- 1College of Energy and Transportation Engineering, Inner Mongolia Agricultural University, Hohhot, China

- 2Inner Mongolia Transportation Group Co.,Ltd., Hohhot, China

In view of the limited application of large-size absorbing materials in asphalt mixture, this study proposes to use micron-sized carbonyl iron powder as absorbing functional filler to design microwave-responsive asphalt mortar by replacing mineral powder with equal volume. A total of 6 groups of carbonyl iron powder modified asphalt mortars with different replacement ratios were prepared. Through rheological tests and indoor microwave heating tests, the rheological properties and heating healing characteristics of carbonyl iron powder modified asphalt mortars with different replacement ratios were explored. The best replacement ratio was determined by comprehensive thermal-rheological-healing properties. The double-piece healing test was used to explore the enhancement mechanism of carbonyl iron powder on the healing effect of asphalt mortar under microwave induction. The results show that carbonyl iron powder can improve the fluidity, heating characteristics and healing repair ability of modified asphalt mortar. The high temperature fluidity of carbonyl iron powder modified asphalt mortar increases with the increase of replacement ratio, but the high replacement ratio will deteriorate the low temperature performance, and the healing effect and flow state are the best at 50 °C. Through grey correlation analysis, it is concluded that 20% of equal volume replacement is the best replacement ratio, and its heating rate is 1.298 °C/s, which can meet the demand of healing temperature. The instantaneous healing rate (R0) of modified asphalt mortar increased by about 21% after equal volume replacement of 20% mineral powder by carbonyl iron powder. Carbonyl iron powder enhanced the healing effect by improving its flow performance and microwave absorption heating capacity.

1 Introduction

During long-term service, asphalt pavement is susceptible to fatigue cracking and other forms of damage due to the combined effects of traffic loading and environmental factors, and in the road project can use the self-healing properties of asphalt materials on asphalt pavement maintenance in a timely manner, thus effectively extending the fatigue life of the road surface (Zheng et al., 2020). Traditional maintenance techniques cannot repair hidden diseases such as crack damage inside the pavement and have obvious limitations. In recent years, self-healing technology provides new ideas for extending the life of pavement by enhancing the automatic healing ability of asphalt molecules such as infiltration and diffusion. However, the self-healing ability of asphalt is limited by the molecular diffusion rate and ambient temperature, which is often insufficient to repair the damage in time under actual loading (Li et al., 2022), and external induction or additives are usually required to enhance its self-healing ability.

Microwave heating technology has become the most promising means of inducing self-healing in asphalt pavements due to its penetrating, efficient and energy-saving properties. Compared with traditional heating methods, microwave heating can selectively heat polar media (Chao et al., 2022) and warm asphalt through heat conduction, prompting a reduction in asphalt viscosity and accelerating molecular diffusion, avoiding the problems of asphalt aging and carbonisation. Furthermore, microwave heating can penetrate the interior of the asphalt mixture, enabling uniform heating and minimizing temperature gradients (Bevacqua et al., 2021), while also offering the advantage of low energy consumption, thereby enhancing cost-effectiveness (Zhang et al., 2023).

In order to achieve efficient microwave thermal response of asphalt mixtures to enhance self-healing performance, scholars have tried to introduce wave-absorbing materials to modify asphalt mixtures: For instance, Gulisano et al. (2021) performed a comparative analysis of the dielectric properties of conventional slag asphalt mortar and electric arc furnace slag asphalt mortar, demonstrating that the addition of electric furnace slag yields superior microwave heating for deicing and surface layer restoration. Phan et al. (2018) replaced 30% of normal coarse aggregate with steel slag and the results showed that the healing effect of the asphalt mixture was enhanced and steel slag in hot mix asphalt mixtures contributes to sustainable development, as reported by Yang et al. (2023) carbon fiber, steel fiber, and steel wool were utilized as wave-absorbing materials, with steel fiber exhibiting the most effective enhancement of mechanical properties and self-healing capacity. Additionally, waste metal materials (Yalcin, 2021; González et al., 2018) used as additives can effectively improve the microwave absorption capacity and self-healing performance of asphalt mixtures. Moreover, Lou et al. (2021) substituted limestone filler with ferrite, thereby effectively improving the microwave heating uniformity and self-healing performance of steel slag asphalt mixtures. Although previous studies have achieved significant advancements in enhancing the wave-absorbing properties of asphalt mixtures, they predominantly focus on the use of large particle size wave-absorbing materials as aggregates, or even entirely replacing aggregates in the preparation of asphalt mixtures. However, this method still has operational feasibility problems in practical engineering, on the one hand, the grading reconstruction of large particle size wave-absorbing aggregate will increase the construction complexity, on the other hand, the high dosage of wave-absorbing aggregate significantly increase the cost of maintenance, which restricts the promotion of the project. Considering the adhesive role of asphalt mastic in asphalt mixtures, its self-healing property directly affects the fatigue life of the pavement, which can be utilised to maintain the asphalt pavement in time, thus effectively extending the fatigue life of the pavement (Zheng et al., 2020).

To address the above problems, this study proposes to use modified asphalt mastic as a self-healing functional carrier, and micron-sized carbonyl iron powder is used to replace part of the mineral powder to form a modified asphalt mastic to enhance the microwave responsiveness of asphalt mixtures. Compared with the traditional wave-absorbing materials, hydroxy iron powder has excellent magnetic permeability and dielectric loss characteristics, and the industrial production is mature, through the test of different replacement ratio of carbonyl iron powder modified asphalt mastic rheological properties, microwave heating characteristics and self-healing ability, the carbonyl iron powder on the asphalt mastic thermal-rheological-healing properties of the systematic investigation of the law of the influence of the carbonyl iron powder on the thermal-rheological-healing properties of asphalt mastic. The grey correlation degree analysis was used to comprehensively obtain the optimal replacement ratio, and based on the optimal replacement ratio, the enhancement mechanism of the healing effect of carbonyl iron powder modified asphalt mastic was analysed. This study aims to provide a solution for the microwave maintenance technology of asphalt pavement and to promote the transformation of wave-absorbing functional pavement from laboratory to engineering practice.

2 Materials and experimental methods

2.1 Raw materials

2.1.1 Asphalt

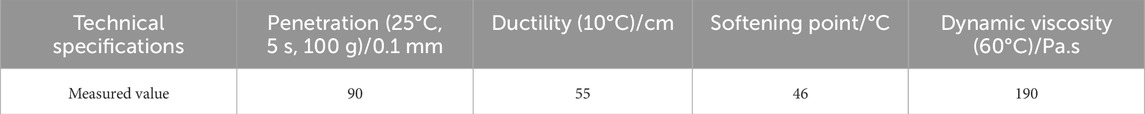

This study utilizes 90#A base asphalt. In accordance with JTG E20-2011 “Test Specifications for Asphalt and Asphalt Mixtures for Highway Engineering,” the fundamental performance indices of the asphalt were measured. The basic performance parameters are listed in Table 1.

2.1.2 Filler

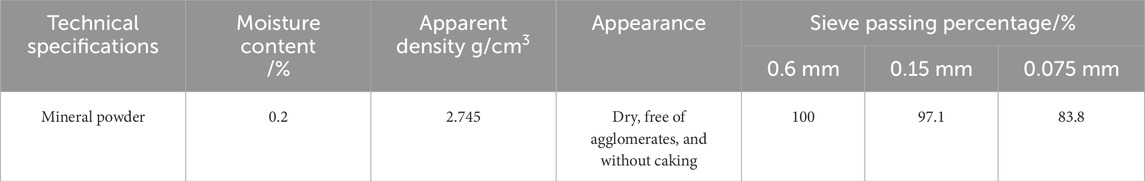

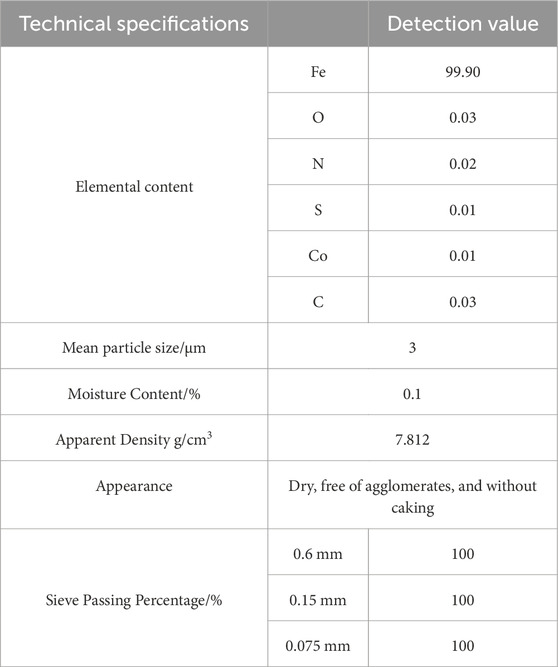

Limestone mineral filler was selected, produced by Ordos Lutai New Material Technology Development Co., Ltd., and carbonyl iron powder sourced from Yingtai Metal Materials Co., Ltd., Nangong City, Hebei Province, was employed as the wave-absorbing functional material. The basic performance test indexes are shown in Tables 2, 3, respectively.

In road engineering, when applying wave-absorbing functional fillers for rapid maintenance of highway asphalt pavement, the fillers must exhibit stable properties, high temperature resistance, and high thermal conductivity. Carbonyl iron powder (CIP) is a high-purity ultrafine iron powder synthesized via the carbonyl process. The key procedure entails the thermal decomposition of iron pentacarbonyl (Fe(CO)5), resulting in the formation of nanoscale or microscale spherical iron particles (Kong, 2023). As shown in Figure 1, it exhibits excellent microwave absorption capability, efficiently converting microwave energy into thermal energy. This makes it suitable for the functional modification of asphalt pavement and provides the following advantages when applied to microwave-induced rapid maintenance of asphalt pavement:

(1) It possesses a high complex dielectric constant and superior thermal conductivity. During microwave-induced crack repair, carbonyl iron powder absorbs energy from external microwave radiation and rapidly heats up, softening and mobilizing the surrounding asphalt to fill cracks, thereby enhancing the healing efficiency;

(2) It demonstrates good thermal stability and high-temperature performance. The stable material properties enhance its practical application value;

(3) Carbonyl iron powder particles are spherical with excellent dispersibility, enabling uniform distribution within the asphalt and thereby enhancing the overall healing uniformity.

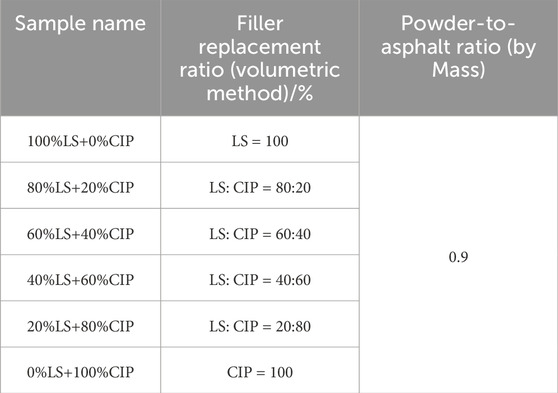

2.2 Preparation method of asphalt mastic

Asphalt mastic functions as an interfacial adhesive within the asphalt mixture system, bonding coarse and fine aggregates to enhance mixture stability and significantly affecting the overall pavement performance of the mixture. Research indicates that the powder-to-asphalt ratio for continuous dense-graded mixtures ranges from 0.6 to 1.4, with the optimal range for self-healing properties being 0.6 to 0.9 (Xu, 2021). Accordingly, this study selected a powder-to-asphalt ratio of 0.9 to prepare asphalt mastic specimens. Given the differing densities of mineral powder and carbonyl iron powder, an equal volume replacement method was utilized, substituting mineral powder with carbonyl iron powder at 20%, 40%, 60%, 80%, and 100% by volume. The required mass of carbonyl iron powder was calculated using Equation 1. Six groups of samples were prepared, as detailed in Table 4.

In the equation:

The specific preparation procedure is as follows:

(1) Place the weighed filler and asphalt into an oven for heating; dry the filler at 140°C for 2 h, and keep the asphalt at 130°C for standby;

(2) Maintain the oil bath temperature at 150°C, and gradually add the preheated filler into the asphalt in small portions while manually stirring to achieve uniform mixing;

(3) Employ a high-speed mixer to combine the asphalt and filler. Set the mixer speed to 500 r/min and stir for 5 min. Subsequently, increase the speed to 1,300 r/min and continue stirring for 30 min to ensure thorough integration of the filler with the asphalt. Finally, reduce the speed back to 500 r/min and stir for an additional 5 min to remove bubbles generated during high-speed mixing, thereby completing the preparation of the asphalt mastic.

2.3 Experimental methods

2.3.1 Rheological testing

A DHR-2 dynamic shear rheometer (DSR) manufactured by TA Instruments, USA, was employed to conduct temperature and frequency scans on the asphalt mastic. The DSR fixture had a diameter of 25 mm and a gap of 1 mm. Temperature scanning tests were performed from 46°C to 82°C at 6°C intervals, with a strain of 10% and a loading frequency of 10 rad/s. Frequency scanning was conducted over a range of 0.01 Hz–10 Hz, at temperatures from 30°C to 80°C with 10°C intervals, and a strain of 0.1%.

The low-temperature performance of the asphalt was evaluated using a TE-BBR bending beam rheometer. Asphalt mastic beam specimens were initially cooled at room temperature for 1 h, then conditioned in a cooling chamber at (−5 ± 5)°C for 5–10 min to prevent deformation during demolding. Creep tests were subsequently performed at −6°C, −12°C, and −18°C.

2.3.2 Microwave heating test

Initially, the shear-prepared asphalt mastic was placed into paper dishes with a bottom diameter of 5 cm and a height of 2 cm (filled to two-thirds of the dish height) and cooled to room temperature for subsequent testing, ensuring that each specimen was tested with an identical volume. The temperature measurement was conducted using a FOTRIC-613C infrared thermal imager, featuring an infrared resolution of 160 × 120 pixels (19,200 pixels), a temperature measurement range from −20°C to 350°C, and an emissivity set at 1.00. Selected microwave power of 800W, microwave frequency 2.45 GHz, with heating durations ranging from 0 to 60 s. During this process, thermal images of the samples were rapidly captured every 10 s using the infrared thermal imager. Three parallel specimens were used for each set of tests and the final results were averaged.

2.3.3 Fatigue-healing-fatigue test

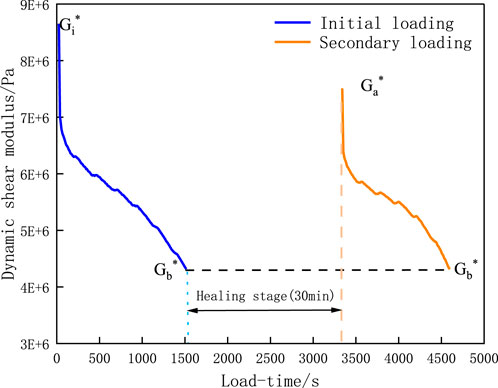

The fatigue-healing-fatigue test of asphalt is conducted under a strain-controlled mode. Based on the typical temperature range for cracking in actual pavements (10°C–30°C), the fatigue temperature is set at 25°C, with a loading frequency of 10 Hz and a strain of 4%. Research indicates that asphalt begins to exhibit healing behavior at 30°C, with the healing rate decreasing near the softening point (Zhang, 2019). To encompass the entire temperature range, the healing temperature is set between 30°C and 70°C, with intervals of 10°C for each healing temperature during the study. Five healing temperatures are employed in the tests, each with a healing duration of 30 min. Given the fatigue temperature of 25°C, fixtures with an 8 mm diameter and a 2 mm spacing were selected. Fatigue healing tests on the asphalt mastic were conducted under preset parameters, as illustrated in Figure 2. The testing procedure comprised two loading stages: the initial loading caused the dynamic shear modulus G* of the asphalt mastic to decrease continuously to a predetermined damage level (G b* = 50% of G i*), followed by a 30-min self-healing recovery period at the specified temperature. Thereafter, a secondary loading was applied until G* again decreased to 50% of G i*, marking the end of the test. Each test group consisted of three parallel specimens, and the final results represent the average values.

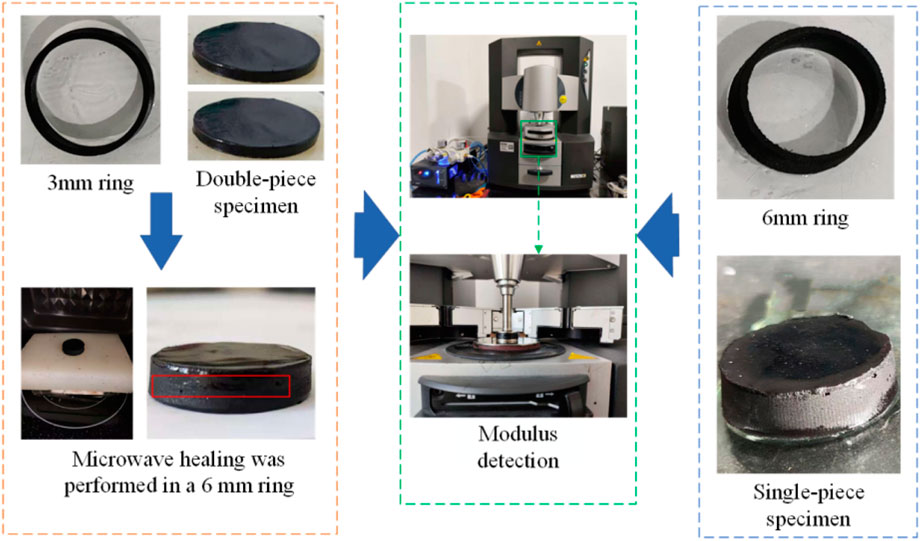

2.3.4 Double-fracture healing test

The double-fracture healing test employs a specially designed test ring to prepare specimens, as illustrated in Figure 3. Two circular asphalt mastic specimens, each 3 mm thick, are cast and overlapped to simulate the crack interface. These specimens are placed within a 6 mm thick test ring and subjected to microwave heating to induce healing. Upon reaching a specified healing temperature, the crack interface progressively heals due to molecular diffusion across the interface. This approach not only incorporates microwave heating but also facilitates the evaluation of healing performance. As indicated by the red box in the figure, it is evident that after microwave heating-induced healing of the double-piece specimens, varying degrees of cracking occur at the interface between the two pieces. A dynamic shear rheometer operating in time sweep mode was utilized to measure the interface strength of the healed double-piece specimens and to calculate the strength as a percentage of that of the single-piece specimens at the same time point; this metric served as an evaluation criterion for the healing performance.

Specimens were categorized into two types: double-piece specimens (3 mm + 3 mm with prefabricated cracks) and single-piece specimens (6 mm), both with a diameter of 25 mm. The double-piece specimens simulate the actual crack repair process via interfacial healing. The test parameters were established as follows: fixture diameter of 25 mm, gap of 5 mm, test temperature of 25°C, angular frequency of 10 rad/s, and normal force of 0.4 N. The testing procedure comprised two stages: initially, microwave-induced healing treatment was applied to the double-layer specimen group for durations ranging from 10 s to 60 s at 10 s intervals. After cooling to room temperature, the specimens were placed on the loading platform and maintained at 25°C for 10 min, followed by application of a 0.001% microstrain (Mazzoni et al., 2017) (to prevent secondary damage) during a 1-h time sweep test, with real-time monitoring of dynamic shear modulus changes. The single-layer specimen group underwent an identical testing procedure except for the omission of the microwave-induced healing step. Temperature was maintained constant throughout the entire testing process to eliminate thermal effects on the results. Each test group included three parallel specimens, and the final data represent the average values.

3 Results and discussion

3.1 Rheological properties of asphalt and asphalt mastic

Asphalt mixture is a composite material with self-healing potential, capable of autonomously healing microcracks after a certain rest period under specific conditions, thereby gradually restoring the performance of the asphalt mixture. This phenomenon is attributed to thermodynamic processes such as penetration, diffusion, and mutual dissolution within the asphalt mastic (Liu et al., 2023). Therefore, the self-healing characteristics of the mastic directly determine the healing capacity of the asphalt mixture (Xu, 2021). According to the asphalt self-healing mechanism, the flow properties of asphalt play a critical role in the damage healing process. In this section, the rheological properties at high and low temperatures of asphalt mastic containing Carbonyl Iron Powder filler were evaluated using DSR and BBR tests, and the flow property parameters were subsequently modeled.

3.1.1 Complex viscosity and flow behavior index

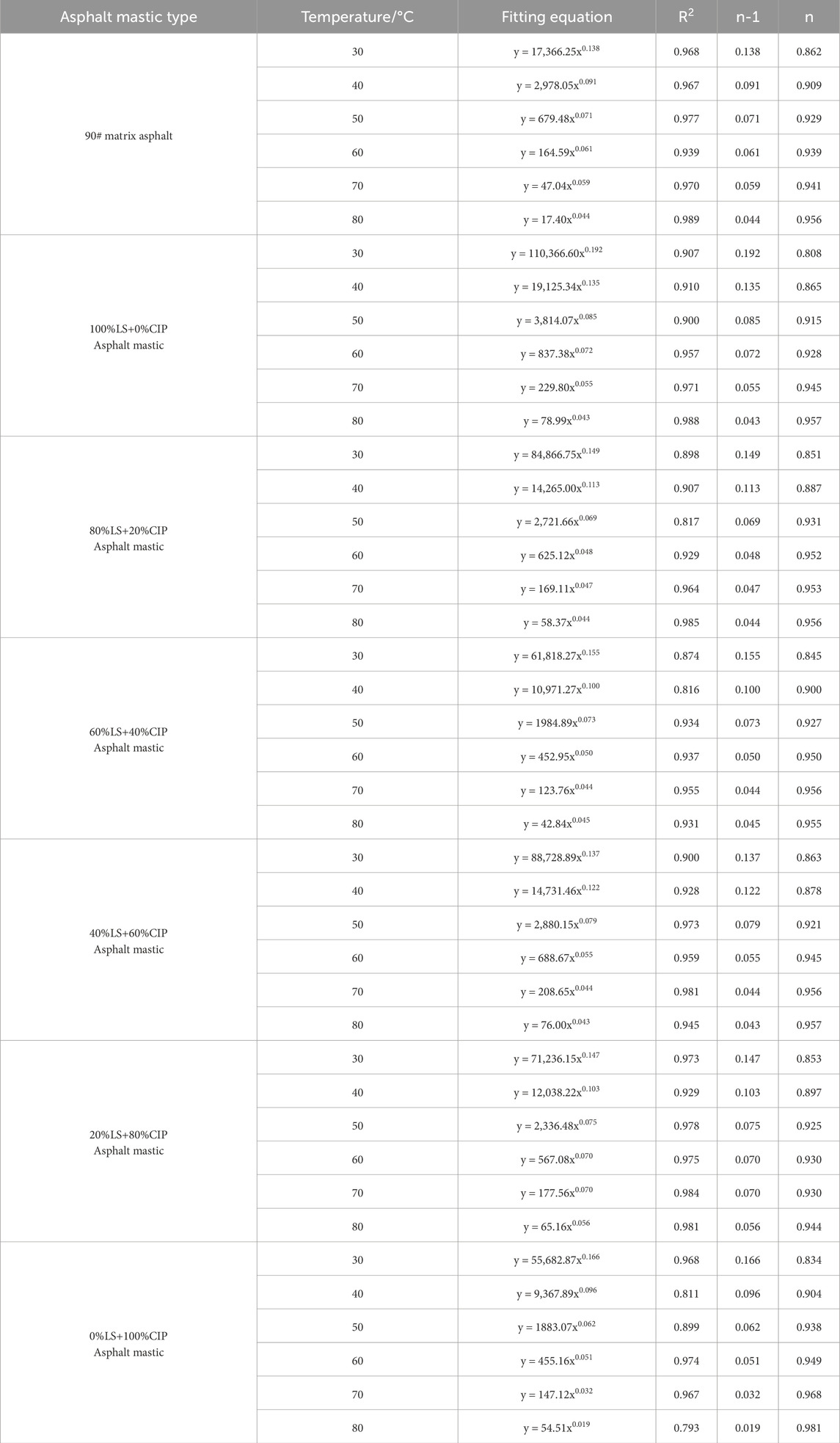

Asphalt, as a representative viscoelastic material, exhibits self-healing performance that is markedly affected by temperature conditions. As temperature increases, the rheological characteristics of matrix asphalt transition from pseudoplastic behavior to Newtonian fluid behavior; at elevated temperatures, asphalt can be approximated as a Newtonian fluid. The variation curves were fitted using Equation 2 to determine the viscoelastic properties of different asphalt mastics at various temperatures.

In the equation: η*—complex viscosity (Pa·s); ω—angular frequency (Hz); m—fitting parameter; n—dimensionless parameter (flow behavior index).

According to rheological theory, when n = 1, asphalt exhibits Newtonian fluid behavior; when n < 1, it demonstrates pseudoplastic fluid characteristics. In the range of 0.9 ≤ n < 1, it is classified as a near-Newtonian fluid. At n = 0.9, asphalt behaves as a spontaneously flowing near-Newtonian fluid with exceptionally high fluidity. Within the corresponding temperature range, this condition significantly facilitates the wetting and diffusion of asphalt molecules, thereby enhancing the self-healing performance (Zhiyue, 2023).

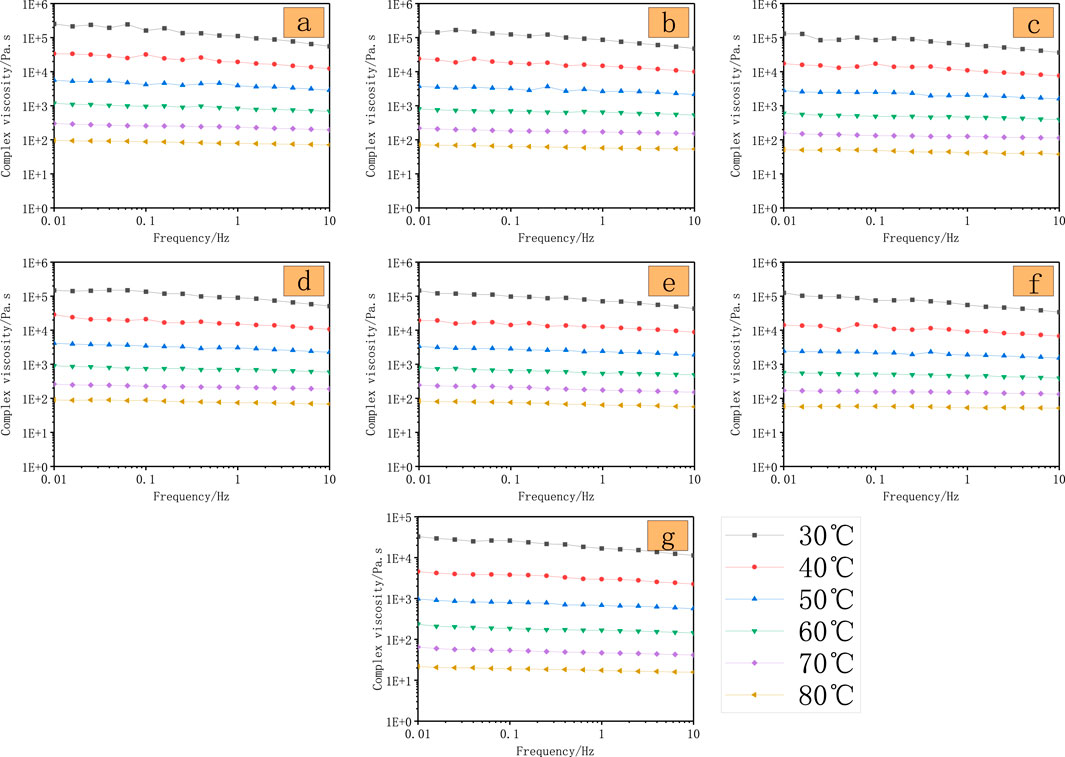

From Figure 4g, it can be seen that both the increase in temperature and frequency decrease the complex viscosity of asphalt, indicating that the resistance to deformation becomes poorer and the flow behaviour becomes stronger, and that the increase in temperature facilitates the flow of asphalt, thus facilitating asphalt healing. Comparison of the seven sets (a-g) of data in the figure shows that the complex viscosity of matrix asphalt is 33 KPa-s under the test conditions of 0.01 Hz and 30°C, whereas the asphalt mastic is all higher than 120 kPa-s, which indicates that the addition of filler makes the asphalt thickened and hardened, which is unfavourable to the flow effect; As can be seen from Figures 4a–f, the complex viscosity values under the same frequency-temperature conditions show a decreasing trend with the increase of the replacement ratio of carbonyl iron powder, and the value under the test conditions of 0.01 Hz and 30°C decreases from 254 KPa-s for the mineral powder mastic to 125 KPa-s for the modified asphalt mastic with 100% replacement ratio of carbonyl iron powder, which indicates that the carbonyl iron powder makes the asphalt mastic’s flow behaviour stronger, and the carbonyl iron powder wave absorber is beneficial to asphalt mastic flow and healing. Using Equation 2, parameter fitting was performed for mastics with varying replacement ratios. The fitting results presented in Table 5 provide the flow behavior index n of the asphalt mastic at different temperatures, illustrating the evolution of rheological characteristics with temperature changes.

Figure 4. Complex viscosity-frequency curves of 90# asphalt and asphalt mastic: (a) 100% LS + 0% CIP; (b) 80% LS + 20% CIP; (c) 60% LS + 40% CIP; (d) 40% LS + 60% CIP; (e) 20% LS + 80% CIP; (f) 0% LS + 100% CIP; (g) matrix asphalt.

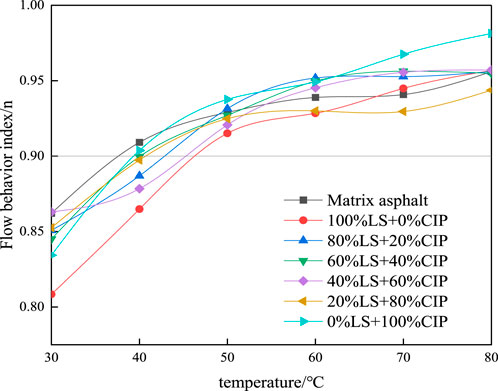

Figure 5 illustrates the influence of varying carbonyl iron powder replacement ratios on the flow behavior index n of asphalt mastic. Overall, the flow behavior index increases with temperature. Across different temperature intervals, the flow behavior index n of asphalt mastic demonstrates distinct trends: in the low-temperature range (30°C < T < 50°C), the n value of matrix asphalt exceeds that of asphalt mastic. This is attributed to the addition of filler, which reduces asphalt fluidity, increases viscosity, and diminishes flow properties. Nevertheless, the n values of carbonyl iron powder-modified asphalt mastic at various replacement ratios are all higher than those of limestone mastic, indicating that carbonyl iron powder improves the flow properties of asphalt mastic. Within this temperature range, the flow behavior index of the asphalt mastic increases to above 0.9, indicating that the asphalt transitions into a near-Newtonian fluid and crack healing initiates.

In the high-temperature range (50°C ≤ T ≤ 80°C), the rate of increase of the flow behavior index (n) markedly slows and gradually stabilizes. This phenomenon occurs because, at elevated temperatures, the variation in complex viscosity of the asphalt mastic diminishes, causing its flow characteristics to progressively approximate those of a Newtonian fluid. At T = 80°C, the flow behavior index of the asphalt mastic closely matches that of the matrix asphalt.

In summary, the addition of filler reduces the flow behavior of the matrix asphalt, while the incorporation of carbonyl iron powder enhances the flow properties of the asphalt mastic.

3.1.2 Rutting factor

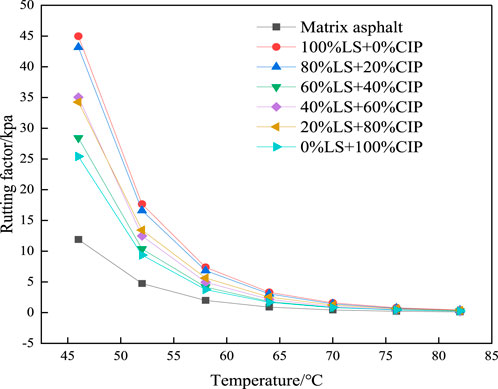

The rutting factor G*/sinδ is a critical parameter of asphalt rheological properties, based on capillary mechanical theory (), where capillary flow within asphalt microcracks facilitates crack closure, playing a vital role in assessing the self-healing performance of asphalt mastic. Figure 6 presents the G*/sinδ-temperature curves for asphalt and mastic.

As shown in Figure 6, the rutting factor decreases progressively with increasing temperature, with the rate of decline stabilizing once the temperature reaches 70°C. This phenomenon occurs because, as temperature increases, asphalt molecules become more active, causing the asphalt to soften from a rigid state and eventually transition into a fluid state, as demonstrated by the continuous reduction in the Rutting Factor. In the temperature range of 70°C–82°C, the Rutting Factor of both asphalt and asphalt mastic remains essentially unchanged, due to the asphalt exhibiting a viscous behavior within this interval and the filler exerting negligible influence on the asphalt’s viscosity. These results indicate that the flow properties of the asphalt mastic are enhanced while its resistance to high-temperature deformation diminishes; overall, the temperature increase facilitates the self-healing of the asphalt mastic.

At the same temperature level, the incorporation of filler significantly increases the rutting factor of asphalt, reflecting an enhancement in the high-temperature performance of asphalt and a reduction in its flow properties, which adversely affects the healing performance of asphalt. Based on varying rutting factor levels, asphalt mastic can be categorized into four groups: the asphalt mastic with a 20% carbonyl iron powder replacement ratio closely resembles limestone mineral powder mastic and demonstrates the optimal deformation resistance capacity; The mastics with 60% and 80% replacement ratios rank next, exhibiting the second highest deformation resistance capacity; The mastics with 40% and 100% replacement ratios are at the same level, ranking second lowest in deformation resistance capacity; the matrix asphalt demonstrates the poorest deformation resistance capacity.

This phenomenon indicates that the addition of Carbonyl Iron Powder filler enhances the fluidity of the asphalt mastic, due to differences in surface morphology and roughness between the two filler types, which prevent the full formation of an interlocking interface structure (Zhao et al., 2024), thereby weakening the interaction with asphalt and improving the flow properties of the asphalt mastic. This facilitates the acceleration of the self-healing process in the asphalt mastic. Concurrently, it suggests that limestone mineral powder mastic requires a higher healing temperature to achieve the same healing effect as Carbonyl Iron Powder-modified asphalt mastic. However, in practical applications, the replacement ratio should not be excessively high to avoid compromising high-temperature performance. Concerning high-temperature performance, a 20% replacement ratio is the most suitable choice.

3.1.3 Low-temperature rheological behavior

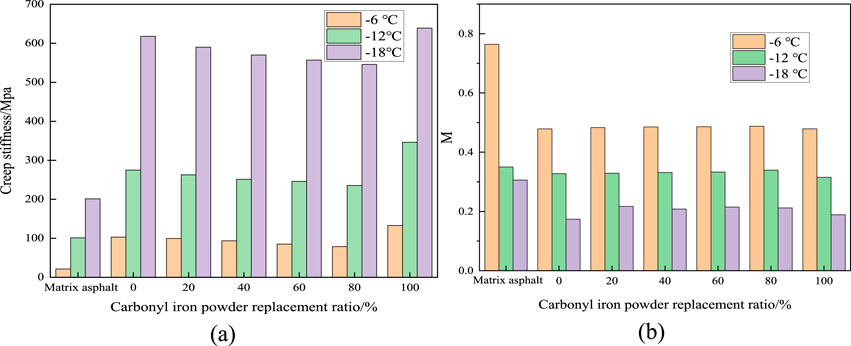

The asphalt low-temperature bending beam rheological test (BBR) is a widely used method for evaluating the low-temperature rheological properties of asphalt materials. Typically, the creep stiffness modulus S and creep rate m are utilized to assess the low-temperature rheological behavior of asphalt. The creep stiffness modulus S reflects the flexibility of asphalt materials under low-temperature conditions. The S-value is inversely proportional to the material’s flexibility; The creep rate m characterizes the change in stiffness over time and represents the stress relaxation capability of asphalt materials at low temperatures. The m-value is directly proportional to the asphalt’s stress relaxation capacity. The BBR test results for various modified asphalts are presented in Figure 7.

Figure 7. Low-Temperature Creep Behavior of Asphalt and Asphalt Mastic (a) creep stiffness modulus S (b) creep rate m.

As illustrated in Figure 7, the incorporation of filler increases the stiffness modulus of the matrix asphalt while reducing the creep rate. The low-temperature rheological behavior of asphalt mastic at three temperature levels demonstrates a clear trend: with increasing Carbonyl Iron Powder content, the low-temperature performance initially improves and subsequently declines, exhibiting a single-peak pattern. The peak occurs at an 80% replacement ratio, corresponding to optimal low-temperature rheological properties. Beyond this, at a 100% replacement ratio, the rheological performance markedly deteriorates. This trend is observed consistently in both the creep stiffness modulus and creep rate metrics.

Furthermore, the lower the temperature, the more pronounced the trend of low-temperature rheological behavior initially increasing and then decreasing, with the most significant effect observed at −18°C. As the replacement ratio increases, the low-temperature rheological behavior is markedly improved, owing to the reduction of free asphalt content in the mastic caused by the increased filler content (Ji et al., 2024). Carbonyl iron powder absorbs fewer light asphalt components on its surface compared to limestone mineral powder. However, with increasing replacement ratio, due to the equal volume replacement method, the amount of carbonyl iron powder increases exponentially, leading to an excessive proportion of carbonyl iron powder. A turning point occurs at an 80% replacement ratio, beyond which the low-temperature rheological behavior of the asphalt mastic begins to deteriorate. Therefore, when using carbonyl iron powder as filler, its dosage should be controlled to avoid negatively impacting low-temperature rheological behavior.

3.2 Microwave heating characteristics of asphalt and asphalt mastic

3.2.1 Heating uniformity

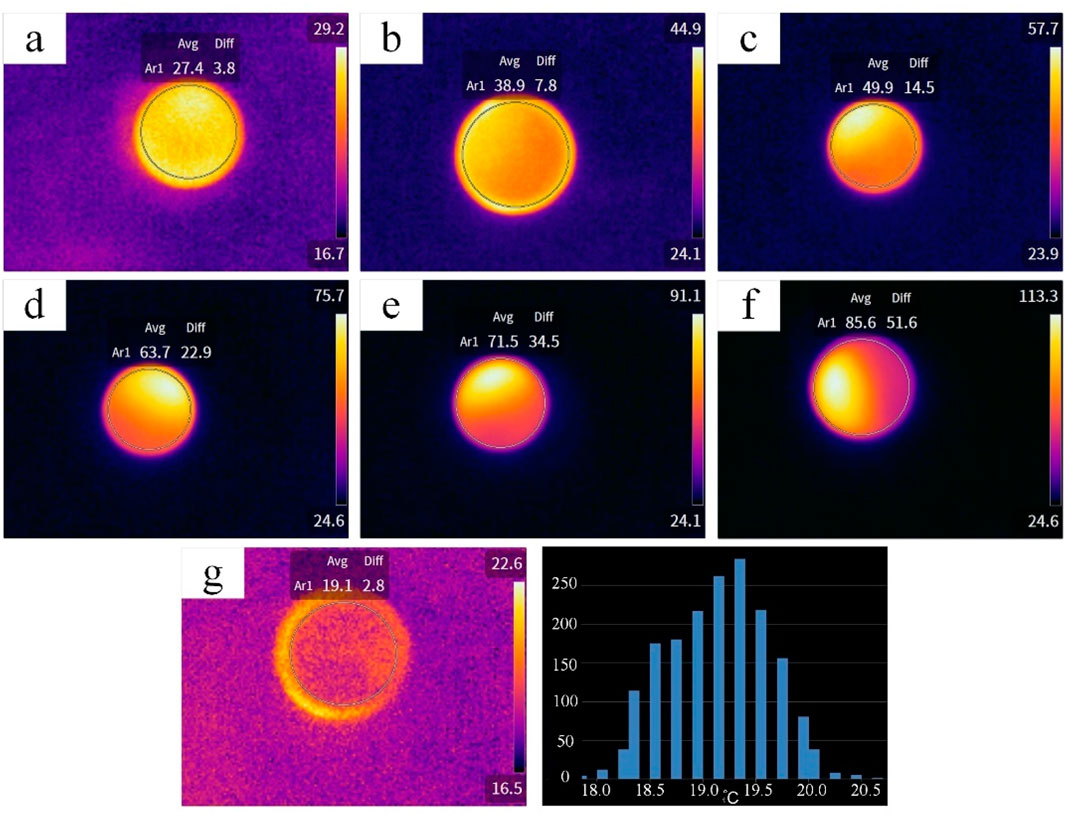

The uniformity of the wave-absorbing modifier distribution within the mastic is directly correlated with performance metrics and self-healing efficacy. Utilizing carbonyl iron powder as a strong dielectric loss-type wave-absorbing modifier to prepare asphalt mastic, and given that asphalt itself does not absorb microwaves, microwave heating temperature rise experiments were conducted. The temperature pixel distribution in infrared imaging was analyzed, and statistical methods were employed to assess the uniformity.

Infrared thermal images obtained after a heating duration of 20 s were selected for analysis. At this temperature, the temperature variations among asphalt mastics with different replacement ratios were pronounced, thereby facilitating detailed analysis. The acquired infrared images were imported into AnalyzIR software for further analysis. A circular rule is formulated for the image to obtain the average temperature and temperature difference within the circular region, and also to derive a histogram of the temperature distribution within the circular region, with the X-axis representing temperature values and the Y-axis indicating pixel count, as illustrated in Figure 8.

Figure 8. Infrared imaging and temperature histogram after 20 s of microwave Heating(a) 0% CIP asphalt mastic; (b) 20% CIP asphalt mastic; (c) 40% CIP asphalt mastic; (d) 60% CIP asphalt mastic; (e) 80% CIP asphalt mastic; (f) 100% CIP asphalt mastic; (g) infrared imaging and temperature histogram of matrix asphalt.

The colors shown in the infrared images directly represent the temperature distribution characteristics of the samples. The matrix asphalt and limestone mineral powder mastic samples display uniform isothermal regions, whereas the mastic samples containing carbonyl iron powder exhibit a gradient temperature distribution. This is due to the exothermic effect of carbonyl iron powder upon microwave absorption. Furthermore, as the replacement ratio of carbonyl iron powder increases, both the average temperature and temperature variation rise. To more precisely analyze the dispersion uniformity of carbonyl iron powder, pixel-temperature curves from seven sample groups were combined to visually depict their temperature distributions, and the temperature standard deviation across all pixels was calculated to quantitatively evaluate dispersion uniformity.

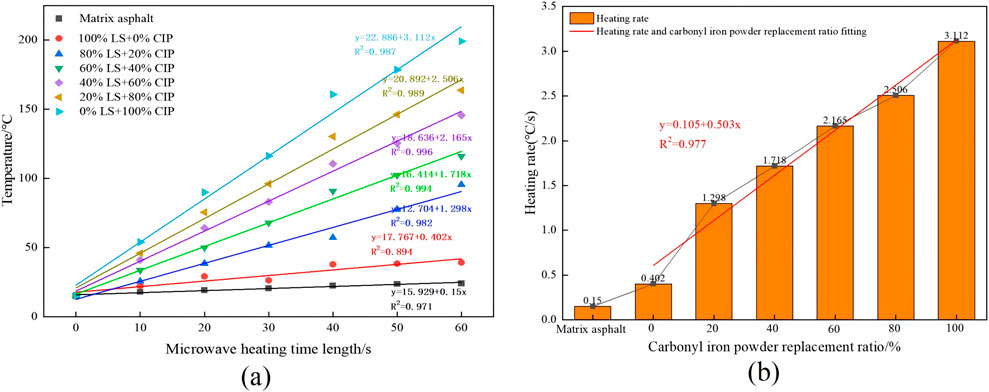

As shown in Figure 9a, the temperature range of the matrix asphalt is the narrowest, spanning only 17.8°C–20.6°C. Upon incorporation of carbonyl iron powder, the temperature range of the asphalt mastic progressively broadens, with the curve shifting toward higher temperature intervals. The microwave absorption and heating capability of the carbonyl iron powder-modified asphalt mastic is markedly improved. At a 100% replacement ratio, the temperature range extends to 58.3°C–113.2°C, exceeding that of the matrix asphalt by over 228%. Furthermore, the pixel count curve exhibits no significant peaks, indicating that Carbonyl Iron Powder is well dispersed and demonstrates excellent heating uniformity within the asphalt mastic system. The 'peaks' observed in the figure result from the narrow temperature range, which causes pixel counts to concentrate within a small interval. Figure 9b illustrates that the standard deviation increases progressively with the replacement ratio, rising from 0.62 initially to 16.1, reflecting a marked increase in temperature variability. This indicates that lower replacement ratios yield better heating uniformity, a factor that should be carefully considered in practical applications.

Figure 9. Surface temperature pixel distribution and standard deviation analysis (a) Surface temperature pixel distribution; (b) Standard deviation.

3.2.2 Heating rate

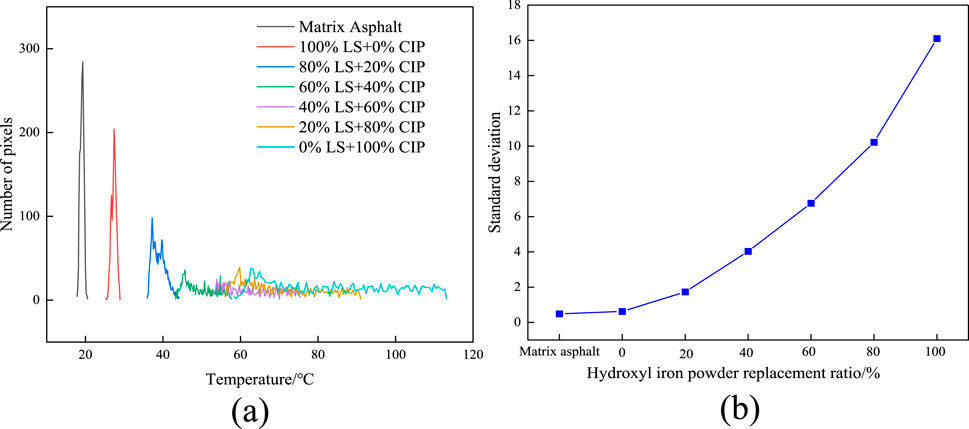

Microwave heating tests were performed on asphalt and asphalt mastic samples with heating durations from 0 s to 60 s. The average temperature of the samples was recorded at 10 s intervals. The effect of carbonyl iron powder on the heating behavior of asphalt mastic was systematically evaluated through temperature rise fitting and heating rate fitting. The results are presented in Figure 10.

Figure 10. Temperature rise fitting of asphalt and asphalt Mastic (a) temperature rise fitting; (b) heating rate fitting.

The linear fitting results of the average surface temperature of asphalt and asphalt mastic are illustrated in Figure 10. The study revealed that, as shown in Figure 10a, the temperature variation of the matrix asphalt and mineral powder mastic during microwave heating was minimal. Specifically, the heating rate of the limestone mineral powder mastic was 0.402 C/s, whereas that of the matrix asphalt was only 0.15 C/s, indicating a weak microwave response from both the matrix asphalt and mineral powder. Upon the addition of carbonyl iron powder, the asphalt mastic exhibited a pronounced linear heating behavior.

Figure 10b illustrates that the heating rate increases monotonically with the iron powder replacement ratio. Replacement ratios of 0%, 20%, 40%, 60%, 80%, and 100% correspond to heating rates of 0.402 C/s, 1.298 C/s, 1.718 C/s, 2.165 C/s, 2.506 C/s, and 3.112 C/s, respectively, confirming that carbonyl iron powder enables controllable thermal energy release through microwave absorption. A distinct inflection point is observed in the heating rate; when the replacement ratio exceeds 20%, the increase in heating rate markedly decelerates, with an increase of approximately 140% from 20% to 100%, compared to a 223% increase from 0% to 20%.

By integrating the optimal temperature range for self-healing of asphalt mastic (45°C–55°C) with the analysis of the thermal aging threshold (Cui et al., 2021), a 20% replacement ratio can both meet the effective heating requirement, i.e., a heating rate of 1.298 C/s, and prevent asphalt performance deterioration due to overheating. Therefore, considering the microwave heating controllability and economic efficiency, a 20% replacement ratio is deemed optimal.

3.3 Self-healing performance

Asphalt mastic, as a viscoelastic material, undergoes fatigue failure characterized by a dynamic process of energy dissipation and damage accumulation. Accumulated dissipated energy is quantified by calculating the area of the stress-strain hysteresis loop for each loading-unloading cycle, which is intrinsically linked to the viscoelastic behavior. The healing index HIW, defined as the ratio of accumulated dissipated energy (W) before and after healing of the asphalt mastic, is employed to investigate the variations in healing capacity of asphalt mastic with different carbonyl iron powder replacement ratios. The calculation formula for the healing index HIW is presented in Equations 3–5.

In the equation:

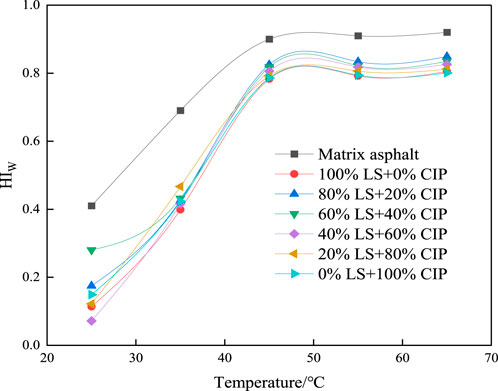

3.3.1 Healing index HIW

Damage cracks in asphalt mixtures primarily develop within the asphalt phase, with minimal cracking observed at the aggregate–asphalt interface (Ding et al., 2020). Therefore, the healing capacity of asphalt mastic constitutes the basis for the healing performance of asphalt mixtures. Within the asphalt mixture system, asphalt mastic fills the voids between aggregates and coats their surfaces; its fluidity, viscoelasticity, and temperature sensitivity directly govern the efficiency of crack healing. This section assesses the healing performance of asphalt and asphalt mastic based on the DSR fatigue-healing-fatigue test, employing the ratio of cumulative dissipated energy before and after healing as the healing index. The experimental results are presented in Figure 11.

As illustrated in the figure, the healing rate of matrix asphalt is generally higher than that of asphalt mastic, while the carbonyl iron powder-modified mastic exhibits a higher healing rate compared to the mineral powder mastic. This suggests that the incorporation of filler negatively impacts the healing capacity of matrix asphalt, and this detrimental effect is alleviated when carbonyl iron powder partially replaces mineral powder. The healing rate of asphalt and asphalt mastic continuously increases with rising temperature. Both materials exhibit a consistent upward trend in healing rate with respect to temperature. This increase can be divided into two stages: between 30°C and 50°C, the healing rate rises rapidly. Based on the previously discussed rheological properties of asphalt mastic, within this temperature range, asphalt transitions from an elastic state to a viscoelastic fluid, beginning to exhibit near-Newtonian fluid characteristics with spontaneous flow capability, thereby facilitating rapid fatigue repair. Between 50°C and 70°C, the rate of increase in healing rate significantly diminishes, indicating that beyond a certain temperature threshold, further temperature elevation has a limited effect on enhancing the healing rate of asphalt mastic.

Further analysis indicates that the inflection point at which the healing rate declines (50°C) corresponds exactly to the softening point temperature of the asphalt mastic. At this temperature, the asphalt mastic demonstrates excellent fluidity, identifying it as the optimal healing temperature. The healing rates of asphalt mastic at the optimal healing temperature are 78.3%, 82.5%, 81.8%, 80.6%, 79.2%, and 78.6% for replacement ratios of 0%, 20%, 40%, 60%, 80%, and 100%, respectively. Incorporation of carbonyl iron powder enhances the healing rate of the asphalt mastic; however, the healing rate progressively decreases as the replacement ratio increases. Analysis indicates that carbonyl iron powder enhances the fluidity of asphalt mastic, resulting in higher molecular diffusion and migration efficiency at the same healing temperature, which leads to a healing rate exceeding that of mineral powder-modified asphalt mastic. The replacement of carbonyl iron powder is conducted via volume substitution, causing the filler density of the asphalt mastic to increase with the replacement ratio. This increase reduces molecular migration efficiency and extends the diffusion path. Consequently, the asphalt mastic with a 20% replacement ratio demonstrates the optimal healing rate.

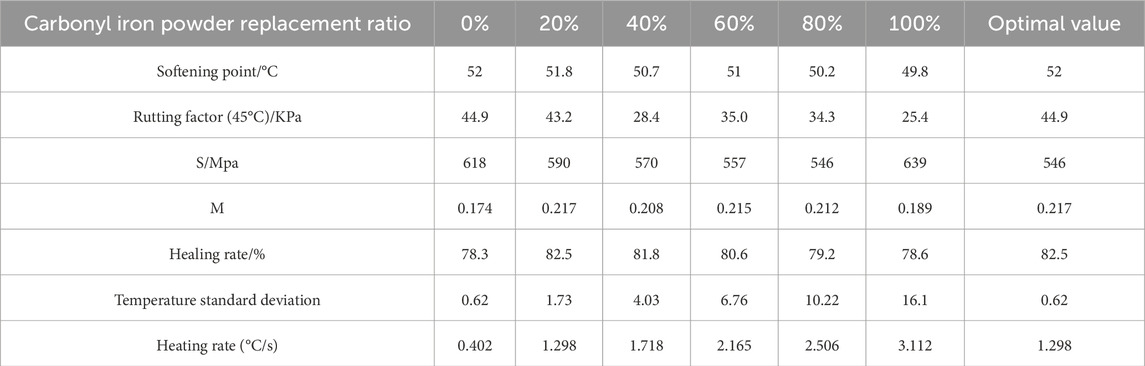

3.4 Determination of the optimal carbonyl iron powder replacement ratio

Based on the key factors affecting the healing performance of microwave thermal induction in asphalt mastic—namely rheological properties, heating characteristics, and healing capacity—seven evaluation indices were established for correlation analysis: Softening Point, Rutting Factor, s-value, m-value, Temperature Standard Deviation, Heating Rate, and Healing Rate. The optimal replacement ratio should be determined by the degree of correlation between the data for each replacement ratio and the standard values (optimal values for each index); a higher correlation indicates superior overall performance. First, the optimal value sequence was established according to the characteristics of each index. Since Softening Point, Rutting Factor, m-value, and Healing Rate all improve with increasing values, the maximum values were selected as the optimal sequence. The s-value and temperature standard deviation should be minimized; the smallest value is selected as the optimal value. The heating rate was selected based on the previous analysis of the asphalt mastic with a 20% replacement ratio, identifying it as the optimal heating rate. All indicators are presented in Table 6. The detailed procedure for the grey relational analysis is summarized as follows:

1. Data preprocessing (dimensionless normalization): For positive indicators (where larger values are preferable or an optimal moderate value exists), the actual value is divided by the optimal value; For negative indicators (such as temperature standard deviation, where smaller values are preferable), the optimal value is divided by the actual value, as shown in Equations 6, 7, respectively.

2. Calculate the absolute difference between the dimensionless normalized value of each replacement ratio indicator and 1, as shown in Equation 8.

3. Confirm

4. Calculate the correlation coefficient with a resolution coefficient ρ = 0.5, as shown in Equation 9.

5. Determine the degree of association by averaging all correlation coefficients for each replacement ratio (n = 7 indicators), as shown in Equation 10.

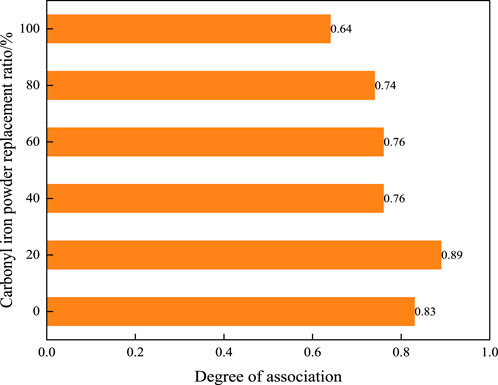

Calculations are complete. The correlation coefficients and degrees of association between each replacement ratio and the optimal value are presented in Figures 12, 13, respectively.

From the relational degree results presented in the figure, the order from highest to lowest is: 20% > 0% > 60% > 40% > 80% > 100%. The asphalt mastic with a 20% carbonyl iron powder replacement ratio achieved the optimal comprehensive evaluation, with a relational degree of 0.89; limestone mineral powder mastic ranked second with a correlation of 0.83 due to the superior high temperature performance aspects, but the healing effect of the asphalt mastic mainly depended on the microwave-induced warming ability and the fluidity performance, which was manifested in the increase of the healing index. Therefore, based on the comprehensive evaluation of seven indicators, 20% is identified as the optimal replacement ratio of carbonyl iron powder in asphalt mastic.

3.5 Optimization study of healing performance

3.5.1 Self-healing performance

Bommavaram et al. (2009) the study revealed that healing is a process whereby interfacial cohesion and molecular mutual diffusion between wetted surfaces enhance material strength. Beginning with the macroscopic mechanical properties of asphalt and integrating surface energy theory with molecular diffusion theory, the self-healing performance of asphalt mastic is evaluated using the intrinsic healing function Rh(t), as expressed in Equation 11. The form of the healing function employed is as follows:

In the equation: t—time;

This healing function model was developed for simple polymer molecules and short-term healing processes. The model is primarily expressed as: (1) instantaneous strength gain of the material induced by cohesive forces at the crack interface (denoted by the parameter

In the equation:

3.5.2 Shear modulus

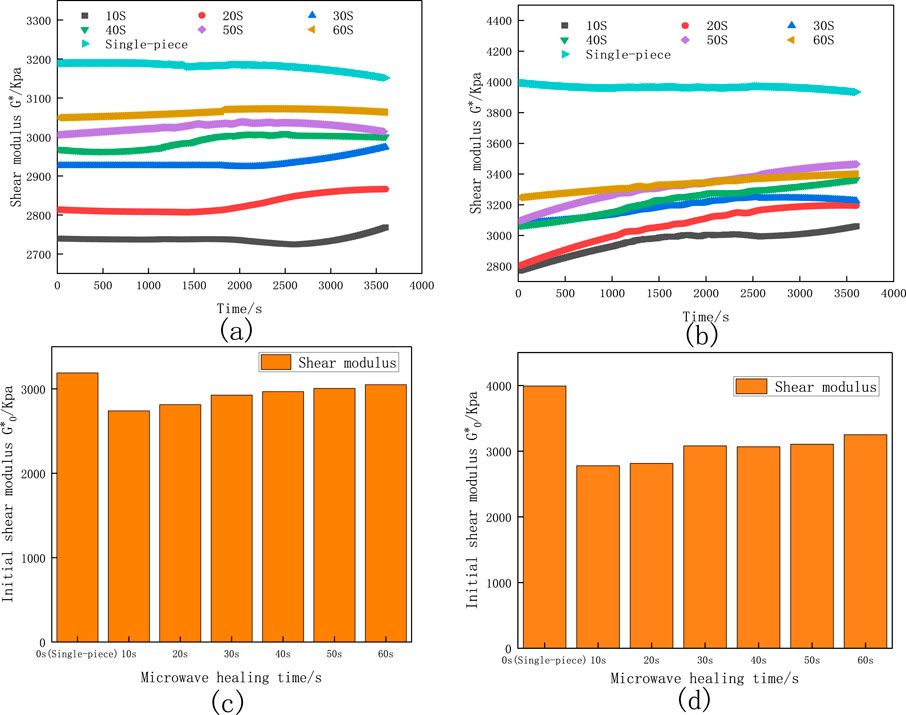

The shear modulus values of single specimens and microwave-induced healed double-specimen assemblies were measured using the time sweep module of a dynamic shear rheometer. The test results are presented in Figure 14.

Figure 14. Results of complex shear modulus testing (a) Shear modulus of asphalt mastic modified with 20% CIP; (b) Shear modulus of asphalt mastic with 0% CIP; (c) 20%CIP Initial Shear Modulus G*0; (d) 0% CIP Initial Shear Modulus G*0.

As illustrated in Figures 14a,b, the shear modulus of double-fracture healing specimens increases over time; however, the rate of increase gradually diminishes with extended microwave-induced healing duration, most notably in the 20 vol% (equal volume replacement) carbonyl iron powder asphalt mastic. The reduction in shear modulus over time observed in intact single-fracture specimens may be due to slight geometric alterations caused by the application of normal load (albeit minimal) and other related factors. Moreover, the shear modulus of the 20 vol% carbonyl iron powder-modified asphalt mastic is lower than that of the limestone mineral powder asphalt mastic, indicating enhanced flow properties, which aligns with the results reported in Section 3.1.

The initial shear modulus of the two asphalt mastic specimens is defined as G*0. To standardize the results and minimize errors, the shear modulus measured at 1 min into the test is considered the initial shear modulus. Figures 14c,d present these initial shear modulus values. As the duration of microwave-induced healing increases, the initial shear modulus correspondingly rises; this trend is particularly evident in carbonyl iron powder-modified asphalt mastic. This phenomenon occurs because prolonging the microwave-induced healing time significantly elevates the temperature of the asphalt mastic, thereby enhancing the healing process. As indicated in Section 3.2, microwave heating of 20% vol carbonyl iron powder-modified mastic for 30 s can raise the temperature to approximately 50°C, which is equivalent to the softening point temperature of the mastic. The temperature increase of limestone mineral powder mastic after microwave heating is minimal, and the initial shear modulus increases gradually. According to capillary diffusion theory (Song et al., 2021), during the interfacial wetting stage, the temperature rise reduces the viscosity of asphalt, facilitating rapid wetting and closure of asphalt cracks. In the molecular diffusion stage, elevated temperature enhances molecular kinetic energy, accelerating molecular diffusion healing. This temperature increase promotes the recovery of the asphalt shear modulus, thereby improving the healing capacity of the asphalt mastic. The results indicate that after the microwave-induced healing duration reaches 30 s, the increase in the Initial Shear Modulus begins to decelerate. Thus, the enhancement of the Initial Shear Modulus can be approximately divided into two phases: a rapid growth phase from 10 s to 30 s and a slower growth phase from 30 s to 60 s. The critical time is identified as 30 s (corresponding to a critical temperature of 50°C). This finding aligns with the outcomes of the fatigue-healing-fatigue test, thereby mutually validating the reliability of the results. This suggests that once the temperature attains a certain threshold, further temperature elevation to promote the healing of asphalt mastic is limited. Therefore, in practical engineering applications, the healing temperature should not be excessively elevated during microwave induction of asphalt mixtures to achieve a high self-healing rate.

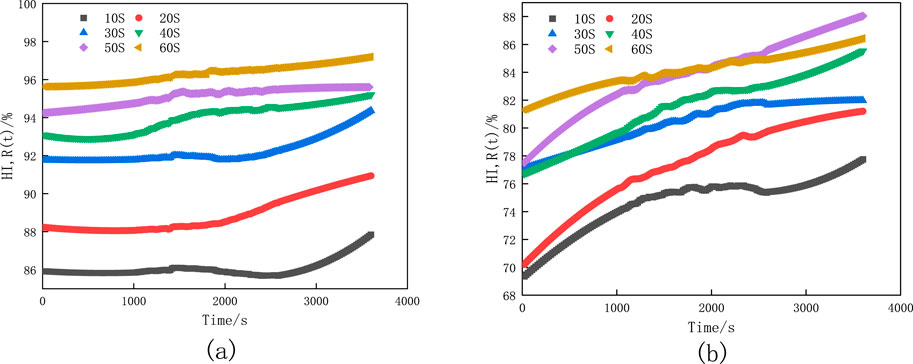

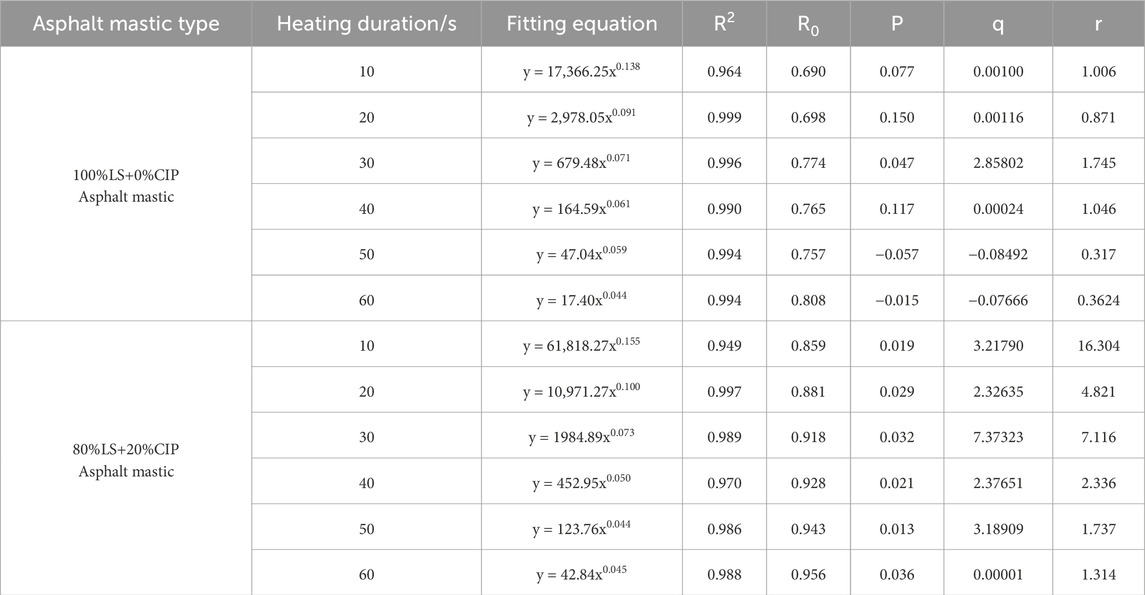

3.5.3 Healing rate R(t) fitting

The healing rate R(t) is defined as the ratio of the shear modulus of the double-layer asphalt mastic specimen at any given time to that of the single-layer asphalt mastic specimen. Figure 15 presents the relationship between the healing rate R(t) and time. As shown in Figure 15a, the healing rate R(t) increases over time, with the rate of increase diminishing as the duration of microwave-induced healing is prolonged. This is attributed to the healing process comprising two stages: the Self-Healing Development Phase and the Self-Healing Stable Phase, wherein the self-healing rate during the development phase is markedly higher than that during the stable phase. During the Self-Healing Development Phase, due to the short duration of microwave-induced healing and the relatively low temperature of the asphalt mastic, double-fracture healing progresses slowly, resulting in considerable damage to the mastic. At this stage, the mastic demonstrates strong performance recovery capability, and the self-healing rate R(t) increases significantly. As the duration of microwave-induced healing increases, the efficiency of double-fracture healing improves, the performance of the asphalt mastic gradually recovers, the degree of damage decreases, and the properties of the damaged specimen approach those of the original state; consequently, the self-healing behavior gradually weakens. In Figure 15b, the healing rate R(t) trends for different microwave-induced healing durations are generally consistent and exhibit a clear increasing trend, indicating that the limestone mineral powder mastic possesses low wave absorption capacity, slow double-fracture healing, significant asphalt mastic damage, and remains within the Self-Healing Development Phase.

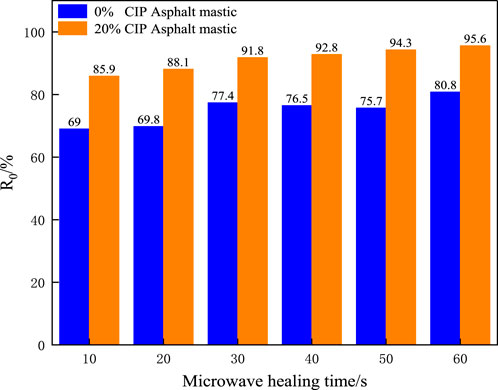

The influence of microwave-induced healing duration on the healing performance was analyzed using the instantaneous healing rate R0, fitted according to Equation 12. In Equation 12, when t = 0,

As illustrated in Figure 16, the instantaneous healing rate of the asphalt mastic modified with 20 vol% carbonyl iron powder is markedly higher than that of the mineral powder asphalt mastic. Relative to the control group, the addition of carbonyl iron powder enhances the healing rate by approximately 21%. Furthermore, the instantaneous healing rate increases progressively with prolonged microwave-induced healing duration, although the rate of increase diminishes gradually as temperature rises. The instantaneous healing rate of mineral powder-modified asphalt mastic remains constant without a significant growth trend, consistent with the previously analyzed results. In summary, two primary factors contribute to this phenomenon: first, the wave absorption capacity of mineral powder is markedly weaker than that of carbonyl iron powder, leading to a slower temperature increase during healing and reduced healing efficiency; Second, incorporating a certain proportion of carbonyl iron powder enhances the flow properties of the mastic, thereby facilitating the self-healing of asphalt mastic.

4 Conclusion

(1) Carbonyl iron powder improves the high-temperature flow behavior and low-temperature creep behavior of asphalt mastic. The addition of fillers increases the modulus of the matrix asphalt, hardens it, and reduces its fluidity, which is detrimental to the healing effect of the asphalt. However, the replacement of some of the fillers by carbonyl iron powder improves the fluidity of the asphalt mastic, and the modulus becomes smaller as the proportion of the fillers is replaced, which is conducive to the healing effect of the asphalt mastic. The low-temperature performance initially improves with increasing Carbonyl Iron Powder content but deteriorates sharply beyond an 80% replacement ratio. Hence, in practical applications, the dosage of Carbonyl Iron Powder must be carefully controlled to prevent detrimental effects on low-temperature performance.

(2) Carbonyl Iron Powder-modified asphalt mastic exhibits excellent heating uniformity and linear temperature rise characteristics. The heating rate increases with higher replacement ratios of Carbonyl Iron Powder, with the most pronounced increase at 20%, achieving a heating rate of 1.298 C/s, which satisfies the requirements for effective heating.

(3) Temperature directly influences the healing performance of asphalt mastic; as temperature increases, the healing rate steadily improves. The optimal healing temperature is 50°C, at which the asphalt mastic transitions from pseudoplastic fluid behavior to near-Newtonian fluid behavior. Carbonyl Iron Powder improves the healing rate of asphalt mastic, with the highest healing rate achieved at a 20% replacement ratio.

(4) Considering the rheological properties of asphalt mastic at high and low temperatures, microwave heating temperature rise characteristics, and healing rate comprehensively, grey relational analysis identifies the asphalt mastic with a 20% Carbonyl Iron Powder replacement ratio as having the optimal overall performance, representing the best replacement ratio for microwave thermal induction self-healing of asphalt mastic.

(5) The optimal replacement ratio of carbonyl iron powder modified asphalt mastic, the healing effect under the microwave heat-induced effect is significantly improved, the instantaneous healing rate (R0) increased by about 21%, carbonyl iron powder mainly through the improvement of the flow properties and wave-absorbing warming ability to enhance the healing efficiency of the asphalt mastic. Modified asphalt mastic has greater molecular kinetic energy to promote healing at the beginning of microwave heating healing, and the molecular kinetic energy increases with the increase of microwave heating time.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

LZ: Conceptualization, Data curation, Software, Visualization, Writing – original draft, Writing – review and editing. XY: Conceptualization, Formal Analysis, Funding acquisition, Resources, Writing – review and editing. SM: Data curation, Project administration, Supervision, Writing – review and editing. JG: Data curation, Investigation, Supervision, Writing – review and editing. YL: Conceptualization, Formal Analysis, Funding acquisition, Methodology, Project administration, Resources, Supervision, Visualization, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the Science and Technology Project of the Department of Transportation of Inner Mongolia Autonomous Region (Development and application of microwave synergistic high-sensitive emulsion-assisted self-healing technology for asphalt mixtures, NJ-2024-21); Inner Mongolia Natural Science Foundation Program (Microwave synergistic microwave-sensitive emulsion repair of asphalt pavement microdamage mechanism research, 2025MS05076); Fundamental Research Funds for the Universities (BR230145).

Conflict of interest

Authors XY, SM, and JG were employed by Inner Mongolia Transportation Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bevacqua, M. T., Isernia, T., Praticò, F. G., and Zumbo, S. (2021). A method for bottom-up cracks healing via selective and deep microwave heating. Automation Constr. 121, 103426. doi:10.1016/j.autcon.2020.103426

Bommavaram, R. R., Bhasin, A., and Little, N. D. (2009). Determining intrinsic healing properties of asphalt binders: role of dynamic shear rheometer. Transp. Res. Rec. 2126 (1), 47–54. doi:10.3141/2126-06

Chao, P., Yudong, H., Zhanping, Y., Hao, Y., Yutao, N., Tianhao, W., et al. (2022). Preparation and anti-icing performance of acrylic superhydrophobic asphalt pavement coating with microwave heating function. Constr. Build. Mater. 2022, 344. doi:10.1016/j.conbuildmat.2022.128289

Cui, Y., Jun, Z., and Lin, Z. (2021). Evaluation of the microstructure and self-healing performance of asphalt mastic under thermal aging. J. Build. Mater. 24 (06), 1271–1279. doi:10.3969/j.issn.1007-9629.2021.06.020

Ding, X., Ma, T., Gu, L., and Zhang, Y. (2020). Investigation of surface micro-crack growth behavior of asphalt mortar based on the designed innovative mesoscopic test. Mater. and Des. 185, 185108238–108238. doi:10.1016/j.matdes.2019.108238

González, A., Norambuena-Contreras, J., Storey, L., and Schlangen, E. (2018). Self-healing properties of recycled asphalt mixtures containing metal waste: an approach through microwave radiation heating. J. Environ. Manag. 214, 242–251. doi:10.1016/j.jenvman.2018.03.001

Gulisano, F., Gallego, J., Trigos, L., and Apaza Apaza, F. (2021). Dielectric characterisation of asphalt mortars for microwave heating applications. Constr. Build. Mater. 308, 125048. doi:10.1016/j.conbuildmat.2021.125048

Ji, J., Zhang, Z., Wen, L., You, P., Ma, T., and Huang, C. (2024). Influence of powder-to-binder ratio on the low-temperature performance of coal direct liquefaction residue composite modified asphalt mastic and mixture. Mater. Rev. 38 (22), 182–188. doi:10.11896/cldb.23090053

Kong, B. (2023). Study on microwave heating self-healing performance of microwave absorbing asphalt mixture. Chongqing, China: Chongqing Jiaotong University. doi:10.27671/d.cnki.gcjtc.2023.000503

Li, J., Ji, X. p., Fang, X. z., Hu, Y. l., Hua, W. l., Zhang, Z. m., et al. (2022). Self-healing performance and prediction model of microcapsule asphalt. Constr. Build. Mater. 330, 127085. doi:10.1016/j.conbuildmat.2022.127085

Liu, J., Wang, Z., Jia, H., Jing, H., Chen, H., Zhou, L., et al. (2023). Characteristics and properties of asphalt mortar containing Fo Filler. Constr. Build. Mater. 392, 132039. doi:10.1016/j.conbuildmat.2023.132039

Lou, B., Sha, A., Barbieri, D., Liu, Z., Zhang, F., and Jiang, W. (2021). Improved microwave heating uniformity and self-healing properties of steel slag asphalt containing Ferrite Filler. Mater. Struct. 54 (1), 9. doi:10.1617/s11527-020-01577-7

Mazzoni, G., Stimilli, A., Cardone, F., and Canestrari, F. (2017). Fatigue, self-healing and thixotropy of bituminous mastics including aged modified bitumens and different filler contents. Constr. Build. Mater. 131, 131496–131502. doi:10.1016/j.conbuildmat.2016.11.093

Phan, M. T., Park, D., and Le, M. H. T. (2018). Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Constr. Build. Mater. 2018, 180503–180511. doi:10.1016/j.conbuildmat.2018.05.278

Song, T., Jiang, B., Li, Y., Ji, Z., Zhou, H., Jiang, D., et al. (2021). Self-healing materials: a review of recent developments. ES Mater. and Manuf., 14. doi:10.30919/esmm5f465

Xu, H. (2021). Study on heat-induced self-healing performance of asphalt and asphalt mixture. Chongqing, China: Chongqing Jiaotong University. doi:10.27671/d.cnki.gcjtc.2021.000643

Yalcin, E. (2021). Effects of microwave and induction heating on the mechanical and self-healing characteristics of the asphalt mixtures containing waste metal. Constr. Build. Mater. 286, 122965. doi:10.1016/j.conbuildmat.2021.122965

Yang, H., Jian, O., Zhao, J., and Ou, J. (2023). Effect of fiber reinforcement on self-healing ability of asphalt mixture induced by microwave heating. Constr. Build. Mater. 362, 129701. doi:10.1016/j.conbuildmat.2022.129701

Zhang, B., Gao, X., Xu, S., Yang, X., Tian, Q., and Liu, J.(2023). Microwave heating healing of asphalt mixture with coal gangue powder and basalt aggregate. Sustainability 15(12986), 12986. doi:10.3390/su151712986

Zhang, S. (2019). Study on self-healing behavior of asphalt mortar based on rheology. Zhengzhou, China: Zhengzhou University.

Zhao, H., Tang, J., and Liu, W. (2024). Investigation of the self-healing behavior of silicon carbide-modified asphalt mastic and determination of optimal dosage. Mater. Rev. 38 (14), 97–108. doi:10.11896/cldb.23040058

Zheng, J., Lü, S., and Liu, C. (2020). Technical system, key scientific problems and technical frontier of long-life pavement. Chin. Sci. Bull. 65 (30), 3219–3229. doi:10.1360/tb-2020-0227

Keywords: asphalt mastic, carbonyl iron powder, microwave induction, rheological properties, self-healing behavior

Citation: Zhao L, Yan X, Mi S, Gao J and Li Y (2025) Study on the self-healing behavior and rheological properties of carbonyl iron powder-modified asphalt mastic induced by microwave heating. Front. Built Environ. 11:1629147. doi: 10.3389/fbuil.2025.1629147

Received: 15 May 2025; Accepted: 11 June 2025;

Published: 26 June 2025.

Edited by:

Chongzheng Zhu, Xiangtan University, ChinaReviewed by:

Jiange Li, Xi’an University of Science and Technology, ChinaPei Sun, Hefei University, China

Copyright © 2025 Zhao, Yan, Mi, Gao and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yongxiang Li, bHl4aWFuZ0BpbWF1LmVkdS5jbg==

Longwei Zhao

Longwei Zhao Xuliang Yan2

Xuliang Yan2 Yongxiang Li

Yongxiang Li