- Department of Civil, Architectural and Environmental Engineering, University of Texas at Austin, Austin, TX, United States

Efficiency in on-site construction has long been a pursuit for project stakeholders, with a focus on enhancing direct-work rates—the time spent by craft workers on installation activities. However, despite the promising potential of methodologies such as Advanced Work Packaging (AWP) and WorkFace Planning (WFP) in being associated with enhancing these rates, there is limited officially published evidence, with much of the available data derived from narrow datasets. This study addresses this research gap by investigating the impact of AWP and WFP implementation on direct-work rates using two distinct datasets spanning from 2015 to 2023. The first dataset comprises 61 projects from a productivity consultant, while the second dataset consists of 23 projects sourced from a large engineering, procurement, and construction (EPC) firm, covering a diverse range of global projects. The findings indicate that projects employing AWP and WFP are correlated with significantly higher direct-work rates and demonstrate improved predictability of direct-work rates compared to those that do not implement these methodologies. This study contributes to the body of knowledge by emphasizing the value of AWP and, more broadly, the significance of systemic management interventions in both front-end and on-site planning. In addition to the specific findings about AWP and WFP, this paper also demonstrates probability-based methods to assess predictability from work sampling data, a novel application for exploring construction productivity.

Introduction

The construction industry plays a pivotal role in driving economic growth and development, with construction projects spanning various sectors such as infrastructure, residential, commercial, and industrial. However, the industry is also notorious for facing challenges related to productivity, efficiency, and project delivery. In response to these challenges, many owner, engineering, and construction organizations in the industrial construction projects sector have turned to Advanced Work Packaging (AWP) as a means to enhance Front-End Planning (FEP), increase alignment between planning and execution activities, streamline work packaging processes, improve field productivity, and enhance overall project performance (COAA, 2016; O’Brien et al., 2011; 2013; O’Brien and Ponticelli, 2015).

AWP was developed by practitioners and further refined and codified by the Construction Industry Institute (CII) and Construction Owners Association of Alberta (COAA) (McTague and Jergeas, 2002; O’Brien et al., 2011; 2013; Slootman, 2007). In 2015, CII designated AWP as a best practice, based on the validation work conducted by CII Research Team 319 (O’Brien and Ponticelli, 2015). It has emerged as a framework for productive and fast track execution of industrial construction projects, and showing great potential to mitigate many of the factors negatively affecting construction productivity (Ponticelli et al., 2015). AWP aligns planning and execution activities across the project lifecycle, from project setup to startup and turnover (O’Brien et al., 2013). One of the key components of AWP is a process called WorkFace Planning (WFP). It is a short-interval planning process developed by COAA members in the early 2000s, with some parallel efforts by firms operating the US Gulf Coast. Inspired by Lean Construction planning (Ballard and Howell, 1994), a goal of WFP is to organize and deliver all necessary information and resources needed for the construction crafts to deliver high-quality work in a safe, effective and efficient manner (Ryan, 2009; Virtue, 2006). Constraint removal is a core tenant of WFP. The process of planning and removing constraints is reported to be associated with increased productivity in the field not only because of resource availability but also because of greater craft worker motivation (Gardner, 2006).

Industrial projects implementing AWP and WFP are correlated with significant benefits. Slootman (2007) conducted a case study on two similar refinery-upgrade projects in Alberta oil sands and reported a 50% more efficient rate of pipe installation (in meters/mhr), on-time project delivery, and lower rework when aspects of AWP and WFP were implemented (Slootman, 2007). Similarly, a large EPC firm reported superior safety performance (0.21 TRIR), 11% improvement in productivity factor, 10% cost savings, and reduced rework when aspects of AWP and WFP were implemented (COAA, 2010). Based on twenty-seven case studies, six expert interviews, and questionnaire surveys CII research teams 272 and 319 reported several benefits of AWP and WFP implementation such as improved productivity, improved safety, improved predictability, less rework, improved stakeholder alignment, reduction in RFIs, and improved client satisfaction (O’Brien et al., 2011; 2013; O’Brien and Ponticelli, 2015). Implementation of AWP and WFP has been associated with promising results in achieving predictable outcomes in cost, schedule, quality, and safety. Furthermore, productivity improvements of up to 25% in the field, with corresponding reductions of 10% of Total Installed Cost (TIC) compared to baseline, have been reported (O’Brien and Ponticelli, 2015; Virtue, 2006).

While previous studies (BrandSafway, 2017; O’Brien and Ponticelli, 2015; Pappas et al., 2019; Virtue, 2006) have indicated benefits through case studies or limited datasets, there has been a lack of broader contemporary quantitative evidence across diverse projects since AWP’s formalization as a best practice. The novelty of this research, therefore, lies in its use of two extensive, independent datasets and its explicit focus on direct-work rates and their predictability using probabilistic methods, addressing this gap. Unlike previous studies that often rely on limited datasets from individual projects, this study leverages two extensive and independent datasets encompassing 61 projects from a productivity consulting firm and 23 projects from a large EPC organization. This breadth of data, collected between 2015 and 2023, allows for a more robust and generalizable analysis of the relationship between AWP/WFP implementation and project outcomes across diverse industrial sectors. The timeframe of 2015–2023 was selected because 2015 marks the year CII designated AWP as a best practice, leading to a period of adoption over a broader range of companies and locales and providing a distinct period to compare projects with and without these interventions. Data collection for the datasets used in this study concluded in 2023. Furthermore, this study explicitly addresses the scarcity of research directly linking systemic management interventions like AWP and WFP to direct-work rates and their predictability, a crucial aspect often overlooked in existing literature. By focusing on these key metrics, the research offers valuable insights into the relationship between AWP/WFP implementation and improved on-site efficiency and project control. This detailed, quantitative analysis provides a significant advancement beyond anecdotal evidence and limited case studies, offering a more compelling and evidence-based argument for the wider adoption of AWP and WFP within the industrial construction sector. The findings of this study are not only relevant to academics seeking a deeper understanding of advanced project management methodologies but also to practitioners looking to optimize project performance through data-driven decision-making and the implementation of best practices.

The paper is structured as follows: It begins with a review of the literature on work-sampling, AWP, WFP, direct-work rates of on-site workers, and predictable project outcomes in industrial construction projects. This is followed by an explanation of the methodology, including data collection and analysis. Next, the paper presents exploratory and statistical analyses to test the research hypotheses, examining the relationship between AWP and WFP implementation and direct-work rates. Then, it discusses the probability distributions of datasets to gain insights into direct-work rate predictability in different project contexts. The results of the analysis are outlined next, followed by a discussion of their implications for practice and theory, along with suggestions for future research directions. Finally, the paper concludes by summarizing key findings, highlighting contributions, and providing recommendations.

Literature review

The problem of poor productivity in the construction industry has been widely recognized and documented (Mettler, 1983; Teicholz, 2004). Construction labor productivity is a subset of overall construction productivity, but it is a key component affecting productivity because labor costs represent 40%–60% of the total installation costs on a typical industrial project (Hanna et al., 1999; Smith, 2013). Thus, improving construction labor productivity is critical for improving overall construction productivity.

A need for improving management practices to improve construction labor productivity has been highlighted as a solution to the productivity problem by several researchers in the past (Hewage and Ruwanpura, 2006; Kim et al., 2024; Lo and Kam, 2022; Logcher and Collins, 1978; Oglesby et al., 1989; Sanvido, 1984). In a study investigating the factors affecting construction productivity researchers found that 35 out of 51 factors affecting construction productivity were related to management (Hewage and Ruwanpura, 2006). Numerous management practice interventions have been documented in the literature (Aboseif and Hanna, 2023; Ghodrati et al., 2018). While there are many perspectives, there is a strong consensus on the need to improve management systems, leading to an emphasis on practices such as Lean Construction and AWP. This paper focuses on the AWP implementation in industrial construction projects. Several Lean Construction tools and techniques have been deployed to enhance construction productivity (Alarcón, 2007; Bajjou and Chafi, 2020; Egan, 1998) and production plan reliability (Ballard, 2000; Liu and Ballard, 2008). Similarly, AWP and its subset, WFP, have emerged as systemic management interventions often associated with enhancing the efficiency of fast-track industrial construction projects. These interventions have been observed to exhibit significant potential in alleviating many of the factors that negatively impact construction productivity and project predictability (O’Brien and Ponticelli, 2015; Ponticelli et al., 2015).

The following sections review key concepts and literature related to work-sampling, AWP, WFP, and predictable outcomes in construction projects. They also identify research gaps that motivate this study.

Work sampling

One of the widely used techniques for assessing workface labor productivity is work-sampling, also known as time-on-tools or wrench-time studies. Work-sampling or time-on-tools measurements have the benefits of being relatively easy to assess and easily comparable across projects, something more difficult to accomplish with direct measurements of productivity (Yates, 2014); as such work-sampling has become a primary tool for assessing and comparing productivity within and across projects. Work sampling is conducted by randomly taking observations by touring a construction site (Thomas and Holland, 1980). Each observation is classified in predefined categories. These categories vary from project to project but generally fall into three broad categories: direct-work, support-work, and delays. Direct-work refers to activities or tasks directly related to the physical construction process. These are the primary tasks that contribute directly to the progress and completion of the project. Direct-work typically involves the actual construction, installation, assembly, or fabrication activities performed by skilled tradespeople, laborers, or specialized contractors on the construction site. Support-work refers to activities or tasks that are necessary for the continuation or completion of primary construction tasks but are not directly involved in the physical construction process. Delays are interruptions or setbacks in the construction process that prevent or hinder the timely completion of tasks. These can arise from various factors such as adverse weather conditions, unforeseen site conditions, supply chain issues, design changes, equipment failures, labor shortages, unscheduled worker breaks, or on-site travel times (Dai et al., 2009; Durdyev and Mbachu, 2011; Kumaraswamy and Chan, 1998; Lindhard and Wandahl, 2014; Thomas and Daily, 1983).

Work-sampling is a robust method for measuring wasted time on construction projects (Wandahl et al., 2022). The focus is on its application towards improving management effectiveness (Josephson and Björkman, 2013; Thomas, 1981) and process efficiencies (Josephson and Björkman, 2013; Yates, 2014) rather than evaluating individuals, crews, or contractors. A statistically significant relationship between direct-work and construction labor productivity has been established by several studies in the past (Liou and Borcherding, 1986; Neve et al., 2020; Tsehayae and Fayek, 2012), however there are some studies that have also pointed out that work-sampling study objectives and definition of work categories can make it difficult to estimate labor productivity by simply measuring where craft workers spend their time (Josephson and Björkman, 2013; Salling et al., 2022; Thomas, 1991).

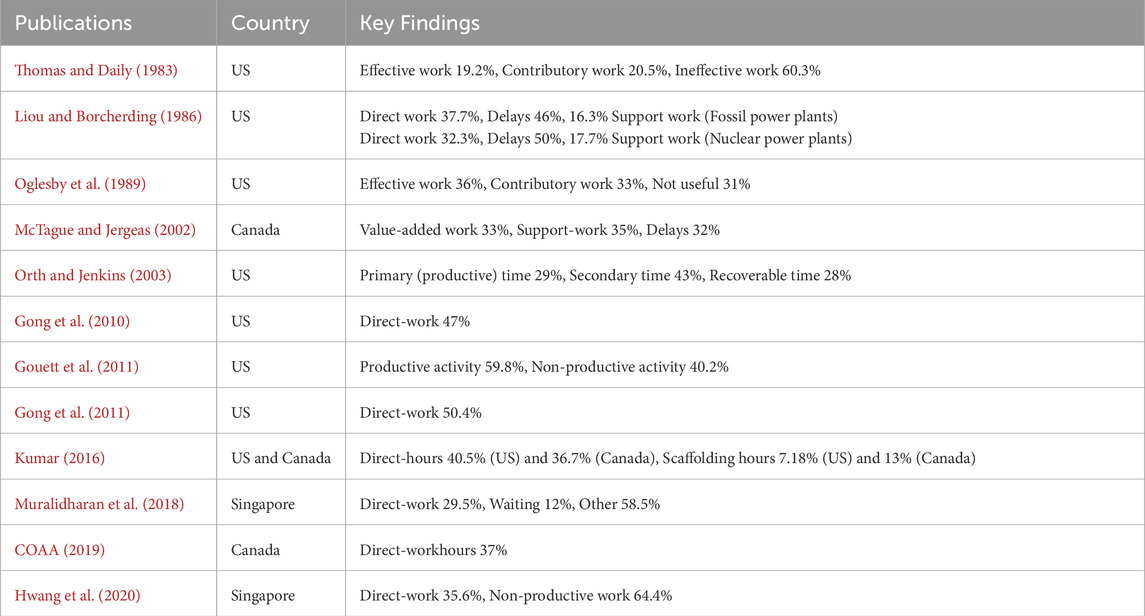

Despite its limitations, work sampling remains a popular tool for diagnosis and measurement of project performance. Direct-work rate, in particular, is widely accepted as a measure of on-site construction worker productivity. It has been successfully utilized to make meaningful changes in management practices and work processes aimed at enhancing on-site labor productivity (CII, 2019; Demirkesen et al., 2022; Ghodrati et al., 2018; Neve et al., 2022; Wandahl et al., 2022). Work-sampling has been utilized to evaluate direct-work rates across various construction projects, including industrial, infrastructure, residential, and commercial projects. In the literature, direct-work rates have been reported as ranging from as low as 17.5% (Strandberg and Josephson, 2005) to as high as 61.1% (Hajikazemi et al., 2017). Furthermore, as illustrated in Table 1, direct-work rates as low as 19.2% (Thomas and Daily, 1983) and as high as 50.4% (Gong et al., 2011) have been documented specifically in industrial construction projects. Table 1 highlights the varying terms used by different authors to describe direct-work, support-work, and delays. These terms reflect each author’s specific definitions of these concepts. Generally, “effective work” and “primary time” closely align with “direct-work,” while “contributory work” and “secondary time” correspond to “support-work.” Similarly, “ineffective work” and “non-useful time” are often associated with “delays.”

Advanced work packaging

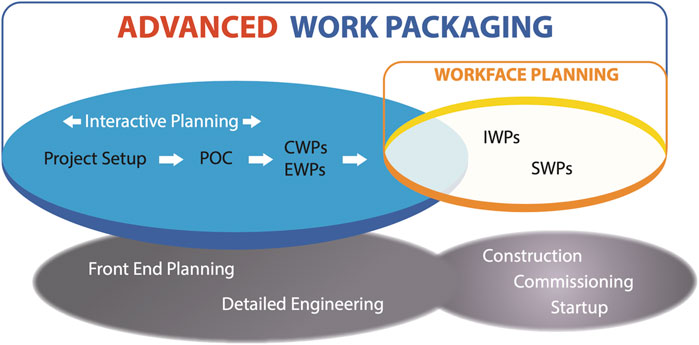

Advanced Work Packaging (AWP) is a meticulously planned and executable process that spans the entirety of a project’s lifecycle, from initial planning to detailed engineering and construction execution (Figure 1). It serves as the overarching framework for organizing the execution of an EPC project, encompassing construction, engineering, installation, and system work packages (CWPs, EWPs, IWPs, and SWPs). These work packages are used as a means of conveying information and tracking progress (CII, 2020; O’Brien et al., 2013; Ryan, 2017).

Figure 1. Advanced work packaging (AWP) and WorkFace planning (WFP) [Adapted from CII (2023)]

The AWP framework is specifically designed to assist practitioners in effectively structuring work by integrating construction execution, supply chain management, commissioning, and startup knowledge into the early planning stages. A fundamental aspect of this process is fostering collaboration among engineering, procurement, construction, and commissioning teams during the initial project planning phase. This collaborative effort aims to establish a constraint-free work environment in the field. By breaking down the project scope into construction work packages and aligning them with engineering work packages, the project sequence is optimized to support construction activities using a concept called Path of Construction (PoC), while ensuring that the supply chain is appropriately sequenced (O’Brien et al., 2011; 2013).

WorkFace Planning (WFP) is an AWP process designed for short interval production planning and control (Ryan, 2009). WFP refers to organizing and delivering all required components for a complete installation work package (IWP) prior to beginning activities on the work front (O’Brien et al., 2011). WFP is designed to enhance communication and better organize tools, and material coordination at the job site, with the goal of increasing safety, effectiveness, and efficiency of craft workers.

Similar to WFP, other management interventions, such as Lean Construction’s Last Planner® System (LPS) (Ballard, 2000; Ballard and Howell, 1994), also aim to enhance project performance through short-interval production planning. WFP and LPS share several similarities such as production shielding by generating workable backlogs (Ballard, 2000; Ballard and Choo, 2011; Ballard and Howell, 1998; O’Brien et al., 2011), constraint management, and focus on short-term planning. One key difference in both practices is their approach to execution planning and work packaging. WFP depends on the installation work packages (IWPs) prepared by upstream efforts of alignment between planning and execution activities using the AWP framework as shown in Figure 1 and on the other hand LPS relies on Phase Pull Planning and milestone scheduling (Ballard, 2000; Ballard and Choo, 2011).

As noted above, data developed by CII research noted through case studies that AWP was reported to increase productivity by up to 25% and decrease Total Installed Cost (TIC) by up to 10% (O’Brien and Ponticelli, 2015). These studies were primarily based on comparisons to project baselines and did not measure absolute productivity, which would be difficult to compare in any case. A further limitation of these studies is their North American-centric projects. These initial studies, while of detailed cases, did not present work sampling data. The only work sampling data of note prior to 2015 are the oft-reported findings from a COAA study of a single project (Virtue, 2006). Since 2015, industry professionals have presented anecdotal evidence indicating direct-work rates of 70% for steel erection, 63% for piping, and 75% for scaffolding work when AWP and WFP are implemented (BrandSafway, 2017; Pappas et al., 2019). Despite these promising results, much of the evidence represents industry-developed case studies reported at professional conferences. Collectively, there is a need for broader contemporary evidence of AWP performance.

Predictable project outcomes in construction

Construction projects frequently exceed their budgets and schedules (Flyvbjerg et al., 2003; Sambasivan and Soon, 2007). The unpredictability of project outcomes is a well-documented issue within the construction industry (Grau and Back, 2015; Jeong et al., 2024; Russell et al., 1997). Fast-tracking strategies, which aim to accelerate, overlap, or compress project schedules, significantly relate to the predictability of achieving planned objectives in terms of time, cost, and quality (Alhomadi et al., 2011; Laufer and Cohenca, 1990). Laufer and Cohenca (1990) found that projects with only 20% of their designs completed at the start of construction are likely to face considerable delays and experience a man-hour variance up to five times greater than projects that begin with 90% of their designs completed.

Several efforts aimed at enhancing project predictability have been reported in the literature (Grau and Back, 2015; Lia et al., 2014; Nightingale and Brady, 2011). One effective approach, originating from Klein and Meckling (1958) and later adopted by Lean Construction practitioners, involves delaying decision-making to the latest possible stages (Ballard and Howell, 2003; Klein and Meckling, 1958). During the construction of Heathrow Terminal-5, the British Airports Authority (BAA) focused on creating a learning organization capable of designing once and building multiple times, employing strategies like the Continuous Improvement Project Process (CIPP) and Framework Contracting to boost predictability. BAA achieved efficiency gains by reusing standardized designs across multiple projects. This approach enabled them to accumulate organizational knowledge, enhancing process predictability and reducing project uncertainties (Nightingale and Brady, 2011). Lean construction’s LPS is another method designed to reduce uncertainties and improve production plan reliability at the construction work face (Ballard, 2000).

Furthermore, implementation of AWP and WFP has shown promising results in achieving predictable outcomes in cost, schedule, quality, and safety in industrial construction projects. Research by the CII Research Team 272 showed that AWP is associated with enhanced project performance predictability. Further evidence from CII IR 272-2 Volume III (2013) suggests that consistent AWP implementation is associated with more reliable estimates and effective project execution (O’Brien et al., 2013). This was supported by CII Research Team 319, which confirmed that AWP consistently is consistently associated with improved project predictability (O’Brien and Ponticelli, 2015). Case studies from this research indicated that AWP is associated with increased predictability across various contractor activities by establishing reliable work estimates and ensuring a constraint-free, executable construction sequence. When AWP and WFP are utilized on a project, it is reported there is less likelihood of craft labor waiting for material, tools, equipment, permits, and access. Also, a higher direct-work rate is often observed when crews spend little time travelling to get material, tools, and information.

Measuring absolute productivity in construction is challenging due to project complexities, measurement errors, and the lack of standardized methods (Garcia and Molloy, 2023). Factors such as scope differences and misreported labor hours further complicate assessments. However, metrics like time-on-tools and direct-work rates are correlated to productivity, and as such, are favored for their simplicity and focus on value-adding tasks (Neve et al., 2020). Labor productivity in construction is typically defined as the output of work divided by the total labor hours expended (e.g., earned value/labor hours) (Thomas and Završki, 1999). While numerous studies have focused on predicting overall labor productivity (El-Gohary et al., 2017; Gurmu and Ongkowijoyo, 2020; Heravi and Eslamdoost, 2015; Thomas and Završki, 1999; Zayed and Halpin, 2005), this research addresses a distinct yet related metric: the direct-work rate. Although direct-work rate can be considered an input factor influencing overall labor output (productivity) in certain industrial construction contexts (Gong et al., 2011), no studies, to the best of our knowledge, have focused specifically on probability distributions of this crucial component. A deeper understanding of the probability distribution of direct-work rates, along with understanding the impact of management interventions aimed at productivity improvement, may be associated with enhancing labor productivity as a higher direct-work rate is generally correlated with greater output for the same amount of labor hours invested.

Researchers conducted a comprehensive literature review to investigate work-sampling, AWP, WFP, the impact of AWP and WFP implementation on direct-work rates, as well as the predictability of project outcomes. Through this review, the researchers analyzed various studies and empirical evidence to understand how systemic management interventions such as AWP and WFP influence direct-work rates and their predictability in industrial construction projects. While, both past research and anecdotal evidence indicate a positive association between AWP and WFP implementation and direct-work rates, there is a lack of contemporary quantitative evidence and research investigating this relationship. Also, despite the numerous studies in the literature on work-sampling, very few have investigated the relationship between direct-work rates and systemic management interventions. This study aims to fill that gap in our understanding.

Methodology

As noted in the literature review, there is a need for a broader range of evidence to examine the benefits of AWP on performance–particularly productivity performance. Given the acceptance of work sampling as a useful and comparable proxy for productivity studies, this study aims to analyze the impact of AWP and WFP implementation on direct-work rates in industrial construction projects. The specific research questions guiding this study are:

1. Are projects implementing AWP and WFP associated with higher direct-work rates for on-site construction workers in industrial construction projects compared to those that do not implement AWP and WFP?

2. What is the relationship between the implementation of AWP and WFP and the predictability of direct-work rates for on-site construction workers in industrial construction projects?

This study draws on existing datasets from a productivity consulting firm and an EPC firm. Purposive sampling was applied by the representatives of the organizations supplying the datasets (Booth et al., 2016), with the selected projects meeting key criteria: they were industrial construction projects, represented a variety of project types, originated from multiple owner and EPC organizations, and were geographically diverse. The description of Dataset-I and II has been enhanced to better clarify the representative data. This wide scope strengthens the reliability and representativeness of the findings.

The research adopts a comparative design (Booth et al., 2016) to explore the relationship between AWP and WFP implementation and direct-work rates. It compares direct-work rates across three project groups: those implementing both AWP and WFP (AWP projects), only WFP (WFP projects), and neither (traditional projects). The null hypothesis posits that there is no significant difference in mean direct-work rates among the three groups. Descriptive and inferential statistics analyze the relationship between AWP and WFP implementation and direct-work rates. Kernel density estimation (KDE) illustrates the distribution of direct-work rates for each group, identifying patterns or differences. Welch’s ANOVA (Welch, 1947) and Brown-Forsythe Test (Brown and Forsythe, 1974) assess the impact of AWP and WFP implementation on direct-work rates, accommodating unequal variances among groups. The Games Howell post hoc test (Games and Howell, 1976) identifies specific pairwise differences. The second dataset, categorizing projects by WFP implementation presence or absence, is analyzed using independent samples t-tests.

To understand the variability and distribution of direct-work rates, Gaussian KDE (Hastie et al., 2009) is used (Equation 1). This non-parametric method estimates the probability density function, revealing how direct-work rates vary for the traditional, AWP and WFP projects. The Gaussian kernel function is defined as:

Where x is the distance from the data point to the point at which the density is being estimated.

The kernel density estimates of the probability density function f(x) at a point x is calculated as the weighted sum of kernel functions (Equation 2) centered at each data point:

Where:

•

• n is the number of data points in the dataset X.

• ℎ is the bandwidth parameter, controlling the smoothness of the estimate. Scott’s rule is utilized to calculate the bandwidth.

• K is the kernel function.

• xi are the data points.

According to Scott’s rule (Equation 3), the bandwidth ℎ is given by:

Where:

•

• n is the number of data points in the dataset.

The Anderson-Darling Test (Anderson and Darling, 1952) assesses the goodness-of-fit of direct-work rate distributions by comparing empirical data with theoretical distributions.

Statistical analyses were conducted using Python, employing SciPy and StatsModels libraries. Assumptions for each statistical technique were verified, with normality assessed using the Shapiro-Wilk test (Shapiro and Wilk, 1965) and homogeneity of variances using Levene’s test (Levene, 1960).

Data description

The datasets for this study were acquired from a productivity consulting firm and an EPC firm, both of which have implemented AWP and WFP to varying extents. The data collection was conducted using the standard work sampling procedure as detailed by Goodrum and Haas (2012). This recognized methodology involves periodic observations of workers and tasks to gather data on how time is distributed among direct-work, support-work, and delays. To build these datasets, experienced construction professionals from the productivity consulting firm and the EPC firm manually collected data by systematically observing project sites during active construction periods. These professionals recorded real-time observations of specific activities at predetermined intervals. These comprehensive datasets form the basis for subsequent analyses and insights into direct-work rates. Each firm has a documented standard procedure for data collection and trains its personnel accordingly. As the firms utilize this data for internal comparisons, they make efforts to ensure the data collection is robust and repeatable.

To supplement the work sampling data, information regarding the extent of AWP and WFP implementation was gathered through interviews with project professionals and an analysis of project documentation. In some cases, these activities were conducted in conjunction with work sampling studies; in other cases, the data were collected retrospectively by personnel within the firm at the researchers’ request. Although precise measurements of AWP and WFP implementation levels were not quantified, the projects in the dataset adhere to the standard AWP and WFP practices outlined in CII RT-272 (O’Brien et al., 2013). This largely divides into WFP, where early AWP planning efforts are not implemented, and AWP, where early planning efforts are implemented along with WFP during field execution.

The datasets were obtained from industrial construction projects where AWP and WFP were identified by project representatives as the primary intervention strategies for project-level productivity improvement efforts. For comparison, the datasets contain projects that did not utilize AWP or WFP. In these cases, most projects utilized FEP (Gibson, 2009) (as part of standard industrial sector project planning practices) but did not have any other significant productivity improvement interventions. Interviews with representatives from the organizations supplying the datasets confirmed that AWP and WFP were the main external interventions used with the aim of enhancing project performance. While some projects incorporated modularization (Choi et al., 2016) the projects in both datasets utilized extensive on-site construction, and any use of modules was generally limited to narrow aspects of the work. (One reason the projects were targeted for work-sampling data collection is the extensive use of on-site labor.) When questioned about the impact of modularization, the practitioners noted that as most work is an off-site practice, it would have a limited impact on the field installation data observed.

Dataset-I, sourced from a productivity consulting firm, comprises 61 projects executed between 2016 and 2023 across diverse geographical regions including the US Gulf Coast, Western Canada, Western Europe, and Asia. While local factors such as geographical conditions, construction methods, and legislation inevitably vary across these locations, the projects within this dataset were predominantly large-scale industrial construction projects. Crucially, they were executed by a limited number of major owner and contractor organizations that are adopting AWP and tend to implement standardized project execution philosophies, engineering, procurement, and construction methodologies across their global portfolios (Charles et al., 2022; Ngowi et al., 2005). Therefore, this study focuses on the impact of AWP and WFP as systemic management interventions within these broadly comparable execution frameworks, where AWP and WFP are associated with making a discernible difference beyond variations stemming from local factors. Data on direct-work rates, support-work rates, and delays were collected through on-site manual work sampling studies conducted by experienced professionals. Projects within this dataset are categorized into three groups based on their implementation of AWP and WFP: 1) Group A1 (21%): traditional projects (neither AWP nor WFP implemented), 2) Group B1 (46%): WFP projects, and 3) Group C1 (33%): AWP projects (implying concurrent WFP implementation as AWP encompasses WFP). Furthermore, the dataset captures project context through classifications of brown-field (40%) and green-field (60%) developments, along with the specific project stage (primarily mechanical and electrical), and regional location. The dataset offers insights into project size and complexity, with total installation cost (TIC) ranging from several hundred million to billions of USD.

Dataset-II, provided by a large EPC firm, consists of 23 industrial construction projects executed between 2015 and 2021. This dataset covers projects located in the US Gulf Coast and East Coast, Australia, Western Canada, South America, Asia, and Central Europe. Similar to Dataset-I, while local factors such as geographical conditions, construction methods, and legislation vary, these projects were predominantly large-scale industrial construction projects executed by this single major EPC organization. This organization implements standardized project execution philosophies, engineering, procurement, and construction methodologies across its global portfolio. Consequently, our study focuses on the impact of AWP and WFP as systemic management interventions within these broadly comparable execution frameworks, aiming to discern their effects beyond the variations attributable to local factors. Also similar to Dataset-I, work sampling studies were employed to collect data on direct-work rates, support-work rates, and delays. The projects are categorized into two groups: 1) Group A2 (65%): traditional projects, and 2) Group B2 (35%): WFP projects. Dataset-II offers additional project context by including the Total Installed Cost (TIC) where available, the project description (e.g., type of facility being constructed), the execution strategy (Self-Perform vs Construction Management/Sub-Contracts), and brownfield/greenfield status. This dataset also offers insights into project size and complexity, with TIC ranging from several hundred million to billions of USD. Execution strategies vary from Self-Performed execution to Construction Management with sub-contracts, indicating differing levels of project complexity and management approaches. The projects span diverse industrial sectors including petrochemical (57%), power (26%), mining (13%), and pharmaceuticals (4%).

While acknowledging the limitations in capturing all potential influencing variables, these two datasets offer a valuable opportunity to analyze the association between AWP and WFP implementation on direct-work rates across a variety of project contexts. The inclusion of project characteristics such as brownfield/greenfield status, project stage, industry sector, and regional location provides a richer context for interpreting the results and understanding the nuanced interplay of these advanced project delivery methods with project-specific factors. While detailed information on workforce composition and project complexity is not consistently available across both datasets, the geographical diversity and range of project types suggest a wide array of workforce skills and compositions, as well as varying degrees of project complexity. Unfortunately, we could not statistically compare subgroups of data; additional data collection may allow more granular investigation. However, the projects as described are representation of a large-scale industrial construction projects.

Data analysis and results

This section presents findings from analyzing Dataset-I and Dataset-II, comparing direct-work rates between projects with and without AWP and WFP implementations. Preprocessing steps ensured data quality and consistency, addressing outliers with the Interquartile Range (IQR) method to mitigate their impact. The Shapiro-Wilk test confirmed the normality of both datasets. For Dataset I, W = 0.962 (p = 0.056), and for Dataset II, W = 0.957 (p = 0.407).

Dataset-I

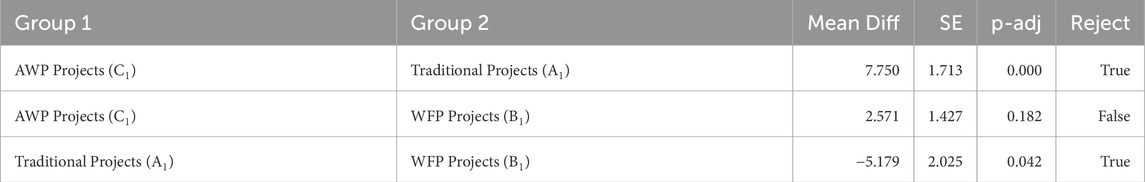

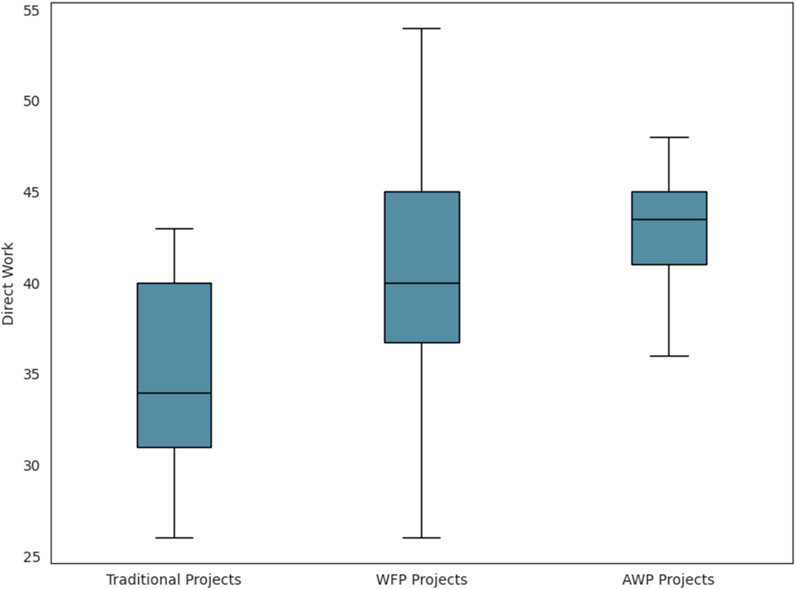

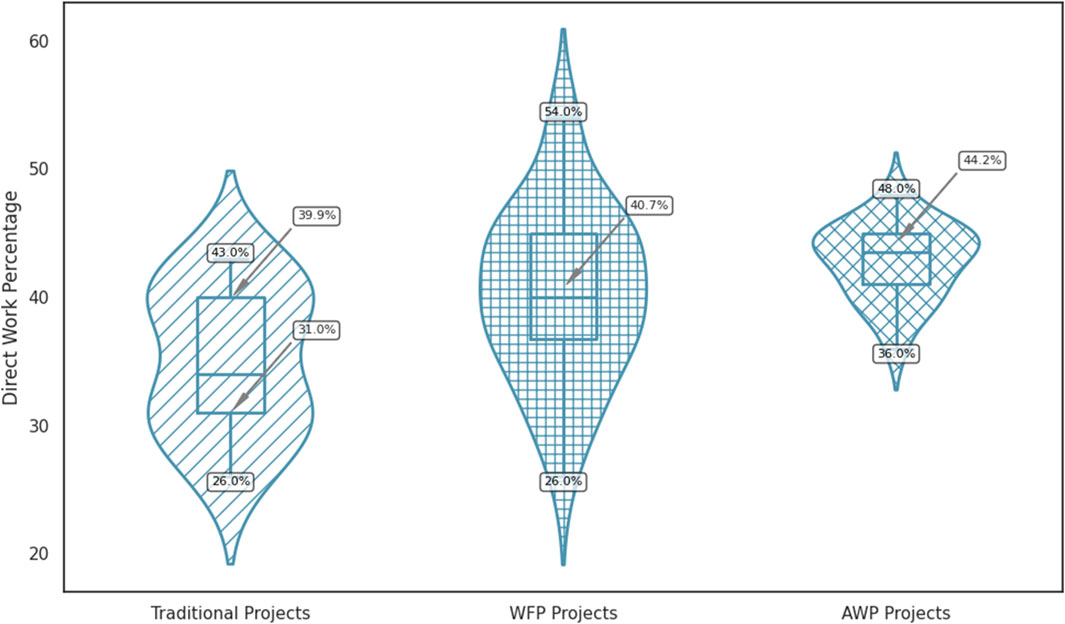

The mean direct-work rate for all projects in Dataset-I is 39.92%, with a standard deviation of 6.11%. The median values for the AWP projects, WFP projects, and traditional projects are 43.5%, 40%, and 34% respectively (Figure 2).

Figure 2. Direct-work box plots for traditional projects (A1), WFP projects (B1), and AWP projects (C1) in the first dataset (Dataset-I).

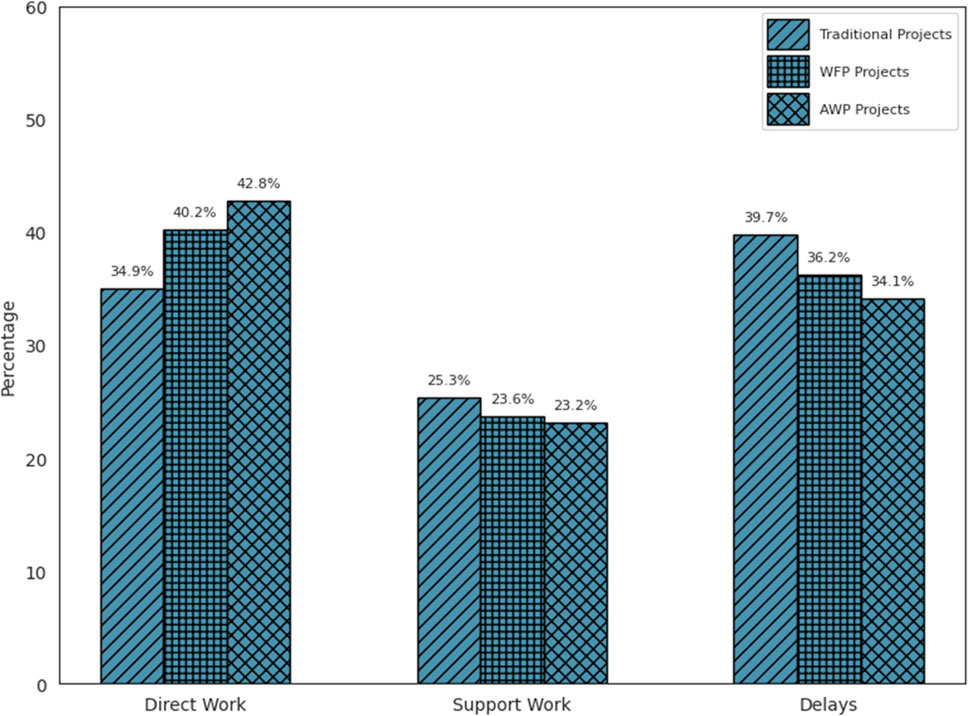

Mean direct-work rate is 42.75% for the AWP projects, 40.18% for the WFP projects, and 35% for the traditional projects. This represents an improvement of 14.8% in mean direct-work rates when only WFP is implemented and 22.14% when both AWP and WFP are implemented, compared to traditional projects. Furthermore, the improvements in direct-work rates for AWP projects is 6.4% as compared to WFP projects. The traditional projects exhibit the highest mean delay rate (39.7%). Conversely, AWP projects demonstrate the lowest mean delay rates (34.1%). For WFP projects, the mean delay rate is 36.2% (Figure 3).

Figure 3. Direct-work, support-work and delays percentages for traditional projects (A1), WFP projects (B1), and AWP projects (C1) in the first dataset (Dataset-I).

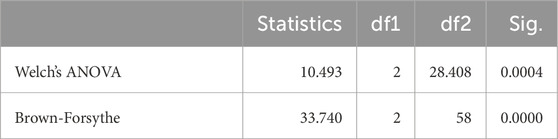

This study assessed the normality of Dataset-I and the respective groups under investigation using the Shapiro-Wilk test and examined the homogeneity of variances using Levene’s test. While Dataset-I and groups A1, B1, and C1 were found to be normally distributed, the variances among the compared groups were not equal. Given the absence of homoscedasticity, this study used Welch’s ANOVA and Brown-Forsythe test for our analysis. Welch’s ANOVA and Brown-Forsythe Test result indicate a significant difference in direct-work rates across the three categories of AWP and WFP implementations, F (2, 28.408) = 10.493, p < 0.0005, η2_p = 0.21, suggesting a moderate effect (Tables 2 and 3).

Games-Howell post hoc test (Table 3) reveals specific pairwise differences in direct-work rates between the different levels of AWP and WFP implementations. Direct-work rates of the AWP projects (C1) and WFP projects (B1) were significantly higher than those of the traditional projects (A1). Interestingly, there was no statistically significant difference in the direct-work rates of WFP projects (B1) and AWP projects (C1).

Dataset-II

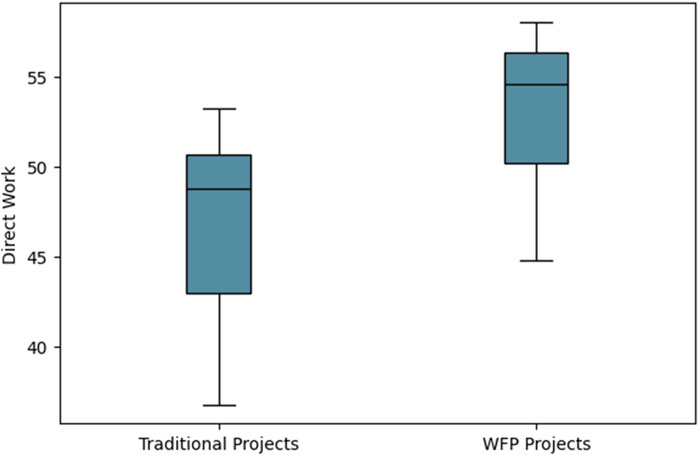

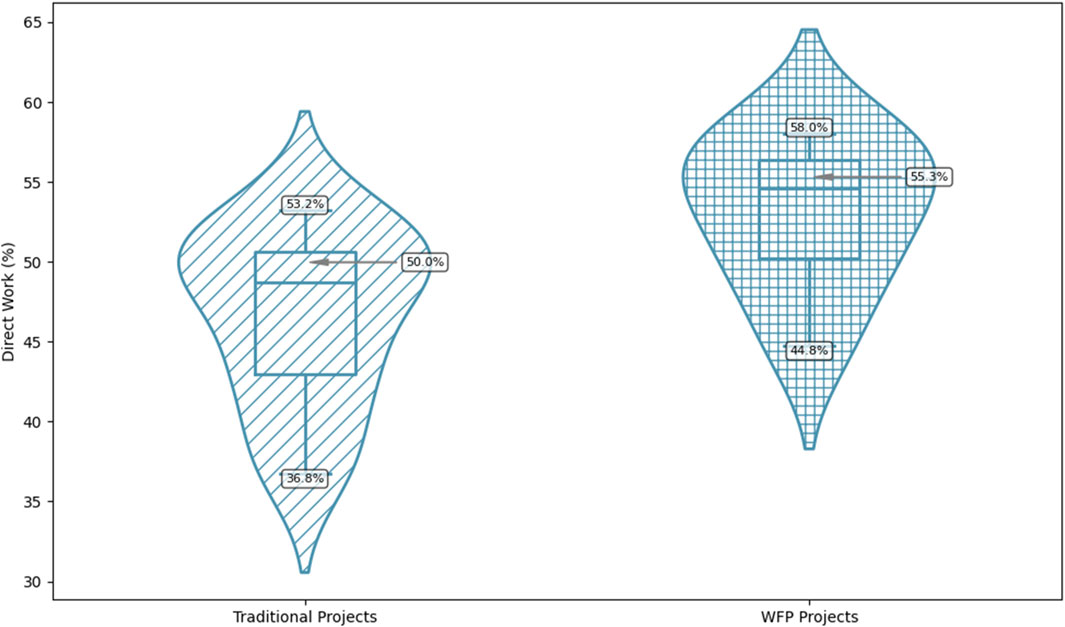

The mean direct-work rate for all projects in Dataset-II is 48.41%, with a standard deviation of 5.95%. The median values for the WFP projects and traditional projects are 54.59% and 48.74% respectively (Figure 4).

Figure 4. Direct-work box plots for traditional projects (A2) and WFP projects (B2) in the second dataset (Dataset-II).

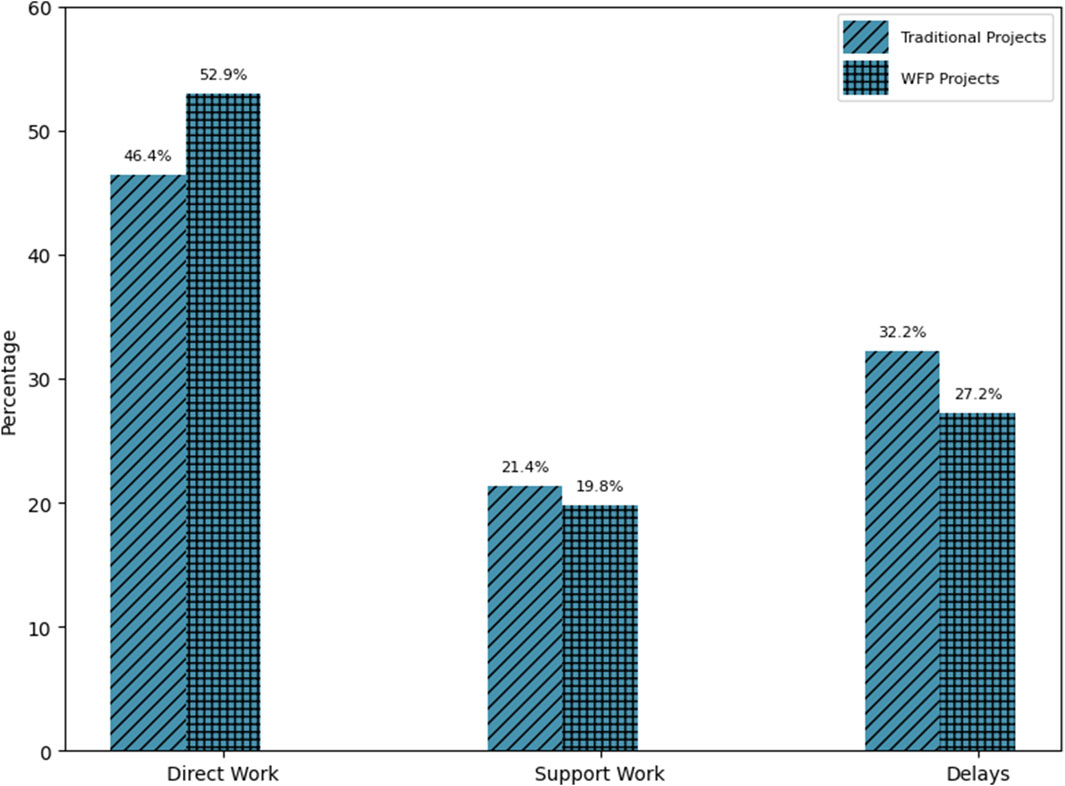

Mean direct-work rate for WFP projects is 52.93% and for traditional projects is 46.44%. This represents an improvement of 13.97% in direct-work rates when WFP is implemented, compared to traditional projects. Mean delay rates for traditional projects were 32.2% and for the WFP projects were 27.2% (Figure 5).

Figure 5. Direct-work, support-work and delays percentages for traditional projects (A2) and WFP projects (B2) in the second dataset (Dataset-II).

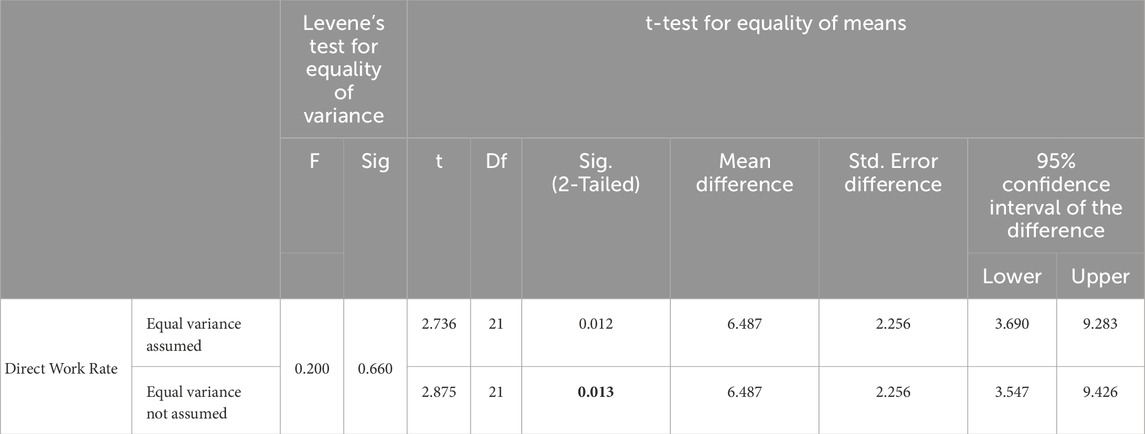

The Dataset-II was found to be normally distributed, and the variances were equal among the groups compared in the test. However, to ensure enhanced statistical robustness, results from Welch’s t-test have been included. This test does not assume equal variances, thereby providing a more comprehensive analysis. Independent samples t-tests demonstrate a significant difference in direct-work rates between WFP projects and traditional projects, t(23) = 2.88, p < 0.02, Cohen’s d = 1.24, indicating a large effect (Table 4). WFP projects exhibit significantly higher direct-work rates compared to the traditional projects.

Table 4. Independent sample T-Test for comparing mean direct work rates of groups A2 and B2 in Dataset-II.

Predictability of direct-work rates

This study analyzes the predictability of direct-work rates across different project groups—AWP projects, WFP projects, and traditional projects—by examining their probability distributions.

Using kernel density estimation (KDE), the study visualizes direct-work rates for three groups (A1, B1, C1) in Dataset-I and two groups (A2, B2) in Dataset-II. The Anderson-Darling Test results show good fit for direct-work rates in all groups, with test statistics (0.5209, 0.2263, 0.5205, 0.5896, 0.2648 for Groups A1, B1, C1, A2, and B2, respectively) exceeding the critical value at a 5% significance level. The KDE plots were generated using Python’s Seaborn library, as shown in Figures 6, 7.

Figure 6. Violin plots report the probability distribution of direct-work rates in percentage for AWP projects, WFP projects, and traditional projects for Dataset-I.

Figure 7. Violin plots report the probability distribution of the direct-work rates in percentage for WFP projects and traditional projects (Dataset-II).

In Dataset-I, the distribution (Table 5) for the first group (Group A1) of traditional projects exhibits multiple peaks (Figure 6), indicating the presence of distinct subgroups within the data. The multimodal nature suggests that there are heterogeneous factors associated with variations in direct-work rates within this group of projects. The distribution for the second group (Group-B1) of WFP projects is unimodal, resembling a normal distribution, but with greater variability in the data (SD: 6.57 and CV: 0.17). The unimodal distribution indicates a relatively homogeneous pattern of direct-work rates associated with WFP implementation on direct-work rates within this group. However, the greater dispersion suggests that there is more variability in direct-work rate outcomes compared to other groups. Strategies to reduce variability and improve consistency in direct-work rates may be beneficial for the projects in this group. The distribution for the third group (Group C1) of AWP projects is unimodal and closely resembles a normal distribution, with less variability in the data (SD: 2.88 and CV: 0.07). The unimodal distribution, with a tighter normal distribution, suggests a consistent and predictable pattern of direct-work rates associated with implementing AWP with its subset WFP on direct-work rates within the group.

The probability distribution, as depicted in Figures 6 suggests that direct-work rates exhibit greater predictability for AWP projects (Group C1) and WFP projects (Group B1). Conversely, traditional projects can experience unpredictable variations in direct-work rates. The violin plots show that the direct-work rates for AWP projects can be predicted with greater confidence and within a narrower range compared to WFP projects and traditional projects. Additionally, traditional projects exhibit a broader dispersion in distribution with multiple modes, suggesting that the likelihood of projects achieving much lower direct-work rates (around 30%) is as high as the likelihood of achieving higher direct-work rates (around 40%), thereby displaying unpredictable behavior. The wider spread of direct-work rates for WFP projects suggests a substantial portion of such projects may either have very low direct-work rates or very high ones. Furthermore, as illustrated in Figure 6, the minimum KDE for direct-work rates in AWP projects (Group C1) is notably higher compared to traditional projects (Group A1), which is consistent with our findings from using the Welch’s ANOVA test.

In Dataset-II, the distribution (Table 5) for the first group of traditional projects exhibits multiple peaks (Figure 7), indicating the presence of distinct subgroups within the data. The multimodal nature suggests that there are heterogeneous factors associated with variations in the direct-work rates within this group. This implies the existence of different subpopulations or conditions within this group of projects that lead to varied outcomes. The distribution for the second group of WFP projects is unimodal, meaning it has one dominant peak, and it exhibits a negative skew, where the tail of the distribution extends to the left. The unimodal distribution with a negative skew suggests that direct-work rates within this group are generally concentrated towards higher values but with some lower values dragging the distribution towards the left.

Based on the probability distribution analyses of Datasets I and II, it can be hypothesized that several factors are associated with the complex relationship between AWP and WFP implementation and direct-work rates. Given that WFP is only a construction-based intervention, projects in this group may not fully benefit from the broader interventions in engineering, supply chain, construction, and commissioning that AWP implementation provides.

Discussion and conclusions

This study explored the impact of Advanced Work Packaging (AWP) and WorkFace Planning (WFP) implementation on direct-work rates in industrial construction projects, addressing a gap in contemporary evidence since AWP was designated a best practice by the Construction Industry Institute (CII) in 2015. By analyzing two distinct datasets spanning 2015 to 2023—one comprising 61 projects from a productivity consultant and the other consisting of 23 projects from an EPC firm—the research highlights the significant association between AWP and WFP implementation and higher direct-work rates.

The findings consistently demonstrate that projects implementing AWP and WFP are correlated with significantly higher direct-work rates compared to those using traditional methods. In Dataset I, which categorized projects based on levels of AWP and WFP implementation, projects with both AWP and WFP implementation exhibited the highest direct-work rates (mean: 42.75%, SD: 2.88%1). These were followed by projects that only implemented WFP (mean: 40.18%, SD: 6.57%), and then by Traditional projects (mean: 35%, SD: 5.48%). This represents a 22.14% higher mean direct-work rate compared to Traditional projects for those where both AWP and WFP were implemented. Similarly, Dataset II, which focused on WFP implementation, showed that WFP projects (mean: 52.93%, SD: 4.78%) exhibited higher direct-work rates than Traditional ones (mean: 46.44%, SD: 5.40%). This represents a 13.97% higher mean direct-work rate compared to Traditional projects for those where only WFP is implemented. The findings reaffirm the positive association between AWP and WFP implementation and outcomes in industrial construction projects, both in terms of prior case study research and industry-reported data (BrandSafway, 2017; COAA, 2013; O’Brien and Ponticelli, 2015; Pappas et al., 2019; Shell, 2019). Furthermore, the global nature of the datasets strengthens the robustness and relevance of these findings, offering an updated perspective on AWP’s impact beyond the initial North American-centric studies (O’Brien and Ponticelli, 2015).

Furthermore, research finding that AWP projects are correlated with higher direct-work rates (42.75%) aligns with the case study by Slootman (Slootman, 2007) who reported significant efficiency gains, and the CII reports (O’Brien and Ponticelli, 2015) which suggested productivity improvements up to 25%. However, this study provides broader quantitative evidence from multiple projects, rather than individual case studies or baseline comparisons.

It is important to acknowledge the limitations of this study when interpreting these findings. The datasets analyzed encompass projects with varying TICs, geographical locations, industry sectors, and execution strategies. These factors represent potential confounding variables that could influence direct-work rates independently of AWP/WFP implementation. While the datasets include some information on TICs, project sectors, and execution strategies, the aggregated nature of the data and the sample sizes within specific sub-categories were often insufficient for robust statistical control of each of these potential confounding variables. For instance, while geographical diversity was a feature of the datasets, unobserved regional variations in local conditions, specific construction methods, or legislative requirements could exist and impact outcomes.

We attempted to mitigate the influence of these confounders by focusing, as detailed in the Data Description section, on projects executed primarily by a limited set of major owner or EPC organizations. These organizations are known to use broadly standardized, high-level project management practices and execution philosophies across their global operations. This consistency in overarching company practices provides a degree of inherent control and a reasonable basis for comparing the impact of AWP/WFP as systemic interventions within these frameworks. Furthermore, interviews with company representatives confirmed that while other standard best practices (such as Front-End Planning - FEP) were typically present, AWP/WFP were identified as the primary new interventions aimed at productivity improvement for the projects studied, with no other significant initiatives introduced concurrently.

However, this focus on organizational consistency does not entirely eliminate the possibility of confounding effects from the unadjusted variables. Therefore, while we observe strong associations between AWP/WFP implementation and improved direct-work rates, the influence of these unadjusted confounding variables (varying TICs, geographies, sectors, and execution strategies) cannot be entirely ruled out. The precise magnitude of AWP/WFP’s contribution relative to these factors warrants further investigation with more granular, project-level data that would allow for such statistical adjustments. Future research employing more granular, project-level data would be beneficial to statistically control for these variables and to isolate more definitively the specific outcomes attributable to AWP/WFP, potentially in more controlled comparative environments.

Beyond observations of higher average direct-work rates, understanding factors associated with enhanced predictability of these rates is also essential. To explore the impact of AWP and WFP implementation and the predictability of direct-work rates, the researchers employed Kernel Density Estimation (KDE) to analyze the probability distribution of these rates. The application of this approach to examining work sampling and direct-work rates data is novel and represents a contribution of this study. By enhancing the traditional methods for analyzing work-sampling data, this approach reveals more detailed insights than standard box-plot representations. The probability distributions derived from the KDE method indicate that projects employing AWP are correlated with higher direct-work rates but also exhibit greater predictability in these rates.

The increased predictability we observed in AWP projects echoes the findings of CII RT 272 and 319 (O’Brien et al., 2013; O’Brien and Ponticelli, 2015), and our novel KDE analysis offers a new quantitative method to demonstrate this.

An essential component of AWP—and by extension, practices like modularization—is the connection between early planning efforts and project execution. AWP has defined processes that integrate planning, design, procurement, construction, and startup, aiming to boost both productivity and predictability. Although WFP and production shielding alone have been associated with productivity benefits, AWP’s integrated approach—promoting early stakeholder collaboration and upfront planning—is associated with improved efficiency and predictability. Examination of the results from Dataset I shows that while WFP is associated with, on average, have higher productivity, the tail of poorer performance is comparable to traditional projects. Dataset-I, with observed higher direct work rates and greater predictability shown in the data progressing from Traditional to WFP and AWP projects, provides robust evidence suggesting the value of maintaining continuity in execution. This highlights potential limitations of field interventions that do not address earlier project planning (e.g., it is difficult to rectify the consequences of late engineering and procurement). A further implication is that practices such as FEP may face challenges when applied in isolation. The benefits of continuity of execution planning and control are clearly shown in the data. These findings warrant further exploration both in the industrial and other construction sectors. For example, researchers may wish to explore how collaborative contracting efforts, such as Integrated Project Delivery, sustain planning efforts through field execution.

The findings of this research offer several actionable insights for industry practitioners seeking to enhance project performance. Firstly, the consistent association of AWP (and to a lesser extent, WFP alone) with higher and more predictable direct-work rates underscores the significant value for owner and EPC organizations to invest in the development and diligent implementation of robust AWP programs. Practitioners should particularly note that the benefits, in terms of both increased direct-work rates and enhanced predictability, appear more pronounced when comprehensive AWP, which encompasses early planning integration across project phases, is implemented. This contrasts with the implementation of WFP in isolation. This suggests that focusing solely on field execution planning, while beneficial, may not yield the same level of consistency or magnitude of improvement as a holistic AWP approach that integrates front-end planning with site execution.

The methodology employed in this study highlights the utility of work sampling as a valuable diagnostic tool. Organizations can leverage work sampling to benchmark their current performance, identify specific areas for improvement in work execution, and track the impact of interventions, regardless of whether they are formally implementing AWP or WFP. Finally, the variability in direct-work rates observed even within projects implementing WFP suggests that the quality and consistency of implementation are paramount. To maximize the benefits of WFP, practitioners should place a strong emphasis on ensuring thorough constraint removal well in advance of work execution and maintaining effective short-interval planning processes. This attention to implementation fidelity is crucial for realizing the full potential of these planning methodologies.

Overall, this research makes a significant contribution to the body of knowledge on AWP and project performance in industrial construction. By providing empirical evidence of the positive association between AWP and WFP implementation and direct-work rates across two distinct datasets, this study offers compelling support for the widespread adoption of these methodologies to enhance project execution. For owner and EPC organizations seeking to enhance labor productivity and overall project performance, this study supports the call to develop robust AWP programs by evaluating their effectiveness through work sampling and other performance metrics, providing comprehensive training, and aligning organizational practices with AWP principles. Moreover, the study’s global scope demonstrates the applicability and success of AWP across diverse project environments. Future research should build on these findings by exploring additional datasets and conducting comparative studies across various disciplines and regions. Acknowledging a limitation of the current study, the classification into “Traditional,” “WFP,” and “AWP” projects, while based on information provided by the data sources, represents a simplification of what is likely a spectrum of implementation maturity and fidelity. A more granular AWP/WFP implementation index or maturity score for each project could provide deeper insights. Consequently, future research could focus on developing or applying such an index to investigate if varying levels of AWP/WFP maturity correlate with differing magnitudes of direct-work rate improvement. This would require more detailed data on the specific AWP/WFP practices implemented on each project.

Data availability statement

The data analyzed in this study is subject to the following licenses/restrictions: Some or all of the data, models, or code generated or used in this study are proprietary or confidential and may only be shared with restrictions (e.g., in anonymized form). Dataset-I is publicly available, while Dataset-II can be provided to qualified researchers subject to the approval from the sponsoring organization. Requests to access these datasets should be directed to Vishal Porwal, cG9yd2FsQHV0ZXhhcy5lZHU=.

Author contributions

VP: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Software, Visualization, Writing – original draft, Writing – review and editing. WO’B: Conceptualization, Formal Analysis, Investigation, Methodology, Project administration, Supervision, Writing – review and editing. JB: Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

1Data found to be approximately normally distributed for Datasets I and II, per Shapiro-Wilk test results presented in the Data Analysis section.

References

Aboseif, E., and Hanna, A. S. (2023). Defining the success status of construction projects based on quantitative performance metrics thresholds. J. Manag. Eng. 39 (2), 04022073. doi:10.1061/JMENEA.MEENG-5123

L. Alarcón (2007). Lean construction (transferred to digital print) (London, United Kingdom: Taylor and Francis).

Alhomadi, A. A., Dehghan, R., and Ruwanpura, J. Y. (2011). The predictability of fast-track projects. Procedia Eng. 14, 1966–1972. doi:10.1016/j.proeng.2011.07.247

Anderson, T. W., and Darling, D. A. (1952). Asymptotic theory of certain “goodness of fit” criteria based on stochastic processes. Ann. Math. Statistics 23 (2), 193–212. doi:10.1214/aoms/1177729437

Bajjou, M. S., and Chafi, A. (2020). Lean construction and simulation for performance improvement: a case study of reinforcement process. Int. J. Prod. Perform. Manag. 70 (2), 459–487. doi:10.1108/IJPPM-06-2019-0309

Ballard, H. G. (2000). The last planner system of production control. University of Birmingham. Available online at: https://etheses.bham.ac.uk/id/eprint/4789/ (Accessed on January 05, 2024).

Ballard, H. G., and Choo, J. (2011). Book review: schedule for sale: workface planning for construction projects by Geoff Ryan. Lean Constr. J., 9–18. doi:10.60164/11c3c1a8c

Ballard, H. G., and Howell, G. (1994). “Implementing lean construction: improving downstream performance,” in2nd annual conference on lean construction at catolica. Santiago, Chile: Universidad de Chile.

Ballard, H. G., and Howell, G. (1998). Shielding production: essential step in production control. J. Constr. Eng. Manag. 124 (1), 11–17. doi:10.1061/(ASCE)0733-9364(1998)124:1(11)

Ballard, H. G., and Howell, G. (2003). Lean project management. Build. Res. Inf. 31 (2), 119–133. doi:10.1080/09613210301997

Booth, W. C., Colomb, G. G., Williams, J. M., Bizup, J., and FitzGerald, W. T. (2016). The craft of research. Fourth edition. Chicago:The University of Chicago Press.

BrandSafway (2017). Innovation, technology and capabilities for access. Houston, TX: AWP Conference.

Brown, M. B., and Forsythe, A. B. (1974). Robust tests for the equality of variances. J. Am. Stat. Assoc. 69 (346), 364–367. doi:10.1080/01621459.1974.10482955

Charles, S. H., and Chang-Richards, A.(Kenneth) Tak Wing (2022). New success factors for construction projects: a systematic review of post-2004 literature. Constr. Innov. 22 (4), 891–914. doi:10.1108/CI-02-2021-0030

Choi, J. O., O’Connor, J. T., and Kim, T. W. (2016). Recipes for cost and schedule successes in industrial modular projects: qualitative comparative analysis. J. Constr. Eng. Manag. 142 (10), 04016055. doi:10.1061/(ASCE)CO.1943-7862.0001171

CII. (2019). How to double productivity (No. DCC-01; p. 120). Austin, TX: Construction Industry Institute.

CII. (2020). Integrating commissioning and startup into the AWP work process (No. RT-364; p. 64). Austin, TX: Construction Industry Institute.

CII. (2023). AWP Execution Planning Guide for Projects and Organizations (No. RT-390; p. 142). Construction Industry Institute.

COAA. (2010). WorkFace planning—lessons learned and benefits obtained. Edmonton, Canada: Construction Owners Association of Alberta (COAA).

COAA (2013). Construction work packages—a best practices guideline. Edmonton, Alberta Canada: Construction Owners Association of Alberta.

COAA (2016). Advanced work packaging/WorkFace planning A best practices guideline. Construction Owner’s Association of Alberta, 7. Available online at: https://coaa.ab.ca/wp-content/uploads/2022/09/COP-AWP-PBP-01-2016-v1-Advanced-Work-Packaging-Summary.pdf (Accessed on January 05, 2024).

COAA (2019). Major Projects Performance Assessment System—Project Performance, Engineering Productivity, Construction Productivity (p. 69). Construction Owners Association of Alberta. Available online at: https://coaa.ab.ca/wp-content/uploads/2022/09/COP-BEN-RPT-03-2019-v1-Alberta-Report-3-Major-Projects-Performance-Assessment-System.pdf (Accessed on January 05, 2024).

Dai, J., Goodrum, P. M., Maloney, W. F., and Srinivasan, C. (2009). Latent structures of the factors affecting construction labor productivity. J. Constr. Eng. Manag. 135 (5), 397–406. doi:10.1061/(ASCE)0733-9364(2009)135:5(397)

Demirkesen, S., Sadikoglu, E., and Jayamanne, E. (2022). Investigating effectiveness of time studies in lean construction projects: case of Transbay Block 8. Prod. Plan. Control 33 (13), 1283–1303. doi:10.1080/09537287.2020.1859151

Durdyev, S., and Mbachu, J. (2011). On-site labour productivity of New Zealand construction industry: key constraints and improvement measures. Constr. Econ. Build. 11 (3), 18–33. doi:10.5130/AJCEB.v11i3.2120

Egan, J. (1998). Rethinking construction. Construction Task Force to the Deputy Prime Minister. Available online at: https://constructingexcellence.org.uk/wp-content/uploads/2014/10/rethinking_construction_report.pdf (Accessed on January 05, 2024).

El-Gohary, K. M., Aziz, R. F., and Abdel-Khalek, H. A. (2017). Engineering approach using ANN to improve and predict construction labor productivity under different influences. J. Constr. Eng. Manag. 143 (8), 04017045. doi:10.1061/(ASCE)CO.1943-7862.0001340

Flyvbjerg, B., Bruzelius, N., and Rothengatter, W. (2003). Megaprojects and risk: an anatomy of ambition. New York: Cambridge University Press.

Games, P. A., and Howell, J. F. (1976). Pairwise multiple comparison procedures with unequal N’s and/or variances: a Monte Carlo study. J. Educ. Statistics 1 (2), 113–125. doi:10.3102/10769986001002113

Garcia, D., and Molloy, R. (2023). Can measurement error explain slow productivity growth in construction? Federal Reserve Board of Governors.

Gardner, G. R. (2006). Effective construction work packages. Morgantown, VA: Association for the Advancement of Cost Engineering.

Ghodrati, N., Wing Yiu, T., Wilkinson, S., and Shahbazpour, M. (2018). Role of management strategies in improving labor productivity in general construction projects in New Zealand: managerial perspective. J. Manag. Eng. 34 (6), 04018035. doi:10.1061/(ASCE)ME.1943-5479.0000641

Gibson, E. (2009). Alignment during pre-project planning: a key to project success. Austin, TX: Construction Industry Institute CII.

Gong, J., Borcherding, J. D., and Caldas, C. (2010). Assessment of direct work utilization at the workface in the U.S. Construction industry (1972–2008). 960, 969. doi:10.1061/41109(373)96

Gong, J., Borcherding, J. D., and Caldas, C. H. (2011). Effectiveness of craft time utilization in construction projects. Constr. Manag. Econ. 29 (7), 737–751. doi:10.1080/01446193.2011.595013

Goodrum, P., and Haas, C. (2012). Construction productivity research program (No. RT-252). Austin, TX: Construction Industry Institute CII.

Gouett, M. C., Haas, C. T., Goodrum, P. M., and Caldas, C. H. (2011). Activity analysis for direct-work rate improvement in construction. J. Constr. Eng. Manag. 137 (12), 1117–1124. doi:10.1061/(ASCE)CO.1943-7862.0000375

Grau, D., and Back, W. E. (2015). Predictability index: novel metric to assess cost and schedule performance. J. Constr. Eng. Manag. 141 (12), 04015043. doi:10.1061/(ASCE)CO.1943-7862.0000994

Gurmu, A. T., and Ongkowijoyo, C. S. (2020). Predicting construction labor productivity based on implementation levels of human resource management practices. J. Constr. Eng. Manag. 146 (3), 04019115. doi:10.1061/(ASCE)CO.1943-7862.0001775

Hajikazemi, S., Andersen, B., and Langlo, J. A. (2017). Analyzing electrical installation labor productivity through work sampling. Int. J. Prod. Perform. Manag. 66 (4), 539–553. doi:10.1108/IJPPM-06-2016-0122

Hanna, A. S., Russell, J. S., Gotzion, T. W., and Nordheim, E. V. (1999). Impact of change orders on labor efficiency for mechanical construction. J. Constr. Eng. Manag. 125 (3), 176–184. doi:10.1061/(ASCE)0733-9364(1999)125:3(176)

Hastie, T., Tibshirani, R., and Friedman, J. H. (2009). The elements of statistical learning: data mining, inference, and prediction. Second edition. New York: Springer.

Heravi, G., and Eslamdoost, E. (2015). Applying artificial neural networks for measuring and predicting construction-labor productivity. J. Constr. Eng. Manag. 141 (10), 04015032. doi:10.1061/(ASCE)CO.1943-7862.0001006

Hewage, K. N., and Ruwanpura, J. Y. (2006). Carpentry workers issues and efficiencies related to construction productivity in commercial construction projects in Alberta. Can. J. Civ. Eng. 33 (8), 1075–1089. doi:10.1139/l06-050

Hwang, B.-G., Krishnankutty, P., Zhu, L., Caldas, C. H., Shounak, A., and Mulva, S. (2020). Improving labour productivity in process construction maintenance and shutdown/turnaround projects. Int. J. Constr. Manag. 20 (7), 822–836. doi:10.1080/15623599.2018.1492664

Jeong, E., Jang, J., Lee, S., Ahn, S., and Kim, T. W. (2024). Quantitative analysis of the factors influencing field installation time for precast concrete building components: an empirical study. J. Manag. Eng. 40 (3), 04024010. doi:10.1061/JMENEA.MEENG-5816

Josephson, P.-E., and Björkman, L. (2013). Why do work sampling studies in construction? The case of plumbing work in Scandinavia. Eng. Constr. Archit. Manag. 20 (6), 589–603. doi:10.1108/ECAM-12-2011-0108

Kim, S., Ghimire, P., Barutha, P., and Jeong, H. D. (2024). Risk-based decision-making framework for implementation of collaboration and integration strategies. J. Manag. Eng. 40 (5), 04024041. doi:10.1061/JMENEA.MEENG-5719

Klein, B., and Meckling, W. (1958). Application of operations research to development decisions. Operations Res. 6 (3), 352–363. doi:10.1287/opre.6.3.352

Kumar, J. (2016). Analysis of oil and gas projects-with focus on SAGD projects. University of Calgary]. Available online at: https://prism.ucalgary.ca/server/api/core/bitstreams/03b770b9-8f2d-417b-b05f-f412467275a5/content (Accessed on January 01, 2024).

Kumaraswamy, M. M., and Chan, D. W. M. (1998). Contributors to construction delays. Constr. Manag. Econ. 16 (1), 17–29. doi:10.1080/014461998372556

Laufer, A., and Cohenca, D. (1990). Factors affecting construction-planning outcomes. J. Constr. Eng. Manag. 116 (1), 135–156. doi:10.1061/(ASCE)0733-9364(1990)116:1(135)

Levene, H. (1960). “Robust tests for equality of variances,” in Contributions to probability and statistics: essays in honor of harold hotelling. Stanford, CA: Stanford University Press, 278–292.

Lia, K. A., Ringerike, H., and Kalsaas, B. T. (2014). “Increase predictability in complex engineering and fabrication projects,” in 22nd annual conference of the international group for lean construction. Oslo, Norway: International Group for Lean Construction.

Lindhard, S., and Wandahl, S. (2014). Exploration of the reasons for delays in construction. Int. J. Constr. Manag. 14 (1), 36–44. doi:10.1080/15623599.2013.875267

Liou, F., and Borcherding, J. D. (1986). Work sampling can predict unit rate productivity. J. Constr. Eng. Manag. 112 (1), 90–103. doi:10.1061/(ASCE)0733-9364(1986)112:1(90)

Liu, M., and Ballard, G. (2008). “Improving labor productivity through production control,” in 16th annual conference of the international group for lean construction. Manchester, United Kingdom: International Group for Lean Construction.

Lo, J. T. Y., and Kam, C. (2022). Innovation of organizations in the construction industry: progress and performance attributes. J. Manag. Eng. 38 (6), 04022064. doi:10.1061/(ASCE)ME.1943-5479.0001093

Logcher, R. D., and Collins, W. W. (1978). Management impacts on labor productivity. J. Constr. Div. 104 (4), 447–461. doi:10.1061/JCCEAZ.0000800

McTague, B., and Jergeas, G. F. (2002). Productivity improvements on Alberta major construction projects: phase I - Back to basics. Alta. Econ. Dev.

Muralidharan, S., Krishnankutty, P., Hwang, B.-G., Caldas, C., and Mulva, S. (2018). Enhancing labour productivity in petrochemical construction and maintenance projects. 829–839. doi:10.24928/2018/0526

Neve, H. H., Wandahl, S., Lindhard, S., Teizer, J., and Lerche, J. (2020). Determining the relationship between direct work and construction labor productivity in North America: four decades of insights. J. Constr. Eng. Manag. 146 (9), 04020110. doi:10.1061/(ASCE)CO.1943-7862.0001887

Neve, H. H., Wandahl, S., Lindhard, S., Teizer, J., and Lerche, J. (2022). Learning to see value-adding and non-value-adding work time in renovation production systems. Prod. Plan. Control 33 (8), 790–802. doi:10.1080/09537287.2020.1843730

Ngowi, A. B., Pienaar, E., Talukhaba, A., and Mbachu, J. (2005). The globalisation of the construction industry—a review. Build. Environ. 40 (1), 135–141. doi:10.1016/j.buildenv.2004.05.008

Nightingale, P., and Brady, T. (2011). “Projects, paradigms and predictability,” in Advances in strategic management. Editors G. Cattani, S. Ferriani, L. Frederiksen, and F. Täube (Leeds, United Kingdom: Emerald Group Publishing Limited), 83–112. doi:10.1108/S0742-3322(2011)0000028008

O’Brien, W. J., Leite, F., Hamdi, O., and Ponticelli, S. (2013). Advanced work packaging: Design through workface execution (No. RT-272; p. 238). Construction Industry Institute CII. Available online at: https://www.construction-institute.org/advanced-work-packaging-design-through-workface-execution-version-3-1 (Accessed on January 05, 2024).

O’Brien, W. J., Leite, F., and Meeks, S. (2011). Enhanced work packaging: Design through workface execution (No. RT-272; p. 204). Construction Industry Institute CII. Available online at: https://www.construction-institute.org/enhanced-work-packaging-design-through-workface-execution (Accessed on January 05, 2024).

O’Brien, W. J., and Ponticelli, S. (2015). Transforming the industry: advanced work Packaging as a standard (best) practice (No. RT-319; Issue RT-319, p. 174). Construction Industry Institute CII. Available online at: https://www.construction-institute.org/transforming-the-industry-advanced-work-packaging-as-a-standard-best-practice (Accessed on January 05, 2024).

Oglesby, C. H., Parker, H. W., and Howell, G. A. (1989). Productivity improvement in construction. New York: McGraw-Hill.

Orth, D. L., and Jenkins, J. (2003). Mechanical and general construction productivity results. AACE Int. Trans.

Pappas, M., Giesbrecht, J., Henderson, S., Lambert, M., Moser, J., and Monteiro, A. R. (2019). What’s in it for me? Houston, TX: AWP Conference.

Ponticelli, S., O’Brien, W. J., and Leite, F. (2015). Advanced work packaging as emerging planning approach to improve project performance: case studies from the industrial construction sector. doi:10.14288/1.0076409

Russell, J. S., Jaselskis, E. J., and Lawrence, S. P. (1997). Continuous assessment of project performance. J. Constr. Eng. Manag. 123 (1), 64–71. doi:10.1061/(ASCE)0733-9364(1997)123:1(64)

Ryan, G. (2017). Even more schedule for sale: advanced work packaging, for construction projects. Authorhouse.

Salling, S., Pérez, C. T., and Wandahl, S. (2022). Breakdown work sampling. 223–234. doi:10.24928/2022/0125

Sambasivan, M., and Soon, Y. W. (2007). Causes and effects of delays in Malaysian construction industry. Int. J. Proj. Manag. 25 (5), 517–526. doi:10.1016/j.ijproman.2006.11.007

Sanvido, V. E. (1984). Designing productivity management and control systems for construction projects. Stanford, CA: Stanford University.

Shapiro, S. S., and Wilk, M. B. (1965). An analysis of variance test for normality (complete samples). Biometrika 52 (3/4), 591. doi:10.2307/2333709

Shell, (2019). Case study: AWP program at Shell deer park manufacturing site. Houston, TX: AWP conference.

Slootman, T. (2007). Planning of mega-projects influence of execution planning on project performance. Calgary, Canada: University of Calgary.

Strandberg, J., and Josephson, P.-E. (2005).“What do construction workers do? Direct observations in housing projects,” in Proceedings of 11th joint CIB interational symposium combining forces, advacing facilities management and construction through innovation. Helsinki: CIB.

Teicholz, P. (2004). Labor-productivity declines in the construction industry: causes and remedies. Available online at: https://aecbytes.com/viewpoint/2004/issue_4.html (Accessed on January 05, 2024).

Thomas, H. R. (1981). Can work sampling lower construction costs? J. Constr. Div. 107 (2), 263–278. doi:10.1061/JCCEAZ.0000961

Thomas, H. R. (1991). Labor productivity and work sampling: the bottom line. J. Constr. Eng. Manag. 117 (3), 423–444. doi:10.1061/(ASCE)0733-9364(1991)117:3(423)

Thomas, H. R., and Daily, J. (1983). Crew performance measurement via activity sampling. J. Constr. Eng. Manag. 109 (3), 309–320. doi:10.1061/(ASCE)0733-9364(1983)109:3(309)

Thomas, H. R., and Holland, M. P. (1980). Work sampling programs: comparative analysis. J. Constr. Div. 106 (4), 519–534. doi:10.1061/JCCEAZ.0000921

Thomas, H. R., and Završki, I. (1999). Construction baseline productivity: theory and practice. J. Constr. Eng. Manag. 125 (5), 295–303. doi:10.1061/(ASCE)0733-9364(1999)125:5(295)

Tsehayae, A. A., and Fayek, A. R. (2012). “A research framework for work sampling and its application in developing comparative direct and support activity proportions for different trades,” in Construction research congress 2012. West Lafayette, Indiana: ASCE Construction Research Congress, 1420–1429. doi:10.1061/9780784412329.143

Virtue, J. (2006). Workface planning COAA best practices XIV. Edmonton, Canada: Construction Owners Association of Alberta COAA.

Wandahl, S., Pérez, C. T., Salling, S., and Lerche, J. (2022). Robustness of work sampling for measuring time waste. 247–258. doi:10.24928/2022/0127

Welch, B. L. (1947). The generalization of ‘student’s’ problem when several different population varlances are involved. Biometrika 34 (1–2), 28–35. doi:10.1093/biomet/34.1-2.28

Yates, J. K. (2014). Productivity improvement for construction and engineering: implementing programs that save money and time. Am. Soc. Civ. Eng.

Keywords: advanced work packaging (AWP), workface planning (WFP), work sampling, time on tools, wrench time, direct-work rate, productivity

Citation: Porwal V, O’Brien WJ and Borcherding JD (2025) Examining the impact of Advanced Work Packaging and WorkFace planning on direct work rates of on-site construction workers: a comparative analysis. Front. Built Environ. 11:1621337. doi: 10.3389/fbuil.2025.1621337

Received: 30 April 2025; Accepted: 12 June 2025;

Published: 03 July 2025.

Edited by:

Muhammad Junaid Munir, Jinan University, ChinaReviewed by:

Savaş Bayram, Erciyes University, TürkiyePravin Minde, MIT World Peace University, India

Copyright © 2025 Porwal, O’Brien and Borcherding. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vishal Porwal, cG9yd2FsQHV0ZXhhcy5lZHU=

Vishal Porwal

Vishal Porwal William J. O’Brien

William J. O’Brien John D. Borcherding

John D. Borcherding