- 1School of Qilu Transportation, Shandong University, Jinan, China

- 2Shenzhen Research Institute of Shandong University, Shenzhen, China

Since the introduction of Deep Cement Mixing (DCM) technology, it has been widely applied to enhance the strength and stability of problematic soil. Among its advancements, the T-shaped DCM column has emerged as an innovative solution in large-scale infrastructure and urban projects. It offers several benefits, including enhanced bearing capacity while significantly reducing settlement in soft ground. This study focuses on optimizing the T-shaped DCM column while ensuring its mechanical strength remains intact through a comprehensive numerical analysis. This study considers three different column types: the conventional DCM, the T-shaped DCM, and the T-shaped column with varied strength. The analysis reveals that the lower portion of the column plays a less significant role in the overall bearing capacity, indicating potential for optimization that could effectively reduce construction costs for the T-shaped DCM column. It is essential to observe that failures in both the T-shaped and varied-strength columns primarily occur at the head and the uppermost section of the body. Notably, the varied-strength T-shaped DCM exhibits a bearing capacity that is two to three times greater than that of the conventional DCM column. Furthermore, the varied-strength column is distinguished by its notably lower construction costs compared to its counterparts. This design alternative is promising, as it maintains a higher bearing capacity and exhibits reduced settlement compared to the conventional DCM, making it a feasible choice for practical field applications.

1 Introduction

Over the past decade, there has been a notable increase in infrastructure development in regions that often present unique challenges for construction projects, which has fostered an enhanced interest in advanced ground improvement techniques. Among these, deep cement mixing (DCM) has emerged as a well-regarded method for improving the strength, stiffness, and overall stability of soft soils (Singh et al., 2023; Choudhary et al., 2025). It effectively addresses important concerns, such as excessive settlement and insufficient bearing capacity, thereby contributing to the long-term stability of structures. The growing demand for reliable foundation solutions in coastal areas, flood-prone zones, and other challenging ground conditions underscores the importance of further exploring and optimizing DCM technology. Numerous studies have been undertaken to enrich the understanding of the mechanical behavior, long-term performance, and environmental considerations associated with DCM columns (Yu et al., 2021; Singh et al., 2025).

In recent years, several researchers have conducted a series of investigations on the bearing capacity of the DCM column-improved soft soil, including the theoretical approaches (Mounir et al., 2009), and physical modelling (Dehghanbanadaki et al., 2016), to field testing (Horpibulsuk et al., 2004). Dehghanbanadaki et al. (2024) employed intelligent approaches and presented a comparative study to predict the bearing capacity of DCM column improved footing. Among these intelligent approaches, Optimized Gaussian process regression models outperformed other predictive techniques in accuracy. Wang et al. (2024) suggested that the premature failure of the column can be avoided if the pile core modulus and pile cap thickness exceed 0.3 GPa and 0.1 m, respectively. The study also optimized the column’s structural arrangement to enhance the pile’s bearing capacity. Dewi et al. (2019) presented that the addition of the 12% calcium carbide residue pozzolanic substantially enhanced the bearing capacity. This is due to the properties of silica and lime in pozzolanic materials, which can bind soil particles. Min et al. (2022) reported that the bearing capacity increases with the increase in the cement content in the case of column punching failure. The pile end influences the overall bearing capacity of the column and increases with the pile top load. Kurbatskiy et al. (2018) reported that the increase in the montmorillonite content decreases the density of the soil and thus reduces the bearing capacity of the DCM column. The study also examines the optimal cement dosage needed to achieve desired strength levels across varying montmorillonite content. Zhou et al. (2018) presented discontinuity layout optimization (DLO) to evaluate the bearing capacity factors for a group of deep mixing columns. The study reported that the bearing capacity of the DCM-improved ground is influenced by the failure mechanism and area replacement ratio of the column. The failure behavior of DCM-improved composite soil depends on the soil conditions. In soft soil or dredged slurry, failure is more likely to occur in the surrounding soil before affecting the column. However, in other cases, column failure may lead to the overall failure of the composite ground (Ni et al., 2019).

Researchers proposed different innovative approaches, including the T-shaped DCM column, which is extensively utilized for ground improvement in problematic soft soils. However, its construction involves significant costs, particularly due to the large quantity of cement required. Given these challenges, this study undertakes a comprehensive three-dimensional numerical investigation to explore cost-efficient design strategies for T-shaped DCM columns. The primary objective is to reduce construction expenses, mainly by optimizing cement usage, while ensuring that the columns maintain their mechanical strength, stability, and critical engineering performance criteria. The study examines three types of columns: the conventional DCM, the T-shaped DCM, and the T-shaped column with varying strength. It focuses on a comparative analysis of their bearing capacity, deformation characteristics, and normalized construction costs. The research aims to evaluate performance under different loading conditions to identify the most effective design strategies for ground improvement, ultimately contributing to more sustainable engineering solutions.

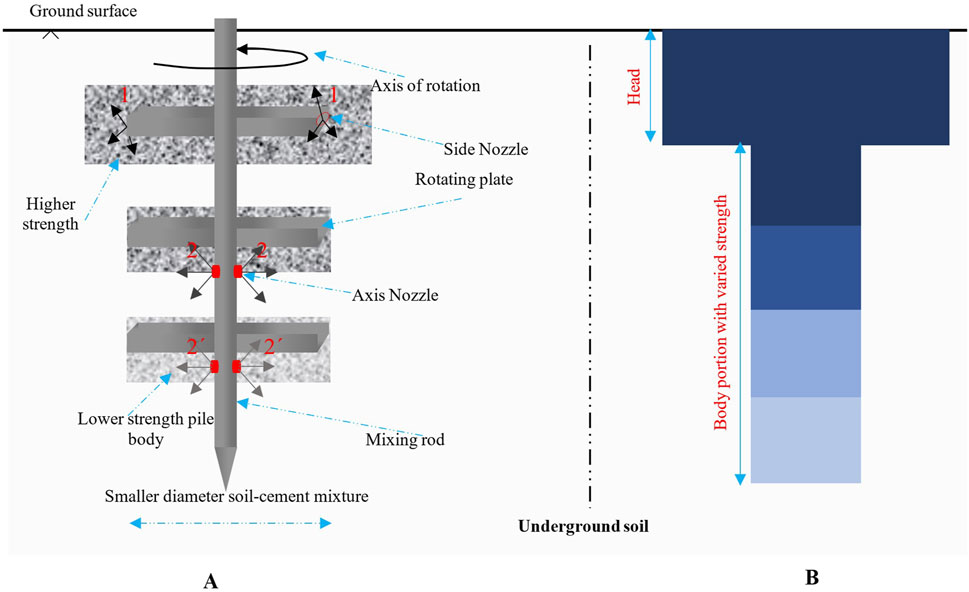

2 Techniques of field implementation

The methodologies employed in the development of the DCM column share many similarities; however, when it comes to the varied strengths of the T-shaped DCM column, different strength levels can be achieved by adjusting the cement content. The cement content for lower-strength columns is typically less than that for higher-strength ones (Chana et al., 2020). However, factors like mixing conditions, curing practices, and curing duration significantly influence the column’s strength. This study primarily emphasizes the water-cement ratio and rotational speed as key factors that significantly impacts the strength development of the varied-strength T-shaped DCM column, assuming that other factors remain constant. Varied-strength columns can be designed with lower-strength segments at the bottom and higher-strength segments at the top, enhancing structural integrity and functionality. The two pairs of nozzles positioned at the rotational axis and the lateral side of the blade are controlled by two separate pumps as illustrate in Figure 1A. When the slurry concentration is adjusted to zero, the nozzles function as if they are closed. Conversely, when the slurry is adjusted to its normal concentration, the nozzles operate as if they are open. The rotational speed facilitates the development of columns with varying strengths. At low rotational speeds, a column with a higher strength portion can be developed, while at elevated rotational speeds, a column with a lower strength portion can be developed. This method of column development has been examined in prior research studies (Wang et al., 2024). Figure 1B illustrates the final design of the column.

3 Methods

This study conducted 3D numerical simulations following the validation of static tests on a T-shaped column by Yi et al. (2017) in Suzhou City, China. The column features a length-to-diameter ratio of 1:3 in the head and 0.5:13.5 in the body. The head and body sections of the T-shaped DCM column have identical properties, with a density of 18 kN/m3, Young’s modulus of 260 MPa, a friction value of 27, and a cohesion of 160.5 kPa. The elastic modulus of the column is assigned in the range between 0.7 and 2.0 MPa (Yi et al., 2017) and is between the permissible range (Jamsawang et al., 2015). The relevant soil parameters based on depth were derived from previous studies (Li et al., 2018). The poison’s ratio is 0.3, and the interface friction between the column and surrounding soil was assigned 1.0 to align with previous researchers (Wonglert et al., 2018). The soil properties up to a depth of 0.75 m are as follows: density of 17.4 kN/m3, Young’s modulus of 2.49 MPa, friction of 11.9, and cohesion of 11.7 kPa. From the depth of 0.75–14.6 m, the corresponding soil parameters are: density of 17.25 kN/m3, Young’s modulus of 5.53 MPa, friction of 8.00, and cohesion of 19.90 kPa. As the depth increases from 14.6 to 16.20 m, the parameters change to a density of 20.70 kN/m3, Young’s modulus of 4.19 MPa, friction of 15.20, and cohesion of 19.70 kPa. For the lowermost soil layer, which spans from 16.20 to 20.0 m, the corresponding parameters are: density of 18.80 kN/m3, Young’s modulus of 5.81 MPa, friction of 30.70, and cohesion of 2.20 kPa. The study adopted the Mohr-Coulomb (MC) model as suggested by previous studies (Huang and Han, 2010; Ni et al., 2021). In the simulation, soil is assumed as a homogeneous and isotropic geomaterial. Here, 3D models were developed, extending 10 m along the X and Y-axes and reaching a depth of −20 m to ensure proper convergence and minimize boundary effects. The model was developed using medium meshing, allowing volumetric deformation only in the Z-direction. During the simulation, an open boundary condition for groundwater movement was established at the far end, while the near end was sealed. The staged construction approach is utilized, assuming that the soil-structure interfaces are either completely bonded.

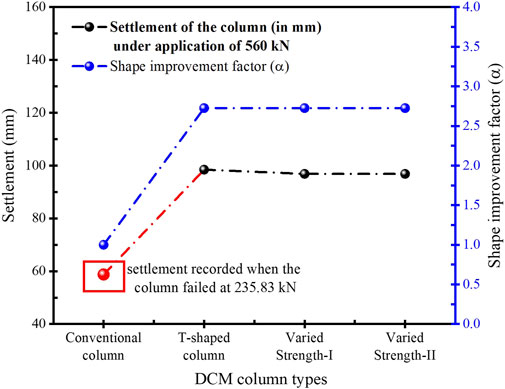

Figure 2 presents the deformation characteristics from numerical simulation and a comparative settlement of the present study and field data from the previous study. The settlement behavior of the representative column, as determined through numerical analysis with incremental static loads, shows a commendable alignment with the settlement behavior documented in field monitoring data. This finding indicates that the numerical models and the associated parameters employed in this research are both robust and reliable.

Figure 2. (A) Deformation characteristics of T-shaped DCM column and (B) validation of the present study.

4 Results

This study presents a comparative analysis of the bearing capacity, deformation characteristics, and construction costs of four DCM columns, i.e., conventional column, T-shaped column, and two different varied-strength (I and II) T-shaped DCM columns. Each column shares an equal volume of 5.007 m3 during the analysis. The body section of the varied-strength T-shaped column is assigned a different Young’s modulus for every length of 2.7 m. In varied-strength I, the first two top body sections and head section are assigned with 260 MPa, and the later sections are respectively 220, 140, and 110 MPa. Similarly, in the case of varied-strength II, the head portion and first top body sections are assigned 260 MPa, while the later sections are respectively 220, 180, and 140 MPa.

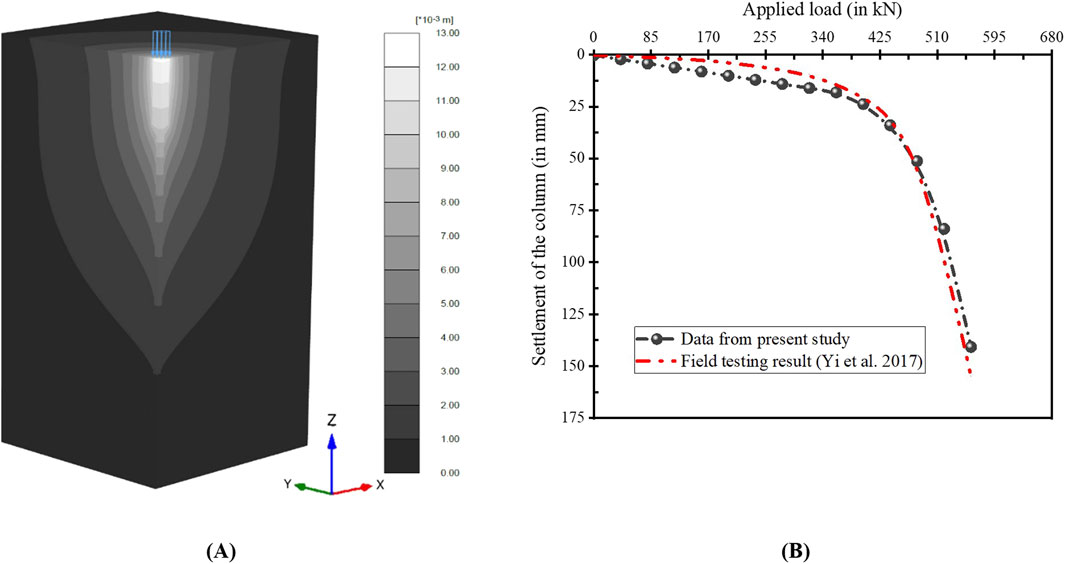

Figure 3 illustrates the variation of the shape improvement factor (Phutthananon et al., 2018) and the corresponding settlement behavior of all considered columns. It is defined as the ratio of the bearing area of the T-shaped DCM column to the conventional DCM column, over the ratio of the shaft area of the T-shaped DCM column to the conventional DCM column. It can be observed that the T-shaped DCM column and the varied-strength columns exhibit a similar ultimate settlement of approximately 98.43 mm when subjected to an external load of 560 kN. This indicates that despite differences in strength configuration in the lower body portion, both column types demonstrate comparable settlement behavior under loading conditions. Furthermore, the shape improvement factor for both columns is calculated as 2.75, signifying an equal enhancement in load-bearing capacity due to their respective geometries. However, in the case of the conventional DCM column, under the continuous increment of the externally applied load, the column undergoes progressive deformation and ultimately fails under a maximum settlement of 58.87 mm, indicating its limited ability to sustain higher loads in construction applications. The maximum external load it can withstand is 242.02 kN. When the stress on a conventional DCM column exceeds a specific threshold, its bearing capacity begins to diminish due to the onset of plastic deformation. This progression can ultimately lead to structural instability, which undermines the integrity of the entire system. Notably, failure in conventional DCM columns often occurs primarily in their uppermost portion, as illustrated in Figure 4A, where the maximum bearing capacity has been recorded at 208.00 kN. This characteristic indicates a critical limit that engineers must consider during the design and evaluation processes.

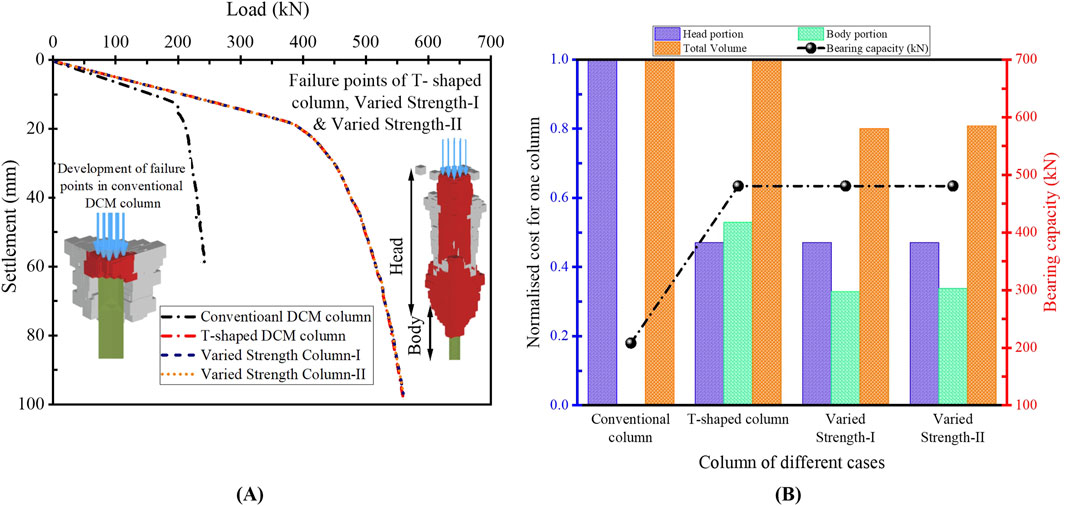

Figure 4. (A) Load displacement curve with corresponding deformation behaviour and (B) comparison of the normalized construction cost of a single column and bearing capacity of various columns.

Interestingly, the T-shaped DCM column and the varied-strength columns share an almost similar bearing capacity of 480.67. The bearing capacity is much higher than the conventional DCM column and is almost in the range of 2–3 times the conventional DCM column. Similar findings were also reported for conventional T-shaped DCM columns by previous studies (Yi et al., 2018; Phutthananon et al., 2021). Furthermore, both the T-shaped DCM column and the varied-strength column demonstrate a more complex behavior under similar loading conditions. Plastic deformation in these columns initiates at two key locations: the uppermost contact point where the external load is applied and the transition zone where the head of the column meets its body. The concentration of failure in these areas can largely be attributed to stress transfer mechanisms. As the load is applied, it shifts from a larger surface area at the head of the column to a smaller cross-sectional area in the body, resulting in increased localized stress. This transition can lead to significant stress accumulation, which may ultimately result in failure. It is important to highlight that the applied loads are primarily borne by the uppermost head and the uppermost body portion of the column. Our investigation reveals that both the varied-strength I and II columns exhibit similar load-deformation characteristics when compared to the T-shaped DCM column. This similarity in behavior persists regardless of the differences in strength observed in the lower body sections of the columns.

Additionally, this study aims to propose an innovative column design that enhances load-bearing capacity and considers construction cost-effectiveness. To illustrate this, a comparative analysis of the construction costs associated with each column type is presented in Figure 4B. The costs are calculated based on the volume of material used and the strength characteristics of each constructed column, as suggested by previous studies (Uddin et al., 1997; Chana et al., 2020). For clarity, these construction costs are normalized, which is the total cost associated with column construction, encompassing both material and construction costs, standardized based on the requirements derived from simulation data validated through corresponding field tests. The findings indicate that the normalized construction cost of the conventional DCM column is notably high, particularly when weighed against its relatively low bearing capacity. In contrast, while the T-shaped DCM column provides a higher load-bearing capacity, it also incurs considerable construction costs, making it less economically viable. The head portion and body portion of the column share 0.47 and 0.53 times the normalized cost, respectively.

However, for the varied-strength I and strength-II columns, the normalized construction cost of a single column is, respectively, 0.80 and 0.81. The proposed varied strength column reduced almost 20% of the normalized cost. The load-bearing capacities of varied-strength T-shaped DCM columns are comparable to those of the conventional DCM column. What sets these varied-strength columns apart is their significantly lower construction costs, making them a more economical option without a substantial compromise on mechanical performance, including load-bearing capability and settlement characteristics. This suggests that the varied-strength designs could be a practical solution for optimizing both structural integrity and construction expenses in engineering applications.

5 Discussion

The analysis presented in the preceding section underscores the significant influence of both the shape and strength of a column on its overall bearing capacity. Conventional DCM columns, while widely used, incur substantially higher construction costs. They are limited in their ability to sustain externally applied loads, with a maximum capacity of approximately 242.02 kN, which restricts their application in higher-stress environments. Notably, the failure mechanism in these columns tends to manifest primarily in the uppermost portion. In contrast, columns characterized by a shape factor of 2.75 or larger demonstrate a marked improvement in load-bearing efficiency. Specifically, the T-shaped DCM column offers a compelling alternative; its construction costs are comparable to those of the conventional column, yet its bearing capacity is significantly enhanced, making it a more viable option for load-intensive applications. The design of the T-shaped column allows it to effectively distribute externally applied loads primarily through the column head and the uppermost body section. This strategic design means that the lower body portion can be constructed with reduced strength, thereby controlling and minimizing overall construction costs without compromising structural integrity. Consequently, the implementation of varied-strength columns, categorized as types I and II, showcases an innovative approach that not only lowers construction expenses but also substantially boosts bearing capacity over conventional DCM columns. The advantages of the T-shaped DCM column and the varied-strength columns highlight the potential for improved structural efficiency, making them preferable choices in modern construction applications.

Future studies have the potential to explore several valuable aspects that have not yet been addressed. These include refining the model utilized in this research, conducting field experiments, and considering additional parameters such as soil-structure interaction and other necessary construction costs. Furthermore, investigating the long-term performance of T-shaped DCM columns with varying strengths is essential for assessing their future applicability in the field. It would also be beneficial for future research to focus on the exploration of more environmentally friendly materials as alternatives to the cement currently used in the lower section of the column to develop more sustainable and efficient construction practices.

6 Conclusion

Deep Cement Mixing (DCM) is a widely used and adaptable method for improving weak ground conditions. With the progress in materials and construction technologies, this technique continues to evolve. Addressing efficiency, sustainability, and long-term performance is crucial, with future research focusing on replacement of cement by environmental friendly materials. Based on the present study, the following conclusions were drawn: The T-shaped DCM columns with varied strengths demonstrate a bearing capacity comparable to that of traditional T-shaped columns. It is noteworthy that the lower portion of the T-shaped DCM column does not significantly contribute to the overall load-bearing capacity, as failures in both T-shaped and varied-strength columns typically occur at the head and uppermost body section. Implementing a varied-strength design results in a cost reduction of nearly 20% per column relative to the normalized construction cost. Both varied strength and T-shaped DCM columns offer a more effective solution for enhancing ground-bearing capacity than their conventional counterparts.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

KY: Writing – review and editing, Writing – original draft, Conceptualization, Validation, Investigation. MS: Writing – original draft, Writing – review and editing, Data curation, Formal Analysis, Investigation, Methodology, Software, Visualization. YR: Writing – review and editing. ZY: Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research is supported by Shandong Provincial Natural Science Foundation (ZR2024LZN002), Shenzhen Science and Technology Program (GJHZ20220913142605010), and Jinan Science & Technology Bureau Project (202333051).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chana, P., Jongpradist, P., Pattaramon, J., Dias, D., and Baroth, J. (2020). Parametric analysis and optimization of T-shaped and conventional deep cement mixing column-supported embankments. Comput. Geotech. 122, 103555. doi:10.1016/j.compgeo.2020.103555

Choudhary, S., Singh, M. J., Kamchoom, V., Choi, C. E., and Borana, L. (2025). Experimental and numerical modelling of time-dependent behaviour in deep cement mixing column improved montmorillonitic clay. Ocean. Eng. 332, 121451. doi:10.1016/j.oceaneng.2025.121451

Dehghanbanadaki, A., Ahmad, K., and Ali, N. (2016). Experimental investigations on ultimate bearing capacity of peat stabilized by a group of soil–cement column: a comparative study. Acta Geotech. 11, 295–307. doi:10.1007/s11440-014-0328-x

Dehghanbanadaki, A., Ahmad, K., Rashid, A. S. A., and Yunus, N. Z. M. (2024). Novel approach to predicting the ultimate bearing capacity of footings located on soft soil improved by DCM columns using Gaussian process regression models – a practical example 0–22. [Pre-print].

Dewi, R., Borgan, W., Zunita, I., Yulindasari, , and Iqbal, M. M. (2019). Effect of deep soil mixing to increasing bearing capacity on peat soil. Int. J. Geomate 17, 126–132. doi:10.21660/2019.63.24554

Horpibulsuk, S., Miura, N., Koga, H., and Nagaraj, T. S. (2004). Analysis of strength development in deep mixing: a field study. Proc. Inst. Civ. Eng. - Gr. Improv. 8, 59–68. doi:10.1680/grim.8.2.59.36367

Huang, J., and Han, J. (2010). Two-dimensional parametric study of geosynthetic-reinforced column-supported embankments by coupled hydraulic and mechanical modeling. Comput. Geotech. 37, 638–648. doi:10.1016/j.compgeo.2010.04.002

Jamsawang, P., Voottipruex, P., Jongpradist, P., and Bergado, D. T. (2015). Parameters affecting the lateral movements of compound deep cement mixing walls by numerical simulations and parametric analyses. Acta Geotech. 10, 797–812. doi:10.1007/s11440-015-0417-5

Kurbatskiy, E. N., Telyatnikova, N. A., Thang, N. N., and Tuan, N. A. (2018). “Study on using laboratory model to research for bearing capacity of soft ground improved by deep cement mixing columns due to embankment load with different montmorillonite contents,” in 2018 IEEE International Conference “Quality Management, Transport and Information Security, Information Technologies (IT&QM&IS), 121–127. doi:10.1109/ITMQIS.2018.8525125

Li, H., Liu, S., and Tong, L. (2018). Field investigation of the performance of composite foundations reinforced by DCM-bored piles under lateral loads. Constr. Build. Mater. 170, 690–697. doi:10.1016/j.conbuildmat.2018.03.112

Min, Z., Zitian, L., Yunshan, H., Pengpeng, N., and Yuanlong, W. (2022). Experimental study on the vertical bearing capacity of stiffened deep cement mixing piles. Int. J. Geomech. 22, 4022043. doi:10.1061/(ASCE)GM.1943-5622.0002355

Mounir, B., Belgacem, J., and Ali, P. (2009). Limit analysis of rigid foundations on floating columns. Int. J. Geomech. 9, 89–101. doi:10.1061/(ASCE)1532-3641(2009)9:3(89)

Ni, P., Yi, Y., and Liu, S. (2019). Bearing capacity of composite ground with soil-cement columns under earth fills: physical and numerical modeling. Soils Found. 59, 2206–2219. doi:10.1016/j.sandf.2019.12.004

Ni, P., Yi, Y., and Liu, S. (2021). Bearing capacity optimization of T-shaped soil-cement column-improved soft ground under soft fill. Soils Found. 61, 416–428. doi:10.1016/j.sandf.2021.01.001

Phutthananon, C., Jongpradist, P., Jongpradist, P., Dias, D., Jamsawang, P., and Bergado, D. T. (2021). Performance-based design optimization of embankments resting on soft soil improved with T-shaped and conventional DCM columns. Acta Geotech. 16, 3301–3326. doi:10.1007/s11440-021-01258-x

Phutthananon, C., Jongpradist, P., Yensri, P., and Jamsawang, P. (2018). Dependence of ultimate bearing capacity and failure behavior of T-shaped deep cement mixing piles on enlarged cap shape and pile strength. Comput. Geotech. 97, 27–41. doi:10.1016/j.compgeo.2017.12.013

Singh, M. J., Choudhary, S., and Borana, L. (2023). Numerical study on stress-strain characteristics of the deep cement mixing column improved soil. Smart Geotech. Smart Soc., 735–740. doi:10.1201/9781003299127-97

Singh, M. J., Yao, K., Hou, Y., Liu, S., Yao, Z., and Borana, L. (2025). Deep cement mixing columns for infrastructure development: a review of research progress, challenges, and future research directions. Geomech. Geoengin., 1–26. doi:10.1080/17486025.2025.2477474

Uddin, K., Balasubramaniam, A., and Bergado, D. T. (1997). Engineering behavior of cement-treated Bangkok soft clay. Geotech. Eng. 28, 89–119.

Wang, Y., Zhang, Y., Zhang, K., Rong, Y., Xu, R., Li, J., et al. (2024). Bearing characteristics of deep cement mixing integrated drilling, mixing and jetting piles based on numerical simulation. Sustainability 16, 9198. doi:10.3390/su16219198

Wonglert, A., Jongpradist, P., Jamsawang, P., and Larsson, S. (2018). Bearing capacity and failure behaviors of floating stiffened deep cement mixing columns under axial load. Soils Found. 58, 446–461. doi:10.1016/j.sandf.2018.02.012

Yi, Y., Liu, S., Puppala, A. J., and Xi, P. (2017). Vertical bearing capacity behaviour of single T-shaped soil–cement column in soft ground: laboratory modelling, field test, and calculation. Acta Geotech. 12, 1077–1088. doi:10.1007/s11440-017-0555-z

Yi, Y., Liu, S., and Puppala, J. A. (2018). Bearing capacity of composite foundation consisting of T-shaped soil-cement column and soft clay. Transp. Geotech. 15, 47–56. doi:10.1016/j.trgeo.2018.04.003

Yu, H., Yi, Y., Yao, K., Romagnoli, A., Tan, W. L., and Chang, A. B. P. (2021). Effect of water/cement ratio on properties of cement-stabilized Singapore soft marine clay for wet deep mixing application. Int. J. Geotech. Eng. 15, 1198–1205. doi:10.1080/19386362.2021.1890939

Keywords: deep cement mixing, T-shaped DCM, numerical simulations, bearing capacity, varied-strength column

Citation: Yao K, Singh MJ, Rong Y and Yao Z (2025) Optimized T-shaped soil-cement deep mixing column for sustainable ground improvement. Front. Built Environ. 11:1628946. doi: 10.3389/fbuil.2025.1628946

Received: 15 May 2025; Accepted: 17 June 2025;

Published: 03 July 2025.

Edited by:

Jie Han, University of Kansas, United StatesCopyright © 2025 Yao, Singh, Rong and Yao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Moirangthem Johnson Singh, bS5qb2huc29uQHNkdS5lZHUuY24=

Kai Yao

Kai Yao Moirangthem Johnson Singh

Moirangthem Johnson Singh Yu Rong1

Yu Rong1