- 1Department of Materials and Energy Sciences and Engineering, Nelson Mandela African Institution of Science and Technology, Arusha, Tanzania

- 2Department of Civil and Irrigation Engineering, Mwalimu Julius K. Nyerere University of Agriculture and Technology, Musoma, Tanzania

- 3Water Infrastructure and Sustainable Energy Futures (WISE-Futures) African Centre of Excellence, The Nelson Mandela African Institution of Science and Technology, Arusha, Tanzania

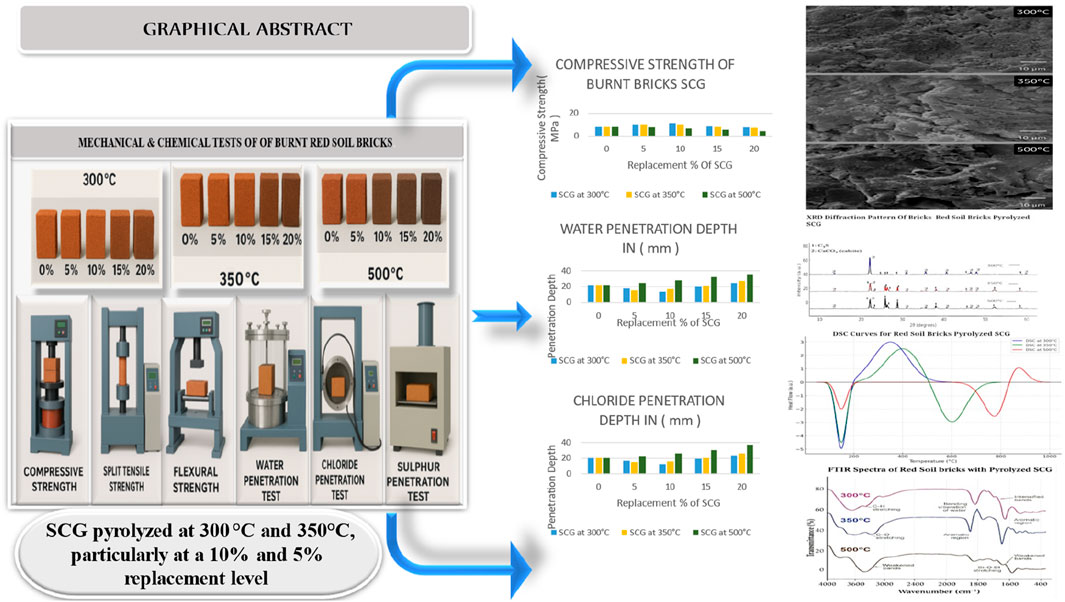

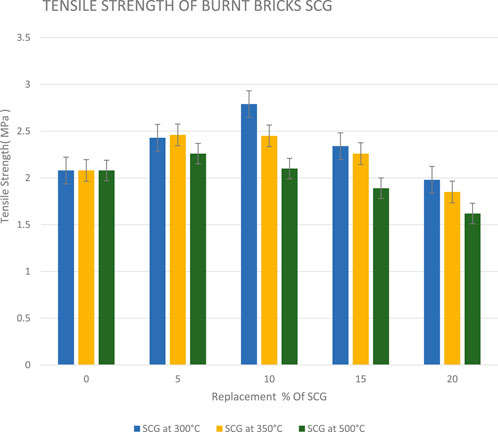

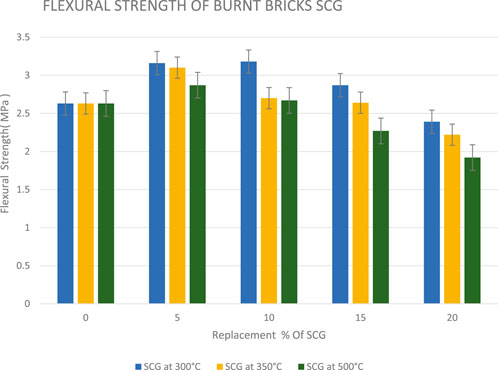

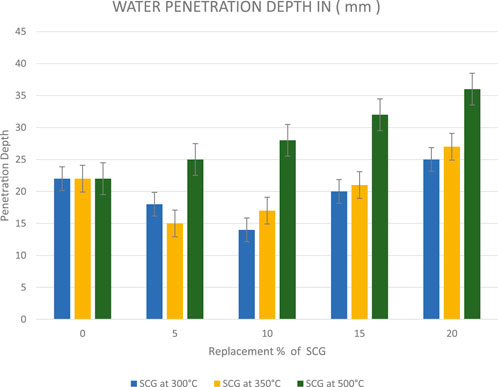

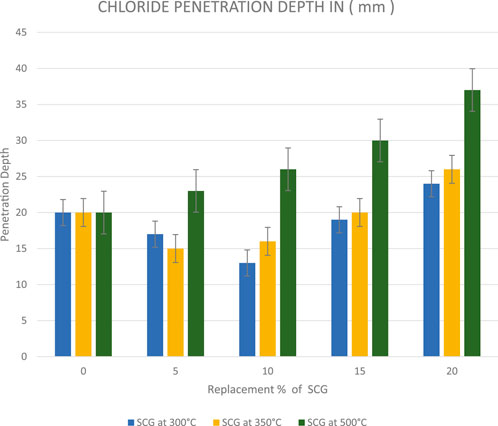

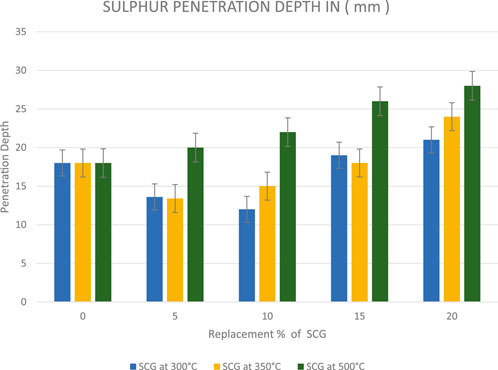

This paper investigates the application of circular economy principles by recycling spent coffee grounds (SCG) to produce coffee ash biochar (CAB), which is then used in the creation of burnt red soil bricks (BRSB) fired at temperatures between 900 °C and 1,100 °C, with 10% Montmorillonite as an additive (Al-Hasani, 2024; Cano and Reyes-Vallejo and Sánchez-Albores and Sebastian and Cruz-Salomón and d. Hernández-Cruz and et al., Sustainability, 2025, 17(1), 99; Chop, Investigation of Coal Combustion Residuals for Ceramic Applications and Production, 2024; Chung et al., Waste and Biomass Valorization, 2021, 12, 6273–6291; George, Electrical and mechanical characteristics of carbonaceous composites, 2023; Goswami and Kushwaha and Kafle and Kim, Catalysts, 2022, 12(8), 817). Comprehensive comparisons were made using coffee ash pyrolyzed at temperatures of 300 °C, 350 °C, and 500 °C, as substitutes for red soil at replacement levels of 5%, 10%, 15%, and 20%. The results indicated a decreasing trend in the mechanical properties of the burnt red soil bricks with increasing coffee ash content. Under optimal water-cement (w/c) ratios, the compressive strength (CS) of red soil bricks containing 5% SCG increased by 49.7% compared to the control when pyrolyzed at 350 °C. For bricks with 10% SCG, compressive strength improved by 53.5%, while flexural strength (FS) increased by 66.1% and splitting tensile strength (TS) rose by 38.4% when pyrolyzed at 300 °C. Additionally, the study found significant reductions in water, chloride, and sulfur penetration by 41.5%, 44.4%, and 34.3%, respectively, indicating improved durability and resistance to environmental factors. The water permeability coefficient remained relatively consistent across samples. This innovative approach addresses the disposal challenges of spent coffee grounds while benefiting both the economy and the environment. This study demonstrates the feasibility of incorporating SCG into burnt red soil bricks and examines the impact of SCG on their performance. Experimental results were analyzed through range analysis and analysis of variance to identify optimal combinations for varying performance requirements. Microstructural evaluations were performed using Scanning Electron Microscopy (SEM), X-ray Diffraction (XRD), Fourier Transform Infrared Spectroscopy (FTIR), and Differential Scanning Calorimetry (DSC) techniques (Singh and Patel, Journal of Material Cycles and Waste Management, 2025, 27(1), 170–192). These analyses provided insights into the structural integrity and bonding mechanisms within the composite materials. The findings suggest that SCG pyrolyzed at 300 °C and 350 °C, particularly at a 10% and 5% replacement level, delivers the best mechanical and chemical performance (Hanfi and Saftah and Alsufyani and Alqahtani and Mahmoud, Radiation Physics and Chemistry, 2025, 226; Mohammed and Joy and Zahid and Rafid, Journal of Materials in Civil Engineering, 2025, 37(5)). The study highlights the environmental benefits of using spent coffee grounds (SCG) in red soil brick manufacturing, reducing landfill waste and carbon emissions. This approach promotes resource efficiency and sustainable construction. Future work will focus on durability and scalability for industrial applications.

1 Introduction

The global challenge of waste management has prompted the exploration of innovative and sustainable solutions, particularly in the context of circular economy (CE) principles. Spent coffee grounds (SCG), a byproduct of the coffee industry, represent a significant waste stream, with millions of tons generated annually. Traditionally, these grounds are disposed of in landfills, contributing to environmental concerns such as greenhouse gas emissions and soil contamination. Recent studies have shown that SCG can be effectively repurposed through pyrolysis (PYR), a thermal decomposition process that converts organic material into coffee ash biochar (CAB). This transformation not only reduces waste volume but also produces a valuable material that can be utilized in various applications, including construction. In particular, pyrolyzed SCG has gained attention as a potential substitute for cement in concrete production (Abdellaoui, 2024, Al-Hasani, 2024).

Tanzania is a significant coffee producer, with an estimated annual production of approximately 81,500 metric tonnes of coffee beans in the 2022/23 season, marking a 22% increase from the previous year’s 66,605 tonnes. Given that spent coffee grounds constitute about 65% of the weight of processed green coffee beans, this translates to an estimated 52,975 metric tonnes of SCG generated annually in the country. This substantial volume of organic waste presents both environmental challenges and opportunities for valorization. Innovative applications, such as incorporating SCG into construction materials, offer sustainable solutions to manage this waste stream effectively.(The Citizen, PubMed Central).

This research focuses on the incorporation of coffee ash biochar into the production of burnt bricks (BRSB), an essential building material. By substituting varying percentages of cement with coffee ash, we aim to evaluate the mechanical properties, permeability, and durability of the resulting bricks.

Additionally, 10% Montmorillonite is used as an additive to enhance the mixture (Gupta et al., 2022; Lin et al., 2021; Muñoz Velasco et al., 2016; Nasr et al., 2023; Nazir et al., 2023; Parthiban, 2025; Perera et al., 2024). Previous investigations have indicated that the optimal pyrolysis temperature for enhancing the properties of SCG is around 300 °C–350 °C. At these temperatures, the biochar retains beneficial characteristics, potentially improving the performance of construction materials (Pontremoli, 2024; Saeli et al., 2023; Tingting et al., 2023; Uysal-Unalan et al., 2024).

Through a series of orthogonal tests, this study aims to determine the effects of different coffee ash replacement levels on the performance of burnt bricks. We hypothesize that incorporating SCG will not only improve the mechanical properties of the bricks but also contribute to sustainable construction practices by reducing the reliance on traditional materials (Zango et al., 2023). This paper seeks to explore the feasibility of using pyrolyzed SCG as a viable alternative in burnt brick production, thus aligning with the goals of sustainability and resource efficiency in the construction industry.

2 Material preparation and methodology

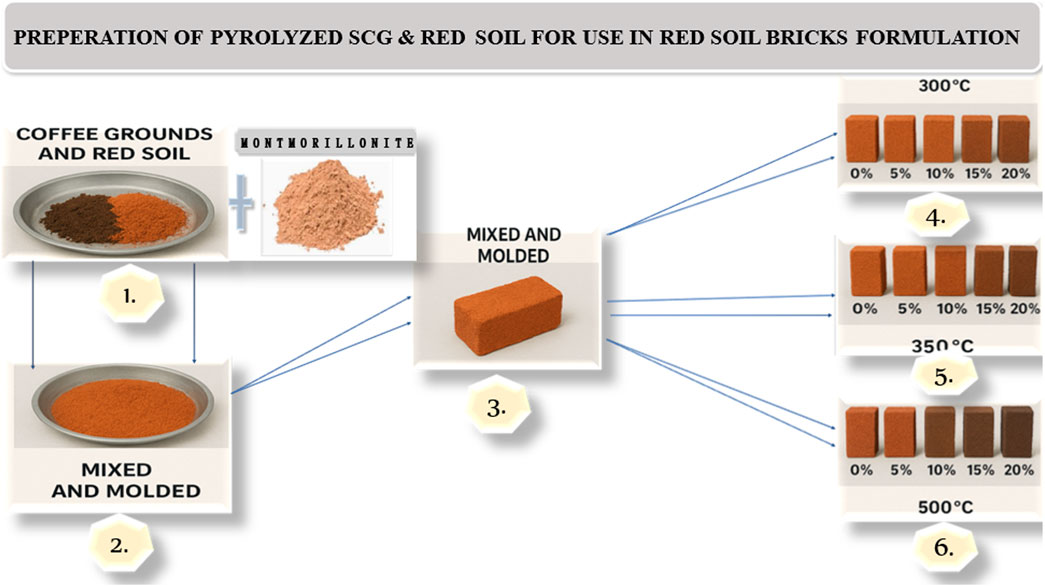

This section outlines the detailed process of material selection, preparation, and the experimental procedures adopted in evaluating the performance of bricks incorporating spent coffee grounds (SCG) pyrolyzed at varying temperatures.

2.1 Materials

The base material used in this study was natural clay, commonly used in traditional brick manufacturing. The additive material was spent coffee grounds (SCG), collected from local coffee shops. The SCG was thoroughly washed to remove organic impurities and then dried at 105 °C for 24 h. The dried SCG was then subjected to pyrolysis at three different temperatures: 300 °C, 350 °C, and 500 °C, each for 2 h in a muffle furnace under an inert atmosphere. The pyrolyzed SCG was then ground to a fine powder to ensure uniform mixing with the clay matrix.

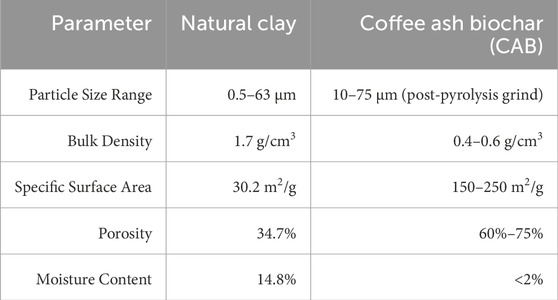

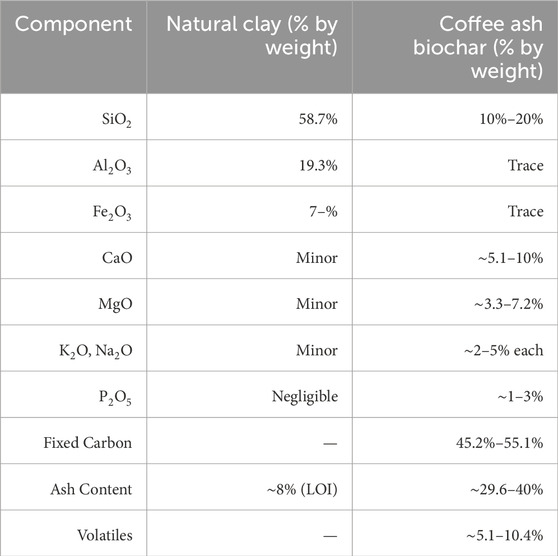

The physical parameters and chemical composition of the natural clay and the coffee ash biochar are presented in Tables 1, 2, respectively, while the proportions used for the mix design are summarized in Table 3. The experimental program, including the mechanical and durability tests conducted on the prepared samples (S1–S13) along with the corresponding reference standards, is detailed in Table 4.

2.1.1 Physical and chemical parameters of natural clay and coffee ash biochar

2.2 Mix proportions

Clay and pyrolyzed SCG were mixed in varying proportions with SCG replacing clay at 0%, 5%, 10%, 15%, and 20% by weight. The mixtures were dry blended to ensure homogeneity and then water was added to attain a workable consistency. Each batch was mixed thoroughly to prevent agglomeration and to distribute the SCG evenly throughout the mix.

2.3 Molding and firing

The mixed material was molded into standard brick dimensions using a manual press. The green bricks were air-dried for 48 h followed by oven drying at 105 °C for 24 h. The dried bricks were then fired in a kiln at a temperature of 900 °C for 6 h. This firing temperature was chosen to ensure adequate sintering and development of mechanical strength while minimizing energy consumption.

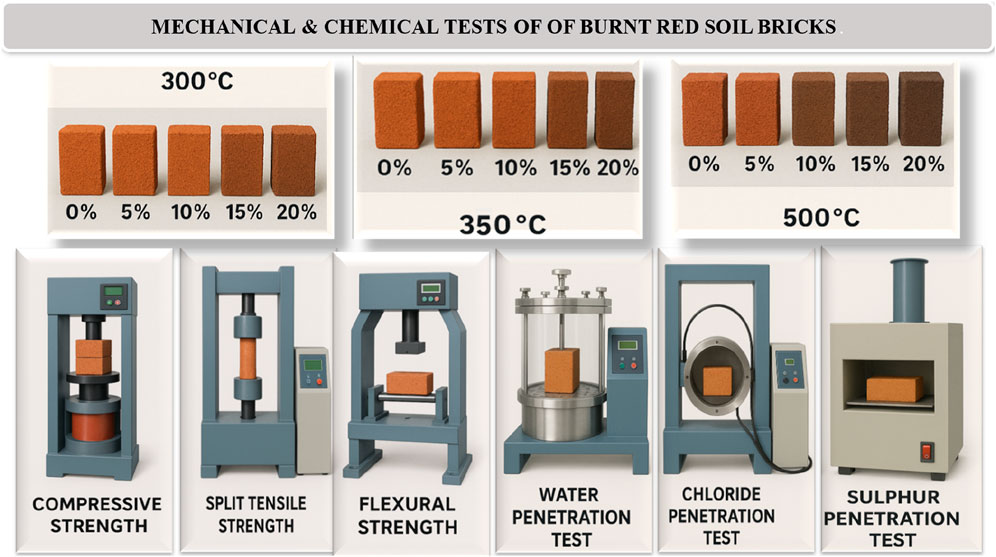

2.4 Testing procedures

The bricks were subjected to a series of tests to evaluate their mechanical and durability properties, ensuring a comprehensive assessment of their performance in construction applications.

2.4.1 Compression test

This was measured according to ASTM C67 using a universal testing machine. The compressive strength tests were crucial for determining the load-bearing capacity of the bricks, which is essential for structural integrity. The compressive strength (CS) of the bricks can be calculated using the formula:

where:

CS = Compressive Strength (MPa).

F = Maximum load applied (N).

A = Cross-sectional area of the brick (mm2).

This formula provides an essential measure of the bricks’ ability to withstand compressive forces, ensuring their suitability for construction applications.

2.4.2 Split tensile test

The split tensile test was conducted to evaluate the tensile strength of the bricks with a cylindrical shape, which is important for understanding their performance under tensile loading conditions. This test measures the resistance of the bricks to splitting when subjected to a tensile force.

The tensile strength (TS) can be calculated using the formula:

where:

TS = Tensile Strength (MPa).

P = Maximum load applied (N).

D = Diameter of the specimen (mm).

L = Length of the specimen (mm).

This formula helps determine the bricks’ ability to resist cracking and failure under tension, providing valuable he split flexural test was performed to assess the flexural strength of the bricks, which is critical for determining their performance under bending loads. This test measures how well the bricks can withstand deformation when subjected to flexural stress.

The flexural strength (FS) can be calculated using the formula:

where:

FS = Flexural Strength (MPa).

P = Maximum load applied at failure (N).

L = Length of the span between supports (mm).

b = Width of the specimen (mm).

d = Depth (height) of the specimen (mm).

This formula provides an important measure of the bricks’ ability to resist bending and cracking, ensuring their suitability for structural applications.

e insights into their structural integrity.

2.4.3 Water penetration test

Conducted by immersing the bricks in water for 24 h, this test measured the depth of water ingress. It provided insights into the bricks’ permeability, which is vital for assessing their suitability in environments where moisture resistance is a concern. The permeability (k) can be calculated using the formula:

where:

k = Permeability coefficient (m/s).

Q = Volume of water that permeated through the sample (m3).

L = Length of the sample (m).

A = Cross-sectional area of the sample (m2).

t = Time of exposure (s).

Δh = Change in hydraulic head (m).

This formula helps quantify the bricks’ ability to resist water ingress, informing their performance in moisture-prone conditions.

2.4.4 Chloride penetration

This was assessed by soaking the bricks in a sodium chloride solution and measuring the penetration depth using silver nitrate. Understanding chloride penetration is important for evaluating the durability of the bricks, particularly in coastal areas or environments where de-icing salts are used. The chloride penetration depth (D) can be calculated using the formula:

where:

D = Chloride penetration depth (mm).

C = Concentration of chloride in the solution (mol/L).

t = Time of exposure (s).

k = Diffusion coefficient of chloride (mm2/s).

A = Surface area of the brick (mm2).

This formula provides insights into the bricks’ susceptibility to chloride-induced deterioration, which is crucial for their long-term durability.

2.4.5 Sulfur penetration

Determined by immersing the bricks in a sulfate solution, this test observed visual degradation and identified chemical reaction zones. It is crucial for assessing the long-term performance of the bricks in sulfate-rich environments, which can lead to serious structural damage. The sulfate penetration depth (D) can be calculated using the formula:

where:

D = Sulfate penetration depth (mm).

C = Concentration of sulfate in the solution (mol/L).

t = Time of exposure (s).

k = Diffusion coefficient of sulfate (mm2/s).

A = Surface area of the brick (mm2).

This formula helps quantify the extent of sulfate-induced damage, providing insights into the bricks’ durability in challenging environmental conditions.

2.4.6 SEM analysis

Scanning Electron Microscopy (SEM) was used to observe the surface morphology and microstructural integrity of the bricks. This analysis provided detailed images that helped identify the effects of SCG incorporation on the microstructure, including bonding and porosity.

2.4.7 XRD analysis

X-ray Diffraction (XRD) was performed to identify crystalline phases and mineral transformations within the bricks. This analysis was essential for understanding how the incorporation of pyrolyzed coffee ash influenced the mineral composition and overall performance of the bricks.

2.4.8 FTIR analysis

Fourier Transform Infrared Spectroscopy (FTIR) was employed to examine functional groups and chemical bonding. This analysis helped elucidate the chemical interactions between the coffee ash and other components in the brick matrix, contributing to improved mechanical properties.

Each test was performed on at least three specimens per sample type to ensure reliability and statistical validity of the results. The data obtained from these tests were analyzed through range analysis and analysis of variance to determine the optimal combination of SCG content and pyrolysis conditions. This rigorous testing framework aims to support the hypothesis that incorporating pyrolyzed spent coffee grounds into burnt bricks enhances their mechanical properties while promoting sustainable construction practices.

3 Test setup and mix design tables

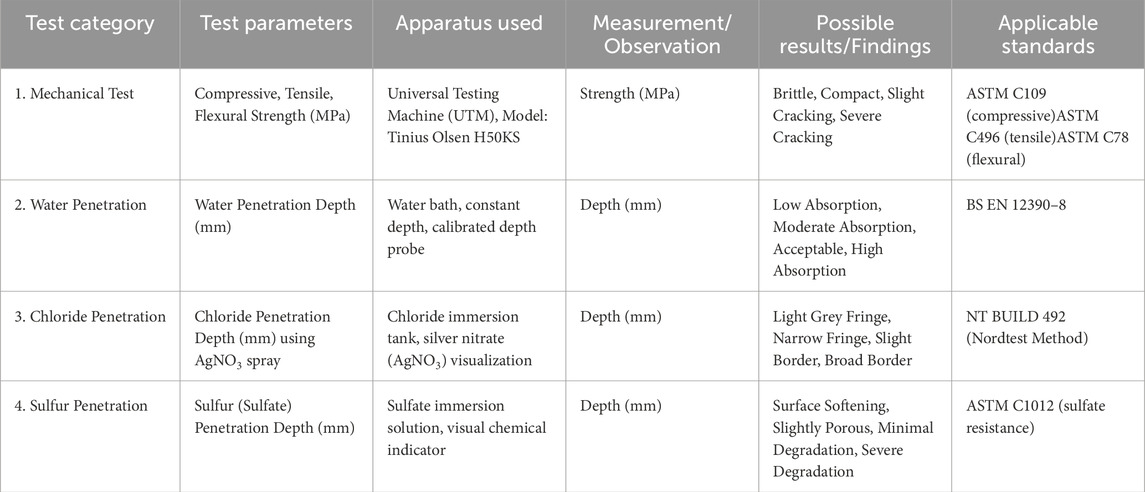

This section presents the mixing parameters, test measurements, and apparatus used for each experimental procedure.

3.1 Mix design parameters

4 Results and discussion

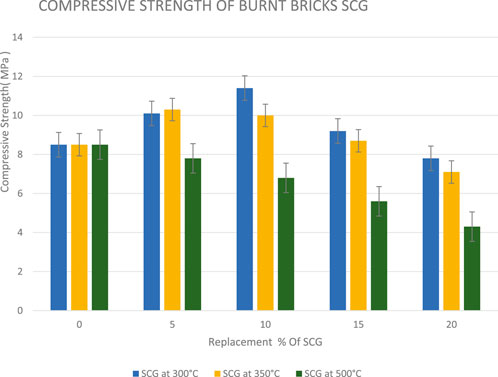

The incorporation of spent coffee grounds (SCG) as a partial substitute for red soil significantly enhanced the mechanical properties of burnt red soil bricks (BRSB). Bricks containing 5% SCG pyrolyzed at 350 °C exhibited a notable increase in compressive strength (CS) by 49.7%, as illustrated in Figures 1–3. Increasing the SCG content to 10% resulted in a further improvement of compressive strength by 53.5%, measured using the Tinius Olsen H50KS Universal Testing Machine (UTM).

Similarly, splitting tensile strength (TS) increased by 38.4% for bricks with 10% SCG pyrolyzed at 300 °C, as shown in Figure 4. The flexural strength (FS) of these bricks increased by 66.1%, demonstrated in Figure 5, indicating that SCG contributes to improved ductility and toughness of the burnt red soil bricks.

This enhancement in mechanical properties can be attributed to several factors. First, the unique porous structure of Coffee Ash Biochar (CAB) allows for improved bonding between the binder and aggregates within the brick matrix. This interlocking mechanism enhances load distribution, leading to increased CS and FS. The presence of micro-pores in the biochar also aids in moisture retention, which can improve the hydration process of the cement, further strengthening the brick.

Second, the thermal stability achieved during pyrolysis (PCG) transforms organic compounds in SCG into carbonaceous materials that reinforce the brick’s structure (Zango et al., 2023). This transformation not only contributes to the overall strength but also enhances the durability of the bricks against environmental factors. As SCG is rich in carbon, its incorporation results in a denser material that can better withstand mechanical stresses and resist degradation over time.

Finally, the use of SCG promotes sustainability by reducing reliance on traditional raw materials, such as cement. The enhanced mechanical properties achieved through the addition of SCG mean that less cement can be used without compromising the strength of the bricks. This reduction not only lowers the carbon footprint of brick production but also aligns with Circular Economy (CE) principles, effectively turning waste into a valuable resource while addressing environmental concerns.

Permeability and Durability (Chemical Properties).

The study also assessed the durability of the SCG (Spent Coffee Grounds)-modified bricks through permeability tests, revealing a 41.5% reduction in water penetration as illustrated in Figure 6. This enhancement in impermeability is critical for preventing water ingress, which can lead to structural damage over time. Water infiltration can compromise the integrity of the bricks, leading to issues such as freeze-thaw cycles that weaken the material. By reducing water penetration, the longevity of the bricks is significantly improved, making them more suitable for various environmental conditions.

Furthermore, the bricks demonstrated significant reductions in chloride and sulfur penetration by 44.4% and 34.3%, respectively, as shown in Figures 7, 8. This indicates an improved resistance to chemical attacks. Notably, chloride penetration is critical because chlorides can cause corrosion of embedded steel reinforcements in concrete structures, compromising their durability and structural integrity. While sulfur can lead to sulfate attack, which deteriorates the material (Al-Hasani, 2024; Cano et al., 2025; Chop, 2024). The enhanced resistance to these chemical agents means that SCG-modified bricks can better withstand harsh conditions, such as coastal environments where salt exposure is prevalent, thereby extending their service life and reducing maintenance costs.

Overall, the findings suggest that incorporating SCG into burnt red soil bricks enhances both their mechanical performance and chemical durability, particularly at a 10% replacement level when pyrolyzed at 300 °C. This research supports the feasibility of using low-temperature pyrolyzed SCG in innovative building materials, paving the way for future exploration in industrial applications and long-term durability studies (Chung et al., 2021; George, 2023; Goswami et al., 2022; Gupta et al., 2022; Lin et al., 2021). The positive results indicate that SCG-modified bricks could become a sustainable alternative in construction, aligning with Circular Economy (CE) principles while addressing the pressing issue of waste management.

4.1 Compressive strength (MPa) of BRSB

4.2 Tensile strength (MPa) of BRSB

4.3 Flexural strength (MPa) of BRSB

4.4 Water Penetration Depth (mm) of BRSB

4.5 Chloride penetration depth (mm) of BRSB

(Lower is better–indicates higher durability).

4.6 Sulphur Penetration Depth (mm) of BRSB

(Lower is better–indicates greater chemical resistance).

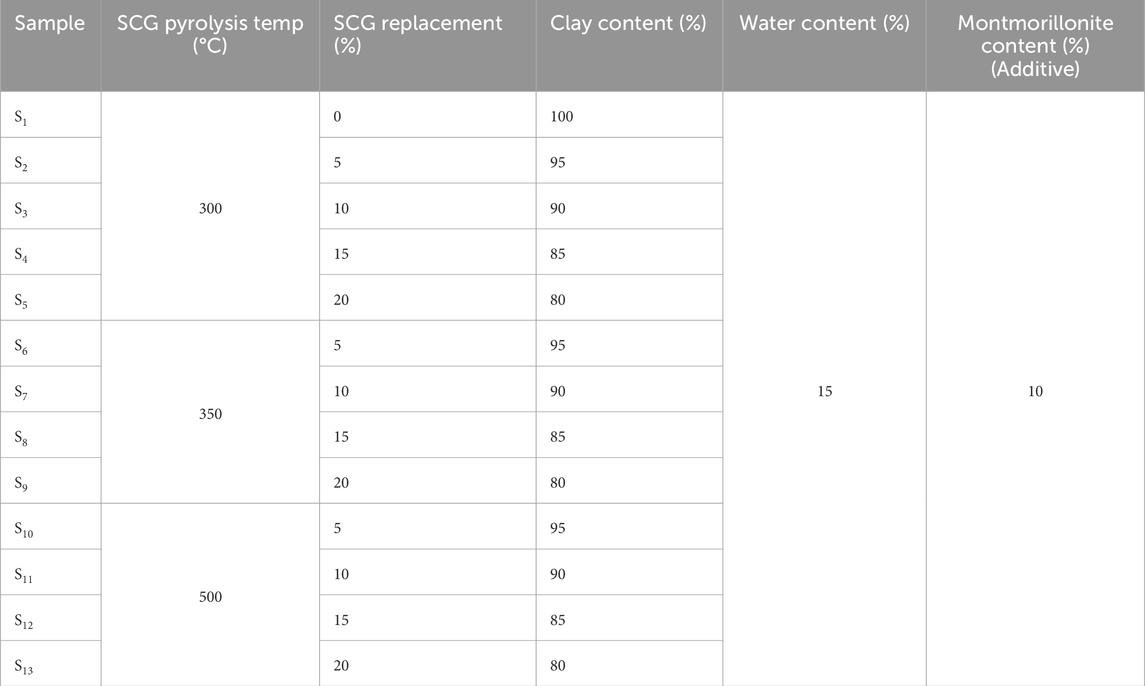

5 Microstructural and chemical analysis

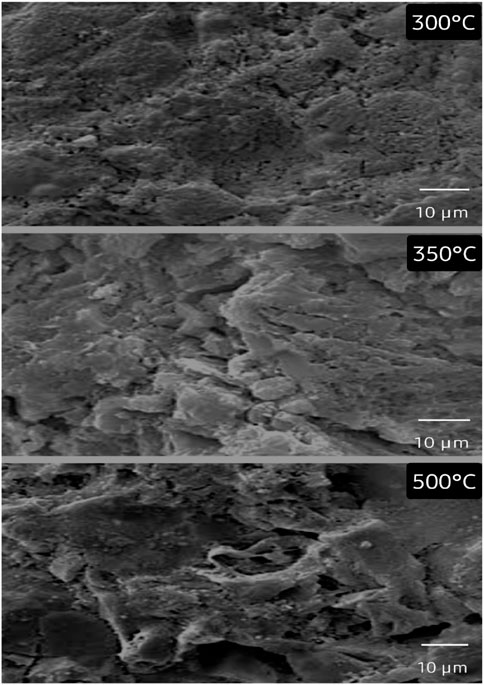

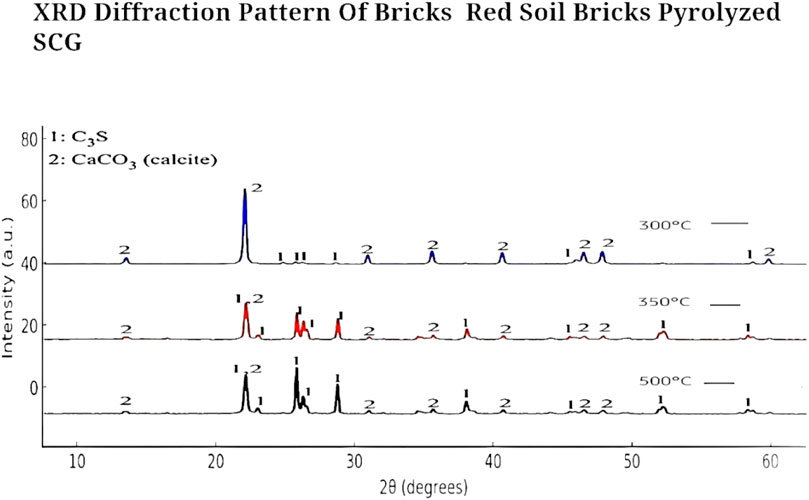

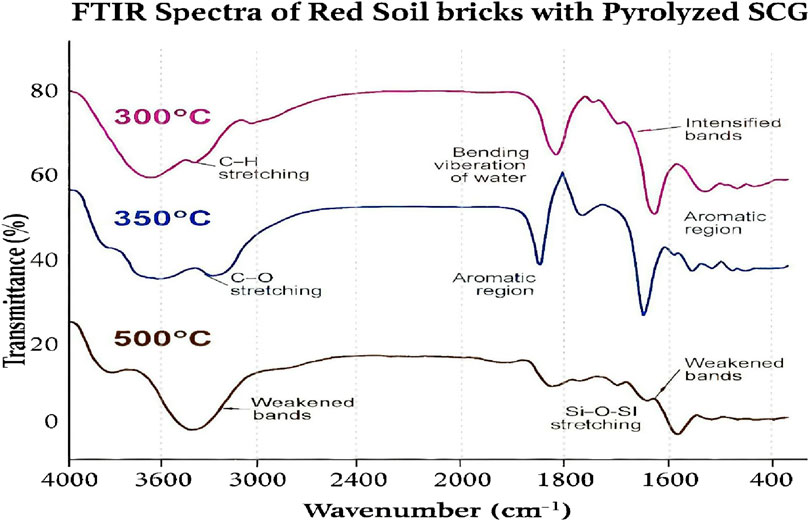

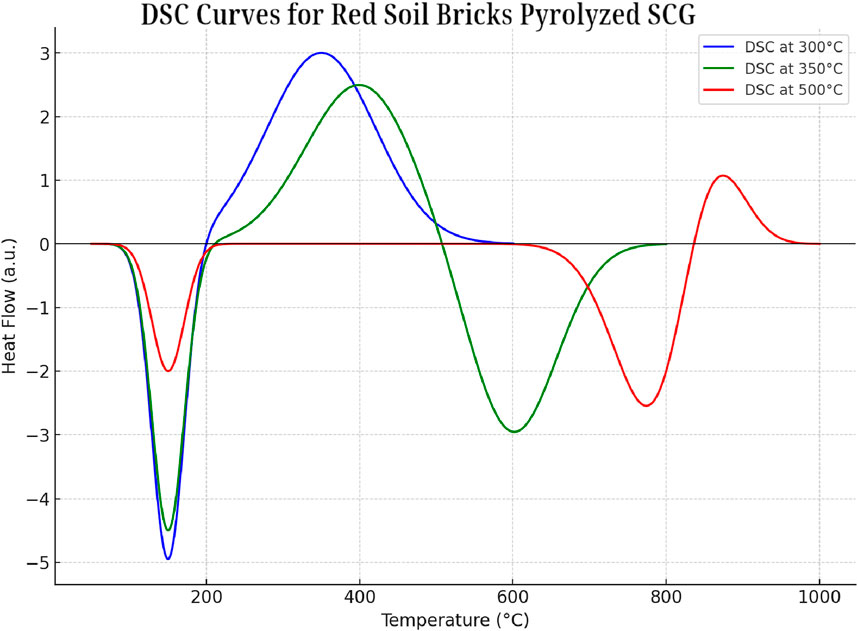

The selection of samples for microscopic and chemical analyses was guided by a systematic approach to ensure representative and meaningful insights into the material’s structural and chemical behavior. Microscopic analysis was performed using Scanning Electron Microscopy (SEM), as demonstrated in Figure 9. Chemical analyses included X-ray Diffraction (XRD), illustrated in Figure 10; Fourier Transform Infrared Spectroscopy (FTIR), shown in Figure 11; and Differential Scanning Calorimetry (DSC), explained in Figure 12.

First, samples were chosen based on their mechanical performance outcomes. Specifically, bricks that achieved the highest compressive, tensile, and flexural strength values—notably those incorporating 5%–10% coffee ash biochar (CAB) pyrolyzed at 300 °C and 350 °C—were prioritized, as these showed the most promising mechanical enhancements and were considered optimal formulations. These optimal samples provided a foundation to investigate the microstructural characteristics (such as particle bonding, porosity, and phase development) that contributed to their superior performance.

Second, control samples with 0% biochar replacement were included as reference baselines to assess the influence of CAB addition and pyrolysis effects. These controls allowed the research team to compare the chemical signatures and microstructural configurations between traditional clay bricks and biochar-enhanced bricks, highlighting specific changes induced by the CAB. Additionally, samples from the higher biochar replacement level (20%) and those pyrolyzed at the elevated temperature of 500 °C—which exhibited comparatively lower mechanical and durability performance—were deliberately selected to serve as contrast cases. This contrast allowed the study to capture how excessive replacement levels or over-pyrolysis negatively affected phase composition, bonding mechanisms, and overall material integrity.

Finally, selection was also informed by statistical significance and repeatability. Only samples showing consistent trends across replicates and demonstrating reproducible results under mechanical, permeability, and durability testing were advanced for microstructural and chemical characterization. This ensured that the detailed analyses were not influenced by outliers or anomalies, thereby providing robust, reliable, and generalizable insights into the underlying mechanisms governing the performance improvements or degradations observed. Through this multi-criteria approach—balancing mechanical performance, comparative baselines, contrasting extremes, and statistical robustness—the study ensured that the microscopic and chemical analysis provided a comprehensive, meaningful understanding of how coffee ash biochar transforms the structural and chemical landscape of burnt red soil bricks.

5.1 Scanning Electron Microscopy (SEM) analysis

5.1.1 300 °C and 350 °C

At these temperatures, Scanning Electron Microscopy (SEM) analysis using the JEOL JSM-IT300 SEM reveals a well-defined microstructure characterized by densely packed particles. The SEM images show that bricks incorporating spent coffee grounds (SCG) pyrolyzed at 300 °C and 350 °C exhibit a relatively dense microstructure with fewer visible pores. This morphology enhances mechanical interlocking, contributing to improved strength and stability (Sobhani and Balooch, 2025; Stempkowska, 2025; Sutcu et al., 2015; Tahwia et al., 2025; Werapun et al., 2025). The active pozzolanic reactions observed result in the formation of additional binding phases that fill voids and enhance the overall microstructure.

The presence of fine particulate matter in the SEM images can improve the material’s surface area and promote reactivity. This fine structure supports the development of a robust microstructure, enhancing the material’s durability (Chindaprasirt et al., 2021; Eliche-Quesada and Leite-Costa, 2016; Koçyiğit, 2022; Pamu et al., 2025). Additionally, the interconnected network of particles can improve the material’s resistance to crack propagation, making it suitable for various engineering applications where mechanical integrity is crucial.

Furthermore, the distinct particle shapes observed, along with the incorporation of 10% Montmorillonite, suggest that the material retains good workability, allowing for easier processing and application. Montmorillonite enhances the plasticity and binding properties of the Burnt Red Soil Bricks (BRSB), improving cohesion among particles and contributing to overall structural integrity. The microstructural features at these temperatures indicate a favorable environment for long-term performance, ensuring that the material can withstand environmental stressors over time. This combination of properties makes BRSB a viable option for sustainable construction practices.

5.1.2 500 °C

In contrast, SEM analysis of the 500 °C treatment reveals significant changes in microstructure. The images show a rougher surface and increased porosity, indicating a less cohesive matrix (Chindaprasirt et al., 2021; Eliche-Quesada and Leite-Costa, 2016; Koçyiğit, 2022; Pamu et al., 2025). This alteration suggests that the over-pyrolysis of organic matter negatively impacts particle bonding, leading to a notable reduction in particle connectivity. The increased porosity observed in the SEM images indicates that the thermal treatment may have led to the formation of voids, which can adversely affect the material’s strength and durability.

Additionally, the loss of finer particles may result in reduced surface area, impacting the material’s reactivity and bonding capabilities. The microstructural changes at this temperature highlight the potential for decreased performance under mechanical and environmental stress (Binici et al., 2010; Binici et al., 2009; Binici et al., 2012). The irregular shapes and sizes of particles also suggest that thermal decomposition may have disrupted the previously established particle network, resulting in a less effective load distribution within the material.

The overall analysis of SEM images provides critical insights into the material’s microstructural evolution across different temperatures (Binici et al., 2010; Beal et al., 2019). The densification observed at 300 °C and 350 °C correlates with improved mechanical properties, while the porosity and reduced connectivity at 500 °C indicate potential weaknesses. Understanding these microstructural changes is essential for predicting how the material will behave under various conditions.

Moreover, the morphology observed in the SEM images can inform decisions regarding processing methods and potential applications (Hanfi et al., 2025; Mohammed et al., 2025; Showaib and ELDeeb, 2025), 37. The favorable microstructure at lower temperatures suggests suitability for applications requiring high strength and stability, particularly in Burnt Red Soil Bricks (BRSB). The inclusion of 10% Montmorillonite enhances the bricks’ plasticity and binding capacity, further improving their structural integrity. However, the altered structure at higher temperatures may limit performance in demanding environments, as the loss of reactive components can compromise the overall durability of the BRSB. Thus, careful consideration of temperature during production is essential to maintain optimal properties (Singh and Patel, 2025; Soliman et al., 2025; Yavaş et al., 2025).

SEM analysis effectively complements other characterization techniques by providing detailed insights into the material’s microstructure. By examining the morphological changes at different temperatures, we can better understand the implications for mechanical properties and potential applications.

5.2 X-Ray Diffraction (XRD) analysis

5.2.1 300 °C and 350 °C

The analysis of Differential Scanning Calorimetry (DSC) and X-ray Diffraction (XRD) at 300 °C and 350 °C reveals critical insights into the thermal behavior and structural integrity of burnt red soil bricks (BRSB) enhanced by pyrolyzed spent coffee grounds (SCG).

At 300 °C, the DSC curve exhibits a notable endothermic peak, signifying the evaporation of both free and bound water. This thermal event is vital for establishing initial stability and promoting the densification of BRSB. The subsequent exothermic peaks correlate with the oxidation of residual organic compounds from SCG, facilitating the formation of secondary mineral phases that improve the microstructure and bonding mechanisms of the bricks.

XRD analysis at this temperature reveals intensified peaks, indicating active pozzolanic reactions. The presence of silicate minerals at 22° (2θ) and 26° (2θ) enhances the material’s ability to react with calcium hydroxide, improving strength and durability (Abdellaoui, 2024; Biswas et al., 2024). Additionally, the presence of calcium silicate (C3S) and calcite (CaCO3) contributes to the formation of a stable mineral framework, enhancing mechanical properties and the suitability for construction applications. Prominent crystalline peaks include 21.0° (2θ) for albite, 22.0° (2θ) for silicate minerals, 26.6° (2θ) for quartz, 29.4° (2θ) for calcite, and 31.0° (2θ) for gehlenite (Chung, 2021; Di Castro Silva, 2025; Imgirne et al., 2025). These structures indicate good thermal stability and promote additional binding phases, enhancing overall stability (Lawanwadeekul et al., 2024; Nascimento et al., 2025).

At 350 °C, XRD analysis continues to show intensified peaks, confirming ongoing pozzolanic reactions. Additional peaks at higher 2θ values include 33.0° (2θ) for dicalcium silicate (C2S), which enhances long-term strength development due to its slower hydration kinetics; 36.5° (2θ) for mullite, known for high thermal stability and strength; 50.0° (2θ) for anorthite, improving resistance to thermal shock; and 58.3° (2θ) for calcium aluminate (CA), crucial for enhancing bonding strength and resistance to sulfate attack.

The formation of these crystalline phases at both temperatures enhances microstructural development, leading to improved inter-particle bonding and better chemical resistance. Overall, these structural characteristics at 300 °C and 350 °C contribute to improved long-term performance regarding load-bearing capacity and longevity.

The analysis confirms that pyrolyzing SCG at 300 °C and 350 °C yields the most favorable thermal and structural transformations. These findings support the use of low-temperature pyrolyzed SCG in BRSB as a sustainable approach, effectively minimizing environmental impacts, promoting resource efficiency, and reducing landfill waste in line with circular economy and green construction strategies.

5.2.2 500 °C

At 500 °C, the DSC analysis reveals diminished moisture loss peaks, indicating that most moisture has been effectively removed in earlier stages. The XRD analysis shows crystalline peaks similar to those at lower temperatures but with weaker intensity, reflecting the impact of increased pyrolysis temperature on mineral formation. While the presence of crystalline phases is still noted, the overall structural integrity is compromised.

The prominent crystalline peaks at 500 °C include 22° (2θ) for silicate minerals, 26° (2θ) for quartz, 29.4° (2θ) for calcite, 31.0° (2θ) for gehlenite, 33.0° (2θ) for dicalcium silicate (C2S), 36.5° (2θ) for mullite, 50.0° (2θ) for anorthite, and 58.3° (2θ) for calcium aluminate (CA). However, the intensity of these peaks is notably weaker compared to those observed at 300 °C and 350 °C. This reduction can be attributed to the excessive degradation of organic matter at higher temperatures, which leads to a loss of carbonaceous bonding phases that are crucial for enhancing structural integrity.

Although the formation of crystalline phases at 500 °C contributes to some degree of microstructural development, the overall performance does not significantly improve compared to results at 300 °C and 350 °C. The diminished presence of key binding phases negatively impacts inter-particle bonding and chemical resistance, both essential for the material’s durability.

Furthermore, the potential for carbonate decomposition at higher temperatures could increase porosity, which may further compromise thermal stability if not adequately controlled. This highlights the importance of maintaining lower pyrolysis temperatures to optimize the balance between structural integrity and energy efficiency.

While pyrolysis at 500 °C yields some crystalline formations, the weaker intensity of these peaks compared to 300 °C and 350 °C indicates a decline in the effectiveness of the bonding mechanisms. These findings suggest that lower pyrolysis temperatures are more beneficial for achieving enhanced durability and mechanical properties in BRSB, aligning with sustainable construction practices and resource efficiency.

5.3 FTIR analysis

Fourier Transform Infrared Spectroscopy (FTIR) is a powerful analytical technique used to identify and characterize the chemical composition of materials based on their infrared absorption spectra. The Bruker Alpha FTIR instrument enhances this analysis by providing high-resolution spectra, yielding insights into the functional groups and molecular structure of substances. This is particularly useful in studying the properties of SCG bricks at varying temperatures. The following sections detail the findings from FTIR analysis conducted at three specific temperatures: 300 °C, 350 °C, and 500 °C.

5.3.1 300 °C and 350 °C

During the pyrolysis at 300 °C and 350 °C, significant chemical transformations occur, as evidenced by the Fourier Transform Infrared Spectroscopy (FTIR) analysis. Notably, the Si–O–Si stretching is observed at approximately 1,000 cm-1, indicating the formation of silicate networks (Biswas et al., 2024; Arnold, 2024; Ayrilmis, 2025; Capasso et al., 2025). This band signifies active pozzolanic reactions within the material, contributing to enhanced structural integrity.

Additionally, the presence of carbonate groups is highlighted by a band around 1,420 cm-1, which corresponds to CO32- vibrations. This band further confirms the chemical transformations taking place at these temperatures (Chung et al., 2021; Cavicchioli and Sant’Anna, 2022; Moujoud et al., 2023). The intensified bands indicate that the reactions enhance the binding properties and durability of the burnt red soil bricks (BRSB).

Moreover, another band near 875 cm-1 reinforces the presence of carbonate groups, emphasizing the complexity of the chemical changes occurring during the pyrolysis process. The analysis also reveals C–O stretching vibrations around 1,100 cm-1 and C–H bending vibrations near 1,450 cm-1, indicating the presence of organic compounds and their transformation throughout the process. Additionally, a significant band at 3,300 cm-1 corresponds to O–H stretching vibrations, reflecting the presence of hydroxyl groups that may play a role in the bonding and stability of the material (Pamu et al., 2025; Yavaş et al., 2025; Wronka et al., 2025).

These findings collectively demonstrate the beneficial effects of pyrolysis on the material’s properties, contributing to improved performance in construction applications.

5.3.2 Pyrolysis at 500 °C

Pyrolysis at 500 °C significantly influences the thermal behavior and structural properties of burnt red soil bricks (BRSB) enhanced by pyrolyzed spent coffee grounds (SCG). However, it is important to note that the effects at this temperature are generally weaker compared to those observed at 300 °C and 350 °C. At this temperature, several key changes occur:

The Differential Scanning Calorimetry (DSC) analysis at 500 °C indicates a continued endothermic process, primarily associated with the further breakdown of organic materials. This temperature facilitates the decomposition of complex organic compounds, leading to the release of volatile components.

FTIR analysis reveals crucial chemical transformations occurring at 500 °C. The Si–O–Si stretching remains prominent, indicating ongoing silicate network formation, which contributes to the material’s structural integrity. Throughout the analysis, the broad and intense O–H stretching band observed around 3,400–3,600 cm-1 signifies the presence of hydroxyl groups, such as those found in alcohols, phenols, or water. This suggests that the material is hydrophilic due to strong hydrogen bonding, which can enhance solubility, viscosity, and thermal properties.

Additionally, C–H stretching bands in the region of 3,100–2,800 cm-1 indicate the presence of organic components, suggesting amphiphilic behavior due to both hydrophilic and hydrophobic regions. The spectrum also reveals significant C=O stretching bands between 1750 and 1,650 cm-1, pointing to carbonyl groups that confer polar and reactive characteristics, enhancing the material’s potential for interaction with nucleophiles. Bending vibrations of water molecules, appearing around 1,630 cm-1, relate to the deformation of water, while vibrations in the aromatic regions (∼1,600–1,500 cm-1) suggest the presence of conjugated systems that contribute to structural rigidity and UV absorption.

At 500 °C, while there is a transition towards stable and compact phases, the overall enhancements in mechanical properties are weaker compared to 300 °C and 350 °C. The continued combustion of organics may lead to a decrease in some beneficial organic compounds that contribute to the material’s durability and strength. Consequently, the increased thermal stress can lead to microstructural changes that are not as favorable for long-term performance.

5.3.3 Comparison with cellulose, hemicellulose, and lignin

When comparing the FTIR spectra of the material with those of cellulose, hemicellulose, and lignin, notable distinctions arise. Cellulose typically shows a significant O-H stretching band at about 3,330 cm-1 and a strong C-O stretching band around 1,050 cm-1. Hemicellulose exhibits similar O-H characteristics, while lignin displays notable aromatic C-H and C=C stretching around 1,600 cm-1 but lacks distinctive bands in the 1,490–1,530 cm-1 range. This comparison suggests that the material shares certain features with cellulose but diverges from lignin and hemicellulose, indicating a unique chemical structure or modification that may enhance its reactivity and application potential.

While pyrolysis at 500 °C plays a role in enhancing the properties of burnt red soil bricks, its effects are generally weaker compared to those observed at 300 °C and 350 °C. The combined effects of thermal decomposition, chemical transformations, and microstructural refinement contribute to material performance, but with reduced efficacy, making these materials less optimal for eco-friendly construction solutions compared to those processed at lower temperatures.

5.4 DSC analysis

5.4.1 DSC analysis at 300 °C and 350 °C

The analysis of pyrolysis at 300 °C and 350 °C provides critical insights into the thermal behavior and structural integrity of burnt red soil bricks (BRSB) enhanced by pyrolyzed spent coffee grounds (SCG).

At 300 °C, the DSC curve reveals a pronounced endothermic peak between 100 °C and 200 °C, indicating the evaporation of free and bound water. This thermal event is vital for establishing initial stability and promoting the densification of BRSB. The subsequent exothermic peaks, observed from 200 °C to 500 °C, are associated with the oxidation of residual organic compounds from SCG. This process facilitates the formation of secondary mineral phases, which enhance the microstructure and bonding mechanisms of the bricks.

The improved microstructural refinement at this temperature is supported by Scanning Electron Microscopy (SEM) and Fourier Transform Infrared Spectroscopy (FTIR) analyses, which confirm better particle packing and the formation of binding gels. These gels help reduce pore connectivity, ultimately enhancing the durability and environmental resistance of the BRSB.

At 350 °C, the DSC curve continues to show similar moisture loss characteristics, with a strong endothermic peak around 100 °C–200 °C. Additionally, dihydroxylation reactions between 450 °C and 750 °C become evident, corresponding to the breakdown of hydroxyl groups in clay minerals. This reaction promotes the formation of more stable and compact phases, further supporting phase stabilization and enhanced bonding structures.

Moreover, the continuous combustion of organic materials at this temperature leads to the formation of amorphous phases, improving overall material integrity. This enhancement results in reduced water and chloride permeability, significantly improving the durability of the BRSB while maintaining low pyrolysis energy inputs. Such characteristics align with circular economy principles and sustainable construction practices.

In summary, pyrolyzing SCG at 300 °C and 350 °C yields favorable thermal and structural transformations, confirming the potential of these temperatures to enhance the performance and sustainability of burnt red soil bricks.

5.4.2 DSC analysis at 500 °C

At 500 °C, the DSC analysis revealed diminished moisture loss peaks, indicating that most moisture had been effectively removed in earlier stages. The curve showed carbonate decomposition between 700 °C and 900 °C, producing CO2 release, which can increase porosity and negatively impact thermal stability if not adequately controlled.

Although exothermic reactions observed indicated mullite phase formation, known for enhancing thermal resistance, the performance at higher pyrolysis temperatures (500 °C) did not significantly improve and even slightly declined compared to 300 °C and 350 °C. This can be attributed to the excessive degradation of organic matter, leading to reduced contribution from carbonaceous bonding phases.

Thus, while mullite and other crystalline phases promote long-term durability, the DSC data and performance tests suggest that higher pyrolysis temperatures may not be as energy-efficient or mechanically advantageous, especially considering the goals of reducing emissions and utilizing lower-energy pyrolysis processes in the circular economy approach.

The DSC analysis across the studied temperatures confirms that SCG pyrolyzed at 300 °C and 350 °C offers the most favorable thermal and structural transformations, leading to enhanced microstructural densification and reduced permeability. This supports the use of low-temperature pyrolyzed SCG in burnt red soil bricks as a viable and sustainable approach, minimizing environmental impacts, promoting resource efficiency, and reducing landfill waste, in accordance with circular economy and green construction strategies.

6 Conclusion

This study was conducted to investigate the potential of incorporating pyrolyzed spent coffee grounds (SCG) into burnt red soil bricks (BRSB) with 10% Montmorillonite as a stabilizing additive. The objective was to evaluate whether this approach could improve the mechanical strength, durability, and microstructural integrity of bricks while promoting sustainable material reuse under the principles of the circular economy.

The experimental findings confirmed that replacing red soil with 5%–10% SCG pyrolyzed at low temperatures (300 °C and 350 °C) significantly improved mechanical performance. Notably, compressive, flexural, and splitting tensile strengths increased compared to the control samples. In addition, durability indicators such as water, chloride, and sulfur penetration were substantially reduced, indicating improved resistance to environmental degradation.

Characterization techniques including Scanning Electron Microscopy (SEM), X-ray Diffraction (XRD), Fourier Transform Infrared Spectroscopy (FTIR), and Differential Scanning Calorimetry (DSC) provided further evidence of enhanced microstructural densification and pozzolanic activity in the bricks treated at 300 °C and 350 °C. These findings directly align with the study’s goals of optimizing brick performance using sustainable, locally available waste materials.

In summary, the results demonstrate that low-temperature pyrolyzed SCG, particularly at 10% replacement, offers a viable, eco-friendly alternative to conventional materials in brick production. This approach contributes to reducing construction-related emissions and landfill waste while enhancing material performance. Future research should focus on full-scale production, long-term durability assessment under field conditions, and cost-benefit analysis to support broader implementation in the construction industry.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

AH: Writing – review and editing, Writing – original draft. YJ: Writing – review and editing, Formal Analysis, Supervision.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the HEAT PROJECT of the Mwalimu Julius K. Nyerere University of Agriculture and Technology (MJNUAT). The aims of the HEAT Project are to strengthen the learning environment, ensure greater alignment of priority degree programs to labor market needs, and improve the management of the higher education system.

Acknowledgments

The authors would like to acknowledge the financial support provided by the HEAT PROJECT of the Mwalimu Julius K. Nyerere University of Agriculture and Technology (MJNUAT). The HEAT PROJECT is a capacity-building initiative co-funded by the World Bank (WB). Without its generous support, this research would not have been possible.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that Generative AI was used in the creation of this manuscript. I used to put statements in proper ENGLISH.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

SCG, Spent Coffee Grounds; PCG, Pyrolyzed Coffee Grounds; CAB, Coffee Ash Biochar; CE, Circular Economy; BRSB, Burnt Red Soil Bricks; XRD, X-ray Diffraction; FTIR, Fourier Transform Infrared Spectroscopy; DSC, Differential Scanning Calorimetry; SEM, Scanning Electron Microscopy; CS, Compressive Strength; TS, Tensile Strength; FS, Flexural Strength.

References

Abdellaoui, Y., Bougaa, I., Limami, H., Elboukili, G., Rahmani, A., and Khaldoun, A. (2024). “Analysis of spent coffee grounds as an additive in unfired clay bricks,” in AIP conference proceedings 3241, 020007. doi:10.1063/5.0247159

Al-Hasani, F. K. K. (2024). Physicochemical characteristics of crude holocellulose powder from date pits after in Vitro incubation with ruminal fluid. Sultan Qaboos University. doi:10.1007/s11250-024-04071-2

Arnold, L. L. (2024). Valorization of fired clay bricks debris (grog) using egg shell and coconut shell in the synthesis of an ecological compressed Earth blocks: microstructure and engineering properties. Sustain. Chem. Eng., 530–549. doi:10.37256/sce.5220245166

Ayrilmis, N. (2025). Use of pencil slat and graphite pencil shavings as reinforcing filler in thermoplastic composites. Wood Material Sci. and Eng., 1–11. doi:10.1080/17480272.2025.1234567

Beal, B., Selby, A., Atwater, C., James, C., Viens, C., and Almquist, C. (2019). A comparison of thermal and mechanical properties of clay bricks prepared with three different pore-forming additives: Vermiculite, wood ash, and sawdust. Environ. Prog. and Sustain. Energy 38 (6), 13150. doi:10.1002/ep.13150

Binici, H., Arocena, J., Kapur, S., Aksogan, O., and Kaplan, H. (2009). Microstructure of red brick dust and ground basaltic pumice blended cement mortars exposed to magnesium sulphate solutions. Can. J. Civ. Eng. 36 (11), 1784–1793. doi:10.1139/l09-103

Binici, H., Aksogan, O., Temiz, H., Kaplan, H., and Ulusoy, A. (2010). The use of fly ash and basaltic pumice as additives in the productionof clay fired brick in Turkey. Int. J. Mater. Res. 101 (7), 887–893. doi:10.3139/146.110349

Binici, H., Kapur, S., Arocena, J., and Kaplan, H. (2012). The sulphate resistance of cements containing red brick dust and ground basaltic pumice with sub-microscopic evidence of intra-pore gypsum and ettringite as strengtheners. Cem. Concr. Compos. 34 (2), 279–287. doi:10.1016/j.cemconcomp.2011.10.001

Biswas, S., Hossiney, N., Mohan, M. K., and Kumar, S. L. (2024). Valorisation of coffee husk as replacement of sand in alkali-activated bricks. Case Stud. Constr. Mater. 21, e03440. doi:10.1016/j.cscm.2024.e03440

Cano, F. J., Reyes-Vallejo, O., Sánchez-Albores, R. M., Sebastian, P. J., Cruz-Salomón, A., Hernández-Cruz, M. d. C., et al. (2025). Activated biochar from pineapple crown biomass: a high-efficiency adsorbent for organic dye removal. Sustainability 17 (1), 99. doi:10.3390/su17010099

Capasso, I., D’Angelo, G., del Río Merino, M., Campanile, A., Caputo, D., and Liguori, B. (2025). CDW-based geopolymers: pro and cons of using unselected waste. Polymers 17 (5), 570. doi:10.3390/polym17050570

Cavicchioli, A., and Sant’Anna, L. G. (2022). The production of protective earth-based mortars for earth constructions in southeastern Brazil during the 19th century coffee economy. An. do Mus. Paul. História Cult. Mater. 30, e12. doi:10.1590/1982-02672022v30e12

Chindaprasirt, P., Srisuwan, A., Saengthong, C., Lawanwadeekul, S., and Phonphuak, N. (2021). Synergistic effect of fly ash and glass cullet additive on properties of fire clay bricks. J. Build. Eng. 44, 102942. doi:10.1016/j.jobe.2021.102942

Chop, H. (2024). Investigation of coal combustion residuals for ceramic applications and production.

Chung, L. L. (2021). The utilisation of spent coffee grounds in manufacutring alkali-activated unfired clay bricks and cement bricks. Swinburne. doi:10.25916/sut.26280505.v1

Chung, L. L. P., Wong, Y. C., and Arulrajah, A. (2021). The application of spent coffee grounds and tea wastes as additives in alkali-activated bricks. Waste Biomass Valorization 12, 6273–6291. doi:10.1007/s12649-021-01453-7

Di Castro Silva, M. (2025). Mineralogical characterization of mortars in ancient Portuguese tile and embrechado restorations: the cases of maceió (AL) and salvador (BA). Int. J. Archit. Herit., 1–17. doi:10.1080/15583058.2025.2450442

Eliche-Quesada, D., and Leite-Costa, J. (2016). Use of bottom ash from olive pomace combustion in the production of eco-friendly fired clay bricks. Waste Manag. 48, 323–333. doi:10.1016/j.wasman.2015.11.042

George, J. (2023). Electrical and mechanical characteristics of carbonaceous composites. of Auckland: University.

Goswami, L., Kushwaha, A., Kafle, S. R., and Kim, B. S. (2022). Surface modification of biochar for dye removal from wastewater. Catalysts 12 (8), 817. doi:10.3390/catal12080817

Gupta, P., Gupta, N., and Dash, S. (2022). Biochar for sustainable environmental management. BioChar: applications for bioremediation of contaminated systems, 147.

Hanfi, M. Y., Saftah, A., Alsufyani, S. J., Alqahtani, M. S., and Mahmoud, K. (2025). Experimental investigation of fired clay bricks for gamma radiation shielding. Radiat. Phys. Chem. 226, 112245. doi:10.1016/j.radphyschem.2024.112245

Imgirne, A., Arkame, Y., Harrati, A., Moustapha, A., Tamri, T., Hassani, F. O., et al. (2025). Potential use of mint waste and bentonite clay in sustainable porous ceramic manufacturing. Euro-Mediterranean J. Environ. Integration 10, 1407–1423. doi:10.1007/s41207-024-00716-8

Koçyiğit, F. (2022). Thermo-physical and mechanical properties of clay bricks produced for energy saving. Int. J. Thermophys. 43 (2), 18. doi:10.1007/s10765-021-02951-5

Lawanwadeekul, S., Srisuwan, A., Phonphuak, N., and Chindaprasirt, P. (2024). Addition of spent coffee grounds and waste glass to enhance the physical–mechanical and thermal properties of fired clay bricks at reduced temperatures. Innov. Infrastruct. Solutions 9 (6), 206. doi:10.1007/s41062-024-01508-3

Lin, J.-Y., Kim, M., Lee, I., Kim, H., and Huang, C. P. (2021). Process optimization for the synthesis of ceramsites in terms of mechanical strength and phosphate adsorption capacity. Chemosphere 278, 130239. doi:10.1016/j.chemosphere.2021.130239

Mohammed, T. U., Joy, J. A., Zahid, C. Z. B., and Rafid, M. Z. (2025). Efficiency of clay-burnt brick fines as an internal curing agent for enhancing mechanical and durability properties of high-strength concrete. J. Mater. Civ. Eng. 37 (5), 04025121. doi:10.1061/jmcee7.mteng-19519

Moujoud, Z., Harrati, A., Manni, A., Naim, A., El Bouari, A., and Tanane, O. (2023). Study of fired clay bricks with coconut shell waste as a renewable pore-forming agent: technological, mechanical, and thermal properties. J. Build. Eng. 68, 106107. doi:10.1016/j.jobe.2023.106107

Muñoz Velasco, P., Mendívil, M. A., Morales, M. P., and Muñoz, L. (2016). Eco-fired clay bricks made by adding spent coffee grounds: a sustainable way to improve buildings insulation. Mater. Struct. 49, 641–650. doi:10.1617/s11527-015-0525-6

Nascimento, E. S. S., Oliveira, H. A. d., Santos, C. P. d., Gomes, M. d. A., Valerio, M. E. G., and Macedo, Z. S. (2025). Sustainable use of gypsum waste for applications in soil-cement bricks: mechanical, environmental, and durability performance. Ceram. (Basel). 8, 83. doi:10.3390/ceramics8030083

Nasr, Y., El Zakhem, H., Hamami, A., El Bachawati, M., and Belarbi, R. (2023). Comprehensive review of innovative materials for sustainable buildings’ energy performance. Energies 16 (21), 7440. doi:10.3390/en16217440

Nazir, G., Rehman, A., Hussain, S., Mahmood, Q., Fteiti, M., Heo, K., et al. (2023). Towards a sustainable conversion of biomass/biowaste to porous carbons for CO 2 adsorption: recent advances, current challenges, and future directions. Green Chem. 25 (13), 4941–4980. doi:10.1039/D3GC00636K

Pamu, Y., and Alugubelli, S. (2025). “Waste to wealth: a comprehensive review of agricultural waste in sustainable building materials,” in E3S web of conferences (EDP Sciences). doi:10.1051/e3sconf/202561603002

Perera, H., Gurunanthanan, V., Singh, A., Mantilaka, M., Das, G., and Arya, S. (2024). Magnesium oxide (MgO) nanoadsorbents in wastewater treatment: a comprehensive review. J. Magnesium Alloys 12, 1709–1773. doi:10.1016/j.jma.2024.05.003

Pontremoli, C. (2024). “Near infrared dyes for photovoltaics, green photonics and biological applications,” in XXII B-MRS meeting proceedings (Santos, SP, Brazil: Sociedade Brasileira de Pesquisa em Materiais).

Saeli, M., Batra, V. S., Singh, R. K., Tobaldi, D. M., and Labrincha, J. A. (2023). The coffee-house: upcycling spent coffee grounds for the production of green geopolymeric architectural energy-saving products. Energy Build. 286, 112956. doi:10.1016/j.enbuild.2023.112956

Showaib, E., and Eldeeb, I. (2025). Sustainable clay brick manufacturing: a review of mechanical properties, firing technologies, emissions, and control strategies.

Singh, R., and Patel, M. (2025). Mechanical, durability, and microstructural characteristics of rice-straw-ash-based clay bricks: a sustainable approach to utilize biomass-based power plant waste. J. Material Cycles Waste Manag. 27 (1), 170–192. doi:10.1007/s10163-024-02101-7

Sobhani, M., and Balooch, A. (2025). Fabrication of lightweight clay-based refractory bricks using recycled EPS polymer. Case Stud. Constr. Mater. 22, e04683. doi:10.1016/j.cscm.2025.e04683

Soliman, W., Ahmed, Y. M. Z., Ghitas, A., El‑Shater, A., and Shahat, M. A. (2025). Green building development utilising modified fired clay bricks and eggshell waste. Sci. Rep. 15 (1), 3367. doi:10.1038/s41598-025-87435-4

Stempkowska, A. (2025). Lightweight aggregates with a special microstructure for use in green roof design.

Sutcu, M., Alptekin, H., Erdogmus, E., Er, Y., and Gencel, O. (2015). Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr. Build. Mater. 82, 1–8. doi:10.1016/j.conbuildmat.2015.02.055

Tahwia, A. M., Abdellatief, M., Salah, A., and Youssf, O. (2025). Valorization of recycled concrete powder, clay brick powder, and volcanic pumice powder in sustainable geopolymer concrete. Sci. Rep. 15 (1), 11049. doi:10.1038/s41598-025-93598-x

Tingting, C., Haiou, Z., Yang, Z., Yingguo, W., Jian, W., Zhen, G., et al. (2023). Study on the microstructure and soil quality variation of composite soil with soft rock and sand. Open Chem. 21 (1), 20230119. doi:10.1515/chem-2023-0119

Uysal-Unalan, I., Sogut, E., Realini, C. E., Cakmak, H., Oz, E., Espinosa, E., et al. (2024). Bioplastic packaging for fresh meat and fish: current status and future direction on mitigating food and packaging waste. Trends Food Sci. and Technol. 152, 104660. doi:10.1016/j.tifs.2024.104660

Werapun, U., Thangprasert, A., Rakkapao, N., Wongpanich, J., Sirikitputtisak, T., Novikov, S., et al. (2025). Influence of cajuput leaf residue on the properties of lightweight expanded clay aggregate. Discov. Mater. 5 (1), 81–12. doi:10.1007/s43939-025-00259-x

Wronka, A., Del Valle Raydan, N., Robles, E., and Kowaluk, G. (2025). Coffee silverskin as a sustainable alternative filler for plywood: characterization and performance analysis. Materials 18 (7), 1525. doi:10.3390/ma18071525

Yavaş, A., Kalkan, Ş. O., Sütçü, M., and Gündüz, L. (2025). Recycling waste polyethylene foam into fired clay bricks: a sustainable solution for lightweight and thermally efficient building materials. Constr. Build. Mater. 473, 140967. doi:10.1016/j.conbuildmat.2025.140967

Keywords: coffee ash biochar, red soil bricks, pyrolysis, mechanical properties, microstructure, sustainability

Citation: Hepautwa AA and Jande YAC (2025) Mechanical, chemical performance, and microstructural behavior of montmorillonite-burnt red soil bricks incorporating coffee ash biochar. Front. Built Environ. 11:1632901. doi: 10.3389/fbuil.2025.1632901

Received: 21 May 2025; Accepted: 18 August 2025;

Published: 17 October 2025.

Edited by:

Mingxuan Shen, Guizhou University, ChinaCopyright © 2025 Hepautwa and Jande. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Amani Abdallah Hepautwa, aGVwYXV0d2FhbWFuaUBnbWFpbC5jb20=

Amani Abdallah Hepautwa

Amani Abdallah Hepautwa Yusufu A. C. Jande1,3

Yusufu A. C. Jande1,3