- Department of Management in the Built Environment, Faculty of Architecture and the Built Environment, Delft University of Technology, Delft, Netherlands

The construction sector is a significant contributor to global waste, highlighting the urgent need for circular practices. While the construction lifecycle includes phases such as construction, maintenance, renovation, and demolition, renovation is particularly complex—and integrating circularity adds further challenges. In circular renovation, material reuse and recovery are central goals. This study focuses on circular renovation within the construction sector, addressing a gap in current research through a systematic literature review of 121 publications. Based on the findings, a three-step process—Planning, Assessing, and Routing—is proposed, and associated methods, approaches, and tools are reviewed. Drawing on these insights, a new framework is developed from a meso-scale perspective, aimed at identifying material reuse cycles. Whereas most existing studies focus on individual projects (micro scale) or urban systems (macro scale), this research emphasizes the underexplored meso scale, promoting reuse across multiple projects through collaborative networks. This approach supports more sustainable construction practices and advances the broader objectives of the circular economy.

1 Introduction

The construction and demolition (C&D) sector is one of the biggest contributors to global waste, accounting for the largest share of waste generation. In 2022, it was responsible for 38% of all waste produced in Europe (Eurostat, 2022). Sustainability in the construction industry has become increasingly important. To promote sustainability in the construction projects, CE principles can be implemented. CE is recognized as an optimal strategy for construction and demolition waste management (CDWM) (Rayhan and Bhuiyan, 2024). The aim of CE is to minimize the extraction of raw materials from the environment and keeping materials in the cycle as long as possible. It is important to distinguish between sustainability and CE: sustainability is the ultimate objective, with the circular economy acting as a means to reach a more sustainable economy (Anastasiades et al., 2020).

Every phase of a construction’s life cycle—construction, maintenance, renovation, and demolition—contributes to environmental impacts and generates waste (Mohammadiziazi and Bilec, 2023). Among these, the renovation stage has been found to have higher environmental impacts compared to both the construction and end-of-life stages (Hossain and Thomas Ng, 2019). However, renovation is generally preferable to demolition, as it preserves resources and minimizes waste. Maximizing the economic and environmental benefits of renovation is crucial for achieving sustainability in the C&D industry. Various methods and approaches can be employed to promote circularity in this process. Since waste production cannot be avoided during renovation, effective recovery and reuse of materials become essential (Jiménez-Rivero and García-Navarro, 2017).

The CE in the construction industry operates at three levels, micro, meso, and macro (Kirchherr et al., 2017). According to a literature review by Anastasiades et al. (2020) many research efforts have focused on products and material recycling, which align with the micro level, while others have primarily examined cities as a whole over extended time periods aligning with the macro level. However, the meso level in the construction sector remains largely underexplored (Liu et al., 2024). The meso scale lies between the micro and macro levels and encompasses projects structured through contracts between clients, contractors, and subcontractors. These interdependencies, combined with the complexity of the construction value chain, create challenges in implementing changes, including the adoption of circular principles (Liu et al., 2024; Munaro and Tavares, 2023). The meso scale contains a complex network of projects and various material reuse cycles. These cycles should be identified during the renovation process. Selecting the destination for secondary materials and reusing them depends on several parameters, which should be considered when studying circularity at the meso scale. This study focuses on implementation of circularity in renovation at the meso level. While the meso level is often associated with eco-industrial parks in the literature (Anastasiades et al., 2020; Ghisellini et al., 2016; Kirchherr et al., 2017), this study also considers multi-project systems and other collaborative networks.

Construction industry encompasses building, repairing, renovating and maintaining the infrastructure and is classified into residential and non-residential sectors. Roads, urban infrastructure like bridges and quay wall, etc. are categorized as non-residential construction (Chaudhery et al., 2022). Therefore, the term “construction” that is used in this research, is broad and encompasses both building structures and various forms of infrastructure. While several research studies have focused on residential construction (building industry), non-residential construction has received limited attention in research. Most existing studies in the construction sector concentrate on residential projects, as they are generally easier and less costly to analyze. Additionally, their relatively shorter lifespans compared to infrastructure projects make them more feasible for investigation (Li et al., 2020). A literature review on material stocks in the built environment revealed that, out of 249 publications, only a small number addressed road (20) and rail (20) infrastructures, with most studies primarily focused on the building sector (Lanau et al., 2019). Furthermore, A review of the flows and stocks of construction materials reveals that most studies focus on buildings, with insufficient attention given to infrastructure such as networks and civil works (Augiseau and Barles, 2017). Most CE literature concentrate more on the private sector than on public, such as urban infrastructure, showing a research gap (Coenen et al., 2023; Klein et al., 2022). Infrastructure accounts for the majority of non-mineral material stocks in the European Union (Wiedenhofer et al., 2015) and is highly resource-intensive (Coenen et al., 2023; Ecorys, 2016). Its environmental impacts are significantly greater than those of residential and commercial constructions (Wu et al., 2014), highlighting the need for further investigation into circularity within infrastructure projects. The infrastructure projects, typically involve multiple contractors and engineering firms (Liu et al., 2024), creating a complex network of stakeholders. This complexity necessitates a meso-scale perspective for studying circularity, aligning with the research gap identified in the previous section.

A research gap regarding circular renovation at the meso scale—where multiple construction projects are considered as an interconnected system—has been identified in the previous paragraphs. To address this gap, it is essential to first identify the key stages of circular renovation and review the methods and strategies associated with each phase. Insights from this systematic review provide the foundation for developing a framework that organizes these renovation stages and highlights key circularity considerations at each step. A comprehensive understanding of existing approaches and frameworks is therefore crucial for informing the design of a practical and integrated meso-scale framework. Accordingly, this study pursues the following two objectives:

1. To investigate the existing research on circular renovation in construction through a systematic literature review (SLR).

2. To develop a new framework for the circular renovation of construction from a meso scale perspective.

To address the first research objective, a systematic literature review (SLR) was conducted. The methodology followed for the SLR is described in Section 2. The findings of the review are presented in Section 3, where a three-step process for circular renovation is introduced, along with various methods and approaches relevant to each stage. To support the development of the proposed framework, this section also includes a review of existing circularity frameworks in construction. Building on the insights gained from the SLR, a new meso-scale framework is developed in Section 4, fulfilling the second research objective. This framework focuses on material-preserving renovation across multiple interconnected projects and highlights the importance of collaboration in multi-project environments. The framework also outlines key considerations for each stage of the renovation process to support implementation. Its practical relevance is demonstrated through an application example. Section 5 discusses the feasibility and application of the framework, addressing potential implementation barriers, the role of regulatory support, and its broader global applicability. Finally, Section 6 concludes the study and outlines directions for future research.

2 Methodology

2.1 Research methodology

The first aim of this study is to review and synthesize existing literature while integrating it into a new approach for resource-conscious renovation of construction. To achieve this, a SLR was conducted. In general, an SLR is a structured method of reviewing research that involves gathering and summarizing multiple studies to answer a specific research question (Gough et al., 2017).

2.2 Systematic literature review

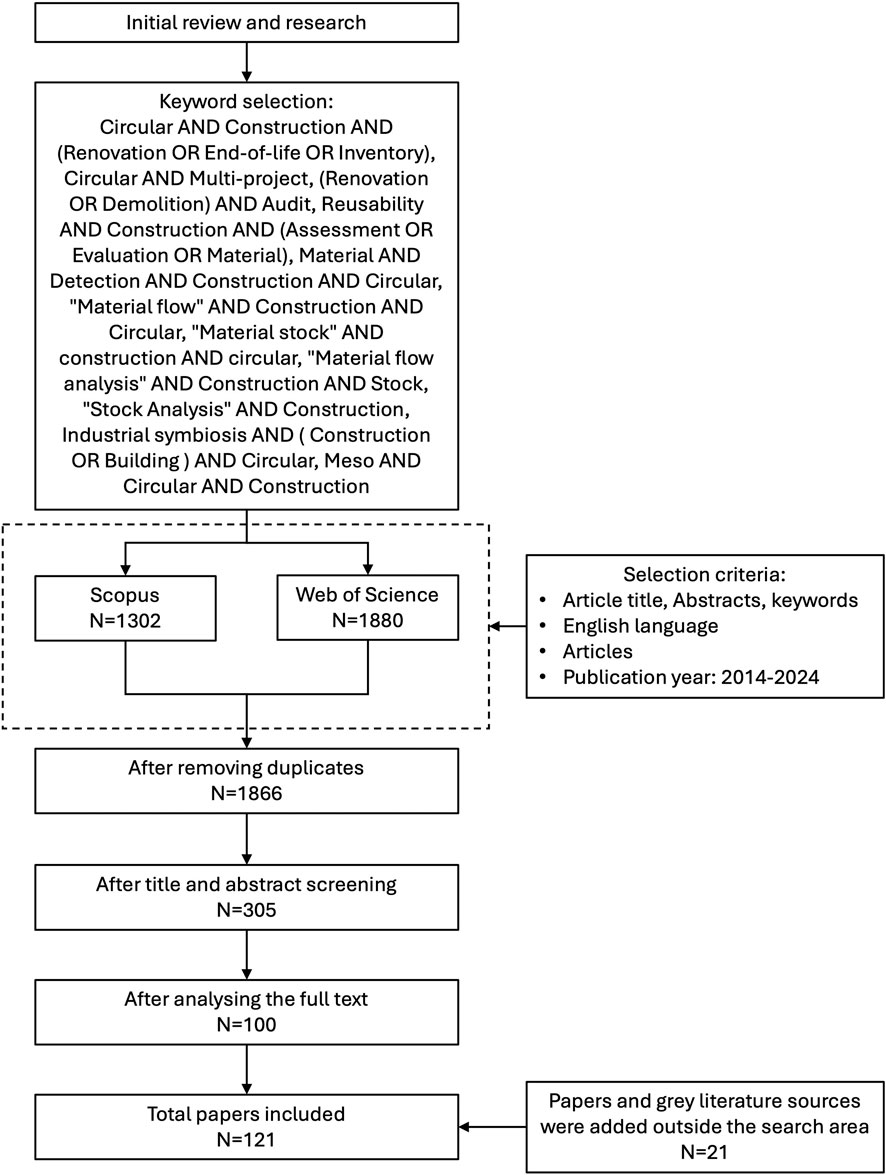

Figure 1 shows the SLR process and the keywords used in the search. To ensure comprehensive and thorough results, eleven groups of keywords were used and searched individually. These keywords were carefully selected to cover all stages of the renovation process. The term ‘construction’ is broad, encompassing both buildings and infrastructure; therefore, it was included as a keyword to capture a wide range of relevant studies. Two databases, Scopus and Web of Science, were used for the search, which was conducted in September 2024. The keywords listed in Figure 1 were applied to search within the titles, abstracts, and keywords of the papers.

Figure 1. Systematic literature review process (N represents the number of papers retrieved at each stage).

2.2.1 Inclusion criteria

Figure 1 presents the number of papers retrieved from each database. For the search, filters were applied to include only English-language articles published within the last 10 years (2014–2024). Based on these criteria, 3,182 papers were initially identified. Research information systems (RIS) files were then exported from the databases and imported into the Zotero software for the screening process. After removing duplicates, 1,866 papers remained.

2.2.2 Screening the articles

In this step, the papers were screened using Zotero software. Initially, the titles were reviewed, and since the term “construction” is broad and used in various fields (e.g., molecular construction), papers unrelated to the building and infrastructure sectors were excluded. Next, the abstracts of the remaining papers were assessed, leading to further exclusions. A total of 305 papers proceeded to the full-text review stage, where they were thoroughly analyzed. Then 100 articles were selected for inclusion in the study. Additionally, 21 sources outside the search criteria were incorporated into the SLR, including relevant conference papers, grey literature, toolkits, and standards. Finally, 121 papers were reviewed in this research study.

2.2.3 Sample characteristics

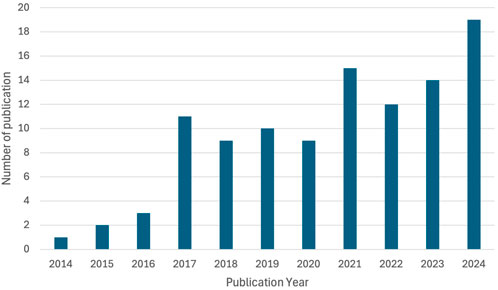

This section discusses the key characteristics of the reviewed papers. Figure 2 displays the distribution of papers by publication year. The bar chart shows a noticeable increase in publications in recent years, indicating a growing interest in circularity. It is worth noting that the research was conducted in September 2024, yet 19 papers from this year were retrieved, which is more than other years. This rising trend emphasizes the importance of this topic.

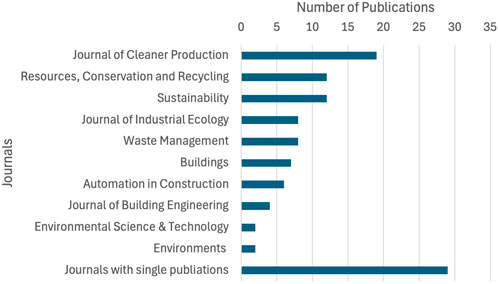

Figure 3 presents the journals that published the reviewed papers. Journal of Cleaner Production, a journal with an impact factor of 9.8, leads with 19 publications, followed by Journal of Resources, Conservation and Recycling and Sustainability, each with 12 publications.

3 Review results

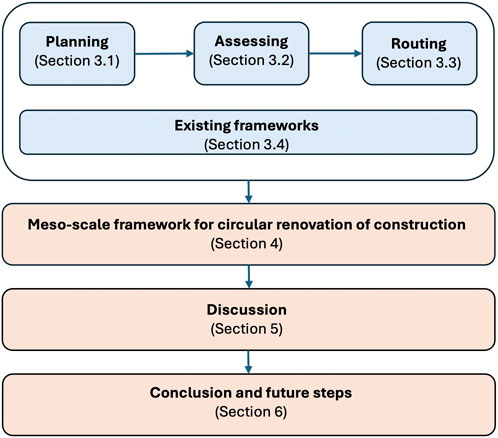

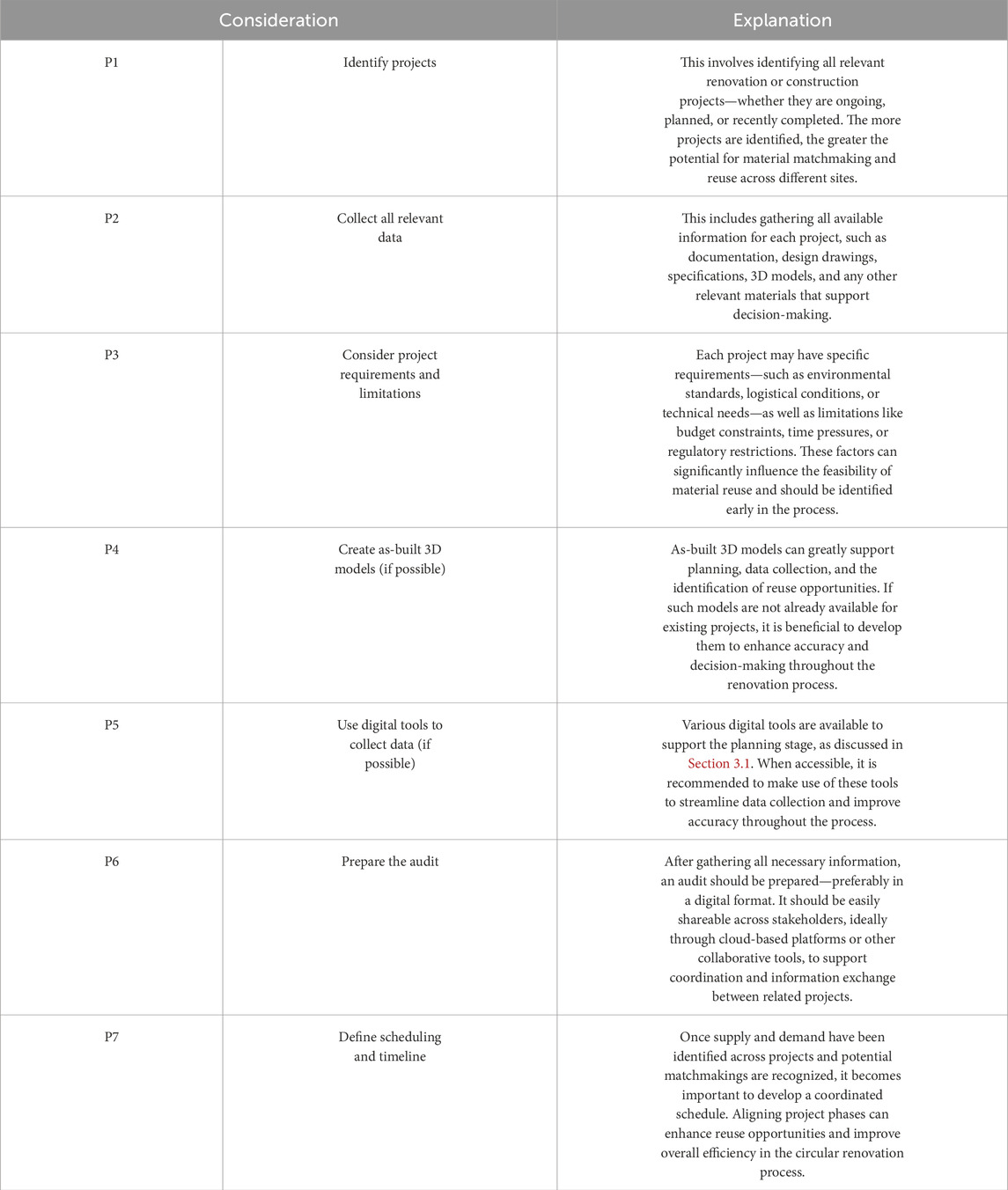

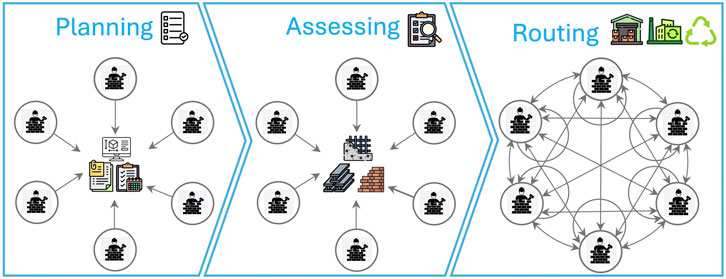

The findings from the SLR are organized into three main sections: Planning, Assessing, and Routing, which represent the proposed phases of the circular renovation process. Renovation projects are complex by nature, and incorporating circularity adds further layers of complexity. A sustainable renovation involves multiple stages, each requiring distinct tools and methods. The first stage, Planning (Section 3.1), includes tasks carried out before the project begins, such as creating a material inventory and gathering all relevant construction data. The second stage, Assessing (Section 3.2), focuses on evaluating various criteria to determine whether reclaimed materials and components, from either past or upcoming renovations, are suitable for secondary use. The final stage, Routing (Section 3.3), involves deciding the destination for reclaimed materials, which includes identifying recovery facilities, storage areas, potential receiving projects, and other possible demands. Each section explores different methods, approaches, and tools that can be applied at each stage. This approach will be further discussed and applied to the meso scale circularity. A graphical abstract of the planning-Assessing-Routing is developed in Section 4.1, Figure 5.

In Section 3.4, existing frameworks on circularity and renovation are reviewed. Section 4 introduces a meso-scale approach and presents a framework. This framework is based on insights gained from the SLR and focuses on multi-project networks and collaboration between different projects. Additionally, the framework details key considerations for each step in the circular renovation process, facilitating effective implementation. Finally, the conclusion and future research directions are discussed in Section 6. Figure 4 illustrates the three-step process alongside the section map.

3.1 Planning

According to a literature review by Timm et al. (2023) on CE strategies in construction, the first stage is planning. Similarly, Fernandes and Ferrão, (2023) propose a circular refurbishment framework that begins with mapping the building’s current state, including its geometry and quality. Movaffaghi and Yitmen, (2023) emphasize that in dynamic circular economy frameworks, inventory-taking is the initial step for identifying reusable materials. Although these frameworks primarily focus on buildings, the underlying principle applies broadly across the construction sector: planning and mapping are essential first steps in any circular renovation process. Accordingly, this paper adopts the term “Planning” to describe the initial stage of circular renovation in construction. It includes actions and methods performed before the project begins, such as making an inventory of materials and collecting other relevant data about the construction. This stage plays a crucial role in collecting the information needed to effectively guide the renovation process. In the Sections 3.1.1–3.1.5 different approaches that can be employed during the planning stage are outlined.

3.1.1 Renovation/demolition audit

A reclamation audit is carried out on constructions slated for partial or complete demolition. The reclamation audit, widely used in various countries and projects. The primary objective of a reclamation audit is to generate a detailed inventory of materials with significant reuse potential. This is the first step in the process of circular renovation and includes key information such as the dimensions, quantities, quality, and technical specifications of the materials (Smeyers et al., 2022). A detailed inventory can significantly increase the potential for reusing materials in new construction projects.

The data for this inventory can be gathered through various approaches, including desk research and on-site surveys (EU Construction and Demolition Waste Management, 2018). Information can also be gathered from project requirements, technical regulations, standards, and, if available, material passports (Bellini et al., 2024). Bellini et al. (2024) argued data on material properties should be collected in an open-access digital format to ensure accessibility and avoid redundant analyses in future projects. The renovation audit provides valuable preliminary insights before a project begins, offering a solid foundation for planning. However, these methods are mostly manual, making them labor-intensive and time-consuming.

3.1.2 Waste indicator

Some mathematical approaches estimate construction and demolition waste (CDW) generation using waste indicators (Li et al., 2013; Mália et al., 2013). This method calculates the amount of waste for each material type generated during C&D activities based on the waste-weight-per-construction-area. A more detailed method, known as the “Global Index,” was suggested by Jalali (2007), categorizing the generated waste by material types. The waste indicator approach offers a valuable estimation of the materials embedded in construction, making it beneficial for resource planning and waste management. However, it does not provide insights into the quality of the materials or the potential for material recirculation opportunities.

3.1.3 Building information modelling (BIM) based methods

BIM can be utilized to quantify secondary materials generated during construction and renovation processes. A literature review of 57 papers on the application of information technology in CDWM revealed that 47% of the studies utilized BIM, making it the most widely adopted technology in this field (Li et al., 2020). A BIM-Based approach (Cheng and Ma, 2013) was developed to estimate demolition and renovation waste of construction. In this method the material quantitative data are extracted from Revit software and can be simply scheduled and categorized. This BIM-based tool is capable of estimating demolition wastes from a properly prepared 3-D model of structure. Negendahl et al. (2022) implemented a generative parametric BIM-integrated approach to predict the material composition of typical historical buildings. In this method, the 3D model is generated based on public building registers, providing material compositions that are useful for waste estimation. This approach offers significantly more accurate results compared to pre-demolition audits. Given that urban infrastructures like quay walls typically have consistent structures and material compositions, Ashrafi et al. (2024) used BIM models to calculate the material-per-meter embedded in urban quay walls. The BIM model determines the material volume for quay walls of varying lengths, offering an effective approach for estimating material stocks in urban infrastructure. BIM has been leveraged to develop a Material and Component (M&C) bank (Jayasinghe and Waldmann, 2020). This system enables the storage and management of material and component information, facilitating C&D waste quantification and secondary use potential. A web-based tool was developed to extract data from BIM models, linking each element through a unique identifier for accurate tracking.

BIM-based approaches provide accurate data regarding material composition and quantities. However, their effectiveness depends on the availability of a well-structured BIM model; Unlike new constructions, older existing structures do not benefit from BIM-based models or digital twins and original drawings may be missing (Li et al., 2020).

3.1.4 Creating as-built models

As mentioned in the Section 3.1.1, the preparation of demolition audit is often manual. To accelerate the process, integrating advanced technologies to create as-built 3D models would be beneficial (Guerriero et al., 2024; Hu et al., 2022; Mêda et al., 2023; Omer et al., 2024; Volk et al., 2018). Such technologies could automate data collection and analysis. Volk et al. (2018) developed a system called ResourceApp, which combines hardware sensors with software modules for automated building auditing, information acquisition, 3D reconstruction, object detection, building inventory generation, and optimized project planning. Omer et al. (2024) developed a method for creating 3D digital models from paper-based drawings. The process involves two steps: first, converting the paper drawings into a digital CAD model, and second, developing the 3D digital model from the CAD file. Augmented reality is also incorporated to correct errors in the digital model. This method facilitates pre-demolition audit preparation, enabling a systematic and quantitative evaluation of the potential for material and product reuse. Mêda et al. (2023) utilized LIDAR technology embedded in mobile devices along with the BIMeo software (BIMeo, 2025) to create 3D models. This approach provides valuable insights for audit preparation before renovation. A key innovation of BIMeo is its ability to deliver an IFC format, ensuring compatibility with other 3D modeling software like Revit. Hu et al. (2022) proposed a framework based on the image-to-BIM technique, which utilizes full-view images of the construction to generate a point cloud. An algorithm capable of detecting line features is then used to create a BIM model of the construction. This approach can deliver accurate results regarding material quantities; however, it is somewhat time-consuming and requires manual intervention at certain stages.

The process of creating as-built BIM models for existing constructions can be both time-consuming and expensive, which may discourage contractors and stakeholders from adopting this method. Nevertheless, it is argued that creating as-built 3D models should be prioritized to minimize CDW in older structures (Banihashemi et al., 2024).

3.1.5 Other information technologies

Another method for predicting the waste generation is image recognition technology (IRT). Yu et al. (2019) conducted a large-scale demolition waste prediction study in Shenzhen, China, utilizing IRT alongside Google Earth. They first obtained the gross floor area, and then, using the waste generation rate and the gross floor area, they estimated waste generation at the urban level. Another valuable tool for identifying and mapping material stocks is geographic information system (GIS) (Oezdemir et al., 2017; Verhagen et al., 2021). GIS-based methods enable reliable estimations of material stocks on a large scale, such as cities or entire regions. Using geospatial data from OpenStreetMaps website, van Engelenburg et al. (2024), investigated the potential of transportation infrastructure from an urban mining perspective. These three approaches offer a promising strategy for optimizing waste management by enabling the identification and separation of materials. They provide reliable estimates of material stocks across large areas, such as cities or regions, and are particularly useful when construction documents are unavailable or access to the interior of structures is restricted.

Lu et al. (2023) developed a machine learning regression-based approach for estimating renovation waste, using a dataset of previous renovation projects. This method predicts the renovation waste of construction projects by inputting project feature data into the model. Big data technology can analyze vast amounts of information and identify connections between various elements. Sprecher et al. (2022) utilized big data in material stock analysis, to create a material intensity database for the Dutch building stock. This database serves as a valuable tool for planning future material recirculation and optimizing resource efficiency in the built environment. The big data analysis provides reliable results; however, they require a large dataset for optimal accuracy.

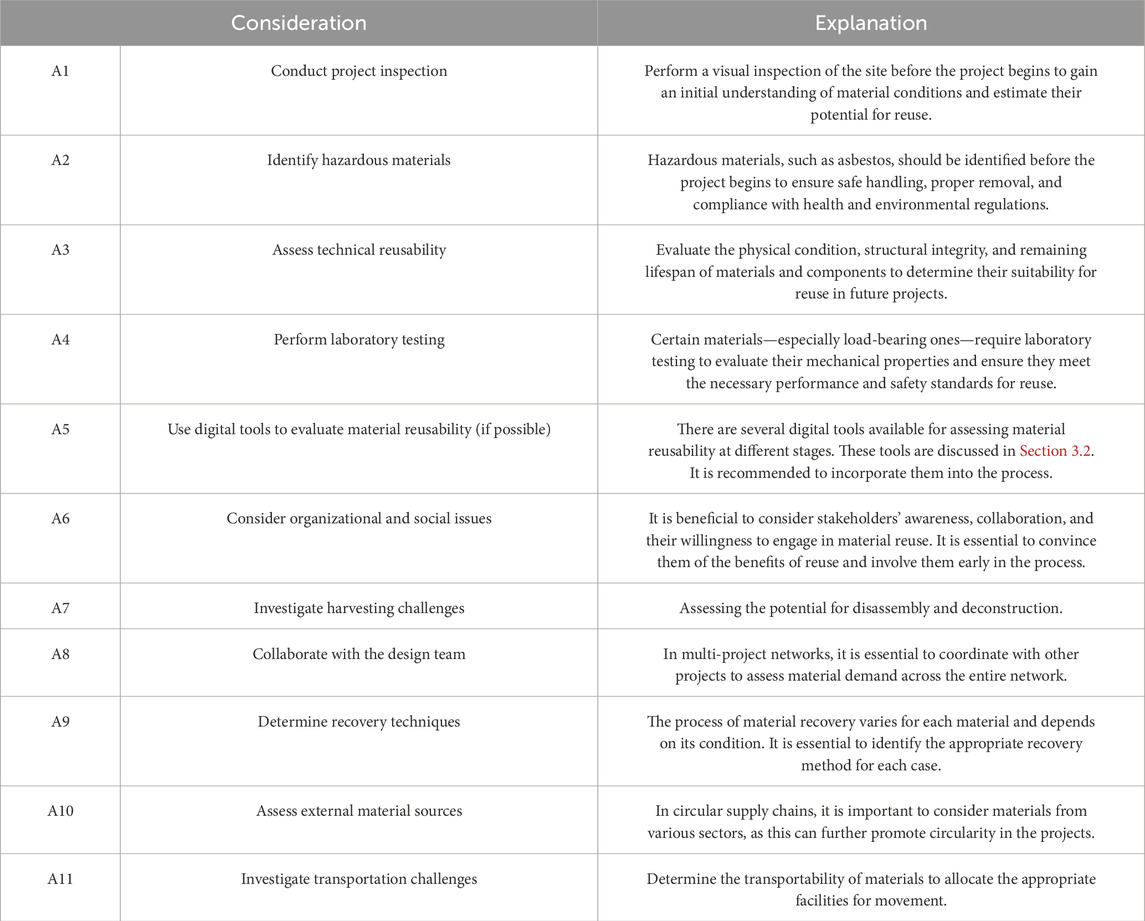

3.2 Assessing

Following the planning step, it is crucial to evaluate the materials that have been or will be reclaimed during the renovation process. “Assessing” refers to the evaluation of various criteria to determine whether materials and components are suitable for reuse. Numerous studies have examined the reusability of materials and components in construction. A recent review of circularity indicators in the sector highlights reusability as one of the most frequently applied indicators (Khadim et al., 2022). In the Sections 3.2.1–3.2.3 reusability criteria and methods to assess these criteria are discussed.

3.2.1 Reusability criteria

The reusability of a component in a construction, is influenced by different factors (Bellini et al., 2024; Coenen et al., 2021; Mollaei et al., 2023; Rakhshan et al., 2020). Rakhshan et al. (2020) categorized the factors influencing the reuse of components into six main categories: economic, environmental, organizational, regulatory, social, and technical. Their results indicate that economic factors play a crucial role in the successful implementation of lifecycle reintegration, followed by technical and organizational factors. Bellini et al. (2024) defined eight information-driven evaluation criteria to assess the reusability of construction products: Environmental evaluation (GHG emissions), Technical requirements, Quality and life expectancy, Possibility for disassembly, Logistic and storage, Location in the project, Risk evaluation and Cost evaluation. Mollaei et al. (2023) argued that regional factors including cultural perception, secondary material market, regulations and landfill fees can also affect the construction material recovery. Coenen et al. (2021) suggest that reusability can be evaluated based on three sub-indicators, disassemblability, transportability and uniqueness. The first two apply to individual components, while uniqueness refers to the asset as a whole. According to this approach, the more disassemblable and transportable a component is, the higher reusability value it has. The disassemblability depends on the internal connections of components and is calculated based on the theory proposed by Elma (2006). This is a quantitative method for assessing reusability, providing precise calculations for each component. However, it requires extensive input data, which may not always be available for every component. Additionally, this approach does not take material quality into account when evaluating reusability.

Alongside the various parameters discussed, the method of material harvesting or demolition plays a crucial role in determining material reusability. Whether a structure is demolished, deconstructed, or repurposed significantly impacts the potential for secondary use (Assefa and Ambler, 2017). Materials obtained through selective deconstruction can be recovered if carefully removed, whereas sudden demolition offers fewer opportunities for material recirculation. Beyond enhancing material reusability, life cycle assessment (LCA) results show that selective deconstruction also offers notable environmental benefits (Antunes et al., 2024). However, this approach is not widely adopted, as many existing structures are relatively old and were not originally designed for disassembly (López Ruiz et al., 2020).

3.2.2 Visual inspection and laboratory testing

Visual inspection is a method for assessing the quality and reusability of construction materials (Devènes et al., 2024; Jiménez-Rivero and García-Navarro, 2016). Devènes et al. (2024) assessed the load bearing reinforced concrete components prior to deconstruction. Based on damages, properties and geometrical attributes they graded the reusability of concrete components in the construction. These studies offer valuable insights into the reusability of specific construction elements; however, they are limited to examining only the external components and visible damages.

In some cases, reclaimed materials undergo laboratory testing to assess their quality and technical performance (Interreg FCRBE, 2019). This process ensures that materials meet the necessary performance standards and are safe for their intended reuse. There are two types of techniques for material testing: non-destructive evaluation (NDE) and destructive testing. NDE methods include ultrasonic testing, radiography, magnetic particle testing, and eddy current testing, while destructive testing involves methods such as failure point analysis (Byers et al., 2024). Agarwal and Krishan (2017) evaluated the reusability of bricks made with CDW aggregates through compressive strength and water absorption tests in the lab. Their results indicate that the bricks made with CDW have comparable strength to conventional bricks, though their water absorption is lower than standard. It is recommended that these bricks be used in non-load-bearing structures. Laboratory testing can provide detailed information on the strength and quality of reclaimed materials, offering valuable insights into their technical performance and secondary use potential. However, testing each material individually is highly labor-intensive and often involves significant time and cost, making it less practical for large-scale projects.

3.2.3 Digital approaches

In recent years, there has been a growing interest in integrating digital technologies into the construction industry. Research by Çetin et al. (2021) highlights that various digital tools can be employed at different stages of a construction project’s lifecycle, including its end-of-life phase, to support CE principles within the built environment.

Gordon et al. (2023) utilized mobile photography alongside smartphone LiDAR technology to conduct recovery assessments of steel floor beams. They then developed a 3D BIM model of the area using photogrammetry and point cloud data analysis. This computer vision method offers insights into the feasibility of recovery by considering the connections between beam elements. However, it does not provide data regarding the quality of the materials. Utilizing more detailed images can help identify visible damage and deterioration in the elements.

Computer vision tools have been employed to identify reusable construction materials (Dai et al., 2024; Raghu et al., 2023). Raghu et al. (2023) employed a computer vision approach alongside Google Street View in the building sector to identify reusable materials from buildings. This approach accurately identifies materials and components, offering customized reuse plans according to their composition and the year they were built. However, it is limited to assessing only the façade and exterior elements of structures. Using street view images and computer vision techniques, Dai et al. (2024) assessed four exterior materials in the building stock of Merthyr Tydfil, Wales. This method enables the assessment of potential component recovery. However, it does not address the quality of the materials. This method is particularly useful for analyzing large areas or extensive groups of structures, such as urban infrastructure components.

Another valuable digital tool is BIM. When a 3D model of a construction exists or an as-built 3D model can be developed, BIM becomes a powerful tool for automating deconstruction and material recirculation processes. In a case study, BIM was utilized during the deconstruction stage for 3D analysis of existing conditions, labeling reusable elements, and 4D deconstruction simulation (Van Den Berg et al., 2021). In another case study, Guerriero et al. (2024) generated an as-built BIM model using point cloud data, then exported it in Industry Foundation Classes (IFC) format and imported it into a platform called Digital Deconstruction (DDC). This platform creates inventories and adds additional properties to annotate the elements. Finally, each element can be assigned a “reuse decision” based on the available information.

AI and machine learning have also been utilized as innovative approaches for assessing material reusability, enabling more accurate and automated evaluation processes (Akanbi et al., 2020; Davis et al., 2021; Rakhshan et al., 2021). Rakhshan et al. (2021) developed a method using machine learning techniques to predict the technical reusability of load-bearing building components. This approach quantifies factors affecting reusability based on expert input collected through an online questionnaire. Their findings reveal that design-related factors, particularly aligning the new structure’s design with the strength of recovered elements, are the most critical. Additionally, they created an easy-to-understand learner that practitioners can use for an initial assessment of the technical reusability of load-bearing components. Davis et al. (2021) developed a deep learning-based method to identify various materials from images of construction waste. This approach enhances both on-site and off-site material sorting and classification, improving the efficiency of waste management and resource recovery. Akanbi et al. (2020) introduced a deep learning method to predict reusable waste in the construction industry. By correlating various building attributes (independent variables) with demolition sector statistics, their model estimates the quantity of materials that can be reused or recycled before demolition occurs. While this approach delivers precise predictions, it depends greatly on having access to extensive data from past renovation and demolition projects. Such datasets may be difficult to obtain, especially for urban infrastructure projects where records are often incomplete or unavailable.

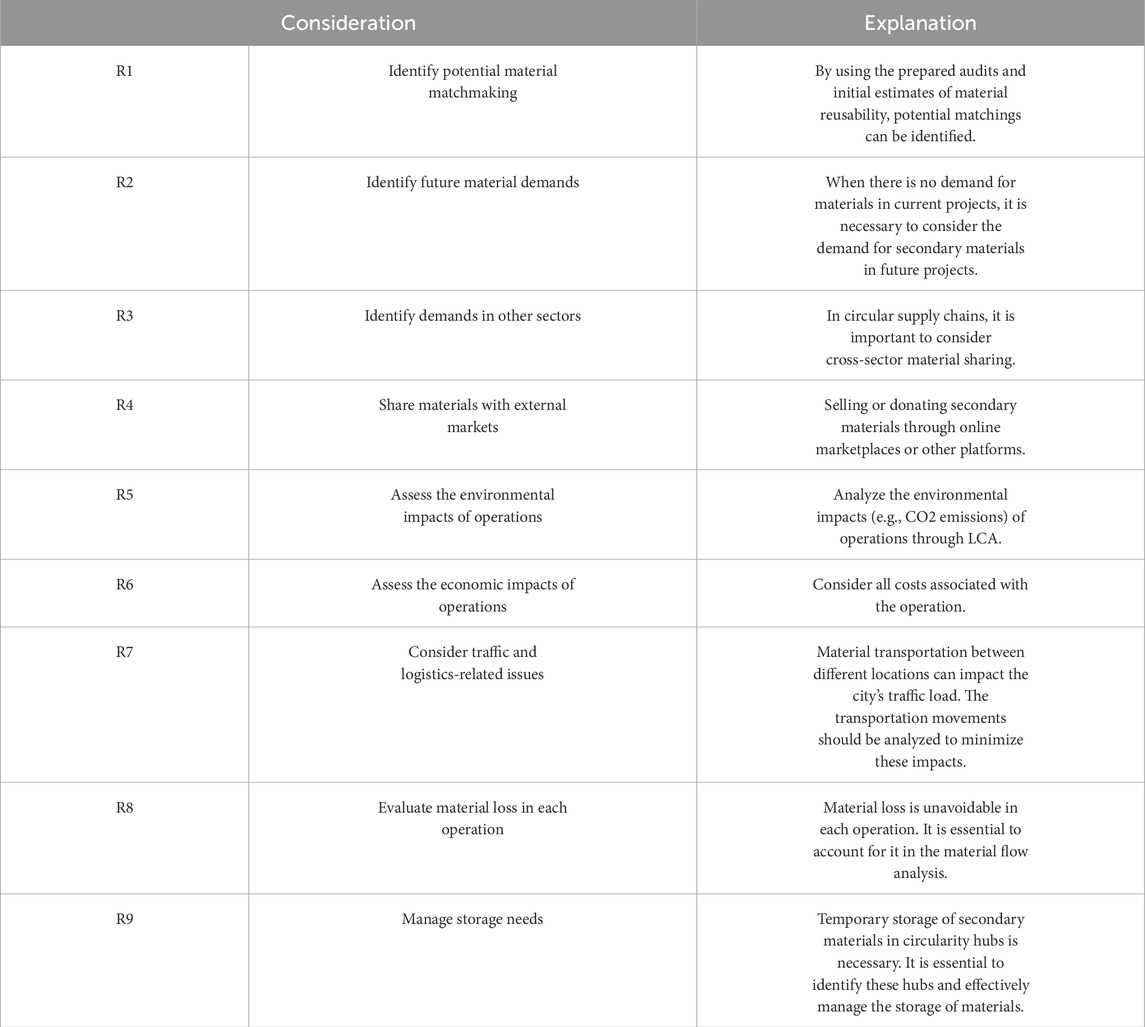

3.3 Routing

After assessing the material and its secondary use potential, the next step is determining how and where the reclaimed material will be sent and reused. This involves identifying recovery facilities, storages, suitable receiving projects or other potential demand. In this process evaluating financial, environmental, and logistical factors associated with the lifecycle reintegration process is necessary. For this step, the term “Routing” is proposed. Routing is particularly crucial for implementing material loop closure at the meso scale, as it enables the identification of potential connections between projects and facilitates the investigation of material flows in a multi-project environment. In the Sections 3.3.1–3.3.5, various aspects related to material routing are discussed.

3.3.1 Multiple routes

In circular material flows, multiple cycles and reuse options exist. In this research, these options are referred to as “routes.” Selecting the appropriate route for reclaimed materials depends on their condition, as well as the specific objectives and constraints of a given project. To promote material loop closure, it is essential to explore all potential routes and assess their feasibility. Material can be whether directly reused as their original functions or be repurposed for entirely different function. Although repurposing materials for alternative uses is generally less favorable in the context of closed-loop systems, a significant portion of demolition waste is downcycled and used as filler material for road construction (Di Maria et al., 2018).

It is not always feasible to reuse or recycle all waste materials within the same supply chain (Farooque et al., 2019). Consequently, collaboration with other sectors can further promote resource cycling in projects. In the circular supply chains, collaborating with other industries is essential to maximize value recovery from waste materials through cross-sector integration (Weetman, C, 2016). Therefore, in the construction sector, particularly in renovation projects, considering other industries can be highly beneficial. Receiving materials from and donating materials to other sectors can further improve circularity within the projects.

Zhang et al. (2021) created a material flow model and highlighted that after deconstruction, materials can be reused during the construction phase as systems, components, or part components, or they can be recycled in the production phase. The latter refers to recycling as an input for new material production, while the former involves reusing materials at the system level, refurbishing at the component level, or recycling for producing part components. Regarding concrete recycling, there are several reuse options, Zhang et al. (2018) analyzed four concrete recycling pathways: 1 improving brick manufacturing, 2 recycling on-site for road base filling, 3 recycling aggregate for prefabricated concrete component and 4 recycling concrete aggregate for structure use. After analyzing each scenario, they found out that on-site recycling for road filler aggregates presents a high performance due to lower transport and greenhouse gases emissions.

There are some criteria that impact material routing. Chinda and Ammarapala (2016) examined four reverse logistics strategies-direct reuse, recycling, remanufacturing and landfill-for decision making on CDWM. They emphasized that decision-making for reverse logistics plans is mainly influenced by two critical factors: economic considerations and site-specific conditions, each consisting of several sub-factors. Through surveys and interviews with experts, they found out that the economic and site-specific factors carried weights of 0.57 and 0.43 respectively.

3.3.2 Industrial symbiosis (IS)

As mentioned in the previous section, within the context of material routing, a key aspect to consider is identifying potential destinations for material secondary use. This is particularly important when studying circularity at the meso scale, where efficient material routing plays a crucial role. This concept aligns closely with industrial symbiosis, to the extent that the meso scale is often regarded as a form of IS in the literature (Anastasiades et al., 2020; Khadim et al., 2022; Kirchherr et al., 2017). The European committee for standardization defined IS in the workshop agreement 17,354 as “Industrial symbiosis is the use by one company or sector of underutilized resources broadly defined (including waste, by-products, residues, energy, water, logistics, capacity, expertise, equipment and materials) from another, with the result of keeping resources in productive use for longer. It presents a systems approach to a more sustainable and integrated industrial economy that identifies business opportunities to improve resource utilization and productivity” (CEN-CENELEC Management Center, 2018). According to the definition of industrial symbiosis (IS), materials can be exchanged not only between construction projects but also across different sectors. Establishing an effective IS network requires identifying various economic activities and selecting feasible symbiotic synergies (Giannoccaro et al., 2023).

A notable application of industrial symbiosis is in eco-industrial parks. Its environmental benefits have been demonstrated in the Rizhao Economic and Technology Development Area (REDA), China (Yu et al., 2015). Sun et al. (2017) integrated MFA and emergy evaluation to assess the environmental benefits of urban IS in Liuzhou city, China. The results showed that IS significantly reduces resource extraction, waste disposal, and CO2 emissions by 2.3 million tons annually, highlighting IS as a key strategy for enhancing resource efficiency and sustainability. Marinelli et al. (2021) investigated the circularity performance of an IS network originating from the production of cement reinforced with recycled fibers. Their results indicate that IS can enhance circularity in the construction sector and effectively reduce both environmental and economic impacts. Overall, sharing materials and resources between different projects—or even across different sectors—can improve resource loop closure and ultimately contribute to greater sustainability in the construction industry.

One major factor that impacts the IS is geographical proximity. The geographical proximity can allow organizations to promote industrial symbiosis (Muzamwese et al., 2024). The implementation of IS in the construction sector is generally limited to local transactions (city or metropolitan areas) due to the high volume and low value of construction materials (Domenech et al., 2019). Transporting these materials over long distances for reuse is often not economically viable.

3.3.3 Material flows and stocks analysis (MFSA)

The routing step is associated with material stocks, such as projects, storage facilities, and recovery centers, as well as the material flows between them. Therefore, routing is closely linked to MFSA. MFSA is a widely recognized approach for evaluating sustainability in the built environment, and it can be effectively adapted to promote circular economy practices. (Guo and Huang, 2019; Pomponi and Moncaster, 2017; Schiller et al., 2017). MFSA can be a useful tool for evaluating financial, environmental, and other factors related to the material recirculation process. Another major.

In the following paragraphs, different aspects and parameters associated with MFSA are discussed.

3.3.3.1 Scale and approach

The spatial scale of MFSA studies in the literature varies, encompassing regional, national, continental, and global levels. The temporal scale also varies from a single reference moment to reference years (spanning decades or centuries). Most scientific research in MFSA tends to focus on large areas and extended timeframes. This research study specifically targets regional and urban scales. Two types of temporal analysis can be distinguished: retrospective and prospective. Retrospective studies examine past flows and stocks, while prospective studies estimate the future evolution of these flows and stocks (Grossegger et al., 2024). The MFSA methods can be classified as either bottom-up or top-down. The bottom-up approach relies on the inventory of materials and elements, while the top-down approach analyzes flows based on statistical data and other estimates. The sustainable renovation process begins with inventory creation, making the bottom-up approach particularly useful.

3.3.3.2 Urban mining potential through MFSA

MFSA can be utilized to identify materials embedded in the constructions and assess their urban mining potential. Kloostra et al. (2022) estimated the material stocks in the municipal road network of Toronto using pavement archetypes and a bottom-up approach. Their results indicate that selecting the most appropriate archetype is a significant source of uncertainty (Arora et al., 2020). applied MFSA to evaluate the urban mining, recovery, and reuse potential of construction materials in residential buildings in Singapore. They employed a material intensity factor and a component demand factor to estimate the recovery potential of selected building components. Their findings indicate that the material outflows from the city of Singapore could be repurposed for constructing approximately 2,200 to 6,030 buildings annually, highlighting significant opportunities for material recovery and reuse in urban contexts.

3.3.3.3 Material loss

Schiller et al. (2017) argued that in the material flow process, there is always material losses. They said that there are two different losses. The first one is capturing losses that is caused when material cannot be separated correctly so the accuracy of sorting operation is highly important. Another type of material loss happens during processing. The processing loss is different for each material, and it depends on the recycling regulations and requirements. Considering both types of material losses, for the bulk material recycling aggregates, only 48% of them meet the standard requirements for recycling (Schiller et al., 2017).

3.3.3.4 Demand versus supply of secondary materials

Another considerable issue is the balance between material demand and supply. An important issue in the circular construction industry is the mismatch between the supply of secondary building materials and the demand. Within a defined region, inequality between supply and demand of material can cause regional material surpluses or shortages (Schiller et al., 2017). According to a research by Verhagen et al. (2021) in the Leiden, the Netherlands, there is a significant mismatch between annual construction material demand and the supply of demolition waste. Moreover, the recycling rate is not high enough to close material cycles until 2050 in the Netherlands that may further limit circularity (Van Oorschot et al., 2023). In China, also the reusing and recycling are identified as an efficient strategy but their rates require a substantial improvement (Han et al., 2018). This significant challenge should be examined within circular systems to determine whether secondary material producers can supply sufficient reclaimed materials for secondary use.

3.3.4 Material routing and environmental/cost analysis

In the material routing process, there are several operations that are associated with environmental impacts. Transportation and logistics for instance. The LCA results shows that minimizing transport distances in the CDW treatment and construction end-of-life strategies can provide considerable environmental benefits (Antunes et al., 2024). A common method to assess environmental impacts of material flows is combined MFA and LCA (Almusaed et al., 2024; Binet et al., 2021; Dahlbo et al., 2015; Heeren and Hellweg, 2019; Meglin et al., 2022; Teh et al., 2018; Zhang et al., 2018). Jiménez Rivero et al. (2016) evaluated the energy and climate impacts of different levels of recycling of plasterboards using material flow analysis (MFA) and LCA. Another approach to minimizing environmental impacts is optimizing the transportation process (Huang et al., 2022; Yang et al., 2023). Huang et al. (2022) integrated BIM and Web Map Service to develop a waste recycling facility selection system. This method enables the identification of the shortest transportation route and the most suitable waste recycling facility, ultimately reducing carbon dioxide emissions. Yang et al. (2023) integrated MFA with a logistics network to evaluate the environmental impacts of material transportation and to identify the location for a circular hub with lower transportation emissions. MFA was implemented for selection of waste recycling plants (Shi et al., 2019); they integrated MFSA model with genetic algorithms and probabilistic optimization method to minimize the cost and environmental impacts. Using this multi-objective location model, they found the optimal location of the recycling site in Guangzhou, China. Saeed et al. (2023) proposed a decision support framework for managing the CDW. By employing an LCA approach and multi-objective optimization-aimed at minimizing costs and maximizing environmental benefits-, they identified the optimal quantities of materials for different recovery scenarios, including reuse, recycling and landfill.

The circular material flow process contains a series of complex operations and each of them associated with costs. Economic analysis is a very important factor in the MFSA. Ahmed and Zhang (2021) investigated the recycling process and found out two types of costs, facility-based and non-facility based. The first one consists of fixed costs, operation costs, handling costs, green tax, storage cost and subsidies which is negative in the calculations and is the budget that governments may allocate to the sustainable projects. The non-facility type involves transportation, logistics operator, environmental and collection costs. Song et al. (2024) developed an optimization scheme for the domestic waste reverse logistics network, focusing on reducing operational costs. Their approach involved the optimal selection of recycling costs, resource sharing of recycling vehicles, and effective vehicle routing optimization scheduling, resulting in a 45.6% increase in recycling volume and an 8% reduction in operating costs.

3.3.5 Digital tools

A tool that is widely used for material routing in the construction industry is the digital marketplace (DM) (DuSpot, 2025; Enviromate, 2025; Insert, 2025; Restado, 2025). DMs facilitate material reuse, contributing to narrowing and closing loops during renovation and demolition stages. DMs can enhance material sharing by connecting donors and receiver within the construction industry and across multiple sectors. However, challenges associated with these platforms include misalignment and insufficient volumes of listed materials, which hinder timely matching of supply and demand (Çetin et al., 2022).

There are some tools that facilitates the collaboration between stakeholders and contractors of construction projects. A Digital Twin (DT)-based approach has been explored to enhance the recycling and reuse of building demolition waste (BDW) (Su et al., 2023). The proposed BDW trading framework integrates IoT, big data, robotics, and 3D printing to enable real-time virtual mapping of demolition sites and waste disposal processes. This system facilitates digital interactions between contractors and recyclers, reducing information gaps and improving the market circulation of BDW. Xing et al. (2020) designed a cloud-based data exchange platform which connects physical building components with their virtual counterparts through RFID tags, allowing designers to explore reusable products from existing building sites. This platform also serves as a marketplace.

A few tools have been developed to facilitate matchmaking for IS (Álvarez and Ruiz-Puente, 2017; Genc, 2021). Álvarez and Ruiz-Puente (2017) developed SymbioSyS, an ICT-based web tool designed to promote sustainable resource use through IS strategies and facilitate collaboration among businesses. The tool enables the creation of a database that stores identifies potential synergies for resource exchange, and conducts feasibility studies. Additionally, it provides georeferenced visualization and mapping of IS networks, allowing for the analysis of key variables such as transportation routes, distances, and optimal facility locations. Genc (2021) developed SymbioConstruction, a database designed to facilitate industrial symbiosis in the construction sector. It consists of three modules that connect waste providers with seekers and help stakeholders establish symbiotic relationships through waste exchange. The evaluation results indicate that SymbioConstruction effectively maps construction-related symbiotic interactions in eco-industrial parks worldwide. Yu et al. (2024) developed an agent-based model (ABM) to identify industrial symbiosis opportunities among various construction activities using a dynamic matchmaking program. The ABM is based on the quantitative similarity between supply and demand in projects. Their results reveal spatio-temporal mismatches between projects; however, the circular hubs are proposed to mitigate these mismatches by allowing for longer waiting times and larger transportation distances.

GIS is an effective technology to study material flows and stocks (Liu et al., 2019). GIS was combined with MFA to show spatiotemporal issues (Han et al., 2018; Chen and Liu, 2021). In the material flow representation GIS can be used for storing, combing and analyzing data. Due to data visualizing abilities of GIS, it can be used to show trends and relations in the CDW management field (Li et al., 2020; Wang et al., 2019). Global positioning system (GPS) can also facilitate the real-time monitoring of CDW flows (Li et al., 2020). In the on-site material and equipment management system, GPS and GIS are used to reduce the construction waste (Li et al., 2005).

In the Section 3.3, the routing stage of the circular renovation process is discussed. The implementation of novel tools, particularly MFSA and digital marketplaces, shows great promise. GIS can effectively visualize material flows and stocks, making it a powerful tool for analyzing these dynamics. The review indicates a solid understanding of reuse cycles, material loss, demand-supply relationships, and other aspects related to circular material flows and stocks. However, it is essential to investigate all of these issues within a single, comprehensive framework.

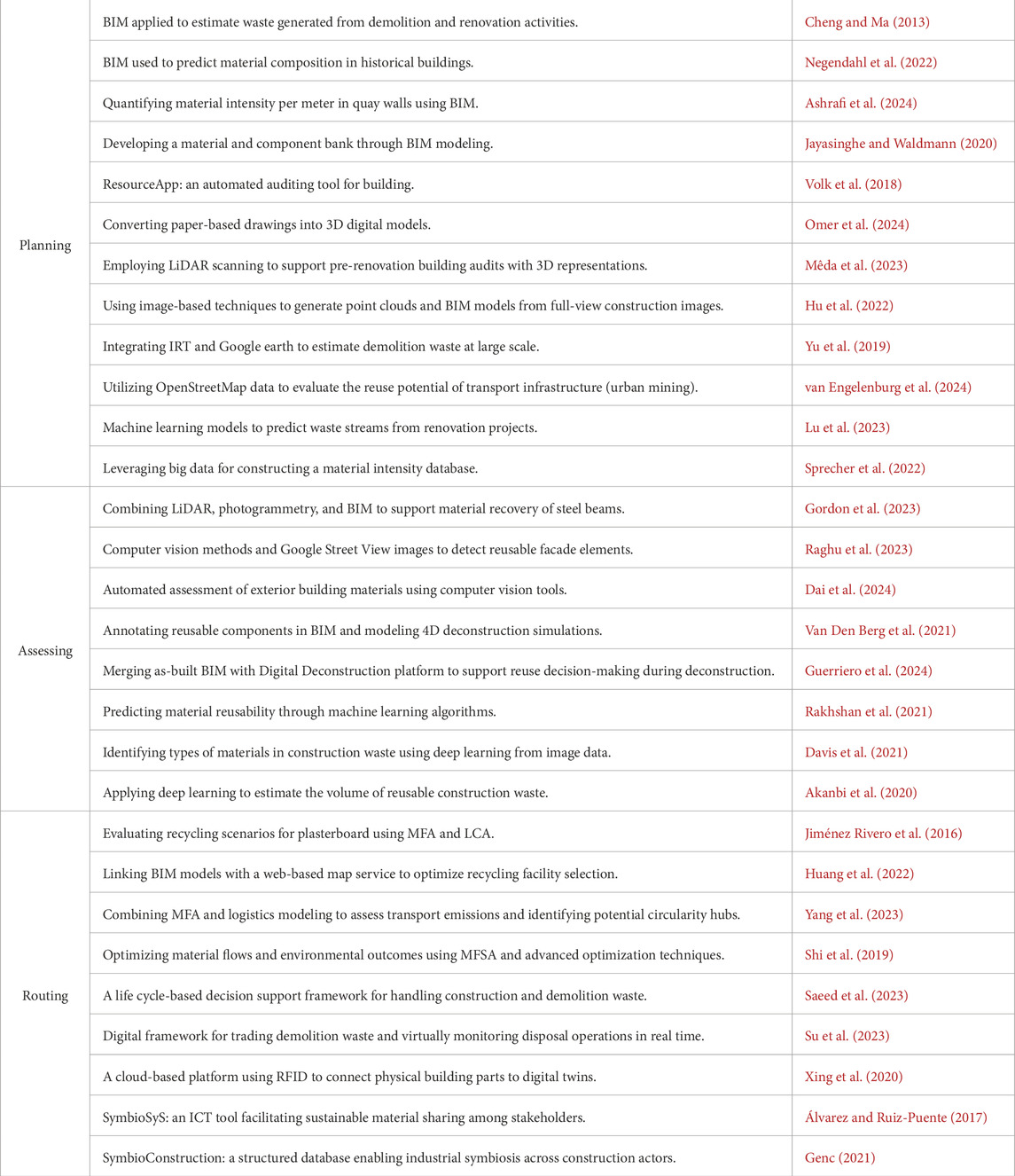

Several tools have been discussed in the Sections 3.1–3.3, each applicable to different phases of the renovation process—planning, assessing, or routing. For ease of comparison, these tools are summarized in Table 1, along with brief descriptions and relevant citations.

3.4 Existing frameworks

The second research aim is the development of a framework from a meso-scale perspective; therefore, relevant existing frameworks are reviewed in this section. Existing frameworks related to the construction renovation and circularity have different approaches. There are several frameworks that assess the sustainability of CDWM plans (Coronado et al., 2011; Dahlbo et al., 2015; Iodice et al., 2021; Mah et al., 2018; Marzouk and Azab, 2014; Nadazdi et al., 2022; Wijayasundara et al., 2018; Yazdanbakhsh, 2018). The spatial scale of these frameworks can vary from the project level to the city, regional, or national level. Each framework considers treatment options such as reuse, recycling, energy recovery, and disposal. These treatment options are evaluated using various indicators, including economic, environmental, and social metrics. Rayhan and Bhuiyan (2024) conducted a comprehensive review of CDWM frameworks, categorizing them based on their methodological approaches. Various frameworks assess the economic, environmental, and social performance of CDWM through different methods, including cost-benefit analysis (Begum et al., 2006; Yuan et al., 2011), LCA (Hossain et al., 2017; Yazdanbakhsh, 2018), system dynamics (Yuan, 2012; Yuan et al., 2011) and model development (Klang et al., 2003). A notable model by Turkyilmaz et al. (2019) evaluates CDWM in construction companies using PESTEL (political, economic, socio-cultural, technological, environmental, and legal) factors. Rayhan & Bhuiyan, (2024) suggest that incorporating a technical factor into performance assessment could further enhance these frameworks.

Various frameworks have been developed to implement CE strategies in the construction industry (Fernandes and Ferrão, 2023; López Ruiz et al., 2020; Rahla et al., 2021; Sáez-de-Guinoa et al., 2022; Timm et al., 2023). These studies offer guidance on which strategies to apply at various stages of the construction lifecycle. However, they do not address collaboration among multiple projects, which is crucial for achieving true circular material flow. López Ruiz et al. (2020) developed a theoretical model for applying CE strategies in the CDW sector. Their model outlines CE strategies that can be implemented across five key lifecycle stages: preconstruction, construction and renovation, collection and distribution, end-of-life, and material recovery and production. Charef (2024) developed a digital framework for implementing CE principles in the construction sector, drawing on expert opinions. While this framework has the potential to significantly enhance circularity in projects, it is highly dependent on well-structured 3D models and the availability of extensive data. Fernandes and Ferrão (2023) developed a framework for the circular refurbishment of construction, comprising six stages: mapping, selective disassembly/demolition, redesign, new products, reconstruction, and operation. Various challenges associated with adopting CE principles in the renovation process were identified and addressed within each stage. Bellini et al. (2024) developed a three-step process for the reuse of construction products: collecting information, conducting information-driven evaluations, and planning for reuse. This process enhances resource cycling and improves material recirculation potential in renovation projects, however, it primarily focuses on individual projects and does not account for collaboration opportunities across multiple projects.

Recent studies have explored the coordination of multiple construction projects, emphasizing improved resource efficiency and environmental performance. For instance (Ghoroqi et al., 2023), addressed multi-mode resource-constrained multi-project scheduling problems by developing a multi-objective model that integrates economic, environmental, and supply-related factors under uncertainty. Similarly (RezaHoseini et al., 2021), proposed an integrated bi-objective optimization model to coordinate procurement, vehicle selection, and project timing across multiple projects, aiming to reduce both logistical costs and emissions. In a related effort, Xiao et al. (2017) applied multi-project management theory to the construction of an industrial park, aiming to enhance internal coordination, optimize resource allocation, and improve overall project efficiency. While these studies offer valuable insights into managing multi-project environments, they primarily focus on logistics, scheduling, and internal optimization. However, they do not explicitly address circularity or the reuse of materials between projects. Given the growing need for sustainable and circular construction practices, this paper extends the discussion by proposing a meso-scale framework focused on planning, assessing, and routing material flows across renovation projects to enable effective material recirculation strategies.

4 Meso-scale approach

4.1 Understanding circularity at the meso scale

The CE can be studied at three scales: micro, meso, and macro. The micro scale focuses on individual products, materials, or construction projects, while the macro scale encompasses broader city-wide or regional systems and policies. The meso scale falls between these two. The concept of meso-scale circularity in the literature is often implicit and usually discussed in the context of industrial symbiosis and eco-industrial parks (Ghisellini et al., 2016; Kirchherr et al., 2017) where energy, waste or by-products from one industrial process serve as input for another. In contrast, the present study explicitly conceptualizes the meso scale as a coordinated system of multiple projects that are planned and managed under a unified framework, typically within a single program or municipal initiative. This perspective represents a novel application of material lifecycle continuity, positioned between micro-scale efforts (individual buildings or sites) and macro-scale strategies (city- or region-wide transitions over longer time horizons).

At the meso scale, projects often share similar material compositions and characteristics, creating potential opportunities for material reuse. Additionally, C&D activities are typically conducted by familiar agents with shared interests, fostering stronger interactions among stakeholders. This enhanced collaboration is crucial for advancing circular practices in the built environment (Munaro et al., 2020). At the meso scale, contractors often oversee multiple construction sites simultaneously, making site-to-site material reuse a viable strategy (Smeyers et al., 2022). This approach increases opportunities for material sharing and lifecycle reintegration, ultimately enhancing circularity across projects.

Furthermore, at the meso scale, integrating project phases where structures act as both donors and receivers within a circular system becomes feasible. Devènes et al. (2024) argued that the ideal integration of phases for reuse occurs when the reusability assessment of the donor structure is conducted before the conceptual design of the receiving structure. At the meso scale, this phase integration is feasible as both the material donor and receiver can be identified during the planning stage, enabling proactive coordination.

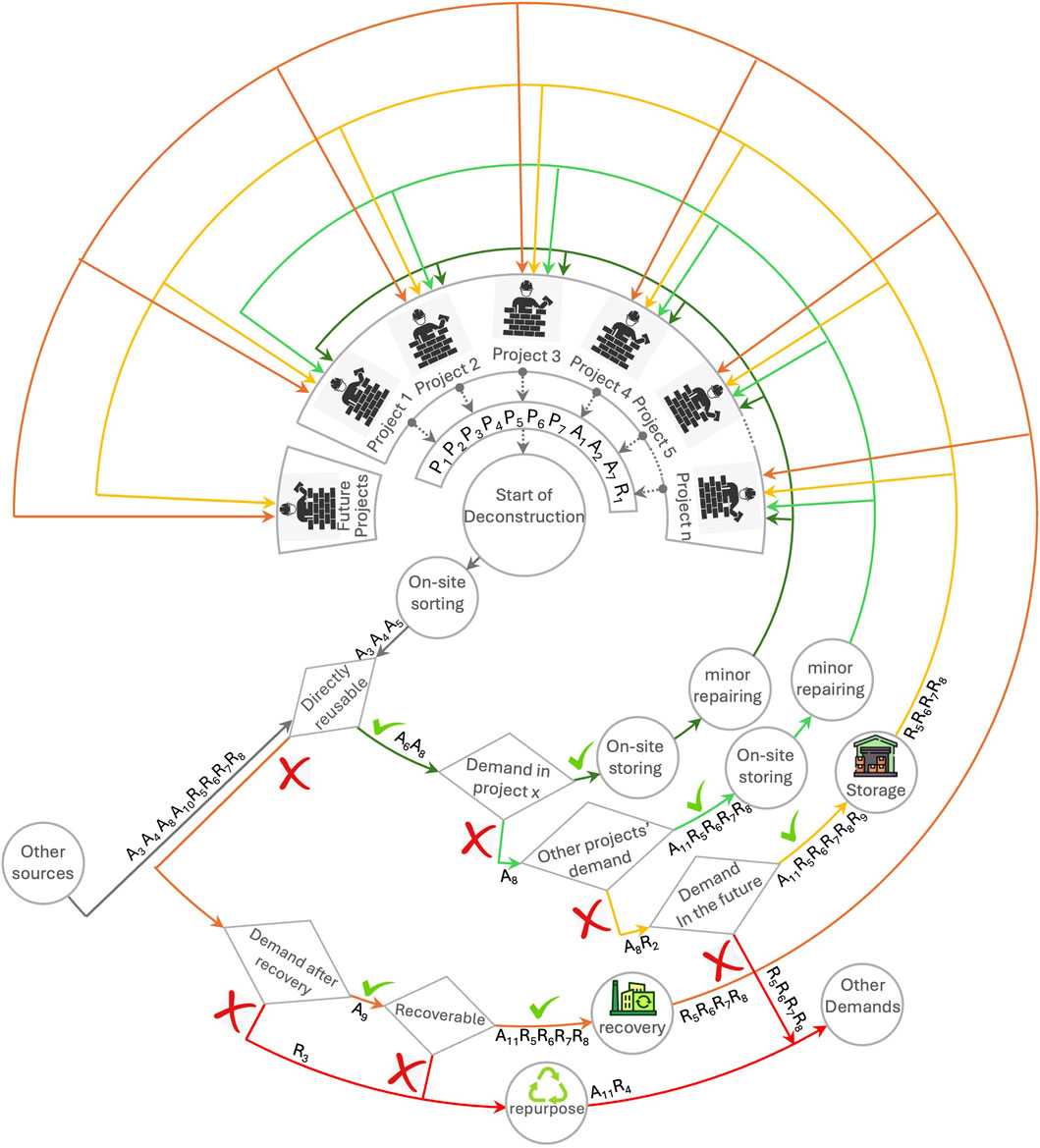

In the previous sections, a three-step approach for renovation in construction was introduced and discussed. The first stage, Planning, includes operations carried out before project execution—such as identifying candidate projects, collecting data, and preparing renovation audits. The second stage, Assessing, focuses on evaluating the suitability of materials and components for secondary use, involving inspections, quality checks, and laboratory testing. The final stage, Routing, determines the destination of reclaimed materials, including identifying recovery facilities, storage locations, receiving projects, and alternative demand sources. This structured process is intended to be applied at the meso scale of circularity, where multiple projects are coordinated within a shared system. A graphical abstract of this approach is presented in Figure 5.

Figure 5. Graphical abstract illustrating the Planning–Assessing–Routing approach for circular renovation at the meso scale.

4.2 Framework development

In the construction sector, multiple renovation projects often occur simultaneously within a city or region. These projects frequently share similar material compositions and demands, creating opportunities for material exchange and reuse. Implementing circular strategies across such a network of projects can significantly improve material efficiency and reduce overall resource consumption. However, realizing these benefits requires a shift from the traditional, project-specific (micro-level) focus toward a broader, multi-project (meso-level) perspective. At this meso level, unique characteristics emerge—such as inter-project coordination, shared material flows, and lifecycle reintegration opportunities—that emerge specifically at the meso scale and are not present in isolated, single-project (micro scale) settings.

One example of meso-scale circularity is urban infrastructure projects (Liu et al., 2024), where multiple renovation or construction projects are coordinated across a city and involve diverse stakeholders, including clients, contractors, and subcontractors. These complex, interconnected systems call for tailored frameworks that can address inter-project coordination and material flows.

Building on the methods, strategies, and frameworks identified through the SLR (Section 3), this section introduces a new framework for circular renovation from a meso-scale perspective. The framework incorporates key considerations associated with each stage of the renovation process as identified in the literature, providing a structured approach to enable circular material flow across multiple projects.

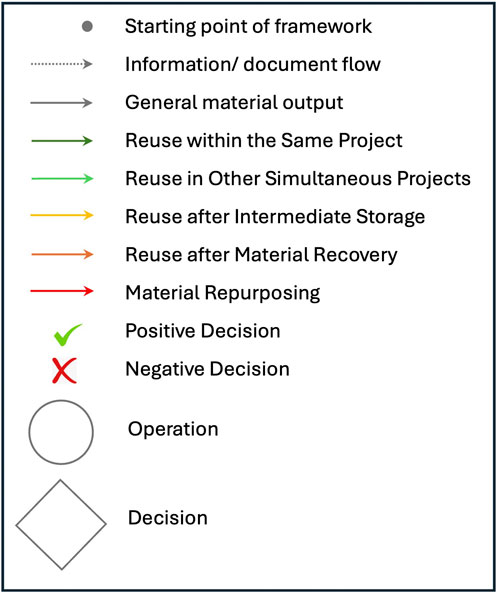

Figure 6 shows the framework, and Figure 7 displays the legend. The core of framework represents a group of simultaneous renovation projects {Project 1, Project 2, Project 3, … , Project n}, along with a symbol representing future projects. The renovation process begins at the grey points in the figure, where documents, information, and all necessary data from each project are collected. The grey dotted arrows ( ) represent the flow of information and documentation. After the necessary considerations, deconstruction takes place. The grey arrow (

) represent the flow of information and documentation. After the necessary considerations, deconstruction takes place. The grey arrow ( ) represents the general material outflow from project x (x ∈ {1, 2, 3, … , n}). When material is extracted from project x, after on-site sorting, it follows one of the reuse cycles depending on demand and quality. The different reuse cycles indicated by arrows in varying colors:

) represents the general material outflow from project x (x ∈ {1, 2, 3, … , n}). When material is extracted from project x, after on-site sorting, it follows one of the reuse cycles depending on demand and quality. The different reuse cycles indicated by arrows in varying colors:

• The dark green arrow ( ) indicates direct reuse of materials within the same project and on the same site. This occurs when there is a demand for the material within the project, and its quality is deemed suitable for direct reuse. In this cycle, on-site storage, minor repairs, and cleaning may be required, as indicated.

) indicates direct reuse of materials within the same project and on the same site. This occurs when there is a demand for the material within the project, and its quality is deemed suitable for direct reuse. In this cycle, on-site storage, minor repairs, and cleaning may be required, as indicated.

• The light green arrow ( ) represents direct reuse in other simultaneous projects at different locations. This occurs when there is a demand for the material in these projects, and its quality is deemed suitable for reuse. In this cycle, on-site storage, minor repairs, and cleaning may be required, as indicated.

) represents direct reuse in other simultaneous projects at different locations. This occurs when there is a demand for the material in these projects, and its quality is deemed suitable for reuse. In this cycle, on-site storage, minor repairs, and cleaning may be required, as indicated.

• The yellow arrow ( ) shows the intermediate storage of materials, allowing for their direct reuse at a later stage. This is relevant when there is currently no demand for the material across any projects, but its quality is deemed suitable for reuse. These materials will be utilized once a demand arises in one of the projects.

) shows the intermediate storage of materials, allowing for their direct reuse at a later stage. This is relevant when there is currently no demand for the material across any projects, but its quality is deemed suitable for reuse. These materials will be utilized once a demand arises in one of the projects.

• The orange arrow ( ) represents material recovery. When direct reuse is not feasible, materials may undergo repair, refurbishment, or remanufacturing. The recovery process depends on whether there will be a demand for the material after recovery and whether the material is suitable for recovery. The specific recovery method and processing facility (destination) vary depending on the material type. After recovery, these materials will be reused once a demand arises in one of the projects.

) represents material recovery. When direct reuse is not feasible, materials may undergo repair, refurbishment, or remanufacturing. The recovery process depends on whether there will be a demand for the material after recovery and whether the material is suitable for recovery. The specific recovery method and processing facility (destination) vary depending on the material type. After recovery, these materials will be reused once a demand arises in one of the projects.

• The red arrow ( ) marks repurposing materials for alternative uses within the construction sector or other industries. This applies when materials cannot be reused or recovered but can still serve a functional purpose in different applications.

) marks repurposing materials for alternative uses within the construction sector or other industries. This applies when materials cannot be reused or recovered but can still serve a functional purpose in different applications.

Figure 7. Legend of the framework shown in Figure 6.

To ensure cross-sectoral collaboration, the framework includes material outflow from other sources, represented by the grey arrow. As indicated, these materials must first undergo a reusability assessment before being integrated into the material cycle.

In this framework, various reuse cycles are illustrated. It is evident that smaller cycles are preferred in the material recirculation process, as they involve fewer operations and tasks. As shown in Figure 6, when materials move to larger cycles, additional operations and considerations are required, which may hinder their secondary use. Therefore, during the circular renovation process, efforts should be made to retain materials within the smaller cycles whenever possible.

As discussed in Section 3, this study defines three key steps for the circular renovation process: “Plan, Assess, Route.” Various considerations for each step identified through the SLR, are presented in Tables 2-4 respectively. These considerations are integrated into each step of the proposed framework (Figure 6). Implementing all of these aspects in the circular renovation process is a novel approach introduced in this research.

4.3 Demonstrative application

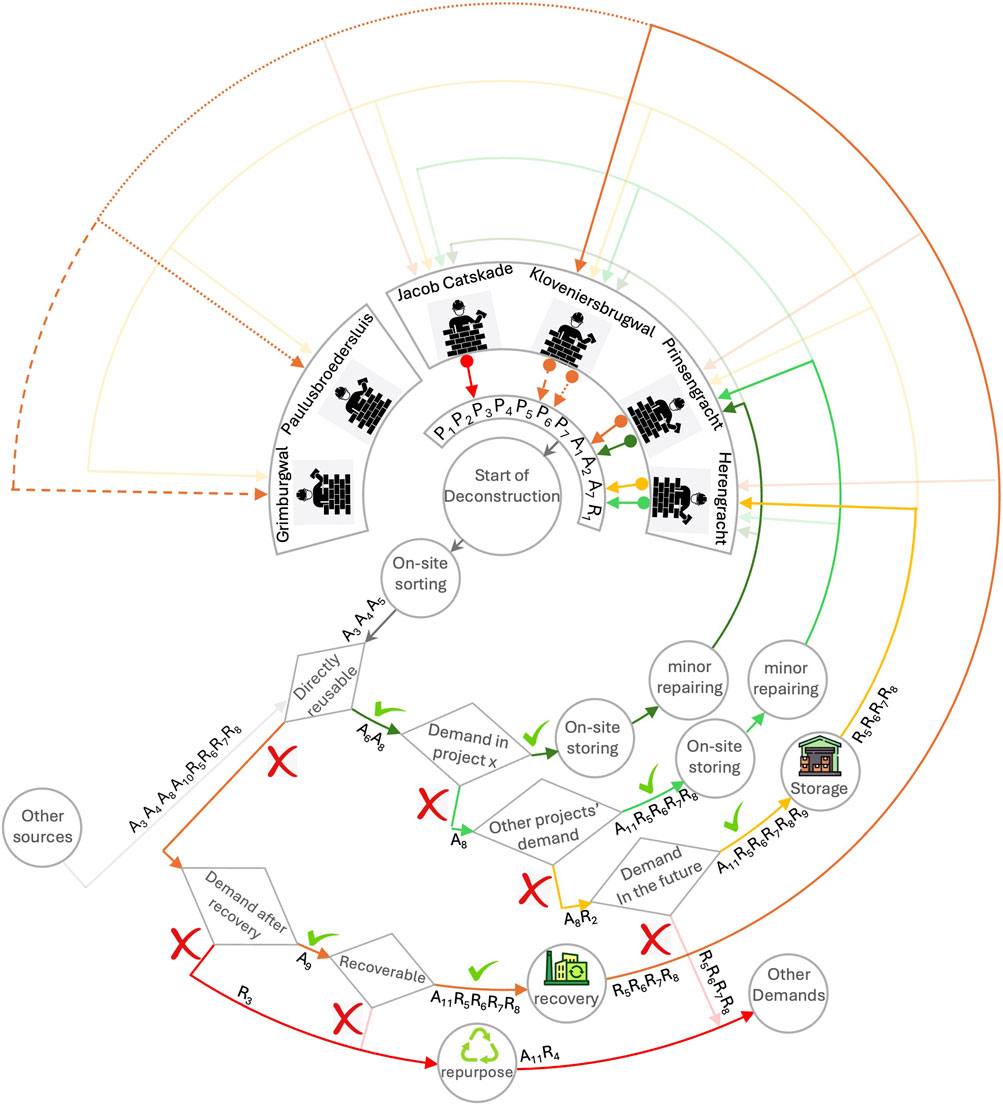

To demonstrate the practical applicability of the framework and support the claim that circular renovation can be effectively organized at a meso scale level, six projects in the city of Amsterdam were selected as an illustrative example of a multi-project system. These include:

Kloveniersbrugwal, Prinsengracht, Jacob Catskade, and Herengracht: These projects involve the renewal of quay walls. All were executed around the same time and share similar structural characteristics and material compositions. The quay walls consist of wooden foundations, concrete, masonry, and soil.

Grimburgwal and Paulusbroedersluis: These projects focus on bridge renewal and are scheduled for the upcoming year. They involve significant use of masonry and concrete.

These projects are considered collectively as a multi-project system and have been analyzed using the meso-scale framework developed in the Section 4.2. The framework (Figure 6) is applied to visualize various material flows within the system (Figure 8). Different types of material flows are illustrated using distinct colors and line styles, while the remaining parts of the framework are shown with reduced transparency, indicating that no material flow occurs in those situations. In total, seven material flows have been identified within the system. These flows have either already been implemented in the projects or have been recognized by experts as potential circular opportunities, although they have not (yet) been executed. These material flows are as below:

• Herengracht–Outflow of Masonry ( ): The masonry from the sidewalk adjacent to the quay wall was removed at the beginning of the project. Due to limited space on-site, transported to temporary storage facilities. At the end of the project, they were brought back and reused at the original location.

): The masonry from the sidewalk adjacent to the quay wall was removed at the beginning of the project. Due to limited space on-site, transported to temporary storage facilities. At the end of the project, they were brought back and reused at the original location.

• Herengracht–Outflow of Capstones ( ): Capstone pieces were removed from the Herengracht quay wall. A demand for these capstones arose in the Prinsengracht project, which had started earlier and was already in its final stages. Therefore, the capstone pieces were sent directly to the Prinsengracht project, where they were cleaned and reused.

): Capstone pieces were removed from the Herengracht quay wall. A demand for these capstones arose in the Prinsengracht project, which had started earlier and was already in its final stages. Therefore, the capstone pieces were sent directly to the Prinsengracht project, where they were cleaned and reused.

• Prinsengracht–Outflow of Soil ( ): The soil behind the quay wall was excavated, stored on-site, and directly reused later in the same project.

): The soil behind the quay wall was excavated, stored on-site, and directly reused later in the same project.

• Prinsengracht–Outflow of Concrete ( ): Harvested concrete was sent to a recycling facility, where the cement paste and aggregates were separated and used to produce new concrete. This recycled concrete was utilized in the prefabricated elements used in the Kloveniersbrugwal project.

): Harvested concrete was sent to a recycling facility, where the cement paste and aggregates were separated and used to produce new concrete. This recycled concrete was utilized in the prefabricated elements used in the Kloveniersbrugwal project.

• Kloveniersbrugwal–Outflow of Concrete ( ): Similar to Prinsengracht, the harvested concrete was recycled and used to manufacture prefabricated elements. These elements are planned to be reused in the Paulusbroedersluis project in the following year.

): Similar to Prinsengracht, the harvested concrete was recycled and used to manufacture prefabricated elements. These elements are planned to be reused in the Paulusbroedersluis project in the following year.

• Kloveniersbrugwal–Outflow of Masonry ( ): Harvested masonry was sent to a recycling facility where it was processed into pulverized masonry. This recycled masonry will be reused in the upcoming Grimburgwal project.

): Harvested masonry was sent to a recycling facility where it was processed into pulverized masonry. This recycled masonry will be reused in the upcoming Grimburgwal project.

• Jacob Catskade–Outflow of Wooden Piles ( ): Wooden piles were removed and transported to temporary storage. As there was no demand for timber in the new foundation, the wood was repurposed for interior design applications and ecological bank protection.

): Wooden piles were removed and transported to temporary storage. As there was no demand for timber in the new foundation, the wood was repurposed for interior design applications and ecological bank protection.

Figure 8. Material flows across multiple infrastructure projects in Amsterdam based on the meso-scale circularity framework.

In the figure, when more than one material flow exists in the same direction, it is represented in grey.

The successful material recirculation flows observed among the six Amsterdam projects are a direct outcome of adopting a meso-scale perspective, which enables a shift from isolated project management to an integrated, meso-level approach. By treating the projects as part of a coordinated network rather than stand-alone endeavors, transparency in both material supply and demand was established at an early stage, allowing for proactive identification of lifecycle reintegration opportunities. This early visibility facilitated precise planning and alignment of project timelines, ensuring that secondary materials—such as capstones, concrete, and masonry—were made available at the right moment for secondary use in receiving projects. Moreover, the coordinated nature of the system enabled strategic decisions regarding storage, transportation, and processing logistics, reducing waste, duplication of effort, and unnecessary material handling. The framework developed in this study plays a central role in enabling such coordination. By clearly outlining the stages of circular renovation and embedding key considerations at each step, it serves as a practical tool for identifying, organizing, and operationalizing reuse opportunities across multiple projects. This structured meso-scale approach not only enhances circularity outcomes but also demonstrates how early-stage collaboration, shared material intelligence, and timeline synchronization can transform theoretical circular strategies into tangible practices. As cities increasingly face the challenge of large-scale infrastructure renewal, this framework provides a scalable and actionable model for embedding resource cycling into multi-project systems, making it a timely and necessary contribution to the field.

5 Discussion

5.1 Feasibility and application of the framework

The meso-scale framework developed in this study was designed to identify and map material flows across multiple circular construction projects. To test its feasibility, a practical implementation was conducted using six quay wall and bridge renovation projects in the city of Amsterdam. These projects were analyzed collectively as a multi-project system, where seven distinct material flows—ranging from reuse of capstones and pavement bricks to recycling and repurposing of concrete and wood—were identified and visualized using the framework. This example confirms that the framework is suitable for visualizing and analyzing complex, inter-project material exchanges. It also enables the identification of underutilized reuse potentials and supports planning for synchronization between supply and demand of secondary materials.

Further steps are required to quantify and simulate alternative scenarios to support decision-making under constraints like cost, scheduling, and environmental impact. Future research could integrate the framework into decision-support tools or agent-based models (e.g., AnyLogic), allowing simulation of scenarios such as early stakeholder coordination or delayed demolition and their impact on material reuse potential.

5.2 Implementation barriers and mitigation strategies

While the framework highlights opportunities for material lifecycle continuity, implementation in real-world contexts faces several challenges. Key barriers include:

• Stakeholder resistance: Traditional procurement models and siloed project management approaches can discourage cross-project coordination. Many actors are not incentivized to explore component recovery options that fall outside their immediate scope.

Mitigation: Early engagement and incentive structures (e.g., performance-based contracts) can foster collaborative behaviors.

• Cost and logistical constraints: Intermediate storage, transport of secondary materials, and mismatch in timing between demolition and construction phases increase operational complexity and cost.

Mitigation: Project synchronization and digital platforms for secondary material exchange can reduce inefficiencies and improve planning.

• Data incompatibility: Heterogeneous data formats and the absence of centralized databases for materials hinder seamless information sharing between projects.

Mitigation: Adoption of standardized BIM protocols and establishment of regional material banks or “digital twins” can facilitate data interoperability.

These barriers are not unique to the Amsterdam context and may manifest differently across regions, depending on institutional and market conditions.

5.3 Policy and regulatory support

Policy instruments play a critical role in enabling circular construction, especially at the meso-scale. In the Netherlands, municipal initiatives have already piloted reuse-oriented procurement strategies, but broader regulatory backing is necessary for scaling up. At the European level, initiatives like the Circular Economy Action Plan and Green Public Procurement guidelines provide a framework to incentivize material reuse and multi-project planning.

Mechanisms such as Extended Producer Responsibility, tax credits for secondary material use, and mandatory digital building logbooks could significantly enhance adoption. Additionally, public sector leadership in mandating circularity targets—particularly in large infrastructure portfolios—can accelerate market transformation.

5.4 Global applicability and adaptability