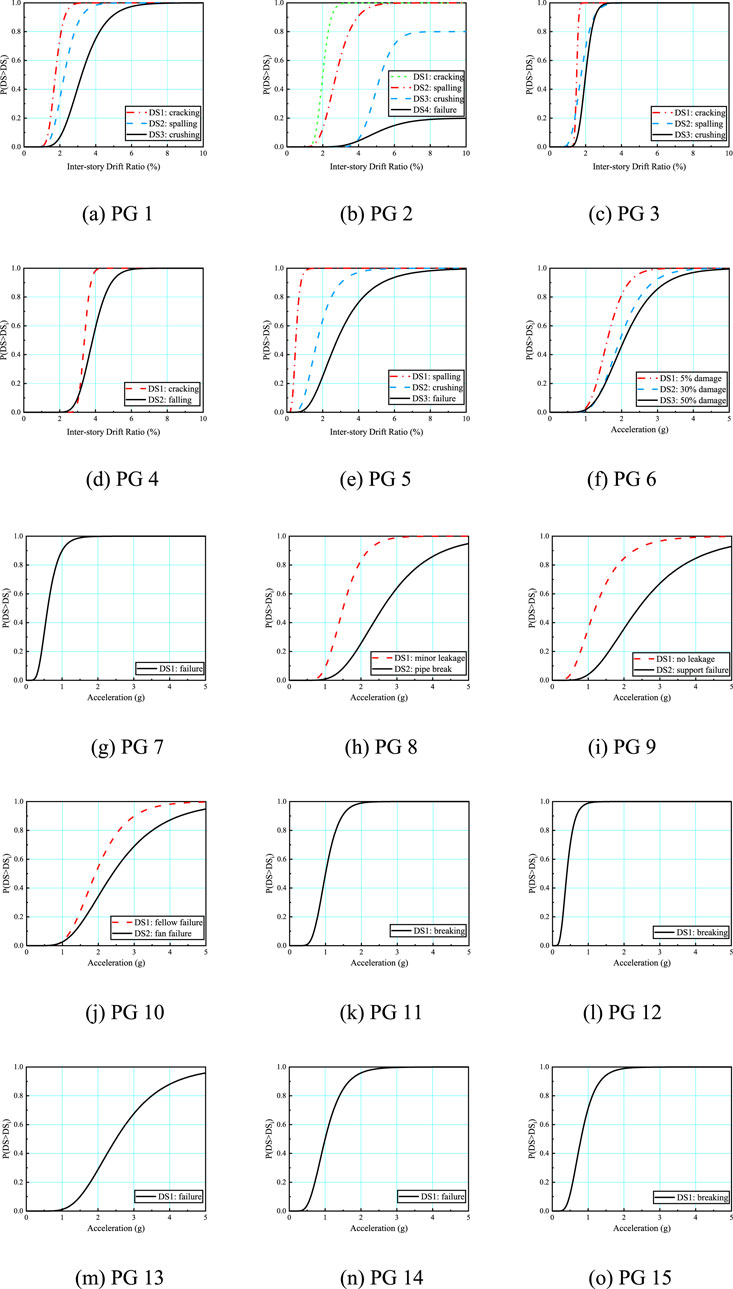

The determination of dispersion was guided by the variability in the damage data, taking into account factors such as building material quality, construction standards, and seismic motion characteristics. This approach ensures that the chosen parameters are not only empirically grounded and statistically significant, but also reflect realistic structural degradation behavior, thus enhancing the engineering validity of the fragility model. Multiple damage states were defined for each performance group. Figure 8 shows the fragility relations used to identify the damage state of each performance group. To illustrate the use of these fragility relations, consider performance group N-ai, as detailed in Figure 8c.

Figure 8. Component fragilities.(a) PG 1. (b) PG 2. (c) PG 3. (d) PG 4. (e) PG 5. (f) PG 6. (g) PG 7. (h) PG 8. (i) PG 9. (j) PG 10. (k) PG 11. (l) PG 12. (m) PG 13. (n) PG 14. (o) PG 15.

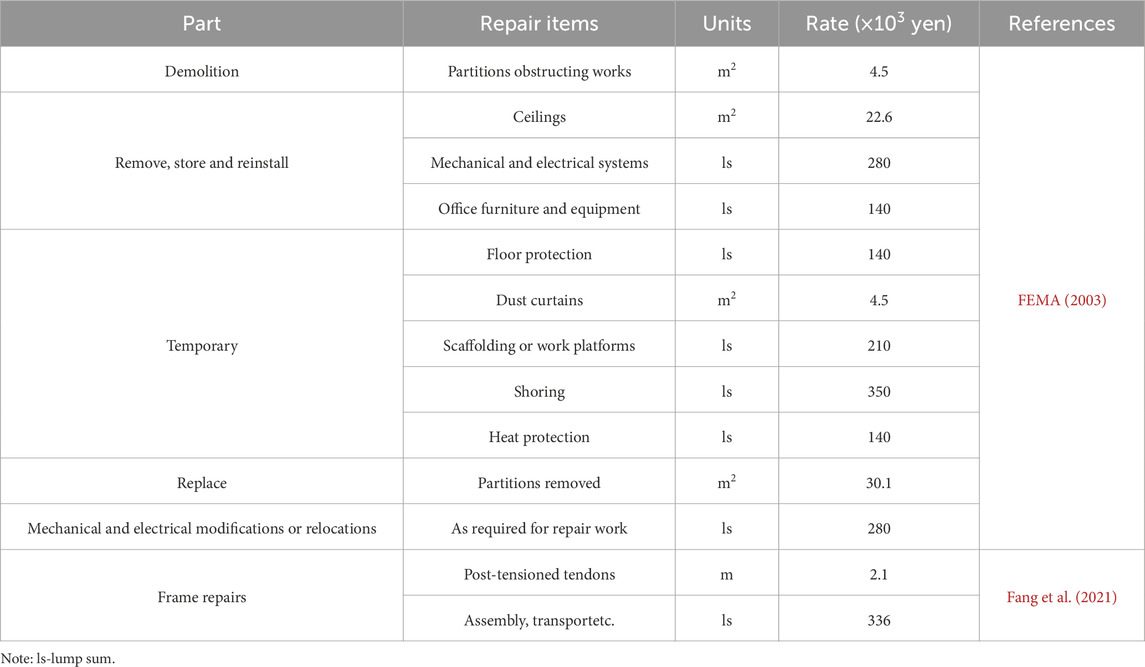

4.3 Calculation of repair cost function

In assessing the repair costs for each damage state (DS) of the considered structure, it’s imperative to recognize that each DS correlates with a distinct probability distribution of repair costs. While FEMA-P58 provides cost functions for essential components within the considered structure, with the notable exception of MT connection, it becomes necessary to conduct market surveys for estimating the repair costs of prefabricated frame structures. Significantly, the average repair costs denoted as ‘Post-tensioned tendons’ and ‘Assembly, transport, etc.’ are derived from market surveys conducted within the United States, Japan, and China, respectively (Fang et al., 2021). This approach ensures that our estimations are grounded in the current market realities of these regions, thereby enhancing the practical relevance and accuracy of our cost predictions for the maintenance of these structures. Table 8 gives the details of the mean repair costs for the different performance parts.

5 Seismic response analysis

5.1 Analytical model

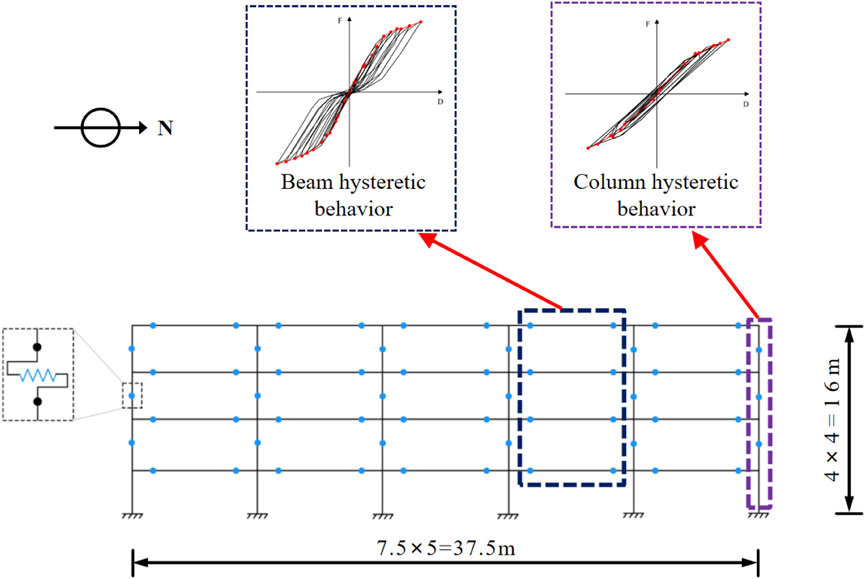

A total of three four-story PC frames, employing the three types of assembly rates, were designed according to the study by Zhao and Takahashi (2024) and serve as the basis for the case study presented in this paper. For ease of reference, the three structures are named as Cast-in-Situ PC, PCa 50% PC, and PCaPC with MT. These structures are located at a stiff soil site in Sendai, Japan, with a ground amplification factor of 0.85, based on data from J-SHIS.

Since the component dimensions and joint designs of “Cast-in-situ PC” and “PCa-50% PC” are identical, the primary differences lie in the construction methods and repair methods. Consequently, the same FE modeling approach is applied to both frames, ensuring that the analysis focuses on how the degree of prefabrication affects the repair methods and repair costs, without being influenced by modeling inconsistencies. This FE analysis does not account for potential differences arising from the standardization and quality control of prefabricated components during manufacturing, nor for variations introduced by different construction methods.

The design and seismic analysis are focused on 2D frames representing the structure in the north-south (NS) direction, as illustrated in Figure 9. The span length was 7.5 m, and the consistent story height was 4.0 m. The four structures have the same boundary frame member sizes and material properties. For structures Cast-in-situ PC and PCaPC with MT, structural elements at the same floor share the same prestressing force, so the main difference is the connection configurations (bonded prestressing strands and unbonded ones, respectively) and deformation mechanism.

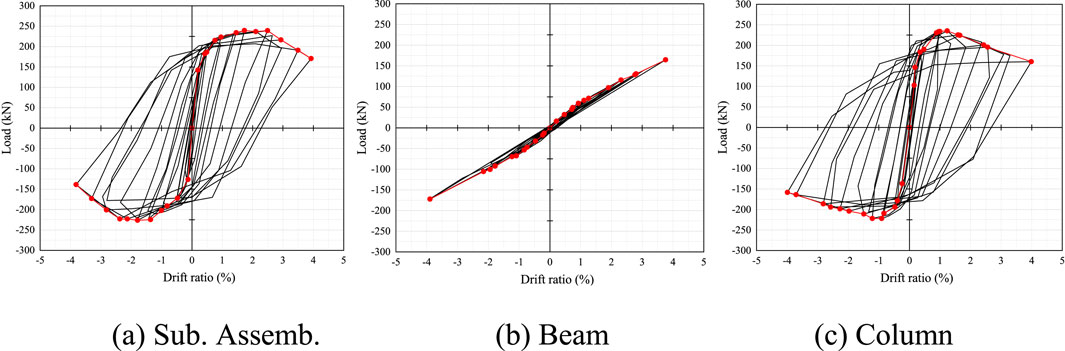

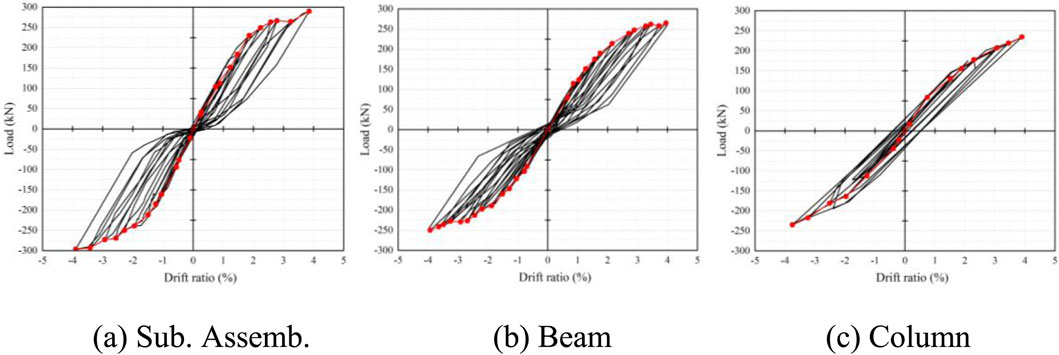

In this study, a component-end spring model was developed to simulate the seismic behavior of the MT connection. To describe the nonlinear behavior and hysteresis characteristics of joints considering major design parameters, the load-deformation relationship of structural elements was defined based on previous FEA. For simplicity in modeling and computations, one-component frame models were proposed combining the Newmark-β method so that the proposed models are conveniently applicable to seismic response analysis. The proposed framework mainly consists of materials and section properties, structural parameters, and restoring force characteristics, as depicted in Figure 10.

While the spring model simplifies the MT connection into an idealized restoring mechanism, the nonlinear hysteresis behavior used as input to this model was derived from detailed finite element simulations conducted in our previous study (Zhao and Takahashi, 2024). These simulations captured localized crushing, slip, and friction effects at the mortise-tenon interface, and validated the joint’s three-stage behavior (closure, hinge relocation, and self-centering). Therefore, the simplified spring representation preserves the essential nonlinear behavior observed in experiments and finite element models, ensuring a reasonable balance between modeling fidelity and computational efficiency in seismic loss assessment.

5.2 Ground motion selection

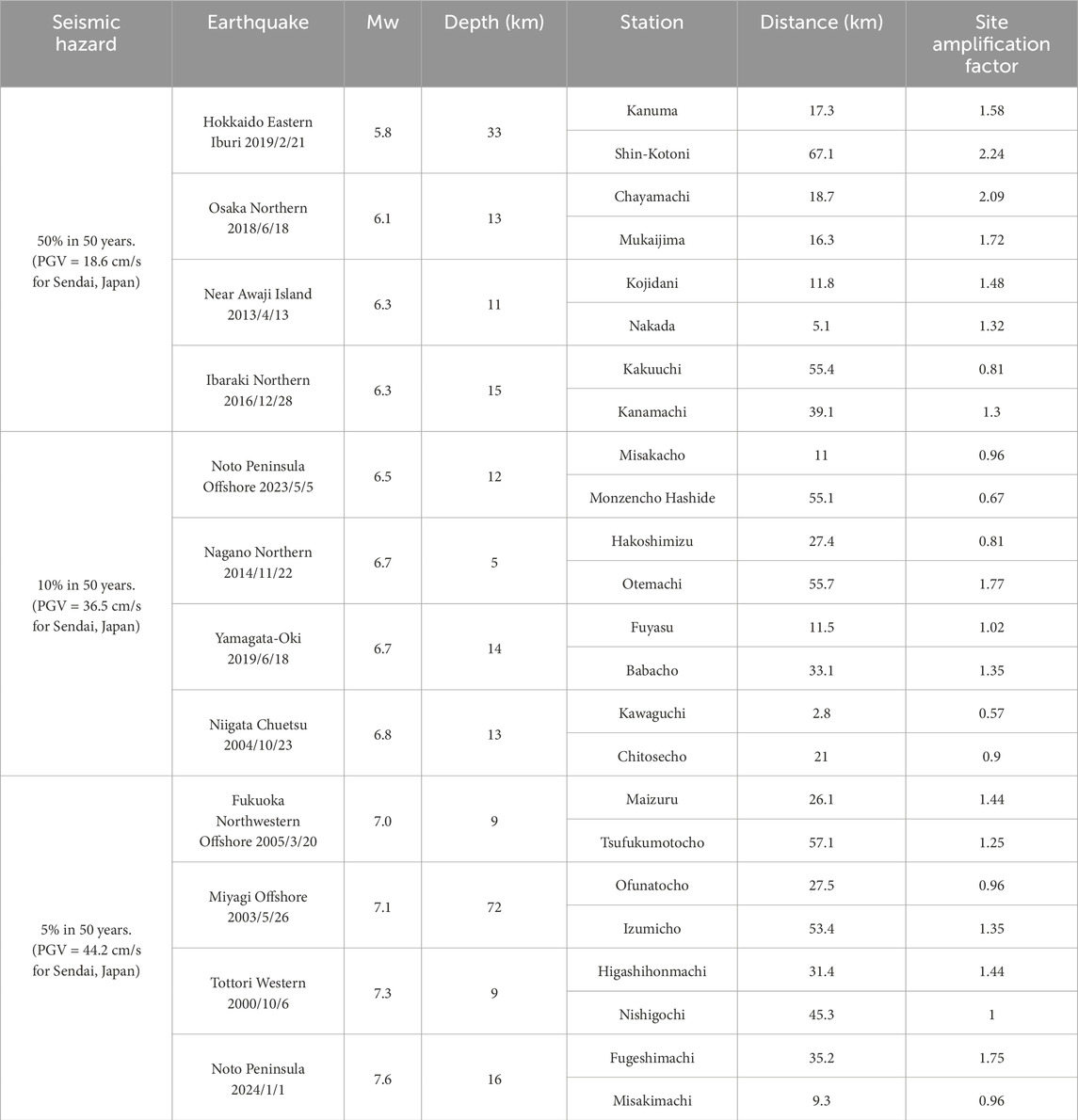

To study the seismic response of the prototype building, suites of NS-direction strong-motion observation data were selected from JMA. This dataset encompasses representative strong-motion observations from major earthquakes that occurred in Japan between 2000 and 2024. Three discrete hazard levels representing the earthquake hazard with a probability of 50%, 10%, and 5% exceedance in 50 years are selected. The PGV values for each hazard level were obtained from J-SHIS for the seismic response analysis, considering the site situated in Tohoku University’s Aobayama Campus (38.2552◦N, 140.8391◦E) within Sendai, Japan. Table 9 shows the four representative ground motions selected for each hazard level presented in the probabilistic hazard analysis, scaled according to the PGV values.

5.3 Structural response

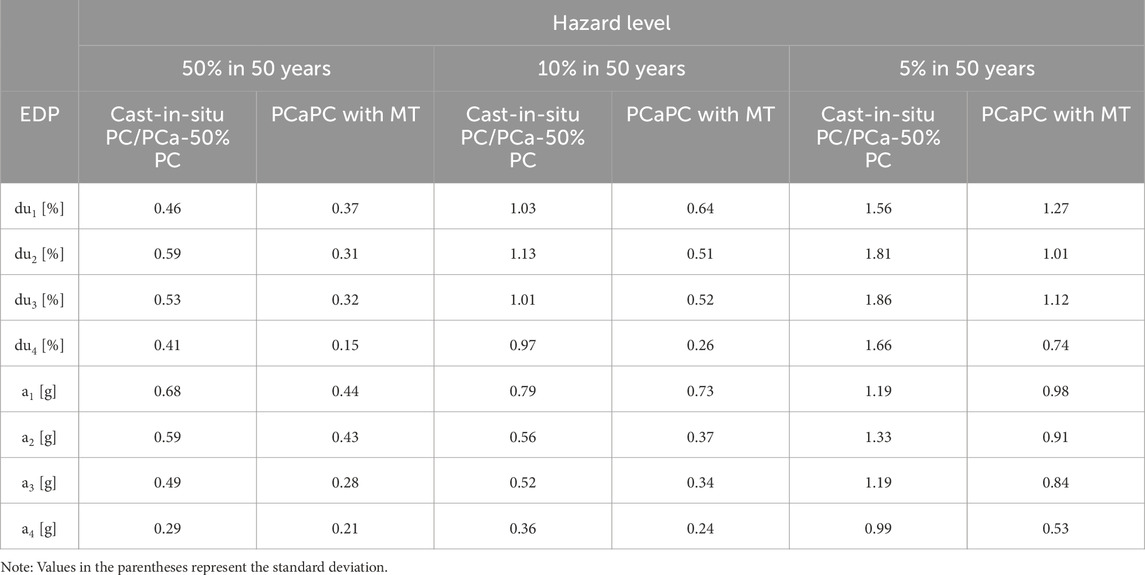

Nonlinear time-history analyses were conducted to evaluate the seismic response of the three frame configurations to each selected scaled ground motion. Table 10 presents the median values of the peak engineering demand parameters obtained in this analysis. The EDPs ‘dui,’ and ‘ai,‘, as shown in Table 10, represent the inter-story drift ratio of the ith story and the absolute floor acceleration of the ith floor, respectively. Although these three frames share identical material properties and geometric configurations, the cast-in-situ PC frame exhibits significantly higher stiffness. This results in greater acceleration transmission to upper floors, making the structure more susceptible to seismic force. In contrast, the PCaPC frame with MT connections reduces seismic demand by allowing rotational movement of beams at the corbels of columns, effectively absorbing seismic energy and mitigating inertial forces. This mechanism contributes to lower peak floor accelerations while maintaining adequate lateral stability.

The comparative assessment of seismic performance across three hazard levels further emphasizes these behavioral distinctions. At the “50% in 50 years” hazard level, acceleration generally diminishes with building height. However, as seismic intensity increases to the “5% in 50 years” level, this trend weakens due to nonlinear effects in the lower stories. Inelastic deformations lead to stiffness degradation, altering energy dissipation patterns and shifting the dynamic response of the structure. Consequently, seismic energy is redistributed more evenly across the height of the structure, reducing the contrast between upper and lower floor accelerations. The nonlinear response also impacts structural damping mechanisms, influencing repair costs and serviceability after an earthquake.

The PCaPC frame experiences a maximum acceleration of 0.98 g, whereas the cast-in-situ PC frame reaches 1.33 g, reflecting its increased stiffness and greater susceptibility to seismic forces. These differences translate into varying degrees of structural damage. The PCaPC frame, with its lower acceleration, primarily suppress damage in non-structural components, thereby shortening recovery time and reducing repair costs. Conversely, the cast-in-situ PC frame, which experiences higher accelerations and larger plastic deformations, is prone to structural cracking, permanent residual displacements, and higher post-earthquake rehabilitation expenses. The observed seismic response patterns align with the hysteresis characteristics discussed earlier, as illustrated in Figures 11, 12 (Zhao and Takahashi, 2024), where the PCaPC frame exhibits narrower hysteresis loops, indicative of controlled energy dissipation, while the cast-in-situ PC frame dissipates seismic energy through larger plastic deformations, increasing structural vulnerability.

Under the 5% in 50 years hazard level, the MT connection in the PCaPC frame exhibited distinct damage-controlling characteristics compared to conventional joint systems. While cast-in-situ joints typically experience plastic hinge in beam ends and may develop joint shear cracking under high seismic demand, the MT connection confines deformation to a localized compressive zone at the mortise-tenon interface. As inter-story drift increases repeated compressive loading initiates localized bearing damage at the joint edges. Once the compressive stress exceeds the elastic limit, minor edge crushing occurs at the corners of the tenon, marking the transition to inelastic behavior.

A key observation is that the localized damage remains stable even under multiple seismic cycles, without significant propagation or rebar rupture. The connection accommodates allowable rotational deformation through localized nonlinear compression at the mortise-tenon interface, while the self-centering mechanism is primarily driven by the restoring force from unbonded post-tensioned tendons. These failure characteristics, along with the post-earthquake reparability of the MT connection, have been confirmed in previous experimental studies (Sakata et al., 2005; Sakata et al., 2006; Nakai et al., 2006). Even under severe seismic scenarios (e.g., intensity level 7), PCaPC frames with MT joints retain sufficient lateral stiffness and primarily undergo hinge-like joint rotation, thereby limiting structural damage and facilitating post-earthquake repair.

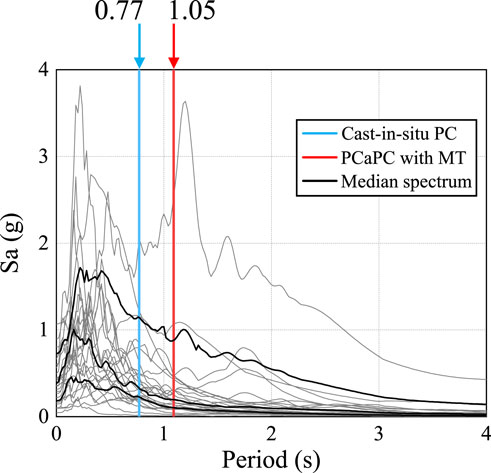

To further explain the reduction in acceleration-sensitive nonstructural damage observed in the PCaPC frame with MT connection, a spectral analysis was conducted to examine the relationship between the structural periods and the predominant periods of the ground motion set scaled by PGV. As illustrated in Figure 13, the equivalent period of the cast-in-situ PC frame is approximately 0.77 s, whereas that of the PCaPC frame is extended to approximately 1.09 s due to hinge relocation and the resulting increase in lateral flexibility introduced by the MT connection. This period elongation leads to a dynamic de-tuning effect, in which the structural period shifts away from the predominant spectral peak of the input motions, thereby reducing the amplification of floor acceleration responses. As a result, the PCaPC frame experiences significantly lower acceleration demands, mitigating damage to acceleration-sensitive nonstructural components such as ceilings, partition walls, and equipment.

Figure 13. Spectral acceleration and equivalent period comparison between cast-in-situ PC and PCaPC with MT connection.

6 Repair cost evaluation

FEMA-P58 provides cost functions for essential components within the structures, as detailed in Table 6 (Performance Group of Components) and Table 8 (Details of Repair Costs). As illustrated in Figure 8 (Component Fragilities), the components are associated with probabilities of various damage states. Based on the EDPs for Cast-in-Situ PC, PCa 50% PC, and PCaPC with MT under three seismic hazard levels, as presented in Table 9, the probabilities for each damage state are derived.

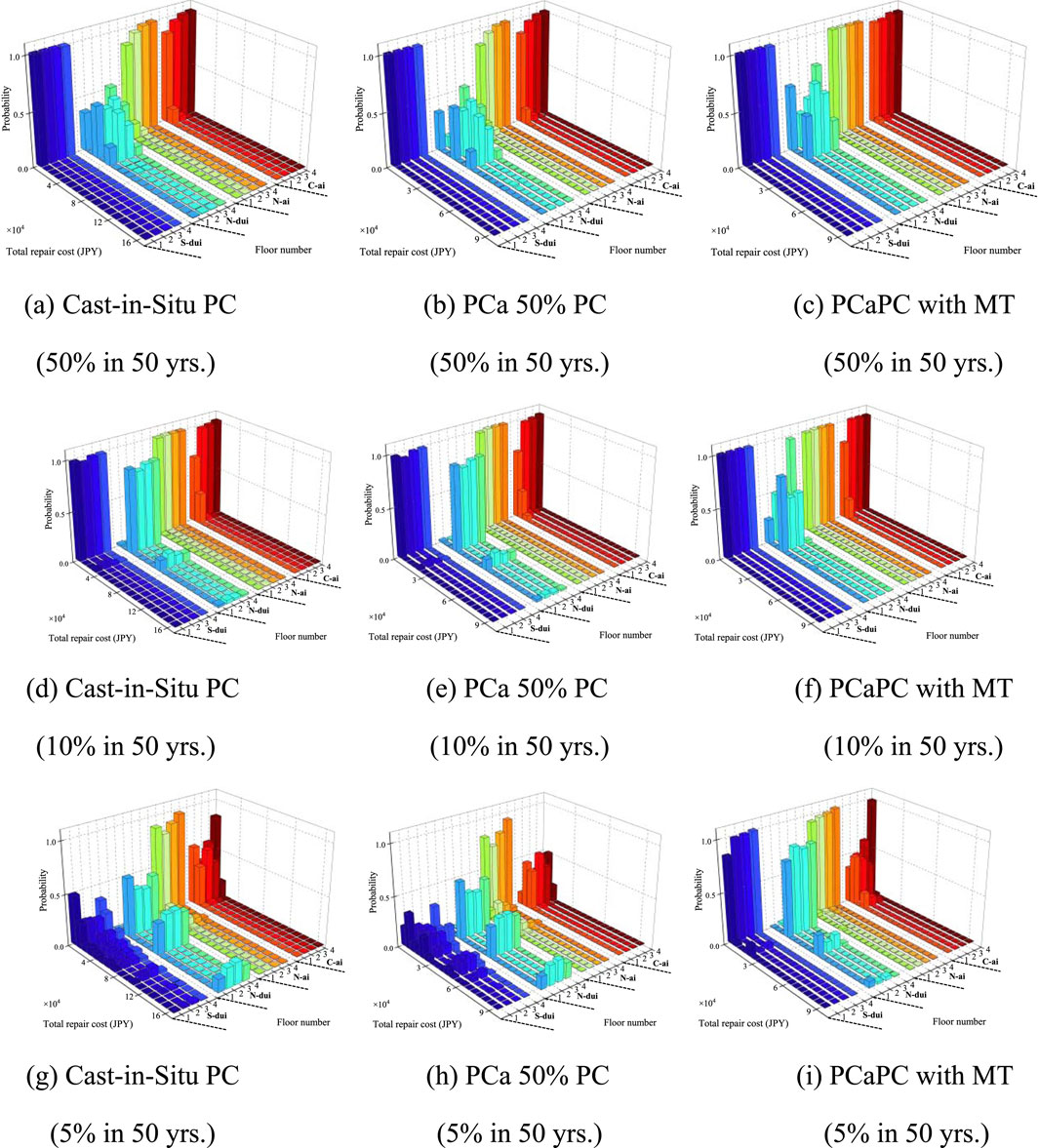

The distribution of repair costs among performance groups is depicted in Figure 14. Under the 50% in 50 years hazard level, repair expenditures are primarily concentrated in inter-story drift-sensitive elements (N-dui performance groups). This trend is attributed to the prestressed nature of the prototype office building, where structural components exhibit high tolerance to floor acceleration effects, reducing their contribution to total repair costs. Conversely, non-structural elements remain vulnerable, particularly unsecured fragile objects and office equipment, which sustain damage when floor acceleration reaches 0.5 g (Figure 8; Table 6). More expensive content, such as electronic devices and modular workstations, experiences significant damage only when acceleration surpasses 1.0 g.

Figure 14. Disaggregation of the total repair cost for the PCaPC frame with MT connection and the Cast-in-situ PC frame. (a) Cast-in-Situ PC (50% in 50 yrs.). (b) PCa 50% PC (50% in 50 yrs.). (c) PCaPC with MT (50% in 50 yrs.). (d) Cast-in-Situ PC (10% in 50 yrs.). (e) PCa 50% PC (10% in 50 yrs.). (f) PCaPC with MT (10% in 50 yrs.). (g) Cast-in-Situ PC (5% in 50 yrs.). (h) PCa 50% PC (5% in 50 yrs.). (i) PCaPC with MT (5% in 50 yrs.).

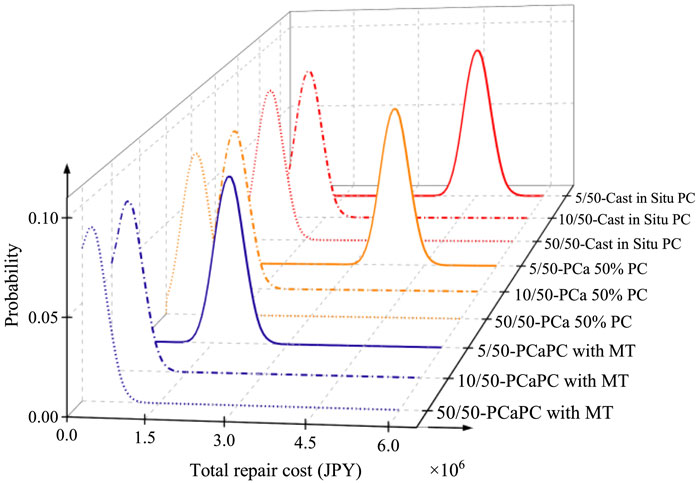

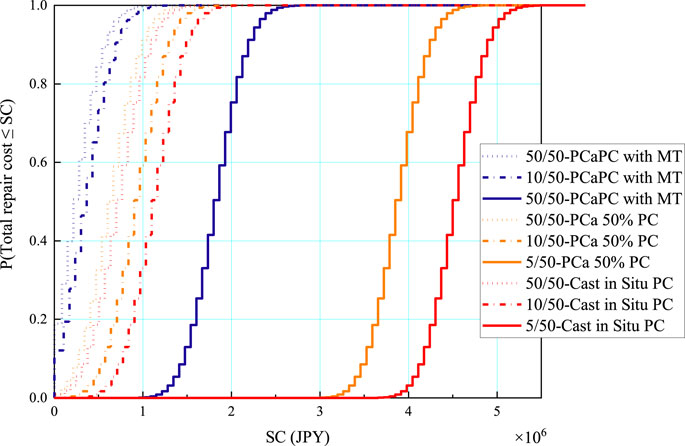

FEMA-P58 recommends using a normal distribution to calculate the probabilities of total repair costs for each seismic hazard level, as illustrated in Figure 15. Furthermore, Figure 16 demonstrates the probability of total repair costs exceeding specific thresholds under a discrete distribution. For instance, if a building owner is interested in the probability of total repair costs not exceeding 1,000,000 JPY, the calculated results indicate that for PCa 50% PC structures, the probability of not exceeding this threshold is 0.65 for the 10% in the 50-year hazard level. At the same time, it is as high as 0.99 for PCaPC structures with MT connections. Similarly, following a seismic event at the 5% in 50 years hazard level, the probability of the repair costs for cast-in-situ PC structures not exceeding 4,000,000 JPY is 0.04, compared to 0.71 for PCa 50% PC structures. This comparison highlights the superior seismic resilience and cost-efficiency of PCaPC structures, which maintain lower repair costs and enhanced post-earthquake functionality, even under severe ground motion conditions.

7 Conclusion

This study investigated the seismic performance and economic feasibility of a PCaPC frame with MT connections, comparing it with a Cast-in-Situ PC frame and a PCa 50% frame. A simplified seismic response analysis model was developed to quantify structural resilience, while a cost estimation framework was employed to assess repair expenditures under different seismic hazard levels.

(1) The findings demonstrate that MT-connected PCaPC frames improve construction efficiency. By eliminating grouting and other complex procedures, this system reduces construction costs by 13% compared to the Cast-in-Situ PC frame, without compromising structural performance. The increased assembly rate and simplified on-site construction process make PCaPC an attractive solution for local contractors.

(2) The seismic response analysis revealed enhanced resilience characteristics in PCaPC frames. The primary yielding mechanism was observed as tenon edge compression, followed by ultimate failure at the MT connection, ensuring a damage-controlled failure mode. Additionally, the restoring force from unbonded prestressed tendons and the self-weight of the upper structure facilitated self-centering behavior, mitigating residual drift post-seismic loading. Under identical seismic hazard levels, the PCaPC frame exhibited lower inter-story drift ratios and acceleration responses, reducing damage to both structural and non-structural components.

(3) The repair cost evaluation further highlighted the economic advantages of PCaPC frames. The probability of repair costs not exceeding 1,000,000 JPY for PCaPC structures was 0.99 under the 10% in 50 years hazard level, compared to 0.65 for PCa 50% PC structures. At the 5% in 50 years hazard level, the probability that repair costs remain below 4,000,000 JPY was 0.71 for PCa 50% PC structures, whereas it was only 0.04 for Cast-in-Situ PC structures. These results underscore the economic feasibility of PCaPC frames in minimizing seismic repair expenditures.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

HZ: Conceptualization, Investigation, Writing – review and editing, Methodology, Writing – original draft, Formal Analysis. NT: Methodology, Formal Analysis, Conceptualization, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by JST SPRING, Grant Number JPMJSP2114.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahn, Y. H., and Kim, K. T. (2014). Sustainability in modular design and construction: a case study of ‘The Stack. Int. J. Sustain. Build. Technol. Urban Dev. 5 (4), 250–259. doi:10.1080/2093761x.2014.985758

Almusallam, T. H., Elsanadedy, H. M., Al-Salloum, Y. A., Siddiqui, N. A., and Iqbal, R. A. (2018). Experimental investigation on vulnerability of precast RC beam-column joints to progressive collapse. KSCE J. Civ. Eng. 22, 3995–4010. doi:10.1007/s12205-018-1518-0

Baghdadi, A., Heristchian, M., Ledderose, L., and Kloft, H. (2020). Experimental and numerical assessment of new precast concrete connections under bending loads. Eng. Struct. 212, 110456. doi:10.1016/j.engstruct.2020.110456

Bournas, D. A., Negro, P., and Molina, F. J. (2013). Pseudodynamic tests on a full-scale 3-storey precast concrete building: behavior of the mechanical connections and floor diaphragms. Eng. Struct. 57, 609–627. doi:10.1016/j.engstruct.2013.05.046

China Construction Industry Association (CCIA) (2022). 2022 Statistical analysis of construction industry development. Beijing, China:China Construction Industry Press.

Campbell, R. D., Griffin, M. J., Bragagnolo, L. J., and Yanev, P. I. (1996). The December 7, 1988 Armenia earthquake effects on selected power, industrial and commercial facilities.

Cavaco, E., Pacheco, I., and Camara, J. (2018). Detailing of concrete-to-concrete interfaces for improved ductility. Eng. Struct. 156, 210–223. doi:10.1016/j.engstruct.2017.10.058

Chiang, Y. H., Chan, E. H. W., and Lok, L. K. L. (2006). Prefabrication and barriers to entry—a case study of public housing and institutional buildings in Hong Kong. Habitat Int. 30 (3), 482–499. doi:10.1016/j.habitatint.2004.12.004

Chida, H., Takahashi, N., and Yamada, T. (2022). Feasibility study on diagnostic imaging system with deep learning for post-quake recconaissance on the 2021 earthquake off the coast of fukushima prefecture. J. Struct. Eng. 68B, 1–8. doi:10.3130/aijjse.68b.0_1

Dal Lago, B., Negro, P., and Dal Lago, A. (2018). Seismic design and performance of dry-assembled precast structures with adaptable joints. Soil Dyn. Earthq. Eng. 106, 182–195. doi:10.1016/j.soildyn.2017.12.016

de Lima Araújo, D., Prado, L. P., da Silva, E. B., and El Debs, M. K. (2018). Temporary beam-to-column connection for precast concrete frame assembly. Eng. Struct. 171, 529–544. doi:10.1016/j.engstruct.2018.05.089

Desnerck, P., Lees, J. M., and Morley, C. T. (2016). Impact of the reinforcement layout on the load capacity of reinforced concrete half-joints. Eng. Struct. 127, 227–239. doi:10.1016/j.engstruct.2016.08.061

Ding, K., Ye, Y., and Ma, W. (2021). Seismic performance of precast concrete beam-column joint based on the bolt connection. Eng. Struct. 232, 111884. doi:10.1016/j.engstruct.2021.111884

Dou, Y., Zhong, L., and Luo, L. (2025). Supply chain resilience of prefabricated construction: perspectives of stakeholder capabilities and vulnerabilities. J. Constr. Eng. Manag. 151 (4), 04025013. doi:10.1061/jcemd4.coeng-15514

Fang, C., Ping, Y., Zheng, Y., and Chen, Y. (2021). Probabilistic economic seismic loss estimation of steel braced frames incorporating emerging self-centering technologies. Eng. Struct. 241, 112486. doi:10.1016/j.engstruct.2021.112486

Ge, Q., Ai, J., Mao, Y., Li, Y., Lu, Y., Xiong, F., et al. (2025). Study of seismic performance and resilience of a precast concrete beam-column joint with a replaceable energy-dissipation component. J. Build. Eng. 112, 112167. doi:10.1016/j.jobe.2025.112167

Ghayeb, H. H., Razak, H. A., and Sulong, N. R. (2017). Development and testing of hybrid precast concrete beam-to-column connections under cyclic loading. Constr. Build. Mater. 151, 258–278. doi:10.1016/j.conbuildmat.2017.06.073

Ghobarah, A., Abou-Elfath, H., and Biddah, A. (1999). Response - based damage assessment of structures. Earthq. Eng. and Struct. Dyn. 28 (1), 79–104. doi:10.1002/(sici)1096-9845(199901)28:1<79::aid-eqe805>3.0.co;2-j

Guerrero, H., Rodriguez, V., Escobar, J. A., Alcocer, S. M., Bennetts, F., and Suarez, M. (2019). Experimental tests of precast reinforced concrete beam-column connections. Soil Dyn. Earthq. Eng. 125, 105743. doi:10.1016/j.soildyn.2019.105743

Jin, K., Hao, L., and Kitayama, K. (2021). Direct evaluation method for load-deformation curve of precast prestressed concrete frame with different tendon forces. Bull. Earthq. Eng. 19 (9), 3597–3626. doi:10.1007/s10518-021-01109-w

Jin, K., and Kitayama, K. (2019). Evaluation method of skelton curve for unbonded PCaPC beam member in exterior beam-column joint subassemblage. Proc. Jpn. Concr. Inst. 41, 481–486. Available online at: https://jglobal.jst.go.jp/detail?JGLOBAL_ID=201902211271343594.

Jin, K., Kitayama, K., Song, S., and Kanemoto, K. O. (2017). Shear capacity of precast prestressed concrete beam-column joint assembled by unbonded tendon. ACI Struct. J. 114 (1). doi:10.14359/51689148

Kurama, Y. C., Sritharan, S., Fleischman, R. B., Restrepo, J. I., Henry, R. S., Cleland, N. M., et al. (2018). Seismic-resistant precast concrete structures: state of the art. J. Struct. Eng. 144 (4), 03118001. doi:10.1061/(asce)st.1943-541x.0001972

Kurosawa, R., Sakata, H., Qu, Z., and Suyama, T. (2019). Precast prestressed concrete frames for seismically retrofitting existing RC frames. Eng. Struct. 184, 345–354. doi:10.1016/j.engstruct.2019.01.110

Li, Z., Shen, G. Q., and Xue, X. (2014). Critical review of the research on the management of prefabricated construction. Habitat Int. 43, 240–249. doi:10.1016/j.habitatint.2014.04.001

Li, Z., Zhang, S., Meng, Q., and Hu, X. (2021). Barriers to the development of prefabricated buildings in China: a news coverage analysis. Eng. Constr. Archit. Manag. 28 (10), 2884–2903. doi:10.1108/ecam-03-2020-0195

Luo, T., Xue, X., Wang, Y., Xue, W., and Tan, Y. (2021). A systematic overview of prefabricated construction policies in China. J. Clean. Prod. 280, 124371. doi:10.1016/j.jclepro.2020.124371

Lv, X., Yu, Z., Yin, J., and Liu, P. (2025). Seismic behaviour and restoring force model of a novel prefabricated element precast concrete frame. J. Build. Eng. 112, 112003. doi:10.1016/j.jobe.2025.112003

Mai, T. P., Doan, D. T., and Ghaffarianhoseini, A. (2025). Utilizing multiskilled resources in addressing labor shortage issues in off-site construction: benefits, challenges, and best practices. J. Constr. Eng. Manag. 151 (4), 04025014. doi:10.1061/jcemd4.coeng-15275

Mao, C., Shen, Q., Shen, L., and Tang, L. (2013). Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: two case studies of residential projects. Energy Build. 66, 165–176. doi:10.1016/j.enbuild.2013.07.033

Matsunaga, K., and Tani, M. (2025). Damage classification method for unbonded PCaPC beams with widened beam ends connected by bearing. J. Struct. Constr. Eng. Trans. AIJ 90 (829), 389–400. doi:10.3130/aijs.90.389

Menichini, G., Gusella, F., and Orlando, M. (2024). Methods for evaluating the ultimate capacity of existing RC half-joints. Eng. Struct. 299, 117087. doi:10.1016/j.engstruct.2023.117087

Miao, Z., Ji, X., Okazaki, T., and Takahashi, N. (2021). Pixel-level multicategory detection of visible seismic damage of reinforced concrete components. Computer-Aided Civ. Infrastructure Eng. 36 (5), 620–637. doi:10.1111/mice.12667

Ministry of Housing and Urban-Rural Development (MOHURD) (2023). Prefabricated building project investment estimation index. China Construction Industry Press.

Mohammed, K., Jameel, M., Ibrahim, Z., and Tan, C. G. (2021). Performance of a ductile hybrid post-tensioned beam-to-column connection for precast concrete frames under seismic loads: a review. Appl. Sci. 11 (16), 7497. doi:10.3390/app11167497

Nadeem, G., Safiee, N. A., Bakar, N. A., Abd Karim, I., and Nasir, N. A. M. (2021). Connection design in modular steel construction: a review. Structures 33, 3239–3256. doi:10.1016/j.istruc.2021.06.060

Nakai, T., Matsuzaki, Y., Sakata, H., and Takeuchi, H. (2006). Experimental study on structural performance of T-shaped frame using PC mild-press-joint. Proc. Jpn. Concr. Inst. Annu. Convention 28 (2), 535–540. Available online at: https://data.jci-net.or.jp/data_pdf/28/028-01-2090.pdf

Negro, P., Bournas, D. A., and Molina, F. J. (2013). Pseudodynamic tests on a full-scale 3-storey precast concrete building: global response. Eng. Struct. 57, 594–608. doi:10.1016/j.engstruct.2013.05.047

Negro, P., and Mola, E. (2017). A performance based approach for the seismic assessment and rehabilitation of existing RC buildings. Bull. Earthq. Eng. 15, 3349–3364. doi:10.1007/s10518-015-9845-8

Parastesh, H., Hajirasouliha, I., and Ramezani, R. (2014). A new ductile moment-resisting connection for precast concrete frames in seismic regions: an experimental investigation. Eng. Struct. 70, 144–157. doi:10.1016/j.engstruct.2014.04.001

Park, Y. J., and Ang, A. H. S. (1985). Mechanistic seismic damage model for reinforced concrete. J. Struct. Eng. 111 (4), 722–739. doi:10.1061/(asce)0733-9445(1985)111:4(722)

Ruiz-García, J., and Miranda, E. (2006). Residual displacement ratios for assessment of existing structures. Earthq. Eng. and Struct. Dyn. 35 (3), 315–336. doi:10.1002/eqe.523

Sakata, H., Kuboyama, H., Sugiyama, T., Ikezawa, M., Wada, A., Matsuzaki, Y., et al. (2005). Experimental study on beam-column joint of damage controlled precast-prestressed concrete frame with P/C mild-press-joint. J. Struct. Constr. Eng. Trans. AIJ 70 (588), 141–147. doi:10.3130/aijs.70.141_1

Sakata, H., Wada, A., Nakano, K., Matsuzaki, Y., Tanabe, K., and Machida, S. (2006). Study on damage controlled precast-prestressed concrete structure with P/C MILD-PRESS-JOINT - Part 2: Experimental study on mechanical behavior of frame with P/C MILD-PRESS-JOINT. Proceedings of the 2nd International fib Congress. Naples, Italy. Available online at: https://www.akira-wada.com/00_img/article/2006/0602s03_Fib2006-8-43.pdf

Shams, A. S., and Ghobadi, M. S. (2021). Development of a high-performance hybrid self-centering building for seismic resilience. Eng. Struct. 226, 111382. doi:10.1016/j.engstruct.2020.111382

Song, L. L., Guo, T., and Chen, C. (2014). Experimental and numerical study of a self-centering prestressed concrete moment resisting frame connection with bolted web friction devices. Earthq. Eng. and Struct. Dyn. 43 (4), 529–545. doi:10.1002/eqe.2358

Song, L. L., Guo, T., Gu, Y., and Cao, Z. L. (2015). Experimental study of a self-centering prestressed concrete frame subassembly. Eng. Struct. 88, 176–188. doi:10.1016/j.engstruct.2015.01.040

Sousa, R., Batalha, N., and Rodrigues, H. (2020). Numerical simulation of beam-to-column connections in precast reinforced concrete buildings using fibre-based frame models. Eng. Struct. 203, 109845. doi:10.1016/j.engstruct.2019.109845

Takahashi, N., Katakai, Y., and Aoki, T. (2020). Optimal structural restoration of historic building in Japan considering lifecycle seismic loss analysis. Jpn. Archit. Rev. 3 (3), 284–297. doi:10.1002/2475-8876.12151

Takahashi, N., and Nakano, Y. (2009). “Seismic repair cost of R/C structures using a geometrical damage estimation model,” in Proceedings of the first international conference on computational design in engineering. Seoul, Republic of Korea, 515–518.

Takahashi, N., Takahashi, E., and Nakano, Y. (2010). “Experimental study on damage quantification of R/C members under earthquakes,” in Proceedings of the 9th U.S. National and 10th Canadian Conference on Earthquake Engineering (Paper No. 237). Milan, Italy

Takahashi, N., and Tsuka, D. (2024). “Loss estimation by employing the crack width distribution characteristics of RC structural members,” in Proceedings of the 18th world conference on earthquake engineering (WCEE 2024). Oakland, CA

Takimoto, K., Nagasawa, Y., and Ishii, K. (2004). Experimental study on evaluation of damage degree of RC members using crack data. Proc. Jpn. Soc. Civ. Eng. 760/V-63, 135–145. doi:10.2208/jscej.2004.760_135

Tambusay, A., Suryanto, B., Suprobo, P., Grieve, F. S., Aitken, M. W., and Don, W. (2024). Influence of reinforcement reductions on the response of reinforced concrete half-joints. Eng. Struct. 321, 118934. doi:10.1016/j.engstruct.2024.118934

Tanabe, K. (2009). The history of PC-building from my viewpoint. J. Prestress. Concr. 51 (1), 46–51. Available online at: https://cir.nii.ac.jp/crid/1520009408580611968

Wang, Y., and Takahashi, N. (2021). Evaluation of crack width distribution characteristics of RC wall using image processing. J. Struct. Constr. Eng. 86, 481–489. doi:10.3130/aijs.86.481

Wang, Y., Thangasamy, V. K., Tiong, R. L., and Zhang, L. (2022). Improved workflow for precast element design based on BIM and lean construction. J. Constr. Eng. Manag. 148 (8), 04022065. doi:10.1061/(asce)co.1943-7862.0002316

Wasim, M., Vaz Serra, P., and Ngo, T. D. (2022). Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction-a review. Int. J. Constr. Manag. 22 (15), 3014–3022. doi:10.1080/15623599.2020.1837720

Wu, G., Yang, R., Li, L., Bi, X., Liu, B., Li, S., et al. (2019). Factors influencing the application of prefabricated construction in China: from perspectives of technology promotion and cleaner production. J. Clean. Prod. 219, 753–762. doi:10.1016/j.jclepro.2019.02.110

Yan, Q., Chen, T., and Xie, Z. (2018). Seismic experimental study on a precast concrete beam-column connection with grout sleeves. Eng. Struct. 155, 330–344. doi:10.1016/j.engstruct.2017.09.027

Yu, J., Zhang, W., Tang, Z., Guo, X., and Pospíšil, S. (2020). Seismic behavior of precast concrete beam-column joints with steel strand inserts under cyclic loading. Eng. Struct. 216, 110766. doi:10.1016/j.engstruct.2020.110766

Yu, M., Ruan, W., Zhou, Y., and Zhao, Y. (2025). Flow shop scheduling for prefabricated components production considering parallel machines and buffer constraints. J. Constr. Eng. Manag. 151 (4), 04025010. doi:10.1061/jcemd4.coeng-15909

Zhao, H., Peng, T., and Ge, P. (2023). Research on damping and restoring force performance of artificial hinge based on the micro-nano ceramic coated steel bar. Nanotechnol. Environ. Eng. 8 (3), 745–752. doi:10.1007/s41204-021-00164-7

Zhao, H., and Takahashi, N. (2024). Seismic behavior of precast prestressed concrete frame with hinge-relocated mortise-tenon connections. Buildings 14 (9), 3007. doi:10.3390/buildings14093007

Zhao, H., and Yin, X. (2022a). Seismic mitigation and self-centering performance of the adaptive structure based on artificial hinge. China Earthq. Eng. J. 44 (2), 1–9. doi:10.20000/j.1000-0844.20210505001

Zhao, H., and Yin, X. (2022b). A prestressed assembled artificial hinge, adaptive damping structure system and its construction method. China Patent—building Science and Engineering. China Natl. Intellect. Prop. Adm. E04B1/98, 1–19.

Zhou, Y., Chen, T., Pei, Y., Hwang, H. J., Hu, X., Yi, W., et al. (2019). Static load test on progressive collapse resistance of fully assembled precast concrete frame structure. Eng. Struct. 200, 109719. doi:10.1016/j.engstruct.2019.109719

Keywords: PCaPC frame, mortise-tenon connection, incremental cost, seismic response analysis, loss estimation

Citation: Zhao H and Takahashi N (2025) Loss estimation of precast prestressed concrete frame structure with cost-efficient mortise-tenon connection under earthquake. Front. Built Environ. 11:1612096. doi: 10.3389/fbuil.2025.1612096

Received: 15 April 2025; Accepted: 09 June 2025;

Published: 19 June 2025.

Edited by:

Pengfei Dang, Ningbo University, ChinaReviewed by:

Rijalul Fikri, Syiah Kuala University, IndonesiaLiangjie Qi, Xi’an University of Architecture and Technology, China

Copyright © 2025 Zhao and Takahashi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hanxi Zhao, emhhby5oYW54aS5zNkBkYy50b2hva3UuYWMuanA=

Hanxi Zhao

Hanxi Zhao Noriyuki Takahashi

Noriyuki Takahashi