- 1Faculty of Graduate Studies, Sabaragamuwa University of Sri Lanka, Belihuloya, Sri Lanka

- 2Faculty of Management Studies, Sabaragamuwa University of Sri Lanka, Belihuloya, Sri Lanka

- 3Department of Engineering, University of Cambridge, Cambridge, United Kingdom

Introduction: Environmental sustainability in the ceramic tile industry has gained global attention due to its significant impact on the building and construction sector. Sustainable production strategies are critical to reducing environmental footprints while maintaining economic growth.

Methods: This study evaluates and compares the environmental impacts of conventional ceramic tile production with four proposed eco-innovation scenarios using a cradle-to-gate life cycle assessment (LCA) approach. Environmental impacts were quantified per square meter of gross floor area of ceramic tile using SimaPro Faculty version. All four eco-innovation scenarios were compared against the conventional (base) scenario. Scenario 1 partially replaces virgin raw materials with waste materials (e.g., fly ash). Scenario 2 focuses on energy recovery for heating during the drying process. Scenario 3 substitutes conventional energy sources with cleaner alternatives. Scenario 4 integrates all these eco-innovative strategies.

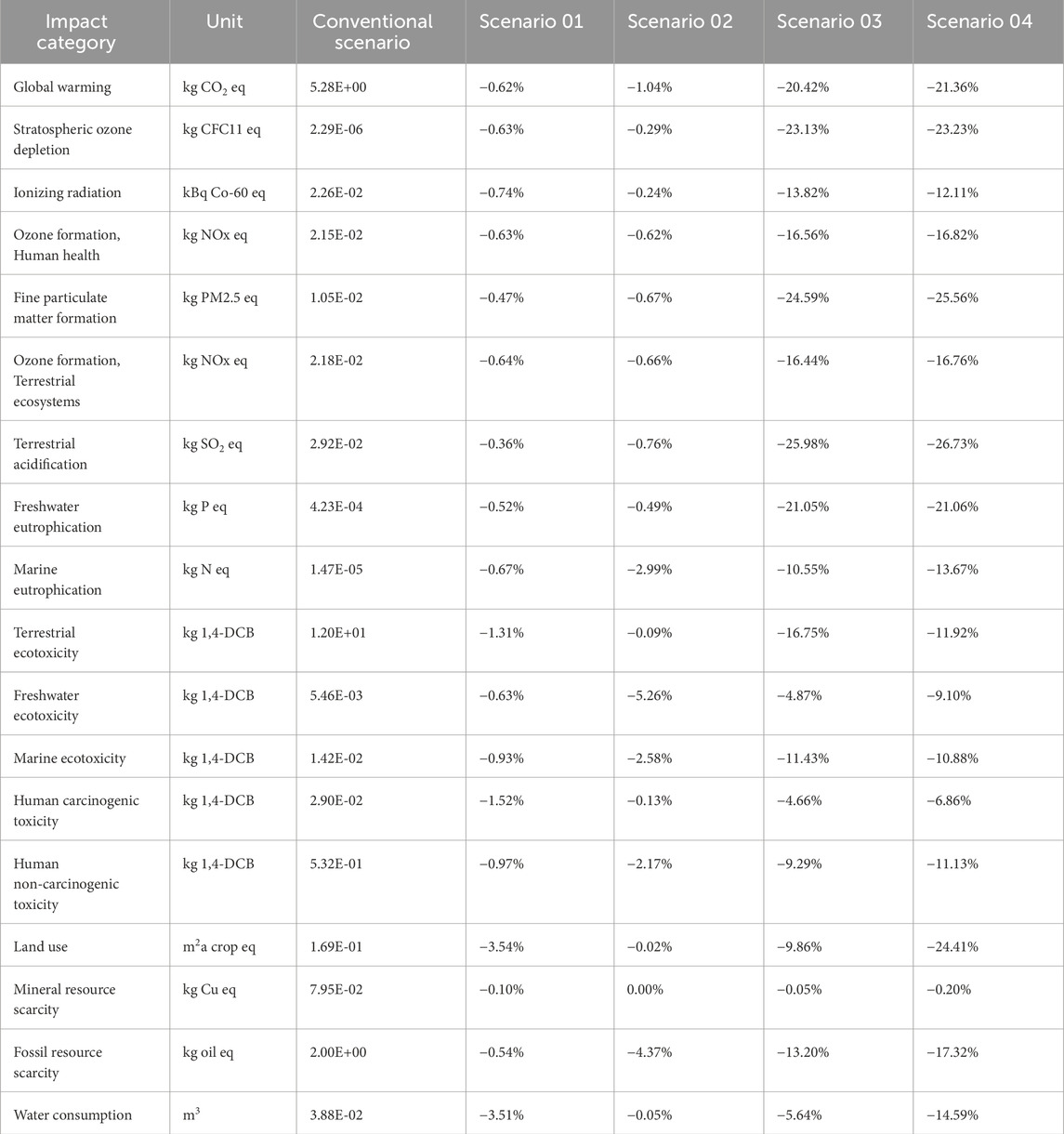

Results: The analysis indicates that human carcinogenic toxicity is the most critical environmental impact across all five scenarios. Among the eco-innovation alternatives, Scenario 4 emerges as the most sustainable, achieving a 26.73% reduction in terrestrial acidification, a 23.23% decrease in stratospheric ozone depletion, and a 21.36% reduction in global warming potential compared to the baseline scenario.

Discussion: These findings provide valuable insights for policymakers and ceramic manufacturers in Sri Lanka, supporting the development of sustainable strategies to enhance environmental performance. By integrating renewable energy, waste materials, and energy-efficient technologies, the ceramic tile industry can transition toward more sustainable production, striking a balance between economic growth and environmental stewardship. This research addresses local challenges and contributes to global efforts in sustainable manufacturing, setting a precedent for other industries.

1 Introduction

Building life cycles require substantial resources, significantly impacting the environment, while population growth intensifies the demand for construction materials. This concern is further emphasized by the alarming rise in the per capita material footprint, which surged from 8.1 metric tons in 1990 to 12.2 metric tons in 2017, representing a 50% rise (United Nations Statistics Division, 2025). Alongside concrete, steel, glass, and wood, ceramic is among the most consumed construction materials (Boschi et al., 2020; Bovea et al., 2010) particularly in residential and commercial buildings (Yuan et al., 2024). Serving as core components of the built environment, construction materials significantly contribute to achieving sustainability (Wanaguru et al., 2025; 2022). The worldwide manufacturing of ceramic tiles has significantly increased in recent years, nearly doubling in volume (Vieira et al., 2023). This widespread use is attributed to their durability, low maintenance requirements, and a wide variety of colors, designs, textures, and sizes (Yuan et al., 2024). Accordingly, the environmental issues associated with the construction industry have drawn attention to the concept of environmental sustainability and how its application to the ceramics industry (Türkmen et al., 2021).

Ceramic tiles, being the most widely used ceramic product in Sri Lanka, play a significant role in building construction compared to other flooring materials (Jayasinghe and Dassanayake, 2024). Further, local floor tile demand grew by 16%, with 60% of the Sri Lankan tile market supplied by local production and the rest by imports (Lanka Tiles Plc, 2020). By 2022, investments and advancements had increased local production capacity to 31 million square meters, meeting and surpassing demand (Daily Mirror, 2023). The increasing demand for raw materials in the Sri Lankan construction industry has led to their scarcity, creating an urgent need to explore alternative materials for a full or partial replacement (Jayasinghe and Dassanayake, 2024). According to Divakara and Attalage (2007), the ceramic sector in Sri Lanka is extremely energy-intensive, employing both thermal and electrical energy (Divakara and Attalage, 2007). Further, ceramic floor tiles, widely used in Sri Lankan construction, are made from natural resources like clay, feldspar, silica sand, and dolomite, with their energy-intensive production posing environmental challenges Kamalakkannan and Kulatunga (2019), enhancing the environmental consciousness of tile manufacturing is essential for promoting sustainability in Sri Lanka (Jayasinghe and Dassanayake, 2024).

Numerous studies have identified key stages in the ceramic tile manufacturing process that contribute significantly to environmental impacts, emphasizing the need for informed decision-making to mitigate these effects (Furszyfer Del Rio et al., 2022; Vieira et al., 2023). Accordingly, it is recognized that the advancements in technology for cleaner production are essential for the sustainable development of the ceramic sector (Wang, 2020). Technological advancements have further improved production processes and formulations, enabling the inclusion of up to a dozen different materials in tile batches, which has led to significant improvements in the technical performance of ceramic tiles (Dondi et al., 2021). In recent decades, the incorporation of scrap materials like fly ash (Yuan et al., 2024), post-treated bottom ash (Schabbach et al., 2012), into ceramic tile manufacturing has enhanced the stability and characteristics, while promoting environmental benefits by partially substituting quartz sand and feldspar. Further, heat recovery systems from flue gases reduce GHG emissions and energy costs while improving process energy efficiency (Furszyfer Del Rio et al., 2022; Ibáñez-Forés et al., 2013) and increased use of renewable energy (Ros-Dosdá et al., 2018) has resulted in significant improvements in the ceramic sector.

Life cycle assessment is a widely accepted and commonly utilized method for quantifying environmental impacts. The LCA findings assist in identifying hotspots for improvement, offering useful data for strategic planning of products or processes, setting design and redesign priorities, and assisting in the selection of environmental performance indicators; all of which help industries gain a competitive edge (Bajdur et al., 2023; Pryshlakivsky and Searcy, 2013), driven by eco-innovation. Eco-innovations in ceramic tile production encompass alterations in product design, enhancements in process efficiency for energy conservation, and transitions to more sustainable energy sources (Ros-Dosdá et al., 2018; Türkmen et al., 2021). LCA helps identify potential product improvements by evaluating all life cycle stages and manufacturing processes for environmental performance, enabling resource reduction through optimal techniques, and minimizing environmental impacts (Türkmen et al., 2021). Technological advancements in cleaner production are essential to the ceramic industry’s long-term viability (Wang, 2020). A significant amount of existing research has concentrated on assessing the environmental impacts of ceramic tile manufacturing (Türkmen et al., 2021). There is a scarcity of studies that investigate the economic and technological feasibility of enhancement strategies aimed at particular production hotspots that have been identified (Wang, 2020).

Further, despite being widely discussed worldwide, the life cycle approach to environmental impact in building construction is still largely unfamiliar in Sri Lanka due to the lack of country-specific data and the high costs and complexities involved in conducting such assessments (Kumarasena and Weerathunga, 2020; Vijerathne et al., 2022). Creating a national database would enhance the precision of environmental impact assessments for construction in Sri Lanka (Vijerathne et al., 2024). This study aims to create a country-specific Life Cycle Inventory (LCI) dataset to evaluate the environmental impacts of ceramic tile production in Sri Lanka and identify the most sustainable eco-innovations by comparing four eco-innovative scenarios. It involves conducting a life cycle assessment using the cradle-to-gate approach to identify environmental hotspots in ceramic tile manufacturing and to compare the sustainable improvement opportunities through cleaner production scenarios, ultimately guiding eco-design strategies. Accordingly, this research provides a fundamental basis for informing evidence-based policy decisions, supporting the adoption of sustainable manufacturing practices, and driving innovation toward environmentally conscious product development in the ceramic industry.

1.1 Environmental impacts and sustainability in global ceramic tile production

The ceramic tile industry has emerged as a significant contributor to global manufacturing, with its environmental footprint and sustainability challenges drawing increasing academic attention. The production of ceramic tiles negatively impacts the environment, both through the extraction of natural raw materials and the emissions produced during the firing process (Luiz et al., 2020), producing around 1.84 million tonnes of carbon dioxide each year globally (Quinteiro et al., 2022). Further, Environmental impact assessment studies have consistently identified energy consumption and water consumption as critical concerns in ceramic tile manufacturing (Mezquita et al., 2017; Wang, 2020) note that natural gas remains the predominant energy source in most facilities, contributing significantly to the industry’s carbon footprint, with its energy mix comprising 85%–92% gas and 8%–15% electricity (Monfort et al., 2010).

The United States Environmental Protection Agency (USEPA) has compiled data from multiple research studies and ceramic manufacturing facilities, indicating that the production of ceramic tiles emits an average of 300 kg CO2/Mg, 1.6 kg CO/Mg, 0.27 kg NOx/Mg, 2.4 kg SO2/Mg and 0.23 kg HF/Mg (Tikul and Srichandr, 2010). Further, fluorine compounds (fluorides, HF) are released from clays during ceramic production at high temperatures (600 °C–700 °C) due to fluoride impurities present in the raw materials (Timellini et al., 2016). The burning of fuels in furnaces and dryers generates SOx, NOx, and CO, and produces CO2 emissions (Atılgan Türkmen et al., 2021). Kilns and dryers utilized in ceramic manufacture are responsible for the majority of fuel-related emissions (Atılgan Türkmen et al., 2021). Consequently, the effective functioning of such equipment is crucial regarding emissions (Atılgan Türkmen et al., 2021). Dust emissions may arise during the shipping, processing, storage, and grinding of raw materials. Emissions of SOx, hydrogen fluoride (HF), hydrogen chloride (HCl), and CO2 arise from the sulfur-containing, chlorinated, fluorinated, and carbonated chemicals present in the raw material (Atılgan Türkmen et al., 2021). The polishing and surface coating phases of baked ceramics processing generate particulate matter and VOC emissions (Ibáñez-Forés et al., 2013). This sector incurs considerable health costs attributable to elevated mortality rates (Furszyfer Del Rio et al., 2022). In Dhaka, Bangladesh, brick production is associated with an estimated 2,200 to 4,000 premature deaths and 200,000 to 500,000 asthma attacks each year (Guttikunda and Khaliquzzaman, 2014).

A singular strategy to substantially reduce emissions in ceramic production is not commonly accepted; rather, a holistic approach encompassing energy efficiency, recycling, resource optimisation, and material replacement is essential (Furszyfer Del Rio et al., 2022). The incorporation of industrial solid waste into ceramic materials can mitigate these impacts, contingent upon the properties of the solid waste and its interaction with ceramic materials during the processing stages (Luiz et al., 2020). In recent decades, the integration of leftover materials has become a normative practice in ceramic tile manufacturing, improving both stability and performance (Yuan et al., 2024). This technique enables the utilisation of waste materials while advancing sustainable manufacturing practices (Yuan et al., 2024). Technological advancements have enhanced production processes and formulations, allowing the incorporation of various elements in tile batches, and significantly improving ceramic tiles’ technical qualities (Dondi et al., 2014). Further, Mezquita et al. (2014) propose several approaches to reduce energy consumption, including heat recovery systems and advanced kiln designs. Ciacco et al. (2017) explore cogeneration systems integration, while Manrique et al. (2018) analyze barriers to implementing energy efficiency measures. Alternative energy sources have gained attention, with Wang (2020) investigating solar thermal integration possibilities and Olofsson and Börjesson (2018) examining biomass utilization potential.

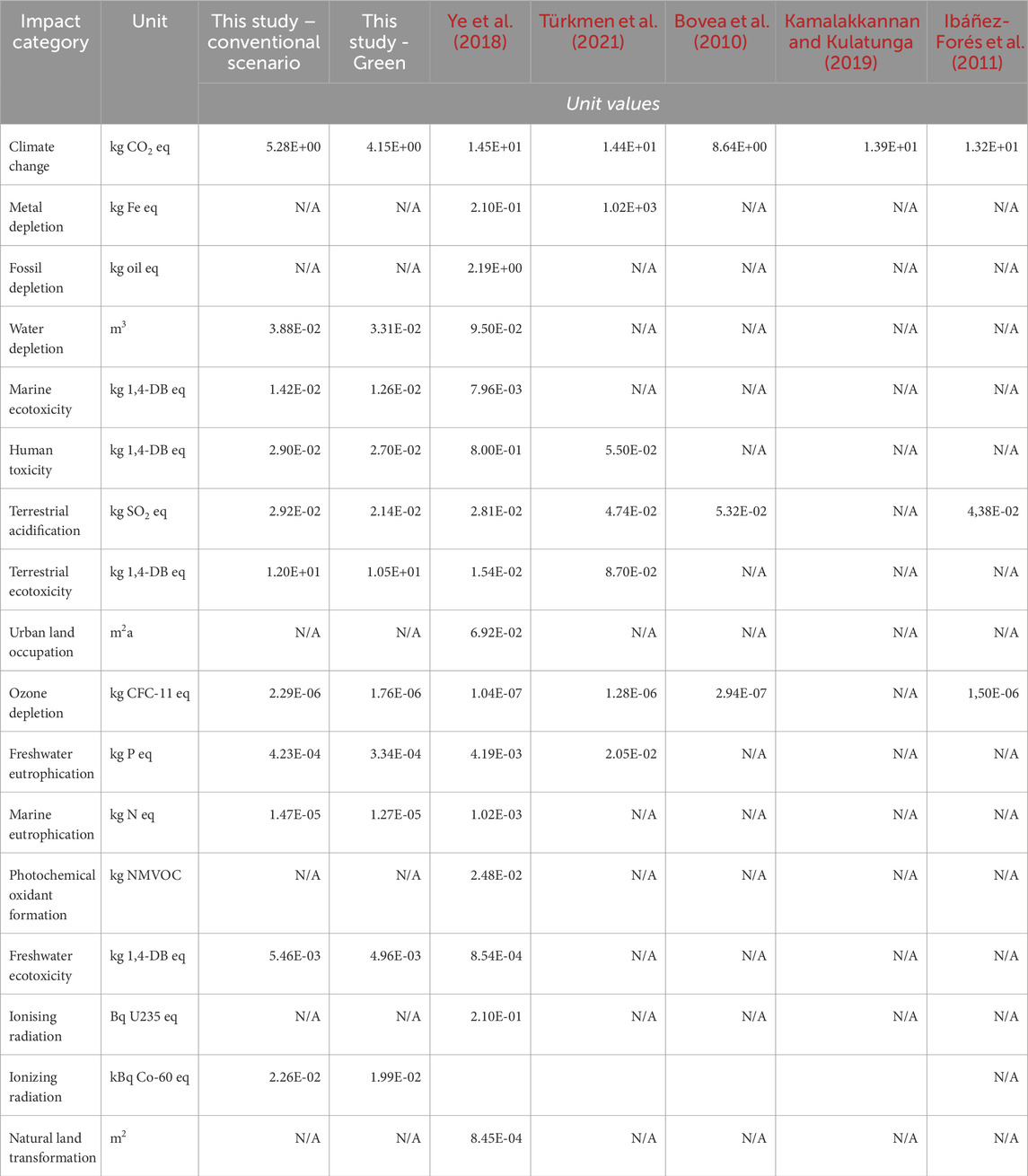

While European manufacturers, especially those in Italy and Spain, maintain technological leadership, emerging markets in South America and Southeast Asia are showing remarkable growth potential (Viana et al., 2025). Boschi et al. (2020) further highlight how Italian manufacturers have maintained their competitive edge through innovation and quality standards, while simultaneously addressing sustainability concerns. China remains the world’s leading producer and consumer of ceramic tiles, accounting for approximately 50% of global tile production and 40% of total tile consumption (Wang et al., 2020), with India and Brazil ranking as the second and third-largest producers of ceramic tiles globally, as illustrated in Figure 1. Spain and Italy are the largest producers of ceramic tile, representing about 70% of the European Union’s total production (Ancona et al., 2022), while being respectively fifth and eighth largest produces on the global scale. Further, countries such as Vietnam, Spain, Egypt, and Iran exhibit output or consumption values between 500 and 900 million square meters, thereby making a moderate contribution to the industry. Sri Lanka exhibits the lowest output and consumption, at merely 31 million square meters, markedly less than all other nations in the dataset.

Figure 1. Ceramic tile production in the year 2022 (in millions of square meters) by global top manufacturing countries, including Sri Lanka. Source: Prepared by the authors based on data from the (Manufacturing Economic Studies, 2024) and average production statistics for Sri Lanka from (Daily Mirror, 2023).

2 Methodology

2.1 Life cycle assessment framework

The LCA is a well-accepted methodology for evaluating the environmental impacts of a product, process, or system throughout its entire life cycle, from raw material extraction to final disposal in a quantified manner, following ISO 14040 and ISO 14044 standards. This comprehensive approach enables organizations to identify opportunities for improvement, reduce resource consumption, and minimize waste, ultimately leading to more sustainable practices. It provides a structured framework that comprises four phases: defining the goal and scope, conducting inventory analysis, assessing impacts, and interpreting the results. Accordingly, this study employs a LCA approach to quantify environmental impacts per square meter of ceramic tile from a cradle-to-gate perspective, using the SimaPro Faculty version.

This study identified the primary environmental criticalities through an integration of quantitative and contextual analyses. Initially, all potential impact categories were evaluated utilising the ReCiPe 2016 midpoint methodology to ensure a thorough assessment for the cradle-to-gate system boundary. The comparative contributions of each impact category were analysed, with those exhibiting the highest percentage contributions to the overall environmental impact considered significant. A hotspot analysis was subsequently performed to ascertain the inputs and processes that contribute most significantly to these categories. Furthermore, local environmental priorities in Sri Lanka, including greenhouse gas emissions, resource depletion, and water scarcity, were taken into consideration to ensure the findings were relevant to regional sustainability issues. This integrated method facilitated the identification of essential effect categories that are both statistically substantial and contextually pertinent, thereby offering a solid foundation for recognising environmental criticalities in ceramic tile manufacturing. Further, this thorough framework ensures an extensive and detailed assessment of environmental burdens, providing a robust basis for comparing conventional and eco-innovative production scenarios.

2.2 Goal and scope of the study

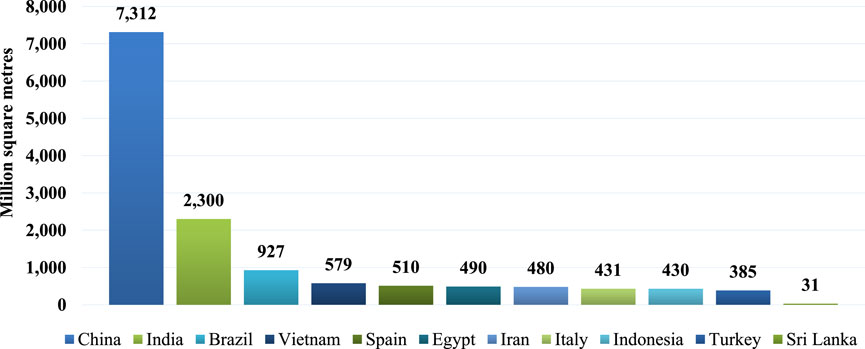

EN 15804:2012 and ISO 21930:2017 were developed to standardise decision criteria for applying LCA to buildings, particularly in specifying the life cycle stages. Accordingly, this study conducts a cradle-to-gate LCA for the reference building, as shown in Figure 2. Further, the declared unit is considered the cradle-to-use environmental impact per 1 m2 of ceramic tile product.

Figure 2. System boundary of the study outlining the cradle-to-gate scope of the ceramic tile manufacturing process. Icon by The Noun Project, https://thenounproject.com/, used under CC BY 3.0.

The process begins with milling and mixing, where these materials are combined to create a chemically and physically uniform mixture, as shown in Figure 2. This mixture is then transferred to the spray drying stage to achieve an optimal moisture content of approximately 6%, necessary for the pressing and forming phase up to 1.70gcm3. In the pressing stage, the spray-dried powder is compacted into unfired tile shapes, which are subsequently subjected to tile drying to enhance their structural strength. After drying, the tiles undergo glazing and printing, where a glaze composed of frit and other raw materials is applied. Following this, the tiles move to the squaring and chamfering stage for edge refinement. The final step is tile firing, where the glazed tiles are fired at temperatures exceeding 1188 °C. This high-temperature process is critical for producing durable and high-strength ceramic tiles.

2.2.1 Eco-innovation scenarios and the mid-point impact assessment comparison

This section explains the three eco-innovative scenarios and the fourth scenario (Scenario 4), which combines all three approaches, including 48% harvested rainwater, replacing groundwater extraction.

2.2.1.1 Scenario 01: replacing virgin material with waste material: fly ash as an alternative to feldspar

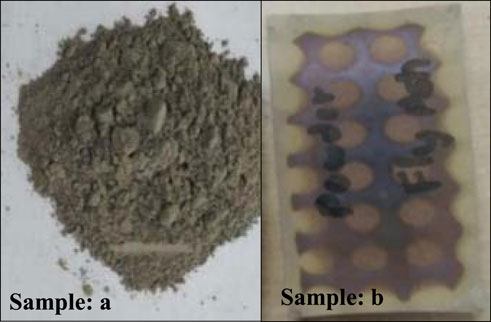

In recent decades, the integration of waste materials into ceramic tile production has been prevalent to improve stability and characteristics while fostering sustainable manufacturing through the use of waste materials, especially fly ash (Yuan et al., 2023). Further, numerous studies concentrate on the characterisation and application of various alternative fluxing agents due to the increased cost of feldspars and the scarcity of proper deposits (Schabbach et al., 2012). The use of waste-derived materials, as alternative raw inputs, also adds value by enabling the productive management of readily available industrial residues, thereby contributing to circular resource flows in material production (Gronba-Chyła et al., 2024). Fly ash, a waste product of coal power generation, is characterized by its gray color, a lump size ranging from 0–5 mm (5 mm sieve), a shrinkage of 6.89%, a Loss of Ignition (LOI) of 4.89%, and a water absorption rate of 18.74%. These properties were considered for this study, where the physical appearance of the fly ash and the test samples (referred to as cookies) is shown in Figure 3. The cookies represent disc-shaped specimens made from the fly ash, which were used to determine relevant characteristics, present in Table 1.

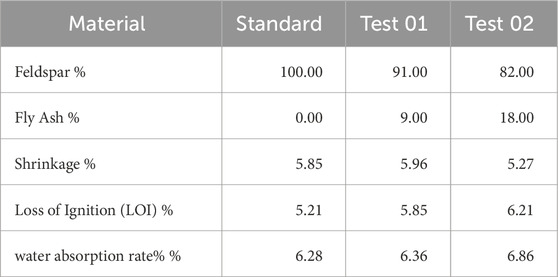

Table 1 summarizes the material composition and fired properties of ceramic bodies with varying percentages of fly ash (0%, 9%, and 18%). The study observes changes in shrinkage, loss of ignition (LOI), and water absorption rates as fly ash content increases, while feldspar content proportionally decreases. Based on the observed properties, Test 01 (9% replacement of fly ash) has been identified as the optimal scenario for proceeding with the eco-alternative solution due to its favorable results as the successful test by the manufacturer.

The zero-burden assumption treats waste or residual materials as burden-free when used as raw materials in a product life cycle, without considering the environmental impacts of waste treatment options for a specific type or amount of waste (Olofsson and Börjesson, 2018). In this study, the zero-burden assumption is applied to fly ash used as a replacement for feldspar. Fly ash, considered a burden-free industrial byproduct, is treated as a raw material in the ceramic tile production life cycle. This assumption focuses solely on the impacts from the collection, processing, and transportation of fly ash, without accounting for alternative waste treatment options.

2.2.1.2 Scenario 02: liquefied petroleum gas savings in spray drying and horizontal dryer through heat recovery at the kiln

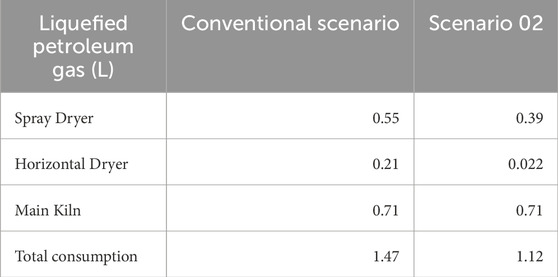

A roller-tunnel kiln with heat recovery technology or a tunnel kiln with wagons is the most effective method for firing ceramics (Manrique et al., 2018), with the roller kiln being used in this scenario. Heat exchangers capture heat from clean or contaminated hot flue gases emitted by the kiln to preheat combustion air, which can then be utilized in either the kiln or the dryer. Further, the ceramic tile sector may save up to 30% on costs by including a heat recovery system from flue gases (Ibáñez-Forés et al., 2013). This is corroborated by other research, which shows that cutting-edge systems that make heavy use of kiln heat recovery can lower fuel energy consumption per unit of production by as much as 60% when compared to conventional units (Furszyfer Del Rio et al., 2022). Accordingly, this scenario achieved a 30% liquefied petroleum gas reduction in the spray drying process with the heat recovery system installation as shown in Table 2.

Table 2. Liquefied petroleum gas consumption reduction in spray dryer with heat recovery system installation.

2.2.1.3 Scenario 03: replacing grid electricity with renewable energy from a solar PV system

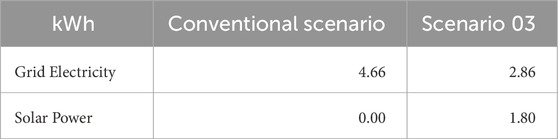

The production of ceramic tiles is an essential field within the building and construction industry, marked by significant energy requirements (Viana et al., 2025), mainly attributable to the technology and energy utilized in kiln fire, drying, and shaping procedures (The European Ceramic Industry Association, 2021). Accordingly, 39% of the grid electricity demand in the conventional scenario is offset by a 6 MW solar PV system, as detailed in Table 3.

2.2.1.4 Scenario 04: integrated green scenario with alternative approaches

Scenario 04 integrates all three eco-friendly approaches (Scenario 01, Scenario 02, and Scenario 03), along with rainwater harvesting, to enhance the sustainability of ceramic tile production. It combines the substitution of feldspar with 9% fly ash, leveraging its favorable fired properties, with a 15% reduction in liquefied petroleum gas consumption through the installation of a heat recovery system. Additionally, 39% of grid electricity demand is replaced with renewable energy generated by a 6 MW solar PV system, and 48% of groundwater usage is substituted with harvested rainwater. Together, these measures reduce resource dependency, enhance energy efficiency, and minimize environmental impact, creating a holistic and sustainable production process.

2.3 Preparation of life cycle inventory (LCI)

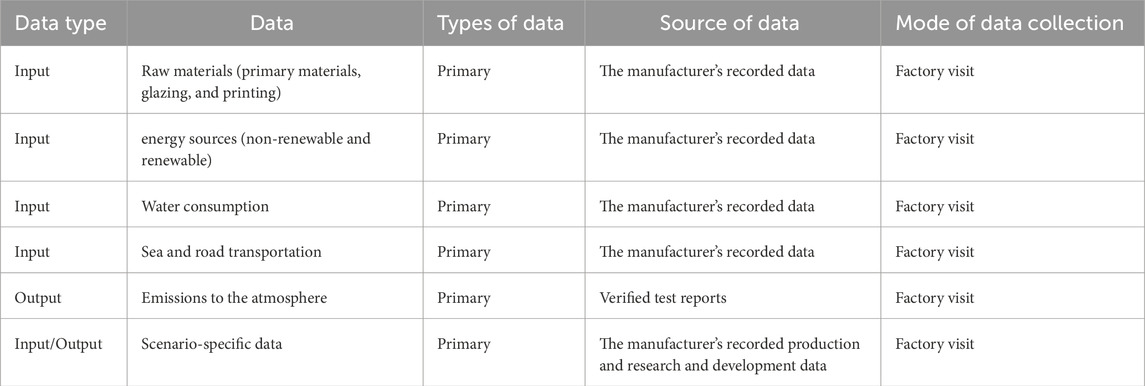

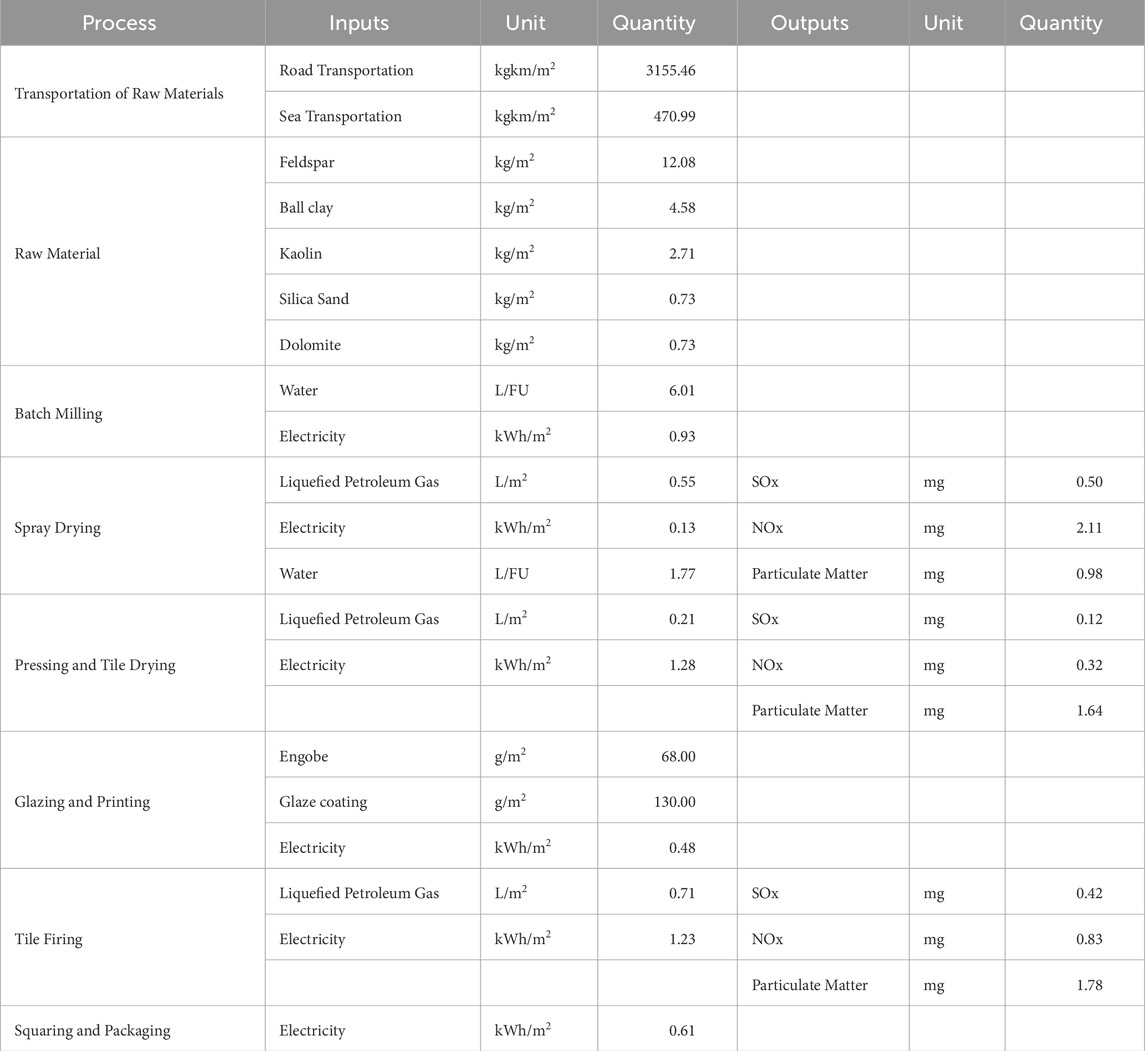

This section presents detailed information on materials, energy, and water consumption, along with the resulting outputs, all measured per the declared unit. The reliability and credibility of the results of an LCA study largely depend on the quality of data used in the LCI stage. Therefore, this research employed a proper plan to collect data, as shown in Table 4. Table 5 summarizes the LCI results, highlighting the inputs required for producing 1 m2 of ceramic tile and the associated emissions and waste generated.

Table 5. Process-based LCI of cradle-to-gate ceramic tile production per 1 m2, based on the 1-year average production data provided by the manufacturer.

2.4 Life cycle impact assessment

SimaPro software facilitates comprehensive environmental impact assessments by offering a robust analytical framework. The ReCiPe method, detailed by Huijbregts et al. (2017), effectively translates LCI data into both midpoint and endpoint impact indicators within this framework (Huijbregts et al., 2017). In this study, an attributional LCA was conducted using the ReCiPe 2016 v1.1 method, which broadens the range of parameters included in environmental impact assessment by encompassing a diverse set of environmental impacts over 18 mid-point categories such as global warming, stratospheric ozone depletion, ionising radiation, ozone formation, human health, fine particulate matter formation, terrestrial ecosystems, terrestrial acidification, freshwater eutrophication, marine eutrophication, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, human carcinogenic toxicity, human non-carcinogenic toxicity, and land use. Also, there are three end-point impact categories: human health, resource depletion, and biodiversity loss. The ReCiPe (H) Characterisation model is an indispensable instrument. It provides detailed insights into the complex relationship between human activities and environmental outcomes.

2.5 Interpretation of the life cycle assessment results

The interpretation phase summarizes the results of the inventory analysis and impact assessment by ISO 14040:2006 and ISO 14044:2006 standards. Aligned with the study’s defined goals and scope, this stage offers conclusions and recommendations to support future actions or decision-making.

3 Results and discussion

This section provides an overview of the life cycle inventory and life cycle impact assessment results for the cradle-to-gate phase of ceramic tile production. The evaluation highlights the potential benefits and trade-offs of adopting eco-innovations compared to traditional methods.

3.1 LCI of the ceramic tile per declared unit

Table 4 presents the process-based LCI for the cradle-to-gate phase of producing 1 m2 of ceramic tile with the statistical mean of the production data for 1 year. This table provides an overview of various inputs and outputs associated with the production of 1 m2 of ceramic tile, including key raw materials such as feldspar, ball clay, kaolin, silica sand, dolomite, and various oxides, with feldspar being the key material. The LCI highlights significant environmental inputs and emissions, particularly during energy-intensive stages such as firing and drying. Accordingly, the tile firing process is the highest consumer of electricity (1.23 kWh/m2) and LPG (0.71 L/m2), and also the major contributor to NOx (0.83 mg/m2) and particulate matter emissions (1.78 mg/m2). The spray drying stage is the second-largest in terms of LPG consumption (0.55 L/m2) and has the highest SOx emissions (0.50 mg/m2). Raw material transportation involves significant energy use, especially road transport (3155.46 kg·km/m2), indicating a notable upstream environmental burden. Among processes, pressing and tile drying also show relatively high electricity use (1.28 kWh/m2).

Previous studies demonstrate how the high volume of ceramics production has harmed the demand for raw materials, especially high-plasticity clays and feldspar (Furszyfer Del Rio et al., 2022). Since 1971, over 575 million tons of feldspathic materials have been mined, primarily for glass and ceramic production, with nearly 29 million tons produced annually (Dondi et al., 2021). Additionally, liquefied petroleum gas consumption is notably higher than electricity consumption in terms of energy usage. The production of ceramic tiles is regarded as one of the most energy-intensive sectors, predominantly reliant on combustion processes with 30–40 kWh/m2. The outputs listed include environmental impacts such as SOx, NOx, and particulate matter. Ceramic tile manufacturing produces its amount of harmful and hazardous gases, emitting 15.89 kg CO2-eq/m2 and 1.14 × 10−5 kg CFC-11-eq, contributing to ozone depletion, while releasing ultrafine and nanosized particles that impact human health (Muthukannan and Chithambar Ganesh, 2019). By offering a country-specific life cycle inventory for Sri Lankan glazed ceramic tile production, this study provides a detailed assessment of the environmental impacts specific to the region.

3.1.1 Mid-point impact analysis of eco-innovation scenarios with the conventional scenario

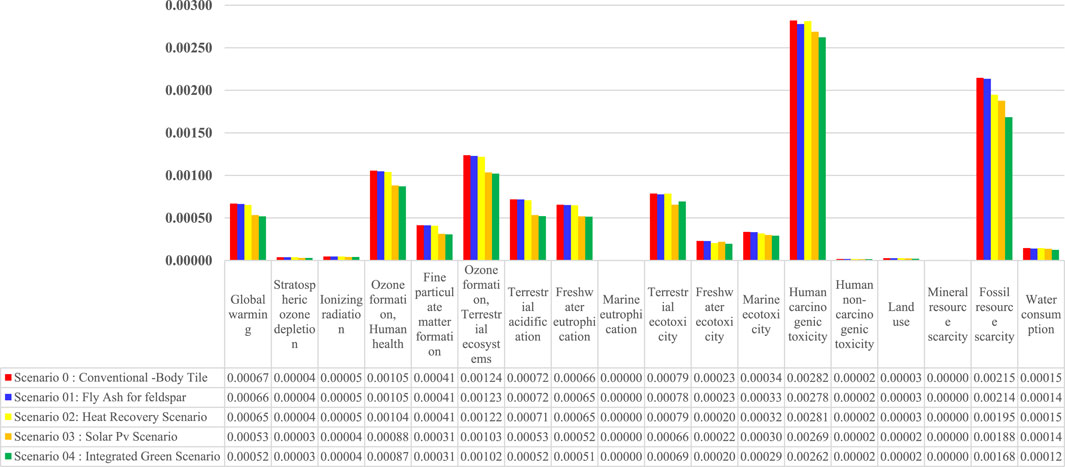

This section compares the environmental impacts of the conventional ceramic tile production scenario with the four proposed eco-innovation scenarios to highlight their relative improvements and key differences. According to Figure 4, the conventional scenario exhibits the most significant environmental impacts in all categories, acting as the benchmark for comparison. Scenario 1 and Scenario 2 demonstrate marginal enhancements in terms of the impact categories, such as global warming, fine particulate matter formation, marine eutrophication, and fossil resource scarcity, compared to the baseline, facilitated by focused interventions of restricted scope. Conversely, Scenarios 3 and 4 demonstrate significant enhancements, indicating the implementation of measures with broader and more impactful environmental advantages. Significantly, Scenario 4 attains the greatest impact reduction by incorporating an extensive array of sustainable elements, while tackling several environmental issues. This trend highlights the necessity of implementing comprehensive and diverse strategies to attain substantial enhancements in environmental performance compared to conventional approaches. In general, human carcinogenic toxicity and freshwater ecotoxicity exhibit significant impacts across scenarios, yet stratospheric ozone depletion and ionising radiation demonstrate minor variance. The human carcinogenic toxicity consistently demonstrates the highest normalised impact across all scenarios, including the conventional scenario, with values (e.g., 0.00282 in the conventional case) significantly higher than those of all other impact categories, highlighting the utmost significance in the environmental assessment of ceramic tile production. The LCIA process contribution results indicate a total human carcinogenic toxicity impact of 0.029 kg 1,4-DCB, with more than 50% attributed to Electric Arc Furnace (EAF) slag treatment (0.008 kg 1,4-DCB) and Basic Oxygen Furnace (BOF) slag treatment (0.006 kg 1,4-DCB). EAF slag has trace elements such as CaO, Al2O3, and FeO, which, at particular concentrations, influence environmental effects and contribute to the distinctive colors and finishes of ceramic tiles. The fossil resources scarcity, which has the second greatest influence among all evaluated impact categories, constitutes 32% of the total, with natural gas production and extraction contributing 0.34 kg oil equivalent and 0.31 kg oil equivalent, respectively. The primary energy source for the analysed ceramic tile production process is natural gas, consumed mainly for kiln burning, with a consumption of 0.701 m3 in the conventional case and 0.614 m3 in the integrated green scenario.

Figure 4. Normalised mid-point environmental impact values (in points) per 1 m2 of produced ceramic tile, covering cradle-to-gate scope generated in simapro faculty version.

The characterized mid-point environmental impacts of four alternative scenarios compared to the conventional scenario are included in Table 6, which is described in the following section.

Table 6. Impact categories in unit values for the scenarios and the improvement rates compared to the conventional scenario.

3.1.1.1 Scenario 01: replacing virgin material with waste material: fly ash as an alternative to feldspar

The extraction of feldspar can result in significant environmental consequences, including the leaching of heavy metals into groundwater, the polluting of adjacent freshwater sources, and elevated air pollution (Laura, 2023). Accordingly, the environmental improvements in freshwater eutrophication (0.52%), global warming (0.62%), and terrestrial ecotoxicity (1.52%) are associated with the feldspar mining process. The power consumption is a main reason for human carcinogenic toxicity (Noviani et al., 2023). Therefore, the power used in feldspar processing may contribute to human carcinogenic toxicity (1.52%). The depletion of natural resources was mainly associated with the utilisation of non-metallic minerals and the consumption of non-renewable energy sources (Wang, 2020). Accordingly, the minimal improvements in impact categories, mineral resource scarcity (0.1%) and fossil resource scarcity (0.54%) are associated with the reduction of virgin raw material consumption (feldspar). The reduction in impact is minimal due to the energy sources and raw materials remaining largely unchanged except for feldspar.

3.1.1.2 Scenario 02: liquefied petroleum gas savings in spray drying through heat recovery at the kiln

Liquefied petroleum gas, produced from 40% crude oil and 60% natural gas, has a global warming potential of 28–36 times over 100 years, with methane emissions from natural gas extraction, processing, and transportation contributing to its environmental impact (Shahrier et al., 2020). Therefore, the reduction in global warming (1.04%), ozone formation: in human health (0.62%) and Terrestrial ecosystems (0.66%), and Stratospheric ozone depletion (0.29%) are associated with CO2 and CH4 reduction due to the reduction in the usage of liquefied petroleum gas in the ceramic tile production process.

3.1.1.3 Scenario 03: replacing grid electricity with renewable energy from a solar PV system

An LCA study conducted by Thanthirige et al. (2022), which focuses on mid and end-point environmental impact evaluation, illustrates that solar photovoltaic power generation is substantially more environmentally sustainable than coal-based power generation (grid electricity) in Sri Lanka. Further, coal power generation is responsible for 100% of climate change, ozone depletion, photochemical oxidation, terrestrial acidification, freshwater eutrophication, and fossil depletion, whereas rooftop solar accounts for only 5% in most of these categories. Solar power significantly reduces human toxicity (20% compared to 90%), particulate matter generation (10% vs. 95%), ionizing radiation (30% relative to 100%), and ecotoxicity consequences (15% for solar against 90% for coal in terrestrial, freshwater, and marine ecotoxicity) (Thanthirige et al., 2022). In this study, terrestrial acidification (25.98%), freshwater eutrophication (4.87%), and fossil depletion (13.20%) are achieved in scenario 3, attributed to the replacement of grid electricity with solar power. Further, the solar power system produces substantially reduced greenhouse gas emissions throughout its life cycle, emitting 1.35 kg of CO2 per kWh of electricity generated, in stark contrast to the 4.81 kg of CO2 per kWh emitted by coal-powered systems (Luo et al., 2024). In this study, 20.42% of Global warming reduction is achieved.

3.1.1.4 Scenario 04: integrated green scenario with alternative approaches

The environmental improvements in scenario 4 are largely attributed to scenario 3, particularly in categories such as global warming, stratospheric ozone depletion, ionizing radiation, ozone formation (human health), fine particulate matter formation, ozone formation (terrestrial ecosystems), terrestrial acidification and freshwater eutrophication, with approximately 95% of the contributions driving the impact improvements. Apart from Scenario 3, Scenario 1 contributed to advantages in human carcinogenic toxicity and land use, while Scenario 2 contributed to advantages in marine eutrophication, human non-carcinogenic toxicity, and fossil resource scarcity impacts in Scenario 4. Specifically, the harvested rainwater consumption in Scenario 5, which is not utilized in the other scenarios, contributed to a 14.59% improvement in water consumption within the water consumption impact category.

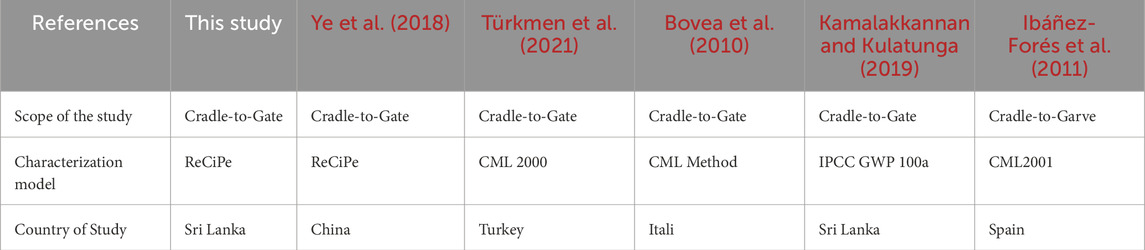

3.2 Comparative analysis of global and local ceramic tile production impacts

This section presents an overview of previous studies on ceramic tile production (per m2). Table 7 outlines the methodological frameworks and geographical contexts of the chosen studies on ceramic tile manufacturing. The studies varied in their selection of impact assessment models, indicating variations in methodological preferences or geographical priorities. The geographic variation between countries like Sri Lanka, China, Turkey, Italy, and Spain can substantially affect the environmental impact outcomes due to discrepancies in energy sources, raw material accessibility, technological advances, and regulatory frameworks.

Table 8 presents the environmental impact results along with their corresponding units. The overall performance of this study is notably lower compared to the other studies referenced. The high environmental impact reported by Ye et al. (2018), with electricity consumption of 0.67 kWh and 2.54 kg of coal usage, may be attributed to energy-intensive processes, reliance on non-renewable resources, or inefficiencies in the production system analyzed. This study exclusively analyzed coal-based electricity generation, which constitutes roughly 73.3% of China’s thermal power output. The fuel utilized in this instance was self-generated water gas (a combination of carbon monoxide and hydrogen), derived from coal. This may reflect the elevated impacts found across many impact categories in comparison to this study. The carbon, hydrogen, and sulfur content in coal is essential for energy production during combustion, but it also leads to the emission of pollutants, including COx, SOx, NOx, particulate matter (PM), and heavy metals. These contaminants accumulate in the atmosphere and aquatic systems, resulting in considerable environmental degradation (Munawer, 2018). Fly ash comprises substantial amounts of arsenic, copper, and selenium, which pose considerable threats to water and soil quality (Ibáñez-Forés et al., 2011). Coal ash mostly comprises oxides of iron, aluminum, silicon, and calcium, which constitute approximately 90% of its makeup (Munawer, 2018). The disposal of coal ash at authorized sites, such as landfills or ponds, may lead to environmental risks, especially through the leaching of toxic compounds into the adjacent ecosystem (Nalawade et al., 2012).

In the study of Türkmen, Duhbacı, and Özbilen (2021), electricity and natural gas were identified as the primary energy sources utilized in the production of glazed ceramic tiles. The results demonstrate that the production of 1 m2 of ceramic tile necessitates an energy input of 221 MJ, yielding a global warming potential (GWP) of 14.4 kg CO2 equivalent per m2 of glazed ceramic tile. The production stage, noted for its significant energy use, is identified as the principal hotspot contributing to most environmental impact categories evaluated in this study. According to a study of Bovea et al. (2010), the hydrocarbons generated from the combustion of natural gas and diesel, along with the emissions of SOx (4.44E-05 mg/m2 compared to 1.04E-06 mg/m2 in this study), released during the production of electrical power used by the machinery, are the main factors contributing to the higher acidification impact observed in this study. This pattern highlights the significant influence of fuel combustion and power generation on the acidification potential of the production process (Bovea et al., 2010). Furthermore, Ye et al. (2018), highlighted that the relatively higher environmental impact observed in Bovea et al. (2010) study can be attributed to the older and less efficient production technologies used during that period. The high impact observed in Kamalakkannan and Kulatunga (2019) study is likely due to the higher energy consumption (6.248 kWh/m2 for raw material mixing to final product firing), which is considered for comparison. In contrast, this study consumes 4.66 kWh/m2 for the same process, with no major changes in other input categories compared to Kamalakkannan and Kulatunga (2019) study. The research conducted by Ibáñez-Forés et al. (2011), emphasizes the atomization phase of ceramic tile production as the most significant across all environmental metrics, primarily attributable to the substantial natural gas usage required for the drying (7.04 kWh/m2) and firing (10.86 kWh/m2) processes, coupled with the resultant emissions of pollutants including CO, NOx, and SOx, underscoring this phase as a pivotal target for mitigating the overall environmental repercussions of ceramic tile manufacturing. The increased environmental impacts noted in that study are probably due to the substantially increased natural gas consumption (35.39 kWh or 4.95 L/m2) in contrast to the 1.47 L/m2 utilized in the present study.

The comparison analysis with previous LCA studies underscores the substantial impact of energy sources and consumption patterns on the environmental consequences of ceramic tile production in across different locations. The variations in fuel sources, ranging from coal-based electricity in China (Ye et al., 2018) to natural gas and diesel in Turkey, Italy, and Spain (Bovea et al., 2010; Ibáñez-Forés et al., 2013; Türkmen et al., 2021), highlighted the urgent need for tailored policy interventions aimed at enhancing cleaner energy adoption and energy efficiency advancements within the Sri Lankan ceramic tile sector. This study’s (eco-innovative scenario) notably reduced energy consumption, compared to Kamalakkannan and Kulatunga (2019), illustrating the advantages of adopting more efficient technologies and practices. Furthermore, regulating emissions from coal combustion and reducing pollutant discharge during the drying and fire processes are critical policy concerns, evidenced by heightened acidification and toxicity effects associated with fossil fuel consumption in numerous studies.

Consequently, regulatory frameworks ought to foster the shift towards cleaner energy sources, advocate for the utilisation of waste materials, and encourage technological advancements that diminish dependence on high-impact fossil fuels. This study’s eco-innovation scenarios offer pragmatic approaches for governments and industry partners to effectively adopt these initiatives. As an example, Scenario 3, which replaced solar photovoltaic technology with grid electricity, exhibits considerable reductions in critical impact categories, realizing a 20.42% reduction in global warming potential and significant decreases in stratospheric ozone depletion (23.13%), terrestrial acidification (25.98%), and freshwater eutrophication (21.05%), underscoring the substantial environmental advantages of cleaner energy adoption in mitigating the carbon footprint of ceramic tile manufacturing. Policymakers can utilise the quantified environmental benefits, such as reduced global warming potential, terrestrial acidification, and ozone depletion, as solid proof to advocate for incentives, regulations, and standards that facilitate renewable energy integration, industrial symbiosis, and energy-efficient technologies in ceramic tile manufacturing. These legislative approaches can expedite the industry’s shift towards sustainability while conforming to national obligations in reducing greenhouse gas emissions and adverse environmental impacts in the construction sector.

For ceramic tile manufacturers, the scenarios illustrate tangible ways to improve resource efficiency and environmental performance while maintaining product quality and economic viability. Manufacturers can reduce operational costs and eliminate environmental hazards by utilising waste-derived raw materials, optimising energy recovery operations, and transitioning to cleaner energy sources, thereby enhancing their competitiveness in local and global markets. These results collectively enhance Sri Lanka’s environmental objectives by promoting sustainable manufacturing practices in the construction sector, reinforcing the nation’s commitment to sustainable development goals, and establishing a benchmark for other industrial sectors to follow.

4 Conclusion

The ceramic industry stands at a critical juncture between traditional manufacturing processes and the imperative for environmental sustainability. While significant challenges remain, particularly in energy consumption and emissions reduction, emerging technologies and innovative approaches offer promising pathways toward a more sustainable future. This study rigorously evaluates four alternative eco-innovation scenarios alongside conventional ceramic tile production in Sri Lanka, aiming to identify key environmental hotspots and identify the most sustainable options with the greatest potential to enhance the ceramic tile industry’s environmental consciousness. Each scenario was developed based on the manufacturer’s research and development strategies to enhance environmental sustainability. A comprehensive LCA evaluated mid-point environmental aspects, revealing that human carcinogenic toxicity, fossil resource scarcity, and ozone formation (human health) had the most significant impacts across all scenarios, including the conventional scenario.

Human carcinogenic toxicity represents the highest environmental impact across all scenarios. The reductions in environmental impact across the 04 eco-scenarios demonstrate differing degrees of enhancement relative to the Conventional Scenario. Scenario 01 demonstrated minimal enhancements, with the most significant being a 3.54% decrease in land use, accompanied by a 3.51% reduction in water consumption and a 1.52% decline in human carcinogenic toxicity. Scenario 02 demonstrated marginally greater improvements, specifically in land use, which decreased by 9.86%, fossil resource scarcity declined by 4.37%, and human non-carcinogenic toxicity was reduced by 2.17%. Notwithstanding these advancements, the reductions are still moderate. Scenario 03 exhibited a notable improvement in environmental performance, demonstrating considerable reductions across multiple impact categories. Significant enhancements were observed in terrestrial acidification (25.98%) and fine particulate matter formation (24.59%), both of which are essential for air quality. Furthermore, stratospheric ozone depletion decreased by 23.13%, and global warming potential experienced a significant reduction of 20.42%. Scenario 4, the integrated green scenario, demonstrated the highest environmental performance compared to the alternative scenarios, achieving a 26.73% reduction in terrestrial acidification, a 23.23% decrease in stratospheric ozone depletion, a 21.36% reduction in global warming potential, and a 25.56% decrease in fine particulate matter formation. The findings suggest that combining multiple approaches, from waste material utilization to renewable energy integration, offers the most effective route to reducing environmental impacts while maintaining product quality.

Although extensive research has investigated emissions reduction in the industrial sector comprehensively, few investigations have concentrated specifically on the ceramics industry. This gap underscores the necessity for increased focus on technological innovations intended to green the ceramics industry. By evaluating the environmental friendliness of four eco-innovative scenarios incorporating waste material reuse, energy recovery, and renewable energy integration, this study identifies key local challenges in Sri Lanka’s ceramic tile industry, such as reliance on coal-based electricity and underutilization of waste materials. By proposing eco-innovation scenarios, such as partial replacement of virgin raw materials with industrial waste, energy recovery during drying, and integration of renewable energy sources like solar PV, the study offers practical solutions tailored to Sri Lanka’s specific environmental and industrial context. These measures help reduce dependence on fossil fuels, lower greenhouse gas emissions, and minimize waste, directly confronting local sustainability issues. Globally, the study contributes to sustainable manufacturing efforts by aligning with circular economy principles through waste valorization and promoting cleaner production techniques. The comprehensive LCA framework and scenario-based analysis provide a replicable methodology for assessing and improving environmental performance in manufacturing. As a precedent, this research can inspire other industries in Sri Lanka and beyond to adopt similar integrated eco-innovation strategies, thereby advancing sustainable industrial development and supporting global climate goals.

Accordingly, this research highlights the importance of country-specific assessments, as environmental impacts can vary significantly based on local conditions, energy sources, and manufacturing practices. For Sri Lanka’s ceramic industry, this study provides a foundational framework for sustainable development, offering evidence-based guidance for immediate improvements such as waste material substitution, energy recovery, and long-term strategic planning including including renewable energy integration, integration of alternative water sources, and process optimization. Accordingly, these immediate and long-term initiatives must be supported by precise policy recommendations and industry-specific measures to improve sustainability in the ceramics tile manufacturing sector. Hence, this research establishes a solid base for enhancing the environmental performance of ceramic tile manufacturing in Sri Lanka by providing essential direction for policymakers in directing industry practices towards more ecologically sustainable techniques, hence contributing to a diminished environmental footprint in the ceramic tile production sector. Further, considering the potential advantages exhibited by these eco-innovation approaches, future studies should concentrate on the scalability and financial viability of the implementation in real-world industrial settings.

5 Limitations

While this research offers valuable insights, certain limitations should be acknowledged. Primarily, the study relied on LCI data from international databases due to the absence of datasets specific to Sri Lanka. Additionally, stages beyond ceramic tile production were excluded, preventing the assessment of the potential benefits of reusing construction components.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

DV: Resources: Investigation, Formal Analysis, Visualization, Data curation, Software, Project administration, Writing – original draft, Methodology, Conceptualization. SW: Supervision, Software, Writing – review and editing, Conceptualization, Resources, Investigation, Project administration. AA: Supervision, Project administration, Writing – review and editing, Conceptualization, Funding acquisition, Formal Analysis, Validation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by University of Cambridge Libraries and Archives.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Correction note

A correction has been made to this article. Details can be found at: 10.3389/fbuil.2025.1720103.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ancona, M., Branchini, L., Ottaviano, S., Bignozzi, M., Ferrari, B., Mazzanti, B., et al. (2022). Energy and environmental assessment of cogeneration in ceramic tiles industry. Energies 16, 182. doi:10.3390/en16010182

Atılgan Türkmen, B., Karahan Özbilen, Ş., and Budak Duhbacı, T. (2021). Improving the sustainability of ceramic tile production in Turkey. Sustain. Prod. Consum. 27, 2193–2207. doi:10.1016/j.spc.2021.05.007

Bajdur, W., Zielińska, A., and Gronba-Chyła, A. (2023). Product life cycle assessment (LCA) as a tool for environmental management. Rocz. Ochr. Środowiska 25, 389–398. doi:10.54740/ros.2023.040

Boschi, G., Masi, G., Bonvicini, G., and Bignozzi, M. C. (2020). Sustainability in Italian ceramic tile production: evaluation of the environmental impact. Appl. Sci. 10, 9063. doi:10.3390/app10249063

Bovea, M. D., Díaz-Albo, E., Gallardo, A., Colomer, F. J., and Serrano, J. (2010). Environmental performance of ceramic tiles: improvement proposals. Mater. and Des. 31, 35–41. doi:10.1016/j.matdes.2009.07.021

Ciacco, E. F. S., Rocha, J. R., and Coutinho, A. R. (2017). The energy consumption in the ceramic tile industry in Brazil. Appl. Therm. Eng. 113, 1283–1289. doi:10.1016/j.applthermaleng.2016.11.068

Divakara, S., and Attalage, R. A. (2007). Assessment of embedded energy in manufacturing wall tiles using two different firing technologies in Sri Lanka. Annu. Trans. IESL, 161–167.

Dondi, M., Raimondo, M., and Zanelli, C. (2014). Clays and bodies for ceramic tiles: reappraisal and technological classification. Appl. Clay Sci. 96, 91–109. doi:10.1016/j.clay.2014.01.013

Dondi, M., García-Ten, J., Rambaldi, E., Zanelli, C., and Vicent-Cabedo, M. (2021). Resource efficiency versus market trends in the ceramic tile industry: effect on the supply chain in Italy and Spain. Resour. Conservation Recycl. 168, 105271. doi:10.1016/j.resconrec.2020.105271

Furszyfer Del Rio, D. D., Sovacool, B. K., Foley, A. M., Griffiths, S., Bazilian, M., Kim, J., et al. (2022). Decarbonizing the ceramics industry: a systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 157, 112081. doi:10.1016/j.rser.2022.112081

Gronba-Chyła, A., Generowicz, A., Alwaeli, M., Mannheim, V., Grąz, K., Kwaśnicki, P., et al. (2024). Municipal waste utilization as a substitute for natural aggregate in the light of the circular economy. J. Clean. Prod. 440, 140907. doi:10.1016/j.jclepro.2024.140907

Guttikunda, S. K., and Khaliquzzaman, M. (2014). Health benefits of adapting cleaner brick manufacturing technologies in Dhaka, Bangladesh. Air Qual. Atmos. Health 7, 103–112. doi:10.1007/s11869-013-0213-z

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F., Stam, G., Verones, F., Vieira, M., et al. (2017). ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147. doi:10.1007/s11367-016-1246-y

Ibáñez-Forés, V., Bovea, M.-D., and Simó, A. (2011). Life cycle assessment of ceramic tiles. Environmental and statistical analysis. Int. J. Life Cycle Assess. 16, 916–928. doi:10.1007/s11367-011-0322-6

Ibáñez-Forés, V., Bovea, M. D., and Azapagic, A. (2013). Assessing the sustainability of best available techniques (BAT): methodology and application in the ceramic tiles industry. J. Clean. Prod. 51, 162–176. doi:10.1016/j.jclepro.2013.01.020

Jayasinghe, D. G. M. P., and Dassanayake, A. H. M. D. R. (2024). Study on the usage of ceramic tile waste as a partial replacement for sand in block manufacturing. Engineer 57, 93–100. doi:10.4038/engineer.v57i4.7669

Kamalakkannan, S., and Kulatunga, A. K. (2019). Advancement of life cycle assessment towards eco-design in ceramic floor tile industry in Sri Lanka.

Kumarasena, M. S., and Weerathunga, U. A. (2020). Deliverable D 4.4: final roadmap report for Sri Lanka.

Laura, X. (2023). Exploring the role of feldspar in the mining industry: a step-by-step process. Available online at: https://www.miningpedia.cn/dressing/Exploring-the-role-of-feldspar-in-the-mining-industry-step-by-step.html.

Luiz, N. F., Cecchin, D., Azevedo, A. R. G., Alexandre, J., Marvila, M. T., Silva, F. C., et al. (2020). Characterization of materials used in the manufacture of ceramic tile with incorporation of ornamental rock waste 1–11. doi:10.15159/AR.20.132

Luo, J., Yang, H., Zhang, L., Liu, H., Wang, Y., and Hao, C. (2024). A comparative study on the combination of life cycle assessment and ecological footprints: solar photovoltaic power generation vs. coal power generation in Ningxia. Front. Energy Res. 12, 1375820. doi:10.3389/fenrg.2024.1375820

Manrique, R., Vásquez, D., Vallejo, G., Chejne, F., Amell, A. A., and Herrera, B. (2018). Analysis of barriers to the implementation of energy efficiency actions in the production of ceramics in Colombia. Energy. 143, 575–584. doi:10.1016/j.energy.2017.11.023

Manufacturing Economic Studies (2024). World production and consumption of ceramic tiles, 12th edition. ed.

Mezquita, A., Boix, J., Monfort, E., and Mallol, G. (2014). Energy saving in ceramic tile kilns: cooling gas heat recovery. Appl. Therm. Eng. 65, 102–110. doi:10.1016/j.applthermaleng.2014.01.002

Mezquita, A., Monfort, E., Ferrer, S., and Gabaldón-Estevan, D. (2017). How to reduce energy and water consumption in the preparation of raw materials for ceramic tile manufacturing: dry versus wet route. J. Clean. Prod. 168, 1566–1570. doi:10.1016/j.jclepro.2017.04.082

Monfort, E., Mezquita, A., Granel, R., Vaquer, E., Escrig, A., Miralles, A., et al. (2010). Analysis of energy consumption and carbon dioxide emissions in ceramic tile manufacture.

Munawer, M. E. (2018). Human health and environmental impacts of coal combustion and post-combustion wastes. J. Sustain. Min. 17, 87–96. doi:10.1016/j.jsm.2017.12.007

Muthukannan, M., and Chithambar Ganesh, A. S. (2019). Kalasalingam academy of research and education, krishnankoil, Tamil Nadu, India. Environ. impact caused by Ceram. industries Assess. Methodol. IJQR 13, 315–334. doi:10.24874/IJQR13.02-05

Nalawade, P. M., Dineshkumar, B. A., and Mule, M. B. (2012). Assessment of groundwater and surface water quality indices for heavy metals nearby area of parli thermal power plant. Univers. J. Environ. Res. Technol. 2, 47–51.

Noviani, L., Haryono, E., Supartono, W., Sahali, I., and Juliani, F. E. (2023). Environmental impact analysis of PCC cement products (portland composite cement) using LCA (life cycle assessment). IOP Conf. Ser. Earth Environ. Sci. 1190, 012003. doi:10.1088/1755-1315/1190/1/012003

Olofsson, J., and Börjesson, P. (2018). Residual biomass as resource – life-Cycle environmental impact of wastes in circular resource systems. J. Clean. Prod. 196, 997–1006. doi:10.1016/j.jclepro.2018.06.115

Pryshlakivsky, J., and Searcy, C. (2013). Fifteen years of ISO 14040: a review. J. Clean. Prod. 57, 115–123. doi:10.1016/j.jclepro.2013.05.038

Quinteiro, P., Almeida, M. I., Serra, J., Arroja, L., and Dias, A. C. (2022). Life cycle assessment of ceramic roof tiles: a temporal perspective. J. Clean. Prod. 363, 132568. doi:10.1016/j.jclepro.2022.132568

Ros-Dosdá, T., Fullana-i-Palmer, P., Mezquita, A., Masoni, P., and Monfort, E. (2018). How can the European ceramic tile industry meet the EU’s low-carbon targets? A life cycle perspective. J. Clean. Prod. 199, 554–564. doi:10.1016/j.jclepro.2018.07.176

Schabbach, L. M., Andreola, F., Barbieri, L., Lancellotti, I., Karamanova, E., Ranguelov, B., et al. (2012). Post-treated incinerator bottom ash as alternative raw material for ceramic manufacturing. J. Eur. Ceram. Soc. 32, 2843–2852. doi:10.1016/j.jeurceramsoc.2012.01.020

Shahrier, F., Eva, I. J., Mahi, A., Alam, C. S., and Rashid, H. (2020). “Literature review on LCA of LPG as a transportation and cooking fuel,” in Proceedings of the international conference on industrial and mechanical engineering and operations management. Presented at the international conference on industrial and mechanical engineering and operations management (Dhaka, Bangladesh), 1–7.

Thanthirige, T. R. M., Galappaththi, U. I. K., Kadabadu, J. C. K., Busawon, K., and Wedage, T. D. G. (2022). “Life cycle analysis of solar photovoltaic and coal-based electricity generation: case study refers to sri lanka’s domestic energy consumption,” in 2022 7th international conference on environment friendly energies and applications (EFEA). Presented at the 2022 7th international conference on environment friendly energies and applications (EFEA) (IEEE, Bagatelle Moka MU, Mauritius), 1–6. doi:10.1109/EFEA56675.2022.10063822

The European Ceramic Industry Association (2021). Ceramic roadmap to 2050 - continuing our path towards climate neutrality.

Tikul, N., and Srichandr, P. (2010). Assessing the environmental impact of ceramic tile production in Thailand. J. Ceram. Soc. Jpn. 118, 887–894. doi:10.2109/jcersj2.118.887

Timellini, G., Resca, R., and Bignozzi, M. C. (2016). “Ceramic industry air quality. Emissions into the atmosphere from ceramic tile processes,” in Comprehensive analytical chemistry (Elsevier), 707–729. doi:10.1016/bs.coac.2016.04.005

Türkmen, B. A., Duhbacı, T. B., and Özbilen, K. Ö. (2021). Environmental impact assessment of ceramic tile manufacturing: a case study in Turkey. Clean. Techn Environ. Policy 23, 1295–1310. doi:10.1007/s10098-021-02035-w

United Nations Statistics Division (2025). The lifestyles of people in the richest nations are heavily dependent on resources extracted from poorer countries [WWW Document]. Ensure sustainable consumption and production patterns. Available online at: https://unstats.un.org/sdgs/report/2019/goal-12/#:∼:text=The%20material%20footprint%20per%20capita,increase%20of%2050%20per%20cent (Accessed September 1, 25).

Viana, P., Bastos, J., Silva, D., Cabral, A., Ledoux, A., and Mesquita, E. (2025). Mapping the environmental footprint: tracing ceramic tile production’s impact on sustainable goals. J. Build. Rehabil. 10, 2. doi:10.1007/s41024-024-00510-7

Vieira, A. W., Rosso, L. S., Demarch, A., Pasini, D., Ruzza, S. P., Arcaro, S., et al. (2023). Life cycle assessment in the ceramic tile industry: a review. J. Mater. Res. Technol. 23, 3904–3915. doi:10.1016/j.jmrt.2023.02.023

Vijerathne, D., Wahala, W. M. P. S. B. W., Illankoon, C., and Silva, N. D. (2022). “The life cycle environmental impact assessment of building construction industry in Sri Lanka: a life cycle assessment-based conceptual framework,” in Presented at the the 13th international conference on sustainable built environment, 54–66.

Vijerathne, D., Wahala, S., and Illankoon, C. (2024). Impact of crushed natural aggregate on environmental footprint of the construction industry: enhancing sustainability in aggregate production. Buildings 14, 2770. doi:10.3390/buildings14092770

Wanaguru, K., Mallawaarachchi, H., and Vijerathne, D. (2022). “Circular economy (CE) based material selection: development of a CE-based ‘10R’ evaluation framework for building construction projects in Sri Lanka,” in Proceedings of 10th World Construction Symposium 2022. Presented at the 10th World Construction Symposium (Moratuwa, Sri Lanka: Building Economics and Management Research Unit (BEMRU), University of Moratuwa), 208–219. doi:10.31705/wcs.2022.18

Wanaguru, K., Mallawaarachchi, H., and Vijerathne, D. (2025). PRISMA-Based review and development of a circularity assessment framework for building construction material selection. BEPAM 15, 557–573. doi:10.1108/BEPAM-11-2023-0201

Wang, S. (2020). The influence of the prefabricated rate on the environmental performance of buildings in a life cycle perspective (DEGREE PROJECT). Stockholm, Sweden: KTH Royal Institute of Technology, School of Architecture and the Built Environment.

Wang, Y., Liu, Y., Cui, S., Sun, B., Gong, X., Gao, F., et al. (2020). Comparative life cycle assessment of different fuel scenarios and milling technologies for ceramic tile production: a case study in China. J. Clean. Prod. 273, 122846. doi:10.1016/j.jclepro.2020.122846

Ye, L., Hong, J., Ma, X., Qi, C., and Yang, D. (2018). Life cycle environmental and economic assessment of ceramic tile production: a case study in China. J. Clean. Prod. 189, 432–441. doi:10.1016/j.jclepro.2018.04.112

Yuan, Q., Robert, D., Mohajerani, A., Tran, P., and Pramanik, B. K. (2023). Sustainable ceramic tiles incorporated with waste fly ash from recycled paper production. J. Clean. Prod. 425, 138814. doi:10.1016/j.jclepro.2023.138814

Keywords: ceramic tile, life cycle assessment, eco-innovation scenarios, mid-point environmental impacts, sustainable construction

Citation: Vijerathne DT, Wahala SB and Asmone AS (2025) Advancing environmental sustainability of ceramic tile production: a cradle-to-gate life cycle assessment case study from Sri Lanka. Front. Built Environ. 11:1654253. doi: 10.3389/fbuil.2025.1654253

Received: 26 June 2025; Accepted: 18 August 2025;

Published: 29 August 2025; Corrected: 16 October 2025.

Edited by:

Piero Bevilacqua, University of Calabria, ItalyReviewed by:

Viktoria Mannheim, University of Debrecen, HungaryRoberto Alonso González-Lezcano, CEU San Pablo University, Spain

Copyright © 2025 Vijerathne, Wahala and Asmone. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ashan Senel Asmone, YXNhNzlAY2FtLmFjLnVr

Dimuthu Thisna Vijerathne

Dimuthu Thisna Vijerathne Sampath Bandara Wahala2

Sampath Bandara Wahala2 Ashan Senel Asmone

Ashan Senel Asmone