- 1Faculty of Business, UNITAR International University, Petaling Jaya, Malaysia

- 2The Department of Environmental Sciences and Engineering, NOVA School of Science and Technology, Universidade NOVA de Lisboa, Caparica, Portugal

- 3Faculty of Education and Humanities, UNITAR International University, Petaling Jaya, Malaysia

1 Introduction

The global urban population is projected to rise from 55% in 2025 to 70% by 2050, adding approximately 2.5 billion people to cities (WorldBank, 2021). The demand for construction is expected to surge in response; however, despite its growth, the construction sector is considered the least efficient industry and is widely recognized as the major contributor to global resource consumption. The sector uses around 50% of all extracted materials and is responsible for a significant percentage of total waste production and emissions (Prochazkova et al., 2021).

While sustainability is intended to be the central theme in this sector (Shahidi Hamedani et al., 2025b), the dominant production and consumption patterns are still driven by a linear take-make-dispose mindset, one closely associated with resource extraction, emissions, and waste creation (Tan et al., 2022). According to the International Resource Panel, global extraction of materials is projected to exceed 165 Gt in 2060 if business-as-usual scenarios persist, doubling the extraction levels of 2011 (OECD, 2019). Global warming, biodiversity loss, and changes in the nitrogen cycle may irreversibly alter the Earth’s ecosystem (Mason et al., 2022).

CE minimizes resource depletion, waste, and emissions by maintaining products, components, and materials at their highest utility and value (AlJaber et al., 2023). CE seeks to alter the “take-make-dispose” patterns that threaten to undermine Earth’s sustainability and approach its limits (Norouzi et al., 2021).

In recent years, the concept has moved beyond revenue streams to become a key part of sustainability discussions, especially in CE (Geissdoerfer et al., 2020). As a result of this shift, CBMs are emerging. CBMs take a broader view of value, encompassing the environment, society, and a wider range of value chain partners than conventional business models (Jayakodi et al., 2024).

In addition to what a company sells, they rethink how it's created, delivered, held onto, and repurposed to add value to society (Geissdoerfer et al., 2020). Embracing the CE necessitates the development of novel CBMs.

Although CE is gaining traction in construction, it has historically been more limited than other sectors, often limited to recycling and waste minimization. In existing studies, material efficiency and circular design strategies were emphasized (Norouzi et al., 2021). In contrast, the circular business model has received significantly less attention (Guerra et al., 2021; Mackenbach et al., 2020). As Jayakodi et al. (2024) note, there is still a notable lack of clarity surrounding the theoretical conceptualization and practical applicability of CBMs in construction. This paper contends that CBMs are the critical enabler and the “missing link” needed to effectively convert CE from fragmented practices to a scalable and systemic transformation of the construction industry. Embracing circularity in this context requires more than material innovation; it demands the creation of novel business models that support long-term value retention, economic viability, and resource regeneration.

This Opinion article aims to contribute to ongoing discussions about accelerating the construction industry’s circular transformation. The paper does not present new empirical findings; instead, it draws on existing evidence and literature to provide an interpretive perspective. More precisely, it contends that Circular Business Models (CBMs) form the “missing link” between discontinuous circular practices and systemic change in construction. The article is structured around three organizing themes: (1) how CBMs are defined and framed in construction, (2) what obstacles stifle their use, and (3) which enablers and policies could support their wider implementation.

The deliverable of the paper set is a conceptualization of how Circular Business Models (CBMs) can contribute to advancing the circular economy in construction. Given the sector’s diversity, the discussion concentrates on building construction and renovation, where the use of cement, steel, and timber is most intensive and demolition waste is particularly substantial. These subsectors provide the clearest ground to illustrate how CBMs can help retain value, close resource loops, and reshape patterns of value creation. Rather than offering a detailed mapping exercise, the paper draws attention to points in the material, energy, and waste flows where CBM practices can intervene most effectively.

2 Scope and approach

This article presents a focused conceptual discussion rather than a systematic review. The literature considered was chosen selectively to highlight the most relevant strands of debate on the circular economy and circular business models in construction and related fields. These include key reviews, recent policy initiatives, technological advances, and illustrative industry cases. The purpose is not to provide an exhaustive survey of all existing studies, but to develop a clear conceptual perspective on CBMs in construction.

3 Reframing the circular economy through a business lens

The construction sector is responsible for nearly 40% of global carbon emissions and a similar proportion of energy usage (Mosca, 2024). Sustainability has become a real concern in the construction sector, with implications for all agents and levels, from planning to deconstruction (Regúlez et al., 2023). Adopting the CE principle in the construction industry promotes the use of sustainable materials, maximizes material recovery, and avoids unnecessary waste generation and waste disposed of in landfills (Akanbi et al., 2018). Nonetheless, while these practices contribute to minimizing environmental impact, they largely emphasize material efficacy rather than a holistic view of business operations (Mohapatra et al., 2024).

Beyond construction, businesses in other sectors have also demonstrated how Circular Business Models can operationalize circular economy principles. In the automotive industry, for example, firms are adopting Industry 4.0-enabled lifecycle frameworks to support vehicle remanufacturing and material recovery, especially in the transition to electric mobility (Yu et al., 2022). In manufacturing and ICT sectors, companies are using digital tools such as IoT, AI, and product–service systems to extend product lifespans, improve traceability, and facilitate reverse logistics (Shahidi Hamedani et al., 2025a; Han et al., 2023; Perotti et al., 2024). These wider industry experiences provide a useful reference point for understanding how similar business logics may be adapted and applied in the construction sector.

A CBM describes how an organization creates, delivers, and captures value within a circular system designed to prevent or postpone obsolescence and favor the use of resources (Geissdoerfer et al., 2020). CBMs aim to help firms devise suitable strategies to slow, close, and narrow resource loops, which can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling methods. CBM is mentioned as one of the financial enablers in implementing CE principles in the built environment (Prochazkova et al., 2021). Successfully transitioning to a circular built environment requires construction firms to reconsider their core business logic, integrating circularity into repeatable organizational processes and unique project execution (Jayakodi et al., 2024).

This shift in perspective, from focusing merely on circular practices to fundamentally rethinking the business model, is essential for accelerating CE uptake, managing risks, and capturing new opportunities in the digital age (De Wolf et al., 2024). The CE effort in construction risks remaining fragmented if this strategic business model lens is not adopted (Prochazkova et al., 2021).

Several industries, including electronics and manufacturing, demonstrate the potential for circular business models. For example, Philips developed a Product-as-a-Service model by providing lighting and extending product life (Yang et al., 2017). Manufacturers maximize resource efficiency and support remanufacturing through data analytics and lifecycle tracking (Kerin and Pham, 2020). Insights into the construction industry’s transition to circularity can be obtained from these sectoral shifts, which illustrate the economic and operational viability of CBMs.

4 Understanding circular CBM

Using CBMs, organizations can create, deliver, and retain value within ecological limits. Unlike conventional business models, CBM stresses sustainability as a core principle, reducing waste and extending product lifespans. Competitive advantages and operational efficiency depend on CE principles. As Brändström et al. (2024) explained, CBMs enable firms to design, maintain, repair, reuse, remanufacture, refurbish, and recycle strategies to reduce resource loops. Construction is particularly resource-intensive and project-based, so this shift transforms the firm from a one-time seller to a steward of value across the product lifecycle.

The transition toward CBMs is an environmental imperative and a significant economic opportunity. The circular economy is estimated to unlock $4.5 trillion in value by 2030 as businesses benefit from lower costs, enhanced customer and employee relationships, increased sales, and reduced risks associated with linear models; furthermore, applying CE principles to five key material areas—cement, aluminum, steel, plastics, and food—could eliminate 9.3 billion tons of CO2 emissions by 2050, equivalent to cutting all current transport emissions to zero (WBCSD, 2023). These projections highlight the strategic importance of embedding CBMs in the construction industry.

One such archetype is Product-as-a-Service (PaaS), which replaces ownership. For example, Philips’ “Pay-per-Lux” model, piloted in Amsterdam’s Schiphol Airport, provides lighting as a service, promoting long-term product responsibility and reducing waste (De Wolf et al., 2024). Resource Recovery Models focus on extracting value from used materials, particularly during demolition or renovation, through reuse, recycling, or remanufacturing. Madaster in the Netherlands is a digital platform that registers building materials to support reuse and reduce waste. Platforms like the Circular Initiative in Germany facilitate material reuse through a platform that connects deconstruction outputs with new building projects (Heisel and Rau-Oberhuber, 2020). Life-extension models promote modular and flexible buildings that can be easily adapted or disassembled at the end of life. These CBM archetypes—supported by real-world applications—demonstrate how the construction industry can move beyond traditional material efficiency toward systemic lifecycles.

In construction, the potential of CBM archetypes becomes clearer when they are linked to materials and processes rather than described in general terms. For example, product-as-a-service models have been discussed in relation to building services such as lighting, HVAC, or elevators, where long-term service contracts shift attention toward durability and ongoing maintenance instead of replacement. Resource recovery is especially relevant for structural materials like steel and timber, which can often be reused or remanufactured without major loss of quality. Still, it may also extend to selected fractions of demolition waste when proper separation is carried out. Life-extension strategies are visible in renovation and fit-out projects, where façades, flooring systems, or interior partitions can be designed in modular form and later disassembled. Finally, sharing approaches can be applied in areas such as construction logistics, for instance, with machinery, scaffolding, or other temporary equipment. These examples illustrate, in a practical way, how CBM archetypes could operate within construction rather than remaining at the level of general principle.

5 Barriers to circular business model adoption

Adopting CBM is essential for accelerating the impact and upscaling of the CE in the built environment. However, companies face numerous barriers in progressing toward this stage. According to Brändström et al. (2024), these barriers can be broadly categorized as ‘hard’ (technical and economic) and ‘soft’ (institutional and social). Among these, cultural barriers have emerged as particularly significant to the circular economy transition in the EU, The industry is often described as having conservative cultural resistance, exhibiting risk aversion, and limited flexibility to adopt new practices, largely due to perceived financial risks. This mindset can lead to resistance to changes that disrupt established norms. There can also be a lack of interest in CE principles with a preference for new materials, often overlooking the value embedded in construction and demolition waste; addressing this requires a fundamental change in mindset and practice (AlJaber et al., 2023).

Additional barriers include market challenges, e.g., high upfront investments, regulatory obstacles (e.g., restrictive laws and policies), and technological limitations (e.g., insufficient circular design solutions and a scarcity of large-scale implementation projects) (Brändström et al., 2024).

The fragmentation of the value chain is another major, frequently cited barrier (Geissdoerfer et al., 2020). This fragmentation hinders effective communication, coordination, and collaboration among stakeholders. Construction’s project-based nature is unique, meaning CE adoption requires a different perspective than in other sectors, often reinforcing short-term project logic over lifecycle value. Poorly connected information flows consequently hinder the successful implementation of circularity (AlJaber et al., 2023).

Furthermore, current procurement systems often prioritize the lowest price over emphasizing or accounting for circular value. This cost-focused approach disincentivizes practices like careful on-site sorting or deconstruction in favor of cheaper, linear waste disposal methods. The main obstacles are difficulties in demonstrating a strong circular business case and an unclear financial case. The financial uncertainty associated with reused materials can also augment the investment challenge (Jayakodi et al., 2024).

The implementation is also hampered by insufficient regulatory support, accessible financing mechanisms, and investor awareness (Brändström et al., 2024). The absence of comprehensive CE policies and legislation creates uncertainty and confusion regarding rules and compliance requirements (Kazancoglu et al., 2020). Moreover, there are no specific CE regulations and laws regarding the end-of-waste. In addition to the high upfront investment costs associated with adopting circular practices, such as investing in new technologies or retrofitting structures, many other challenges are associated with adopting circular practices. The digital gap and the skills gap are also notable barriers. Building design lacks adequate information, such as detailed material data, which makes end-of-life planning difficult. Stakeholders may lack the necessary knowledge or skills to adopt certain technologies like BIM effectively, and there is a general need for more standardization in areas like material passports to improve traceability and trust. Implementing technologies also require specialized hardware, software, and training, which can be a barrier for smaller firms.

6 Strategic enablers and policy imperatives

In order to achieve construction CBM, strategic enablers and targeted policy imperatives must be in place (Brändström et al., 2024). Coordinating policy, finance, and technology will help achieve this goal. To achieve this, construction policy frameworks and procurement standards must incorporate CBMs (Hina et al., 2022). The government drives CBM by providing incentives and setting clear guidelines. The government can incentivize businesses and consumers to adopt CBM (AlJaber et al., 2023). Strict regulations and laws can ensure professionals adhere to set targets and regulations. Legislation based on CE can set standards for the design, construction, operation, and use of reused and recycled materials, energy efficiency, and waste management.

For example, the European Union is revising the Construction Product Regulation to establish a harmonized framework that includes digital solutions and gradually embeds extended producer responsibility in sectors like cement and steel. Several policy documents, such as the revised Energy Performance of Buildings Directive (EPBD), explicitly refer to tools like Digital Building Logbooks (DBLs) to promote CE principles throughout the building lifecycle and outline concepts such as building renovation passports. A bill of materials could improve the accuracy of DBLs and make them more relevant to policy (De Wolf et al., 2024).

CBM innovation also requires aligning financial incentives and tax reforms. It has been widely recognized that financial incentives are important enablers of CE in overcoming several obstacles. Implementing sustainable practices, often linked to CBMs, can also lead to cost savings in building operations and construction phases through full digitalization. (Hina et al., 2022; Prochazkova et al., 2021).

Finally, leveraging digital tools, particularly Building Information Modeling (BIM) and digital twins, is essential to support CBMs. Digital transformation holds great potential for the transition to a circular economy. BIM is crucial for circularity, facilitating detailed exploration of circular operations across the lifecycle and providing necessary information integration and continuity (De Wolf et al., 2024; Norouzi et al., 2021). BIM is a powerful enabler capable of mitigating a wide range of CE barriers.

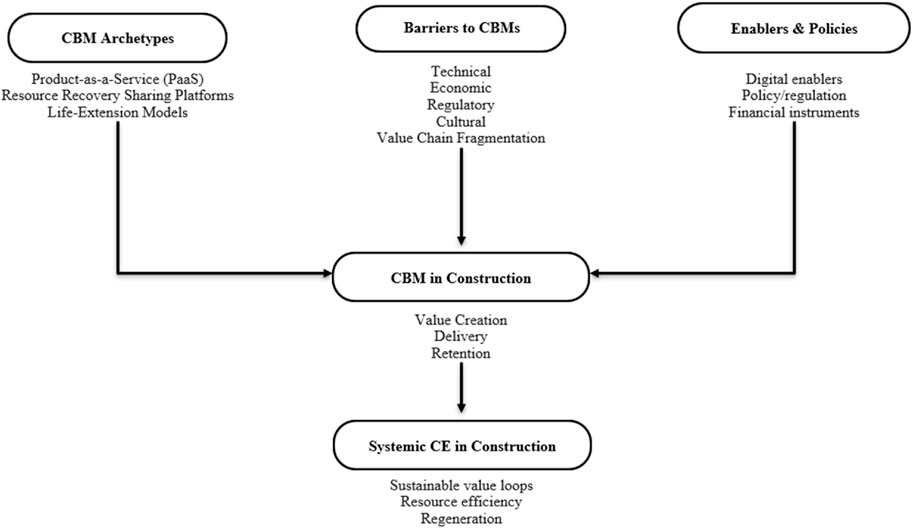

In order to achieve zero-carbon buildings and support reverse supply chains, scanning technologies and BIM technologies are needed. Components can be reused or refurbished with these tools throughout their lifecycles (De Wolf et al., 2024). To consolidate these insights, Figure 1 presents a conceptual framework positioning CBM archetypes, barriers, and enablers. These interactions drive value creation and retention, ultimately supporting systemic circular economy outcomes such as sustainable value loops, efficiency, and regeneration.

7 Conclusion and opinion reinforcement

A paradigm shift from a traditional linear model in the construction industry to a sustainable and regenerative model is urgently needed. However, this transition is hindered by a fundamental lack of business logic regarding CE within the fragmented structure and conservative industry culture. CE is a promising approach to preserving finite resources and reducing environmental impact, yet the sector’s current implementation remains largely superficial. However, these efforts fail to address the deeper transformations needed. Scalable and meaningful circularity cannot be achieved through technical interventions alone; rather, it can be achieved by adopting CBMs. CBMs redefine value creation, delivery, and retention in the construction industry. CBMs operationalize CE principles across the project lifecycle, from Product-as-a-Service and resource recovery platforms to life-extension strategies and digital tools like Building Information Modeling (BIM).

In the absence of CBMs, the pursuit of CE in construction risks becoming fragmented, uncoordinated, and ultimately non-sustainably on a large scale, failing to go beyond niche projects into a sustainable, large-scale effort. However, a broad adoption of CBMs faces significant obstacles, including structural inertia, fragmented value chains, outdated procurement practices, and a lack of financial and regulatory support. A circular transformation of construction must be anchored in business model innovation, whether academic, industrial, or policy-driven, so that circularity is not just a practice but the underlying logic for the industry.

8 Final thoughts

The discussion presented in this article shows that a circular business model in construction can be understood as the value logic that sustains resources across the building lifecycle by moving beyond one-off transactions and linear material use. Such models emphasize product-as-a-service, modular and adaptable design, selective deconstruction, and digital traceability through BIM and material passports. In doing so, CBMs create new revenue structures, foster long-term collaborations, and reshape procurement practices to embed circularity in everyday operations. They are particularly relevant in modular projects, renovation and deconstruction activities, and service-based contracts. Framed in this way, CBMs provide a consolidated concept that links barriers, enablers, and sector practices into a coherent pathway for advancing the circular economy in construction.

Author contributions

SS: Writing – original draft, Validation, Conceptualization, Writing – review and editing. SH: Investigation, Writing – review and editing. SA: Writing – review and editing, Supervision, Methodology, Writing – original draft, Validation, Conceptualization, Resources.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

The authors gratefully acknowledge UNITAR International University for their financial support in covering the APC for this study.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akanbi, L. A., Oyedele, L. O., Akinade, O. O., Ajayi, A. O., Davila Delgado, M., Bilal, M., et al. (2018). Salvaging building materials in a circular economy: a BIM-based whole-life performance estimator. Resour. Conservation Recycl. 129, 175–186. doi:10.1016/j.resconrec.2017.10.026

AlJaber, A., Martinez-Vazquez, P., and Baniotopoulos, C. (2023). Barriers and enablers to the adoption of circular economy concept in the building sector: a systematic literature review. Buildings 13 (11), 2778. doi:10.3390/buildings13112778

Brändström, J., Jazairy, A., and Roos Lindgreen, E. (2024). Barriers to adopting circular business models: a cross-sectoral analysis. Bus. Strategy Environ. 33 (5), 4331–4350. doi:10.1002/bse.3653

De Wolf, C., Çetin, S., and Bocken, N. M. (2024). A circular built environment in the digital age. Springer Nature. Available online at: https://library.oapen.org/handle/20.500.12657/86890.

Geissdoerfer, M., Pieroni, M. P. P., Pigosso, D. C. A., and Soufani, K. (2020). Circular business models: a review. J. Clean. Prod. 277, 123741. doi:10.1016/j.jclepro.2020.123741

Guerra, B. C., Shahi, S., Mollaei, A., Skaf, N., Weber, O., Leite, F., et al. (2021). Circular economy applications in the construction industry: a global scan of trends and opportunities. J. Clean. Prod. 324, 129125. doi:10.1016/j.jclepro.2021.129125

Han, Y., Shevchenko, T., Yannou, B., Ranjbari, M., Shams Esfandabadi, Z., Saidani, M., et al. (2023). Exploring how digital technologies enable a circular economy of products. Sustainability 15 (3), 2067. doi:10.3390/su15032067

Heisel, F., and Rau-Oberhuber, S. (2020). Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster, 243.118482

Hina, M., Chauhan, C., Kaur, P., Kraus, S., and Dhir, A. (2022). Drivers and barriers of circular economy business models: where we are now, and where we are heading. J. Clean. Prod. 333, 130049. doi:10.1016/j.jclepro.2021.130049

Jayakodi, S., Senaratne, S., and Perera, S. (2024). Circular economy business model in the construction industry: a systematic review. Buildings 14 (2), 379. doi:10.3390/buildings14020379

Kazancoglu, I., Kazancoglu, Y., Yarimoglu, E., and Kahraman, A. (2020). A conceptual framework for barriers of circular supply chains for sustainability in the textile industry. Sustain. Dev. 28 (5), 1477–1492. doi:10.1002/sd.2100

Kerin, M., and Pham, D. T. (2020). Smart remanufacturing: a review and research framework. J. Manuf. Technol. Manag. 31 (6), 1205–1235. doi:10.1108/jmtm-06-2019-0205

Mackenbach, S., Zeller, J. C., and Osebold, R. (2020). A roadmap towards circularity-modular construction as a tool for circular economy in the built environment. IOP Conf. Ser. Earth Environ. Sci. 588 (5), 052027. doi:10.1088/1755-1315/588/5/052027

Mason, R. E., Craine, J. M., Lany, N. K., Jonard, M., Ollinger, S. V., Groffman, P. M., et al. (2022). Evidence, causes, and consequences of declining nitrogen availability in terrestrial ecosystems. Science 376 (6590), eabh3767. doi:10.1126/science.abh3767

Mohapatra, S., Roy, S., Upadhyay, A., and Kumar, A. (2024). Circular value creation through environmental entrepreneurship initiatives: a case-based exploration. Bus. Strategy Environ. 33 (5), 3811–3831. doi:10.1002/bse.3682

Norouzi, M., Chàfer, M., Cabeza, L. F., Jiménez, L., and Boer, D. (2021). Circular economy in the building and construction sector: a scientific evolution analysis. J. Build. Eng. 44, 102704. doi:10.1016/j.jobe.2021.102704

Oecd (2019). “An OECD learning framework 2030,” in The future of education and labor. Editors G. Bast, E. G. Carayannis, and D. F. J. Campbell (Springer International Publishing), 23–35. doi:10.1007/978-3-030-26068-2_3

Perotti, F. A., Dhir, A., Ferraris, A., and Kliestik, T. (2024). Investigating digital technologies' implementation in circular businesses: evidence from the going circular path. J. Manag. & Organ. 30 (3), 421–451. doi:10.1017/jmo.2023.60

Prochazkova, Z., Jaca, C., Rovirás, J., and Pich-Aguilera, F. (2021). “Circular business models for construction products,” in The framework of the CE in construction sector, focused on the use and end-of-life phase of their life cycle.

Regúlez, B., Faria, D. M. V., Todisco, L., Fernández Ruiz, M., and Corres, H. (2023). Sustainability in construction: the urgent need for a new ethics. Struct. Concr. 24 (2), 1893–1913. doi:10.1002/suco.202200406

Shahidi Hamedani, S., Aslam, S., Hamedani, S. S., and Natarajan, V. K. (2025a). Transforming sustainability with digital innovation: enhancing circular economy practices for SDG 12. Conscientia Beam 13 (3), 1080–1098.

Shahidi Hamedani, S., Aslam, S., and Shahidi Hamedani, S. (2025b). AI in business operations: Driving urban growth and societal sustainability. Front. Artif. Intell. 8, 1568210.

Tan, J., Tan, F. J., and Ramakrishna, S. (2022). Transitioning to a circular economy: a systematic review of its drivers and barriers. Sustainability 14 (3), 1757. doi:10.3390/su14031757

WBCSD (2023). Circ. Built. Environ. | WBCSD. Available online at: https://www.wbcsd.org/actions/circular-built-environment/.

WorldBank (2021). World Bank group—International development, poverty and sustainability. Available online at: https://www.worldbank.org/ext/en/home.

Yang, M., Evans, S., Vladimirova, D., and Rana, P. (2017). Value uncaptured perspective for sustainable business model innovation. J. Clean. Prod. 140, 1794–1804. doi:10.1016/j.jclepro.2016.07.102

Keywords: building information modeling (BIM), circular business models (CBM), circulareconomy, sustainability, construction sector, product-as-a-service (PaaS)

Citation: Shahidi Hamedani S, Hamedani SS and Aslam S (2025) Advancing the circular economy in construction through circular business models. Front. Built Environ. 11:1629769. doi: 10.3389/fbuil.2025.1629769

Received: 16 May 2025; Accepted: 22 September 2025;

Published: 03 October 2025.

Edited by:

Paulo Santos, University of Coimbra, PortugalReviewed by:

Tomasz J. Nitkiewicz, Częstochowa University of Technology, PolandCopyright © 2025 Shahidi Hamedani, Hamedani and Aslam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sarfraz Aslam, U2FyZnJhei5hc2xhbUB1bml0YXIubXk=

Sharareh Shahidi Hamedani

Sharareh Shahidi Hamedani Shervin Shahidi Hamedani

Shervin Shahidi Hamedani Sarfraz Aslam

Sarfraz Aslam