- 1Bert S. Turner Department of Construction Management, Louisiana State University, Baton Rouge, LA, United States

- 2LaHouse Research and Education Center, Department of Biological and Agricultural Engineering, Louisiana State University Agricultural Center, Baton Rouge, LA, United States

The design and renovation of industrial plant piping systems demand high levels of dimensional accuracy to prevent costly errors and delays. Traditional methods for field data collection are often time-consuming and susceptible to human error, which can compromise the quality and efficiency of piping designs. This study explores the development of a decision support tool (DST) for the use of three-dimensional (3D) terrestrial laser scanning (TLS) in piping designs, aiming to enhance precision and efficiency in the engineering process. Despite the advantages of TLS technology, there is no dedicated decision support tool to help piping designers determine the appropriateness of using TLS for piping designs. This research employs a triangulation methodology, including a literature review, semi-structured interviews, and case study, to identify key factors influencing the adoption of TLS and to validate the proposed DST. The findings demonstrate that TLS offers significant accuracy, time savings, and safety advantages, making it a valuable tool for industrial piping design projects.

1 Introduction

Piping design is essential in the renovation and operation of industrial plants (Nguyen and Choi, 2018), leading plant piping designers to seek more precise measurement and pipe routing technologies. Industrial plants are comprised of interconnecting piping systems. For design changes in existing piping systems, piping designers must ensure that their new designs are dimensionally accurate to avoid additional costs or time delays (Tang et al., 2022). The piping design engineering process typically begins with an assessment of the as-built status of piping systems and industrial facilities may not have adequate documentation for piping designers to use as a starting point for new piping designs (Nguyen and Choi, 2018). Three-dimensional (3D) terrestrial laser scanning (TLS) as a data acquisition technology offers opportunities to acquire 3D point clouds, reducing costly errors in piping designs and as-built reconstruction over traditional methods (Omar and Nehdi, 2016; Xie et al., 2023).

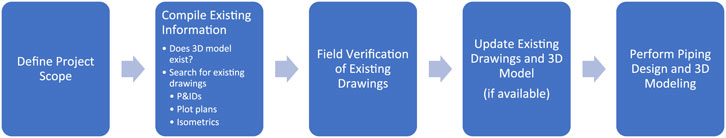

Traditional methods of field data collection are common but are time-consuming, susceptible to human error, and less accurate than TLS (Kim et al., 2024). Industrial piping design begins with defining the scope of work associated with the project. The scope of work includes the purpose and intent of the project and design. As-built data may not have been developed, saved, or properly documented following the completion of a previous project or existing field survey data is inaccurate (Hu et al., 2021; Pătrăucean et al., 2015). Examples of as-built data include piping and instrumentation diagrams (P&IDs), piping isometrics, or 3D models. Use of tape measures, photos, and geospatial tools can be used, but other tools are available that are more accurate and able to collect a larger amount of representative and accurate data over a shorter period (Gumilar et al., 2022). As-built modeling is the process of using the existing field information to create a 3D digital model (Rabbani et al., 2007). Piping designers compile existing information and drawings of the piping system. Designers are tasked with developing or updating two-dimensional drawings and three-dimensional models prior to issuance to a construction company for field execution of the design (Becerik-Gerber et al., 2011). Finding existing information includes a search for P&IDs, plot plans, and piping isometric drawings. If this information is available, designers typically perform field verification to help ensure that the information is still accurate. Figure 1 shows a typical traditional piping design process.

Use of TLS is one of the main tools used in dimensional accuracy and design efficiency (Bosché et al., 2015; Guo et al., 2020a; Guo et al., 2020b; Lee et al., 2017). Three-dimensional TLS is a common technology for acquiring 3D point clouds (Omar and Nehdi, 2016). This results in accurate dimensioning for the installation of piping and equipment that is cost effective by reducing or eliminating design errors and rework during the engineering, fabrication, and construction phases of a project (Nguyen and Choi, 2018). An issue companies face is the understanding and adoption of newer technology such as TLS that was initially costly to implement but has improved over time to be more efficient, highly accurate, and ensures a level of detail that is precisely represented (Li et al., 2025). There is currently no decision support tool (DST) for industrial piping designers to determine when to use TLS over traditional methods.

Several factors must be considered when deciding to use TLS for piping design, with cost and expertise being two of the most important (Aryan et al., 2021). Terrestrial laser scanning for detailed piping design and 3D modeling is costly for companies that do not currently own the necessary equipment to perform laser scans in the field. Third-party engineering firms offer TLS as a service since some companies may not want to purchase, maintain, and train their own employees on the use of laser scanning equipment. Piping designers have been adopting the use of TLS in the engineering design process, but a higher initial cost and other factors may be a deterrent (Chai et al., 2016; Hu et al., 2021). Research efforts have been limited in investigating the development of a decision support tool for piping designers and engineering professionals to use TLS as a data acquisition technology for piping designs.

Therefore, this paper attempts to answer the following research questions.

• What are the most important factors or criteria for the DST?

• What are the appropriate criterial weightings for the DST?

• How does the DST support TLS decision-making prior to the design phase of a piping design project?

This paper aims to fill this research gap by providing a methodology to develop a DST for the use of 3D TLS and modeling for piping designs in industrial plants. This paper takes a triangulation approach and begins with a literature review of previous studies on TLS applications in various industries to identify the benefits, common themes, and gaps of researchers in this field. Semi-structured interviews, and a text analysis is conducted to yield a basis for the criterial weightings. A multi-criteria decision analysis method is applied to allow for an objective comparison of alternatives in the decision-making process. A case study demonstrates the application of a DST developed using this approach for an industrial piping system design.

The contribution of this research is the triangulation approach of multiple research methods to develop a DST for use of terrestrial laser scanning and modeling for industrial piping design. This research aims to provide industry practitioners benefit from the use of a decision support tool to help piping designers in choosing when to apply TLS for industrial piping design. This decision can result in a safer, cost-effective, and accurate design solution.

2 Background

2.1 Terrestrial laser scanning

Three-dimensional TLS is a data acquisition technology that has been adopted in various industries to aid in reducing costly errors and improving efficiency. Three-dimensional TLS captures geospatial information of an area and is used for a wide range of applications such as archaeology (Al-Kheder et al., 2009), Building Information Management (BIM) development of as-built models, topographic mapping, heritage conservation, geomorphology, structural monitoring, and quality control (Kim et al., 2013). The scanner has a laser that rotates at high speeds and emits a pulse of laser light waves to a target or area and measures the distance to the target by timing the round-trip time of the pulse of light (Bhatla et al., 2012). A completed area scan creates a digital representation of that area. Scans are needed from multiple locations to capture all aspects of the objects (Kawashima et al., 2014). This collection of data points is used to generate dimensionally accurate as-built information and is becoming standard practice in engineering design (Omar and Nehdi, 2016). The scans are used to develop 3D computer-aided design (CAD) models to design piping systems (Safa et al., 2015).

Previous research has quantified these benefits. For example, TLS-based surveys have demonstrated dimensional accuracy in the range of 2–6 mm, which depends on scanning distance, compared to traditional tape-based or manual measurement errors that can exceed 20 mm in complex industrial environments (Aryan et al., 2021; Wardius and Hein, 2024). In addition, TLS has been shown to reduce field data collection time by more than 50%, significantly improving project efficiency while reducing safety risks associated with scaffolding and manual verification (Wu et al., 2021). These quantitative improvements provide a compelling case for TLS adoption in piping design.

2.2 Piping design

Piping design requires dimensional accuracy for efficient pipe routing and connections (Nguyen and Choi, 2018). Designers create digital 3D models as part of the design process and the current practice of site as-built data acquisition relies heavily on manual observations (Kim et al., 2013). 3D models aid in improving designs before being built in the field (Becerik-Gerber et al., 2011). 3D models provide realistic visualizations of the final piping design and are used to convey design intent to the construction personnel prior to and during field installation (Rabbani et al., 2007). Terrestrial laser scanning helps minimize human error from the field data collection process and the data are collected efficiently and effectively over a shorter period compared to traditional methods (Aryan et al., 2021). The collected data can then be relayed to the project team faster. Terrestrial laser scanning provides an alternative to traditional piping design and offers many benefits in dimensional accuracy and improved measurement capability (Muralikrishnan, 2021).

2.3 Decision support tools

Decision support tools are used in a variety of industries to make informed decisions by providing structured guidance to make effective decisions (Bagstad et al., 2013; Cooke et al., 2008; Cronemyr et al., 2001). Attia et al. (2013) presented an energy-oriented software tool that facilitated the decision-making process of zero energy buildings. There was a need for the evaluation of biofuel production pathways in the energy sector and a framework for a DST was developed by Perimenis et al. (2011). The cement industry requires the implementation of the most appropriate energy efficiency solutions with the use of DSTs (Mokhtar and Nasooti, 2020). These tools, whose output may vary according to the user’s inputs, may suggest the ideal decision direction (Rose et al., 2016).

3 Methodology

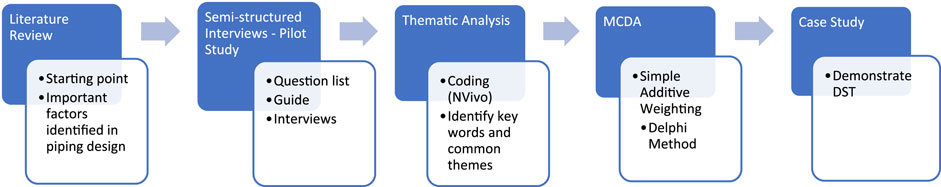

The overarching research methodology is a triangulation or mixed methods approach to develop a DST for use of TLS in piping design engineering. Triangulation studies employ two or more research techniques which are a combination of qualitative and quantitative approaches to give a multidimensional view of the subject (Abowitz and Toole, 2010; Fellows and Liu, 2021). The proposed method is divided into five main stages (Figure 2). A literature review is the first step in understanding TLS benefits and identifying criteria in piping design engineering in past studies. The data from the literature review is used to develop an interview guide as a pilot study for semi-structured interviews followed by a thematic analysis. Simple additive weighting will be used as the multi-criteria decision analysis (MCDA) method for making a decision involving multiple criteria. A case study will demonstrate the use of the decision support tool in determining use of TLS on a piping design project.

The triangulation approach beginning with the literature review gives a broad review of piping design and terrestrial laser scanning. This gives a conceptual framework used to develop the questions in semi-structured interviews. This yields qualitative data in the form of common themes that would influence the use of TLS over conventional methods. Simple additive weighting and the Delphi method would prioritize the criterion by establishing weights agreed upon by experts in the field. A case study then applies the research results for validation. The findings from the literature review, semi-structured interviews, thematic analysis, simple additive weighting, and Delphi method yield the structure of the decision support tool to guide the selection of TLS in piping design. This study was reviewed and approved by the Institutional Review Board (IRB) of Louisiana State University (Protocol #IRBAM-22-0829). The participants provided their written informed consent to participate in this study.

3.1 Literature review

Literature reviews were conducted to identify previous research on the use of 3D TLS and later validate ideas from the researched sources of information. This review is based on 15 selected articles from six journals within the domain of automation in construction, construction engineering and project management. The articles were searched using key phrases such as “piping design” and “terrestrial laser scanning.” The articles were examined to extract common themes, benefits, and challenges associated with 3D TLS.

3.2 Semi-structured interviews

The overall purpose of using semi-structured interviews for data collection is to gather information from key respondents who have professional experiences, attitudes, perceptions and beliefs related to use of TLS for piping design (Dejonckheere and Vaughn, 2019). A semi-structured interview helps gain more insight to understand the needs or viewpoints needed to develop the decision support tool (Kallio et al., 2016). Semi-structured interviews were used to determine key words and common themes based on the interviewees’ responses (Dicicco-Bloom and Crabtree, 2006). This interview structure fosters learning about individual experiences and perspectives (Dicicco-Bloom and Crabtree, 2006). Fisher et al. (2017) used semi-structured interviews with healthcare general practitioners to understand perceptions of provider workloads. Pre-determined open-ended questions are asked to get independent ideas and thoughts from the respondents and used to supplement the other methods in this paper’s triangulation approach (Adams, 2015). A framework is needed to develop an interview guide which considers the common themes derived from the literature review.

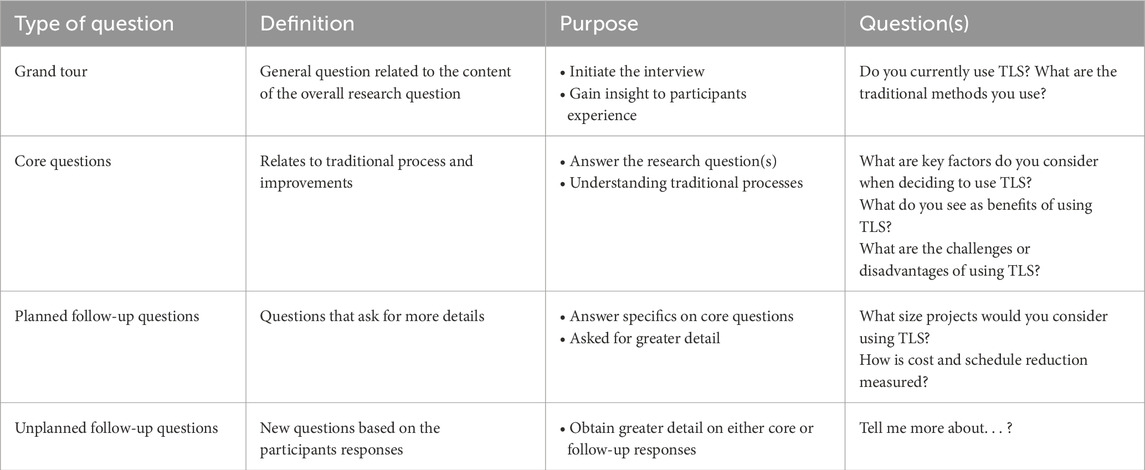

Kallio et al. (2016) produced a framework for the development of a semi-structured interview guide. The steps involved are as follows: (1) identifying the prerequisites to use a semi-structured interview; (2) retrieving previous knowledge from literature reviews; (3) formulating of the preliminary interview guide by creating a list of interview questions by reviewing past observations and identifying gaps in the piping design process; (4) pilot testing; (5) presenting the complete interview guide. Guiding questions including ‘grand tour’ questions, core questions and planned and unplanned follow-up questions are shown in Table 1 (Spradley, 2016). Questions related to the common literature review themes were developed and asked during the interview.

Table 1. Questions in semi-structured interview (Spradley, 2016).

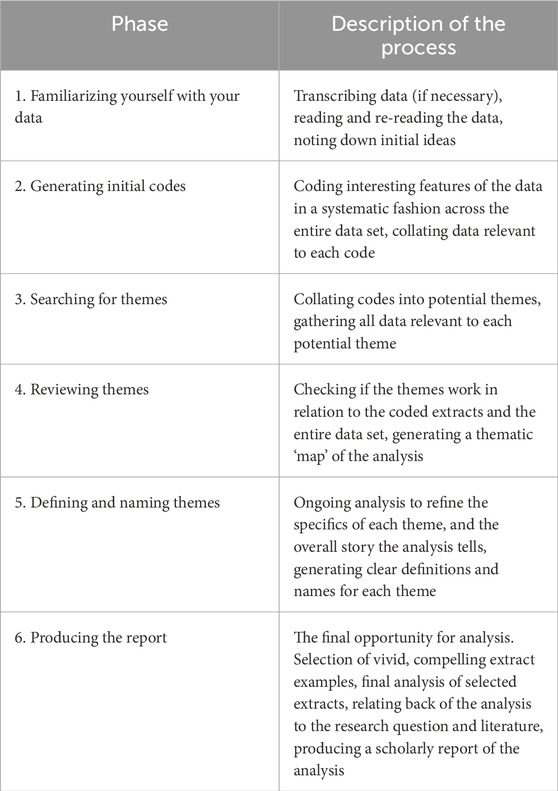

3.3 Thematic analysis

Thematic analysis is a widely used qualitative analytic method (Roulston, 2001). Boyatzis (1998) describes thematic analysis as a tool to use across multiple methods. Braun and Clarke (2006) describe the benefits of thematic analysis and the flexibility it gives as a research method. Braun and Clarke (2006) outline a 6-phase guide to performing thematic analysis shown in Table 2. Following completion of the semi-structured interviews, a qualitative data analysis software application, NVivo 12, will be used to code and perform a thematic analysis of the responses to the interview questions.

Table 2. Phases of thematic analysis (Braun and Clarke, 2006).

3.4 Multi-criteria decision analysis

Simple additive weighting (SAW) is a weighted linear combination or scoring method. It is one of the most often used multi-criteria decision techniques (Afshari et al., 2010). This technique is aimed at determining a weighted score for each alternative by adding the contribution of each attribute multiplied by their weights. The steps of SAW include the following: (1) weighting of criteria (Delphi method), (2) obtaining the criteria/decision matrix, (3) calculating the normalized decision matrix, (4) multiplying the normalized weight of each criterion with respective criteria weighting to yield a ranking of the alternatives (Afshari et al., 2010).

The Delphi method is a technique used to obtain consensus of opinion from a panel of experts within a particular field (Toepoel and Emerson, 2017). This technique involves defining and recruiting experts who possess knowledge in a particular area, who are representatives in the specific discipline, or who have credible relevant professional experience (Hsu and Sandford, 2007; Williams and Webb, 1994). Several advantages of using the Delphi method include the following: time and cost effectiveness, discussion of complex problems, participants have time to synthesize their ideas and have applications in many fields (Akins et al., 2005). The weighting of criteria will be determined by this expert panel.

The expert panel size can vary. An accurate procedure does not exist for identifying the number of panel experts in any individual study (Williams and Webb, 1994). According to Dalkey et al. (1969), the panel size can have an effort on accuracy and reliability has shown to increase linearly between 3 and 11 experts with accuracy improving up to a maximum of 29. If the backgrounds of the participants are homogeneous, studies have shown that a panel of 10–15 experts could be efficient (Hsu and Sandford, 2007). Boulkedid et al. (2011) conducted a systematic review of the Delphi method and found that the minimum number of experts on a panel to be three and the median number to be 17. For this study, the panel of experts consisting of design engineers, design supervisors, project managers, and engineering managers provides homogeneous backgrounds in piping design and terrestrial laser scanning.

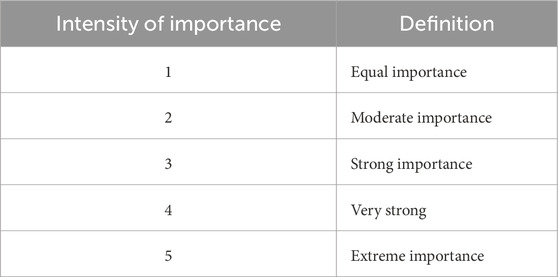

Construction of a decision matrix will include two methods (TLS and traditional) and criteria. The scale of values in Table 3 will be used to identify the intensity of importance for the comparison (Afshari et al., 2010). Normalizing the decision matrix creates a standardization of criteria which helps facilitate the comparison, which will be finally followed by the evaluation of the score of each alternative with respect to each weighted criterion.

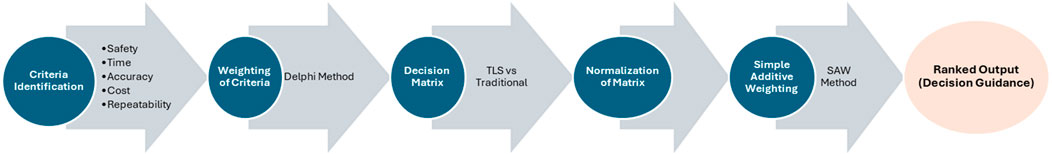

To enhance clarity and usability, a visual representation of the decision support tool (DST) is provided in Figure 3. This figure illustrates the process flow from input criteria selection to final ranking using the SAW method with Delphi-derived weights.

Figure 3. Visual representation of the Decision Support Tool (DST). The flowchart illustrates the DST framework, beginning with the identification of criteria (safety, time savings, accuracy, cost-effectiveness, and repeatability), followed by expert weighting through the Delphi method, normalization of the decision matrix, and application of the Simple Additive Weighting (SAW) technique. The output is a ranked decision between traditional methods and TLS, providing practitioners with a systematic and transparent evaluation process.

3.5 Case study

To demonstrate the use of the DST, a case study was conducted which involved a piping design project at an industrial plant site in southeast Louisiana. The site area is in an operating unit in a 9 × 12-m area. The project scope includes approximately 72 m of 150-millimeter (mm) diameter pipe at multiple elevations with four tie points into existing piping. The DST will be used by a piping designer with 17 years of experience at the site. Demonstration of the tool is based on the criteria weights resulting from the Delphi method, normalization of the decision matrix, and final ranking to determine the better method.

4 Results

4.1 Literature review

Studies have uncovered the effectiveness and usefulness of laser scanning for dimensional quality control (Bhatla et al., 2012). Al-kheder et al. (2009) developed a 3D documentation system for palaces in the Jordan desert using 3D laser scanning. Panella et al. (2020) assessed the benefit of laser scanning in rail tunnel inspections. 3D laser scanning technology’s widespread adoption in applications across various industries continue to grow as the value and benefits are realized (Park et al., 2007). Bosché et al. (2015) used technology for automated comparison of as-built and as-planned cylindrical mechanical, electrical and plumbing components including piping installation. Greaves and Hohner (2009) presented research findings resulting in the benefits of applying 3D laser scanning technology to the design, construction, and operation of industrial plants. Terrestrial laser scanning has been considered as the best available technology to capture 3D information due to its speed and dimensional accuracy (Bosché et al., 2015). Piping design and construction in industrial plants require efficiency and dimensional accuracy (Nguyen and Choi, 2018).

Although these studies show that there are several applications of using TLS in various industries, there are inherent limitations of these studies which does not include a methodology or decision support tool that is useful in deciding whether to use TLS as a data acquisition tool in piping design rather than using conventional methods of measurement (Soudarissanane et al., 2011; Yen Kin et al., 2014). However, overall benefits included reduction of errors, improved planning and design, improved work processes, improved safety, improved quality, enhanced collaboration, project readiness, and accommodation of scope changes. These benefits were used as a starting point for a decision support tool criterion, which includes the following common themes that were used to develop questions in the semi-structured interview stage of this research paper: time savings, cost effectiveness, accuracy and precision, detailed documentation, and safety.

4.2 Semi-structured interviews

Pilot testing was performed using the interview guide with 12 industry professionals with an average of 22 years of experience in piping design. Common themes used to develop questions in the semi-structured interview included the following: dimensional accuracy, safety factors (environmental, less risk in the field), repeatability, cost effective, reduced costs associated with access (scaffolding, personnel lifts), reduced field time. No additional questions were required from the initial pilot testing since there were no new questions based on the participants’ responses. The pilot testing was followed by seven additional semi-structured interviews to compile additional data on common themes resulting from the interviews. The results of the responses and themes are outlined in the next section.

4.3 Thematic analysis

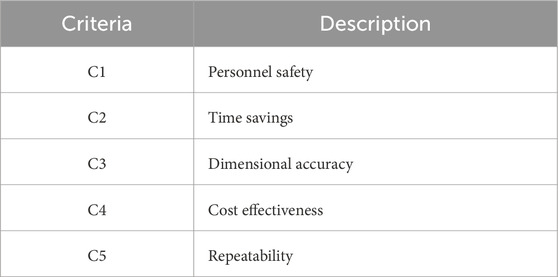

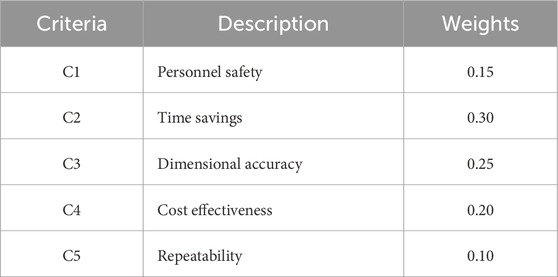

The thematic analysis from the semi-structured interview questions yielded five common themes. Those themes included the following: personnel safety, time savings, dimensional accuracy, cost effectiveness, and repeatability. These common themes were consistent with the results and findings of the literature review. The common themes were used as individual criteria as part of the decision matrix as shown in Table 4.

4.4 Multi-criteria decision analysis

The multi-criteria decision analysis (MCDA) method used in this study was the simple additive weighting (SAW) method. In this SAW approach, the Delphi method was used to determine the criteria weightings. The Delphi panel consisted of 12 industry professionals with substantial expertise in areas directly relevant to piping design and terrestrial laser scanning (TLS). Panelists were selected to provide a balance of perspectives from design engineers, project managers, engineering managers, and design supervisors, each with an average of more than 20 years of experience in industrial plant projects. Importantly, the panel included representatives from both industrial plant operations and third-party engineering service providers, ensuring diversity in professional backgrounds and organizational perspectives. This selection strategy provided credibility to the weighting process by incorporating insights from practitioners with extensive field experience and strategic decision-making responsibilities.

The experts were given a questionnaire to respond with a weighting for each of the five criterion resulting from the thematic analysis (see Table 4). The initial questionnaire started with an equal weight of 0.20 for each criterion. The total weighting of all the criterion would have to equal 1.0 (increments of 0.05). The results were averaged, and then a second questionnaire with those results was shared with the experts. There were two rounds conducted to reach consensus on the weight of each criterion. The sum of the weights should be equal to one. Table 5 shows the results of weightings for each criterion. The experts agreed that time savings were the most important criterion followed by dimensional accuracy.

4.5 Case study

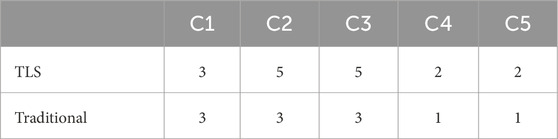

To demonstrate the proposed tool, a case study was conducted involving a typical piping design project at an industrial plant site. The approximate size of the operating unit was 9 × 12-m area. The project scope includes installation of new 150 mm diameter piping approximately 72 m in length that spans multiple elevations. The new piping will tie into four existing piping systems. The DST was used by a piping designer with 17 years of experience at the site. Step 1 includes use the of the criteria matrix and the weights determined by the Delphi method (Table 5). For Step 2, the piping designer determines the intensity of importance for each criterion based on his/her personal experience and scope of the project for each alternative which is the use of TLS or traditional process. Results of the importance scores are shown in Table 6.

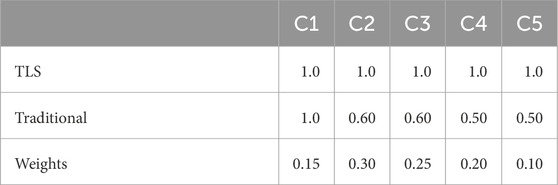

Step 3 normalizes the decision matrix to give a meaning comparison between the criteria (Table 7).

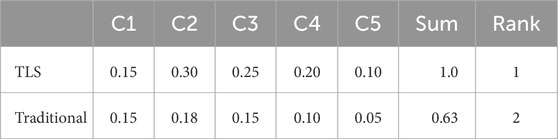

Step 4 evaluates each alternative with respect to the criteria and weight. The sum is then used to rank the two alternatives. Table 8 shows the results and ranking. In this case study, use of TLS ranked higher than the traditional piping design process.

5 Discussion

This research confirms that TLS is a valuable tool for piping design, particularly in projects where accuracy and time savings are critical. The DST developed in this study provides a practical framework for decision-makers, enabling them to assess the benefits of TLS in a systematic and quantifiable manner. The case study results are consistent with findings from other industries, where TLS has been shown to improve design accuracy, reduce rework, and enhance overall project efficiency.

The quantitative benefits observed in previous studies reinforce the results of our case study. TLS adoption not only provides qualitative advantages such as improved safety and reduced rework but also delivers measurable outcomes. Industry benchmarks show that TLS reduces field survey time by more than half while maintaining millimeter-level accuracy in as-built modeling (Aryan et al., 2021; Wu et al., 2021). These measurable improvements help justify the higher initial investment costs in TLS equipment or services, since the reduction in errors, rework, and schedule delays provides long-term value to project stakeholders.

Although the initial cost of TLS may be a barrier for some companies, the long-term benefits in terms of reduced errors, time savings, and improved safety justify the investment. There may be cases where less complex piping designs may not warrant the use of TLS, but a DST can be used in the front-end evaluation to effectively evaluate the alternatives based on a given criteria and weightings. The use of TLS can provide greater cost prediction, optimized design, and retention of model intelligence from concept to construction. Without a DST, a pure qualitive approach would possibly give industry professionals a less beneficial decision that may impact important factors in delivering a successful piping project.

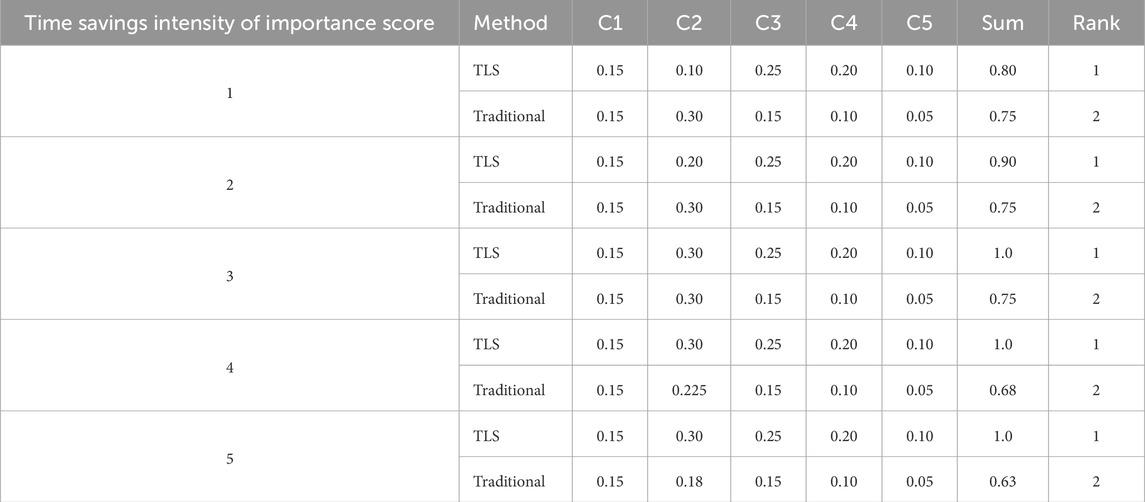

5.1 Sensitivity analysis

A brief sensitivity analysis to test the impact of a different variable assumption regarding the intensity of importance for the time savings criterion is presented in Table 9. With the changes in the time savings intensity of importance scores from one to five, the use of TLS ranked higher in each scenario. Notably, the difference between the sum for each method was closer with the lower time savings intensity of importance scores for TLS. The intensity of importance scores for other criterions for either TLS or traditional methods can yield a different outcome or ranking depending on the expert judgement of the individual assigning the scores.

Table 9. Sensitivity analysis of the method selection for each change of the time savings intensity of importance score.

6 Conclusion

Through this research and the developed decision support tool, piping designers can quantitively evaluate the use of TLS in their piping design process versus the traditional design process of using manual methods of gathering data and measurements which can be inaccurate or even nonexistent. The development of a decision support tool for the use of 3D terrestrial laser scanning in piping designs addresses a critical need in the industry for more accurate and efficient data collection methods. The DST provides a robust framework for evaluating when to use TLS, based on criteria such as safety, accuracy, and cost-effectiveness. The case study demonstrates the practical value of the DST, confirming that use of TLS is a superior method for complex industrial piping design projects versus using traditional or conventional methods. This research contributes to the growing body of knowledge on TLS applications and offers a practical tool for industry professionals to enhance their piping design processes.

In addition to the demonstrated case study, the DST presents opportunities for future validation and broader application. While this study focused on piping design in an industrial plant setting, the framework can be extended to other engineering disciplines such as structural, electrical, and civil design, where dimensional accuracy, safety, and efficiency are equally important. Furthermore, DST can be adapted for integration with Building Information Modeling (BIM) platforms, 4D simulation tools, and other digital construction management systems. Such integration would allow practitioners to embed TLS-based decision-making directly within their existing workflows, improving usability and adoption. Future research can also validate the tool in different geographic regions and project types to assess its robustness and generalizability. These directions highlight the potential of DST not only as a stand-alone evaluation framework, but also as a scalable component of the broader digital transformation in construction engineering and management.

Despite the practical benefits of this study, there are limitations. First, semi-structured interviews included 15 industrial professionals in the southeast Louisiana region. Additional interviews possibly could have resulted in additional major themes which could translate into additional criteria. The number of criterions could be expanded to include other items deemed necessary to make a more informed decision when comparing use of TLS and traditional design methods. Second, the panel of experts selected using the Delphi method was limited to 12 individuals. Future research could involve a different set of experts which may yield a different consensus in the weighting for each criterion. Lastly, the case study was a single demonstration of the DST. A larger number of professionals and additional case studies to demonstrate the use of the DST with various types and disciplines of projects can be considered. The sensitivity analysis could also be expanded to examine the extent to which method selection is affected by changes in values of the intensity of importance score for each criterion. Different scores can lead to different guidance on the selection and use of TLS versus traditional methods of field data collection.

Future research can address challenges in using TLS such as technical training, equipment costs, and cases where use of TLS would not be cost effective or advantageous. Future research can include application of a decision support tool to other engineering design disciplines such as civil, structural, and electrical design. Terrestrial laser scanning can be applied in the design process of these other disciplines to improve efficiency and accuracy of the design work. Further research could explore the application of the DST in other types of piping projects and industries, as well as the integration of TLS with other emerging technologies such as Building Information Modeling (BIM), 4D scheduling, quality assurance, and reality capture.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving humans were approved by Institutional Review Board of Louisiana State University. The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

JM: Conceptualization, Methodology, Writing – original draft. RM: Writing – review and editing. CF: Methodology, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abowitz, D. A., and Toole, T. M. (2010). Mixed method research: fundamental issues of design, validity, and reliability in construction research. J. Constr. Eng. Manag. 136 (1), 108–116. doi:10.1061/(asce)co.1943-7862.0000026

Adams, W. C. (2015). Conducting semi-structured interviews. In: Handbook of practical program evaluation. Hoboken: Wiley Online Library. p. 492–505. doi:10.1002/9781119171386.ch19

Afshari, A., Mojahed, M., and Yusuff, R. M. (2010). Simple additive weighting approach to personnel selection problem. Int. J. Innov Manag. Technol. 1 (5), 511.

Akins, R. B., Tolson, H., and Cole, B. R. (2005). Stability of response characteristics of a Delphi panel: application of bootstrap data expansion. BMC Med. Res. Methodol. 5, 37–12. doi:10.1186/1471-2288-5-37

Al-kheder, S., Al-shawabkeh, Y., and Haala, N. (2009). Developing a documentation system for desert palaces in Jordan using 3D laser scanning and digital photogrammetry. J. Archaeol. Sci. 36 (2), 537–546. doi:10.1016/j.jas.2008.10.009

Aryan, A., Bosché, F., and Tang, P. (2021). Planning for terrestrial laser scanning in construction: a review. Automation Constr. 125, 103551. doi:10.1016/j.autcon.2021.103551

Attia, S., Gratia, E., De Herde, A., and Hensen, J. (2013). Tool for design decision making: zero energy residential buildings in hot humid climate. in Proceedings of building simulation 2013: 13th conference of IBPSA; 2013 August 25–28; Chambery, France. p. 3720–3727. doi:10.26868/25222708.2013.980

Bagstad, K. J., Semmens, D. J., Waage, S., and Winthrop, R. (2013). A comparative assessment of decision-support tools for ecosystem services quantification and valuation. Ecosyst. Serv. 5, 27–39. doi:10.1016/j.ecoser.2013.07.004

Becerik-Gerber, B., Jazizadeh, F., Kavulya, G., and Calis, G. (2011). Assessment of target types and layouts in 3D laser scanning for registration accuracy. Automation Constr. 20 (5), 649–658. doi:10.1016/j.autcon.2010.12.008

Bhatla, A., Choe, S. Y., Fierro, O., and Leite, F. (2012). Evaluation of accuracy of as-built 3D modeling from photos taken by handheld digital cameras. Automation Constr. 28, 116–127. doi:10.1016/j.autcon.2012.06.003

Bosché, F., Ahmed, M., Turkan, Y., Haas, C. T., and Haas, R. (2015). The value of integrating Scan-to-BIM and Scan-vs-BIM techniques for construction monitoring using laser scanning and BIM: the case of cylindrical MEP components. Automation Constr. 49, 201–213. doi:10.1016/j.autcon.2014.05.014

Boulkedid, R., Abdoul, H., Loustau, M., Sibony, O., and Alberti, C. (2011). Using and reporting the Delphi method for selecting healthcare quality indicators: a systematic review. PloS one 6 (6), e20476. doi:10.1371/journal.pone.0020476

Boyatzis, R. E. (1998). Transforming qualitative information: thematic analysis and code development. Newcastle upon Tyne, UK: Sage. Available online at: https://books.google.com/books?hl=en&lr=&id=_rfClWRhIKAC&oi=fnd&pg=PR6&dq=Boyatzis,+R.+E.+(1998).+Transforming+qualitative+information:+Thematic+analysis+and+code+development.+&ots=ECrFCfco4j&sig=txDrCrC11ZvvFofdvWIk2XsxJZk#v=onepage&q=Boyatzis%2C%20R.%20E.%20(1998).%20Transforming%20qualitative%20information%3A%20Thematic%20analysis%20and%20code%20development.&f=false (Accessed March 16, 2025).

Braun, V., and Clarke, V. (2006). Using thematic analysis in psychology. Qual. Res. Psychol. 3 (2), 77–101. doi:10.1191/1478088706qp063oa

Chai, J., Chi, H.-L., Wang, X., Wu, C., Jung, K. H., and Lee, J. M. (2016). Automatic as-built modeling for concurrent progress tracking of plant construction based on laser scanning. Concurr. Eng. 24 (4), 369–380. doi:10.1177/1063293X16670449

Cooke, T., Lingard, H., Blismas, N., and Stranieri, A. (2008). ToolSHeDTM: the development and evaluation of a decision support tool for health and safety in construction design. Eng. Constr. Archit. Manag. 15 (4), 336–351. doi:10.1108/09699980810886847

Cronemyr, P., Rönnbäck, A. Ö., and Eppinger, S. D. (2001). A decision support tool for predicting the impact of development process improvements. J. Eng. Des. 12 (3), 177–199. doi:10.1080/09544820110055547

Dalkey, N. C., Brown, B. B., and Cochran, S. (1969). The Delphi method: an experimental study of group opinion. Santa Monica, CA: Rand Corporation. p. 107. Available online at: https://coilink.org/20.500.12592/bj75n4 (Accessed March 16, 2025).

Dejonckheere, M., and Vaughn, L. M. (2019). Semistructured interviewing in primary care research: a balance of relationship and rigour. Fam. Med. Community Health 7 (2), e000057. doi:10.1136/fmch-2018-000057

Dicicco-Bloom, B., and Crabtree, B. F. (2006). The qualitative research interview. Med. Educ. 40 (4), 314–321. doi:10.1111/j.1365-2929.2006.02418.x

Fellows, R. F., and Liu, A. M. (2021). Research methods for construction. Hoboken, NJ: John Wiley and Sons.

Fisher, R. F., Croxson, C. H., Ashdown, H. F., and Hobbs, F. R. (2017). GP views on strategies to cope with increasing workload: a qualitative interview study. Br. J. General Pract. 67 (655), e148–e156. doi:10.3399/bjgp17X688861

Greaves, T., and Hohner, L. N. (2009). 3D laser scanning: benefits and paybacks for industrial plant design, construction and operation. Danvers, MA: Spar Point Research. Available online at: http://www.global-surveying.com/wp-content/uploads/2013/11/WhitePaper_Laser-Scanning-for-Industrial-Plants.pdf (Accessed March 16, 2025).

Gumilar, I., Farohi, F., Munarda, M., Bramanto, B., and Kartini, G. A. J. (2022). The combined use of terrestrial laser scanner and handheld 3D scanner for 3D modeling of piping instrumentation at oil and gas company. J. Eng. and Technol. Sci. 54 (6), 220603. doi:10.5614/j.eng.technol.sci.2022.54.6.3

Guo, J., Wang, Q., and Park, J.-H. (2020a). Geometric quality inspection of prefabricated MEP modules with 3D laser scanning. Automation Constr. 111, 103053. doi:10.1016/j.autcon.2019.103053

Guo, J., Yuan, L., and Wang, Q. (2020b). Time and cost analysis of geometric quality assessment of structural columns based on 3D terrestrial laser scanning. Automation Constr. 110, 103014. doi:10.1016/j.autcon.2019.103014

Hsu, C., and Sandford, B. A. (2007). The Delphi technique: making sense of consensus. Pract. Assess. Res. Eval. 12 (1), 10. doi:10.7275/pdz9-th90

Hu, C. A., Peng, D., Lv, F., Sun, H., Zhao, T., and Li, W. (2021). Application of terrestrial laser scanner in engineering survey. IOP Conf. Ser. earth Environ. Sci. 783, 1012084. doi:10.1088/1755-1315/783/1/012084

Kallio, H., Pietilä, A.-M., Johnson, M., and Kangasniemi, M. (2016). Systematic methodological review: developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 72 (12), 2954–2965. doi:10.1111/jan.13031

Kawashima, K., Kanai, S., and Date, H. (2014). As-built modeling of piping system from terrestrial laser-scanned point clouds using normal-based region growing. J. Comput. Des. Eng. 1 (1), 13–26. doi:10.7315/jcde.2014.002

Kim, C., Kim, B., and Kim, H. (2013). 4D CAD model updating using image processing-based construction progress monitoring. Automation Constr. 35, 44–52. doi:10.1016/j.autcon.2013.03.005

Kim, H., Kim, J. Y., and Shin, Y. (2024). Reverse engineering of building layout plan through checking the setting out of a building on a site using 3D laser scanning technology for sustainable building construction: a case study. Sustainability 16 (8), 3278. doi:10.3390/su16083278

Lee, M., Lee, S., Kwon, S., and Chin, S. (2017). A study on scan data matching for reverse engineering of pipes in plant construction. KSCE J. Civ. Eng. 21 (6), 2027–2036. doi:10.1007/s12205-016-0929-z

Li, X., Gan, V. J., Li, K., and Li, M. (2025). High-precision 3D BIM reconstruction for mechanical, electrical and plumbing components using terrestrial laser scanning and LiDAR point clouds. J. Build. Eng. 112, 113661. doi:10.1016/j.jobe.2025.113661

Mokhtar, A., and Nasooti, M. (2020). A decision support tool for cement industry to select energy efficiency measures. Energy Strategy Rev. 28, 100458. doi:10.1016/j.esr.2020.100458

Muralikrishnan, B. (2021). Performance evaluation of terrestrial laser scanners—a review. Meas. Sci. Technol. 32 (7), 072001. doi:10.1088/1361-6501/abdae3

Nguyen, C. H. P., and Choi, Y. (2018). Comparison of point cloud data and 3D CAD data for on-site dimensional inspection of industrial plant piping systems. Automation Constr. 91, 44–52. doi:10.1016/j.autcon.2018.03.008

Omar, T., and Nehdi, M. L. (2016). Data acquisition technologies for construction progress tracking. Automation Constr. 70, 143–155. doi:10.1016/j.autcon.2016.06.016

Panella, F., Roecklinger, N., Vojnovic, L., Loo, Y., and Boehm, J. (2020). Cost-benefit analysis of rail tunnel inspection for photogrammetry and laser scanning. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci., 1137–1144. doi:10.5194/isprs-archives-XLIII-B2-2020-1137-2020

Park, H. S., Lee, H. M., Adeli, H., and Lee, I. (2007). A new approach for health monitoring of structures: terrestrial laser scanning. Computer-Aided Civ. Infrastructure Eng. 22 (1), 19–30. doi:10.1111/j.1467-8667.2006.00466.x

Pătrăucean, V., Armeni, I., Nahangi, M., Yeung, J., Brilakis, I., and Haas, C. (2015). State of research in automatic as-built modelling. Adv. Eng. Inf. 29 (2), 162–171. doi:10.1016/j.aei.2015.01.001

Perimenis, A., Walimwipi, H., Zinoviev, S., Müller-Langer, F., and Miertus, S. (2011). Development of a decision support tool for the assessment of biofuels. Energy Policy 39 (3), 1782–1793. doi:10.1016/j.enpol.2011.01.011

Rabbani, T., Dijkman, S., van den Heuvel, F., and Vosselman, G. (2007). An integrated approach for modelling and global registration of point clouds. ISPRS J. Photogram Remote Sens. 61 (6), 355–370. doi:10.1016/j.isprsjprs.2006.09.006

Rose, D. C., Sutherland, W. J., Parker, C., Lobley, M., Winter, M., Morris, C., et al. (2016). Decision support tools for agriculture: towards effective design and delivery. Agric. Syst. 149, 165–174. doi:10.1016/j.agsy.2016.09.009

Roulston, K. (2001). Data analysis and ‘theorizing as ideology. Qual. Res. 1 (3), 279–302. doi:10.1177/146879410100100302

Safa, M., Shahi, A., Nahangi, M., Haas, C., and Noori, H. (2015). Automating measurement process to improve quality management for piping fabrication. Structures 3, 71–80. doi:10.1016/j.istruc.2015.03.003

Soudarissanane, S., Lindenbergh, R., Menenti, M., and Teunissen, P. (2011). Scanning geometry: influencing factor on the quality of terrestrial laser scanning points. ISPRS J. Photogrammetry Remote Sens. 66 (4), 389–399. doi:10.1016/j.isprsjprs.2011.01.005

Spradley, J. P. (2016). The ethnographic interview. Long Grove, IL: Waveland Press. Available online at: https://books.google.com/books?hl=en&lr=&id=KZ3lCwAAQBAJ&oi=fnd&pg=PR1&dq=spradley+the+ethnographic+interview&ots=4qoXkYibrF&sig=bUQnAsePhT4lbmac9h4r2IMlBEk#v=onepage&q=spradley%20the%20ethnographic%20interview&f=false (Accessed March 16, 2025).

Tang, X., Wang, M., Wang, Q., Guo, J., and Zhang, J. (2022). Benefits of terrestrial laser scanning for construction QA/QC: a time and cost analysis. J. Manag. Eng. 38 (2), 05022001. doi:10.1061/(ASCE)ME.1943-5479.0001012

Toepoel, V., and Emerson, H. (2017). Using experts’ consensus (the Delphi method) to evaluate weighting techniques in web surveys not based on probability schemes. Math. Popul. Stud. 24 (3), 161–171. doi:10.1080/08898480.2017.1330012

Wardius, Y., and Hein, S. (2024). Terrestrial laser scanning vs. manual methods for assessing complex forest stand structure: a comparative analysis on plenter forests. Eur. J. For. Res. 143 (2), 635–649. doi:10.1007/s10342-023-01641-1

Williams, P. L., and Webb, C. (1994). The Delphi technique: a methodological discussion. J. Adv. Nurs. 19 (1), 180–186. doi:10.1111/j.1365-2648.1994.tb01066.x

Wu, C., Yuan, Y., Tang, Y., and Tian, B. (2021). Application of terrestrial laser scanning (TLS) in the architecture, engineering and construction (AEC) industry. Sensors 22 (1), 265. doi:10.3390/s22010265

Xie, Y., Teo, M. X., Li, S., Huang, L., Liang, N., and Cai, Y. (2023). As-built BIM reconstruction of piping systems using smartphone videogrammetry and terrestrial laser scanning. Automation Constr. 156, 105120. doi:10.1016/j.autcon.2023.105120

Keywords: 3D CAD, terrestrial laser scanning, piping design, decision support tool, multi-criteria decision analysis, simple additive weighting, delphi method

Citation: Morgan J, Mostafiz RB and Friedland C (2025) Development of a decision support tool for use of 3D terrestrial laser scanning for piping designs. Front. Built Environ. 11:1663869. doi: 10.3389/fbuil.2025.1663869

Received: 11 July 2025; Accepted: 22 September 2025;

Published: 10 October 2025.

Edited by:

Amir Mahdiyar, Princeton University, United StatesReviewed by:

Amirhossein Balali, University of Hertfordshire, United KingdomKetut Tomy Suhari, Institut Teknologi Nasional Malang, Indonesia

Copyright © 2025 Morgan, Mostafiz and Friedland. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Joseph Morgan, am1vcjE2N0Bsc3UuZWR1

Joseph Morgan

Joseph Morgan Rubayet Bin Mostafiz

Rubayet Bin Mostafiz Carol Friedland

Carol Friedland