- 1Wuhan Construction Engineering Group Co., Ltd., Wuhan, Hubei, China

- 2Wuhan University, Wuhan, Hubei, China

- 3Hefei University of Technology, Hefei, Anhui, China

- 4Central South University, Changsha, China

- 5China Academy of Ocean Engineering (Qingdao), Qingdao, China

- 6Qingdao University of Technology, Qingdao, China

- 7Wuhan University of Science and Technology, Wuhan, Hubei, China

The effective disposal of construction and industrial solid waste is vital for sustainable urban development. This study developed a composite cementitious material (CCM) based on mechanically activated waste concrete, blast furnace slag, and carbide slag for sludge solidification. Through paste tests, unconfined compressive strength (UCS), and durability tests, the optimal CCM mix was determined as 30% waste concrete, 60% blast furnace slag, 10% carbide slag, and 10% anhydrous sodium sulfate. After 7 and 28 days of curing, the CCM paste blocks achieved UCS values of 10.89 MPa and 14.17 MPa, respectively. With 18% CCM content, the solidified sludge attained a UCS of 0.82 MPa after 14 days, meeting the bearing strength requirement (≥0.8 MPa) for China’s first-class highways. It also exhibited excellent durability, with a water stability coefficient of 88.5% and even slightly increased UCS after freeze-thaw cycles. X-ray diffraction (XRD) and Scanning Electron Microscopy-Energy Dispersive Spectrometer (SEM-EDS) analyses revealed that hydration products such as ettringite (AFt), dicalcium silicate (C2S), and calcium aluminosilicate hydrate (C-A-S-H) intertwined and cemented sludge particles, enhancing structural density and contributing to improved mechanical and durability performance.

1 Introduction

Cities, being human settlements at the center of the world, generate a substantial amount of waste during the construction, including industrial solid waste, construction solid waste, and sludge from water conservancy projects. The disposal of sludge generated by urban construction and water conservancy dredging projects differs from that of ordinary discarded soil. These sludge, as an inevitable outcome of engineering works, possess a huge volume and unique properties, presenting numerous obstacles for subsequent treatment tasks (Hengyu et al., 2021). High water content not only leads to the expansion of sludge volume, increasing transportation and storage costs, but also makes desludging treatment extremely arduous. High viscosity makes sludge difficult to solidify, further restricting the diversity of its treatment methods (Meng et al., 2018). Specialized methods are required to solidify the sludge prior to transportation, and the fluid slurry needs to be transported by specialized vehicles, which are costly. Some construction units have incurred high costs. If improperly disposed of, it is easy to cause environmental issues (Hongchun, 2021). Currently, the disposal of high-moisture sediment is typically carried out by mechanical compaction method and chemical flocculation method (Hengyu et al., 2021; Jun et al., 2018; Rui et al., 2022).

The mechanical compaction method employs techniques such as wheel-axis compaction to physically extrude the free water in the pore space of sludge through physical compression. However, the mechanical treatment of sludge consumes a significant amount of electricity. Moreover, the bound water in the compacted sludge cannot be discharged and still has a certain water content, so it cannot be directly used to meet engineering needs. Additionally, using traditional binders like cement and lime to chemically stabilize sludge has become a common treatment approach. However, the production of cement, lime, and other traditional binders will lead to a significant carbon footprint and consume a large amount of limestone and other non-renewable resources (Kuang et al., 2023). Thus, it is insufficiently environmentally friendly. It is essential to find a disposal method that is economically reasonable, green, and efficient to resourcefully deal with sludge, a kind of urban waste.

Meanwhile, during the construction of urban infrastructure, a considerable amount of waste concrete (WC) is produced. This waste concrete is difficult to decompose naturally, which can easily cause environmental pollution. Currently, the utilization of WC is mainly achieved by disassembling it and preparing recycled concrete, which is then reused in non-structural engineering positions (Jin, 2019; Liq et al., 2023; Xin et al., 2024). However, recycled concrete still has many issues at present, such as low strength and unstable performance. Although some breakthroughs have been made in the study of the performance of recycled concrete, there are still many problems to be resolved in its application, for example, the production cost of recycled concrete. The industrial development resulting from urbanization also generates a large amount of industrial solid waste. Its production volume is significant, and its composition is complex hence it is difficult to dispose. Effectively treating industrial solid waste and achieving its utilization in nearby urban areas as building materials for urban construction is an important way to carry out resource disposal at a lower cost. At present, many scholars have conducted corresponding studies on the disposal of industrial solid waste. If the waste is not properly handled, it will not only occupy valuable land resources but also release harmful substances through environmental media (such as rain and wind), posing a serious threat to the ecological environment and exacerbating the already fragile environmental system. Most of them are disposed of by chemical and physical methods, but this increases the cost invisibly and restricts resource utilization. For example, most industrial solid waste still has a certain potential activity, and its unstable nature makes it difficult to dispose of through chemical reagents and physical properties. Therefore, it is necessary to find a cheap and easily available raw material that can better dispose of industrial solid waste. Looking at the urban area, the output of construction solid waste is large, and its nature is relatively stable. For instance, sludge is the product of urban construction and water conservancy projects. It has high moisture content and high viscosity, but its nature is relatively stable.

In recent years, there have been studies on the coordinated disposal of industrial waste and waste sludge. For instance, Vichan et al. studied the pozzolanic reaction caused by the mixture of calcium carbide slag (CS) and biomass ash as a stable chemical additive. The results demonstrated that due to the pozzolanic reaction, after curing for 28 days, the strength development of solidified clay mixed with CS and biomass ash was better than that of cement-solidified clay and fly ash and biomass ash mixed cement-solidified clay (Vichan and Rachan, 2013). Chen et al. added cement, blast furnace slag (BFS), fly ash, and gypsum as a new environmental protection curing agent to the sludge and improved the sludge-solidified with fiber reinforcement (Ruimin et al., 2022). Qiao et al. used granulated BFS micro-powder with different contents to cure the sludge. The results showed that the optimal content of curing materials was 20%. The micro-powder of BFS could improve the bonding force and internal friction angle between the soil particles of the sludge-solidified, which reduce the internal porosity of the solidified soil, and increase the strength and dynamic modulus of the solidified soil by more than two times (Jingsheng et al., 2021; Hao et al., 2024a). Wang designed and prepared an industrial waste slag-based composite curing agent with low cement content by using BFS and desulfurized gypsum to replace part of cement in equal parts. The results show that the optimal ratio of mixing BFS, desulfurized gypsum, and cement to solidify sludge is 6:1:3 (Wang et al., 2024). While waste concrete is typically solid waste generated by cement, sand, and stone, some scholars use building solid waste to conduct research on the solidification of silt and soil and collaborative resource disposal. Zhou et al. employed recycled aggregate of building solid waste, blast furnace mineral powder, and ordinary Portland cement to prepare a curing agent for improving and solidifying the dredged silt of rivers and lakes (Zhen et al., 2024). Huang et al. used waste concrete to replace part of the cement to solidify high-moisture silt. The research results indicated that the unconfined compressive strength (UCS) of the silt-solidified soil decreased slightly after 7 days. However, when the content of recycled micro-powder was 10%, the UCS of the solidified soil at 28 days was the same as that of pure cement soil. Additionally, an appropriate amount of calcium hydroxide (Ca(OH)2) can enhance the activity of the regenerated micro-powder (Hui et al., 2022). Gu’s research also shows that the recycled micro-powder of waste concrete has potential activity and can replace part of the cement (Gu et al., 2019). Chan used waste concrete particles and cement-solidified silt to mix the mixed soil as foundation treatment material. The results show that it is feasible to solidify silt by the double mixing of waste concrete particles and cement (Jiale, 2023; Hao et al., 2024b). However, no scholars have carried out collaborative disposal of typical industrial solid waste, construction solid waste, and waste sludge, and their mechanism analysis is not clear enough.

Industrial solid waste possesses potential catalytic activity. Construction solid waste has unhydrated gel components, is loose and porous, and has characteristics of water release and water retention. Silt has good integrability and can provide sufficient reaction space. To explore the collaborative treatment and resource utilization of industrial and construction waste and sludge, this study adopted the collaborative mechanical activation method of waste concrete (WC), BFS, CS to prepare composite cementitious material (CCM) and apply it in the solidification treatment of silt. The optimum ratio of WC, BFS, and CS in the CCM was investigated through the clean pulp test, and the influence of particle fineness on the reaction process was examined. The hydration products of the CCM were investigated by XRD. Through the compaction, UCS, water stability, and freeze-thaw cycle test, the compaction characteristics, mechanical properties, and durability of the CCM silt-solidified soil were investigated, and the engineering application of the sludge solidified soil was evaluated. The curing mechanism and microscopic morphology of the composite cementing material solidified silt soil were investigated by combining XRD and SEM-EDS. This research and development can provide a reference approach for the comprehensive disposal of industrial solid waste, construction solid waste, and silt waste, and then can be applied to the backfill project of construction engineering. On one hand, it solves the problem of disposing of industrial, construction, and silt waste in the city and proposes a new way of collaborative resource utilization of construction waste, industrial solid waste, and silt sites. It can also provide a reference for reducing engineering construction costs, disposing of waste, and solving silt accumulation problems.

2 Materials and methods

2.1 Raw materials

The sludge samples utilized in this experiment were taken from Chengyang district, Qingdao city, Shandong Province, China. The parameters of the sludge samples are shown in Table 1.

Other test raw materials are shown in Figure 1, which mainly comprise the following: BFS (Figure 1a), CS (Figure 1b), anhydrous sodium sulfate (ASS) (Figure 1c), and WC (Figure 1d). The BFS used in the test was taken from Rizhao Iron and Steel Company. CS was obtained from an acetylene gas preparation factory in Henan. ASS was sourced from a chemical company in Shandong, The functions of ASS and CS were to act as the activators in CCM. To facilitate the exploration of the optimal mix ratio of WC and GGBS, the mixing amounts of ASS and CS in CCM remain unchanged. WC were discarded concrete test blocks for laboratory testing (with a storage time greater than 60 days).

2.2 Basic information about raw materials

The chemical element compositions of WC, BFS, and CS are shown in Table 2. The results indicate that the main chemical components of WC are SiO2, CaO, and Al2O3, with contents of 52.46%, 11.436%, and 12.998% respectively, and the total amount exceeds 70%. The abundance of Ca, Si, and Al phase substances implies that WC has the potential to be used in the preparation of cementitious material (Yang et al., 2014). The main chemical composition of BFS is CaO, Al2O3, and MgO, with contents of 30.856%, 15.192%, and 11.365% respectively. The main chemical composition of CS is CaO, and the content is as high as 76.242%.

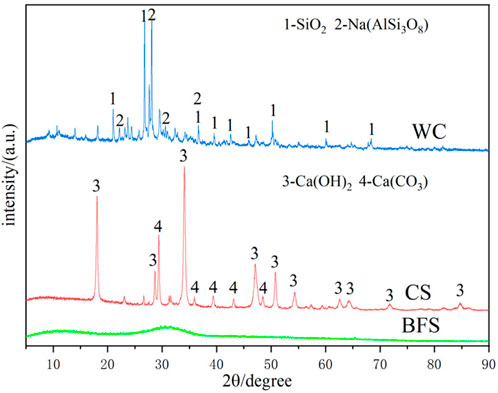

Figure 2 presents the XRD patterns of WC, BFS, and CS. The basic phase composition of WC is SiO2 and Na(AlSi3O8), which is consistent with the results of XRF analysis. CS is mainly composed of Ca(OH)2 and CaCO3. The dispersion peak within the range of 25°–35° in the XRD pattern of BFS is mainly related to the amorphous glass phase, which can provide Si and Al required for the CCM reaction (Yong et al., 2021).

2.3 Preparation of CCM

In this study, WC, BFS, and CS were weighed according to Table 3. Additionally, a 10% ASS configuration mixture was added into the SM-500 test mill. After mechanical activation for 30 min, CCM was prepared. The grinding capacity of each group was 5 kg. After preparation, CCM should be bagged, sealed, and labeled. Figure 3 shows the particle size distribution of CCM-30, and the median particle size of CCM is 25.661 μm.

2.4 CCM paste experiment

A cubic paste block with dimensions of 50 mm × 50 mm × 50 mm was prepared using CCM according to a water-cement ratio of 0.5 (m (water)/m (cement) = 0.5). The bubbles in the samples were removed through vibration. After preparation and molding, the sample is cured to the corresponding age under a standard environment of 95% humidity and 25 °C. The UCS of CCM paste block at different curing ages was tested by a automatic compression and folding test machine (model: DYE-300-10S, made by Hebei Xinglan building Instrument Co., Ltd. in China), and the group with the best mechanical properties was selected. The crushed central sample of the paste block was immersed in anhydrous ethanol for 24 h, then the anhydrous ethanol solution was replaced and the sample was reimmersed for 48 h to terminate hydration for subsequent microscopic testing.

2.5 Soil test

2.5.1 Preparation of sludge solidified soil sample

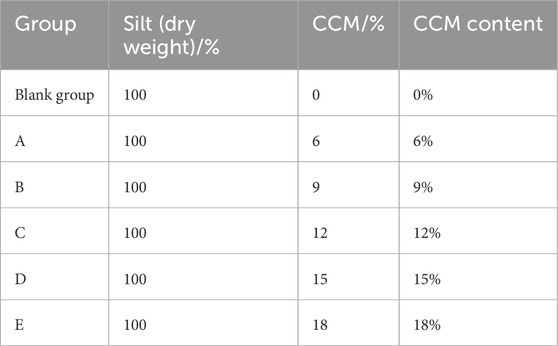

After mixing the air-dried sludge and CCM according to the mix ratio in Table 4, a cylindrical sample of 50 mm × 50 mm was prepared under static pressure at the optimal water content according to a compaction coefficient of 96%. The molding pressure was 20 tons. After forming, the sample was sealed in a plastic bag and maintained at 25 °C ± 2 °C until the corresponding age for subsequent testing of mechanical properties, water stability, and frost resistance.

2.5.2 Geotechnical test

Moisture content, compaction, liquid-plastic limit, and particles analysis of sludge were carried out in accordance with the Standard for Geotechnical Test Method GB 50123–2019 (Code of China, 2019). The compaction test adopted the light-duty test method with 3 layers for compaction, and each layer was compacted 25 times. The UCS of the cured sludge specimen was measured by a pavement materials strength tester (model: TC-10C, made by Zhongke Lujian Instrument Equipment Co., Ltd. in Hebei, China).

Water stability test: the solidified sludge were placed in plastic bags and maintained in curing room with 95% humidity and 20 °C ± 2 °C. After curing 6 days, half of the samples was taken out and immersed in water at 20 °C ± 2 °C for 24 h to test the UCS, and the water surface should be more than 2.5 cm above the top of the specimen. The remaining specimens continued to be cured for 7 days. The water stability coefficient is the ratio of the UCS of submerged specimens to that of non-submerged specimens (Xueqi et al., 2023).

Freeze-thaw test: A freeze-thaw cycle test was carried out when the solidified sludge specimens was cured for 28 days, and a control group was set up (standard curing was continued after 28 days, and the total curing age stayed the same as that of the freeze-thaw group). The freeze-thaw cycle test was conducted using a high and low temperature test chamber (model: BT-HW-50L, made by Shenzhen Beite Instrument Equipment Co., Ltd. In China). The low temperature (−20 °C) freezing lasted for 48 h and the high temperature (40 °C) hot melting lasted for 12 h. This constitutes one cycle. The test ambient humidity was 70%. After 9 freeze-thaw cycles, 3 parallel samples were taken for UCS test.

2.6 Microscopic characterization

The Zetium type X-ray fluorescence spectrometer made by Panalytical Company in the Netherlands was adopted for the XRF test. 3 g of samples that passed through a 200-mesh sieve were collected for sample preparation using the tablet method. Subsequently, the distribution and content of diverse elements within the samples were measured. The X-ray diffractometer of the German D8 Advance model was used for XRD. 1 g of the sample passing through the 200-mesh sieve was taken, and the copper target was used to determine the phase composition through a scanning angle of 5°–90° and a scanning speed of 5°/min. The scanning electron microscope (SEM) model TESCAN MIRA LMS of the Czech Republic was used to observe the micromorphology of solidified sludge with the diameter and thickness are less than 1 cm.

3 Results and discussion

3.1 CCM paste test analysis

3.1.1 UCS of CCM paste cube

The UCS of the CCM paste block is shown in Figure 4. The results indicate that the strength of CCM after cured 1 day increases with the increase in WC content. The UCS of CCM-40 cured for 3 days reached 8.68 MPa. At 7 and 28 days of curing, the UCS of CCM paste exhibited a trend of first increasing and then decreasing with the increase in WC content. This phenomenon can be attributed to the excessive presence of Si-bearing phases in WC, which inhibits the formation of adequate hydration products. The mechanical properties of CCM-30 are the best in the middle and late curing stages, The UCS of curing 7 days and 28 days reached 10.89 MPa and 14.17 MPa respectively. Therefore, CCM-30 was adopted in this study for the subsequent experiment of sludge solidification.

3.1.2 XRD analysis of CCM

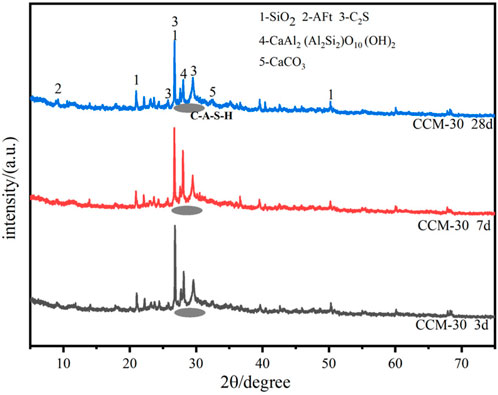

Figure 5 is the XRD pattern of CCM-30 cured for 3 days, 7 days, and 28 days. The results show that the hydration products of CCM are mainly AFt, C2S, and CaAl2(Al2Si2)O10(OH)2. These products filled the internal pores of the paste and cement the particles, thus improved the compactness and strength of the paste. In the XRD pattern of BFS, the envelope peaks corresponding to 25°–35° are mainly amorphous glass phase. However, the CCM-30 samples’ XRD pattern cured for 3 days, 7 days, and 28 days also show an amorphous peak, whose range shifts and increases compared with BFS, indicating that a new amorphous gel was generated. In the XRD pattern of CCM, the amorphous halos between 25° and 32° are mainly composed of the amorphous glass phase in the raw material and the newly formed amorphous C-A-S-H gel in the hydration product (Wang et al., 2018; Wang et al., 2020). Since the hydrated product C-A-S-H gel is an amorphous phase, there is no corresponding diffraction peak. The CS in the raw material is mainly composed of Ca(OH)2. However, the existence of Ca(OH)2 is basically not found in the XRD pattern of CCM, which indicates that Ca(OH)2 in CS was fully involved in the hydration reaction. The characteristic peak corresponding to CaAl2(Al2Si2)O10(OH)2 in the XRD pattern of CCM-30 curing for 28 days is significantly lower than that for 7 days, which is caused by the carbonization of hydration products. Correspondingly, the characteristic peak of CaCO3 in the XRD pattern of CCM-30 curing for 28 days is significantly higher than that of the curing for 3 days and 7 days. With the progress of the hydration reaction, the characteristic peaks corresponding to AFt and C2S in CCM-30 gradually increase, indicating that the hydration degree of CCM-30 gradually increased (Xu et al., 2025; Jia et al., 2025). The hydration products generated in the hydration process of CCM can cement the sludge particles and fill the pores of the sludge, thus improving the density and bearing capacity of the sludge.

3.2 Compaction test analysis of the solidified sludge

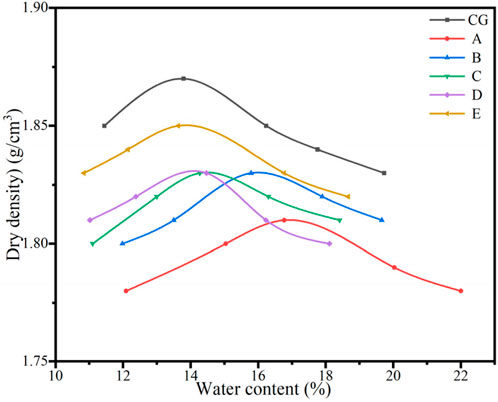

The maximum dry density and optimal moisture content of solidified sludge with different dosages of CCM are shown in Figure 6. The results indicate that the maximum dry density of solidified sludge containing CCM is lower than that of undisturbed sludge. Moreover, the optimal water content of solidified sludge shows no significant rule with the CCM content.

3.3 UCS of solidified sludge

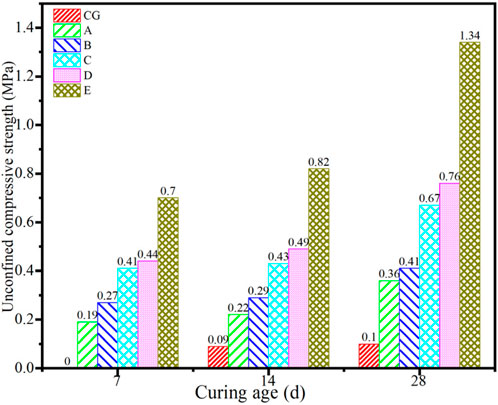

The UCS of solidified sludge after curing different ages are shown in Figure 7. The results show that after curing 7 days, undistributed sludge cannot be detected for UCS and thus cannot meet the bearing requirements of the project. The UCS of the solidified sludge increased with the increase of CCM content. When the CCM content is 6%, the strength of solidified sludge after curing 7 days reached 0.19 MPa, which can meet the bearing requirements of the general storage yard. When the CCM content is 18%, the strength of solidified sludge after 14 days reached 0.82 MPa, which meets the bearing strength requirement (≥0.8 MPa) of China’s first-class road surface (Ministry of Transport, 2015). The UCS of solidified sludge increases with the increase of CCM content. In engineering applications, the CCM content can be adjusted according to the bearing requirements.

3.4 Analysis of soil and water stability of silt solidification

In engineering applications, in some rain-rich or low-lying areas, the bearing foundation often faces the risk of being soaked by water. Therefore, the water stability of solidified sludge is an important evaluation index in engineering applications. Due to its high plasticity index, the water stability performance of sludge is worse than that of ordinary soil. The water stability test results of solidified sludge (Figure 8) show that CCM can significantly improve the water stability coefficient of sludge. Moreover, the water stability coefficient of solidified sludge increased with the increase in CCM content. When the content of CCM in solidified sludge reaches 18%, the water stability coefficient reaches 88.5%, which meets the relevant requirements (Industrial Standard of The People’s Republic of China, 2017).

3.5 Freezing resistance test of silt solidified soil

The freeze-thaw cycle caused by the alternation of warm and cold in seasonal frozen soil engineering is one of the main reasons for project damage. Therefore, it is extremely important to simulate and restore the real state under freeze-thaw action. The freeze-thaw cycle test was employed to investigate the freeze-resistance of solidified sludge. The UCS of the freeze-thaw cycle group and the control group are shown in Figure 9. During freeze-thaw, the hydration products of CCM improved the densification of the solidified sludge, reduced the porosity of the solidified sludge, and decreased the capillary water content in the pores of the solidified sludge. The change of capillary water in the soil phase leads to an overall structural reduction. Meanwhile, the cementation of sludge particles by hydration products in the solidified sludge and the repeated squeezing of soil particles in the freeze-thaw cycle resulted in a stronger bond with hydration products, leading to higher strength. When the CCM content is 9%, the strength of the solidified sludge after 9 freeze-thaw cycles reached 0.83 MPa, which still meets the strength requirement of a primary road base (≥0.8 MPa) (Ministry of Transport, 2015). Meanwhile, the UCS of solidified sludge after freeze-thaw cycles increased with the increase of CCM content. Therefore, in the application of freeze-thaw engineering, the content of CCM can be adjusted according to the bearing requirements.

3.6 SEM-EDS analysis of solidified sludge

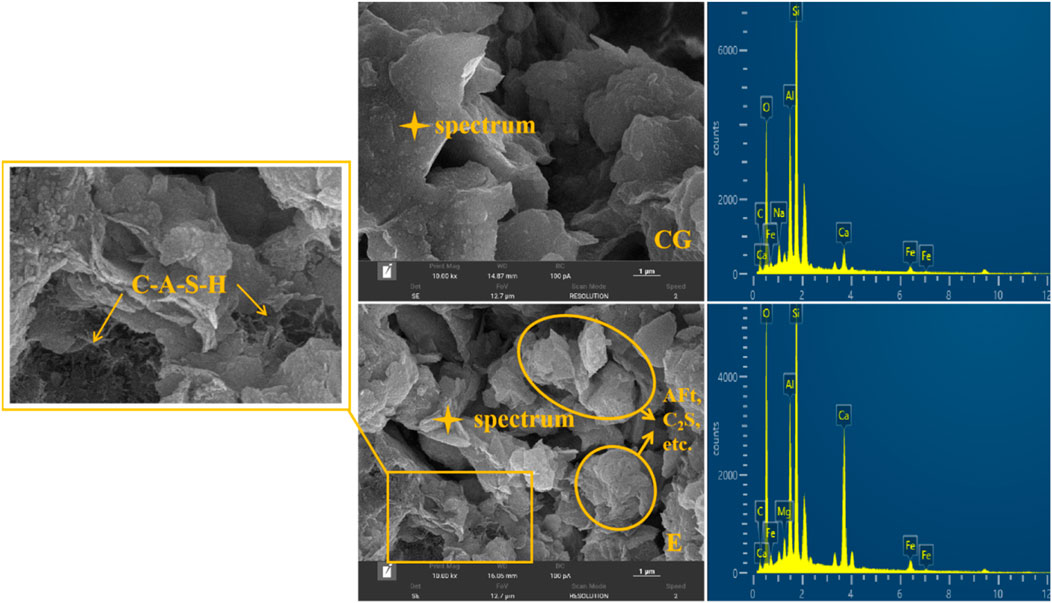

The SEM-EDS images of undisturbed sludge and solidified sludge cured for 28 days are shown in Figure 10. It is clearly display that the undisturbed sludge is mainly composed of massive soil particles. There is a large gap between the soil particles, which leads to the poor density and strength of the undisturbed sludge. In Figure 10, the SEM image of sample E of solidified sludge contains a large number of small flake hydration products. These hydration products fill the sludge pores and cement the surrounding sludge particles, thus improving the strength of the solidified sludge. The energy spectrum of the undisturbed solidified sludge shows that the main elements in the sludge are Si, Al, and O. While in the flake of the solidified soil specimen E, the Ca and O elements are significantly increased. These flake hydration products are mainly Ca salts, which is consistent with the results of XRD analysis by CCM. In addition, sample E of solidified sludge also contains amorphous C-A-S-H gel products. The formation and growth of a large number of hydration products gradually improve the densification of solidified sludge, which is conducive to improving the strength and durability of solidified sludge.

4 Analysis of silt solidification mechanism

Upon the occurrence of a hydration reaction between the CCM within the solidified sludge and the free water as well as capillary water present in the sludge, a series of hydration products, namely, AFt and C-A-S-H gel, were generated. The detailed process unfolds as presented in Figure 11. These hydration products serve to fill the pores that exist among the sludge particles, thereby effectively enhancing the compactness of the solidified silt body and, as a direct consequence, leading to an improvement in the overall strength. Moreover, The hydration reaction consumes the free water and capillary water in the sludge, reducing the frost heaving impact caused by the transformation of the liquid phase in the freeze-thaw environment, thereby improving the frost resistance of the solidified sludge soil. In addition, during the hydration process, hydration products such as AFt and C-A-S-H gel were intertwined with each other and wrap around the sludge particles to form a network skeleton, further enhancing the overall strength and frost resistance of the solidified sludge.

5 Conclusion

This study used typical construction waste WC, in collaboration with typical industrial waste slag BFS and CS activation to prepare CCM to solidify sludge. The main conclusions are as follows.

1. The hydration products of CCM are mainly AFt and C-A-S-H, and the CCM-30, used for subsequent sludge curing, has the best mechanical properties which containing 30% WC, 60% BFS, 10% CS and 10% ASS. The UCS of CCM-30 paste curing for 7 days and 28 days reached 10.89 MPa and 14.17 MPa, respectively.

2. The UCS and water stability coefficient of the solidified sludge increased with the increased of CCM content. When the content of CCM was 18%, the strength of the solidified sludge after curing 14 days of curing reached 0.82 MPa, which meets the bearing strength of the first-class highway in our country (≥0.8 MPa), and the water stability coefficient reached 88.5%. The UCS of the solidified sludge after freezing-thawing cycles was slightly higher than that of the CG, which indicates that the solidified sludge soil has good frost resistance.

3. The continuous improvement of the hydration degree in muck-solidified soil produces a large number of hydration products to fill pores and cement soil particles, thus improving the strength, water stability, and frost resistance of muck-solidified soil. The collaborative disposal of building waste, industrial waste residue, and silt can promote the utilization of urban waste resources and become a new building material. This study can provide an important reference for the collaborative disposal and absorption of urban industry, construction solid waste, and dredging sludge.

Data availability statement

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found below: Not Applicable.

Author contributions

SW: Methodology, Formal Analysis, Conceptualization, Writing – review and editing. AW: Methodology, Conceptualization, Writing – original draft. XF: Methodology, Writing – original draft. XH: Writing – original draft, Conceptualization, Methodology. YZ: Conceptualization, Supervision, Writing – review and editing. XZ: Writing – original draft, Conceptualization, Methodology. ZL: Investigation, Writing – original draft. YW: Writing – original draft. SL: Writing – original draft. YS: Writing – original draft, Investigation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This study was supported by the Hubei Provincial Construction Science and Technology Plan Project in 2021: Key Technologies for the Preparation of Medium and High Quality Recycled Concrete in Urban Renewal (No. 21), Shandong Province Natural Science Foundation (No. ZR2024QE059), Qingdao Natural Science Foundation (No. 24-4-4-zrjj-78-jch), Wuhan Urban Construction Group Co., Ltd. in 2022 Scientific Research Project (2022K-05) and Wuhan Construction Engineering Group Co., Ltd. in 2024 Technical Service Project (2024K-JSFW02).

Conflict of interest

Authors SW and AW were employed by Wuhan Construction Engineering Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Gu, L. L., Zecheng, L., PuiLam, N., et al. (2019). Reusing waste concrete recycled powder in mortar: paste substitution versus cement substitution. J. Mater. Civ. Eng. 36 (5).

Hao, F., Kangle, G., Zhaojun, W., Rihao, M., Chin, C. L., and Ma, C. K. (2024a). Experimental investigation of a novel CFRP-steel composite tube-confined seawater-sea sand concrete intermediate long column. Int. J. Integr. Eng. 16. doi:10.30880/ijie.2024.16.05.035

Hao, F., Jun, T., Shutong, C., Chin, C. L., and Ma, C. K. (2024b). Axial compressive performance of CFRP-Steel composite tube confined seawater sea-sand concrete intermediate slender columns. Constr. Build. Mater. 441, 137399. doi:10.1016/j.conbuildmat.2024.137399

Hengyu, Z., Xiushan, W., Xingxing, H., Zhiqi, X., and Xiaoyuan, Z. (2021). Analysis of influencing factors and mechanism of strength growth of geopolymer solidified silt. Rock Soil Mech. 42 (08), 2089–2098. doi:10.16285/j.rsm.2021.0018

Hongchun, Z. (2021). The direction of ecological civilization construction in the 14th Five-Year plan. China Constr. Inf. (01), 8–11.

Hui, H., and Wenjun, W. (2022). Experimental study on cement solidified sludge from recycled concrete. Low. Temp. Build. Technol. 44 (02), 77–81.

Industrial Standard of The People’s Republic of China (2017). Code for design of concrete structures for railway bridges and culverts(in Chinese). TB 10092-2017.

Jia, R., Ran, B., Tong, L., Yu, Y., Hu, X., and Xu, L. (2025). Synergistic effect of waste concrete powder and traditional SCMs in preparing clinker-free cement: hydration and microstructure evolution. Constr. Build. Mater. 491, 142798. doi:10.1016/j.conbuildmat.2025.142798

Jiale, C. (2023). Study on mechanical properties of waste concrete granular cement-solidified silt. Wuhan, China: Wuhan Institute of Technology.

Jin, D. M. (2019). Discussion on development opportunities and countermeasures of construction waste recycling industry under the background of “waste-free city”. Environ. Health Eng. 31 (04), 76–82. doi:10.19841/j.cnki.hjwsgc.2023.04.013

Jingsheng, Q., Xuying, W., Guanhong, W., and Jianye, Z. (2021). Dynamic characteristics and microscopic mechanism of silty soil solidified by granulated blast furnace slag micro-powder. Bull. Silic. 40 (07), 2306–2312. doi:10.16552/j.cnki.issn1001-1625.20210331.001

Jun, W., Xiyao, Z., Aiwu, Y., and Yanbo, Y. (2018). Experimental study on compressive strength of silty clay solidified by slag-fly ash base polymer. J. Rock Soil Mech. 42 (3), 647–655. doi:10.16285/j.rsm.2020.0918

Kuang, W., Long, P., Zhenxin, D., Hui, Z., and Xinjun, Z. (2023). Study on environmental durability of lake-bottom solidified soil. Geotech. Eng. Technol. 37 (04), 455–460. doi:10.3969/j.issn.1007-2993.2023.04.014

Liqun, W., and Xinyu, L. (2023). Thinking on the standardization development of construction waste resource utilization engineering in China. Eng. Constr. Stand. (03), 73–76. doi:10.13924/j.cnki.cecs.2023.03.004

Meng, C., Guolu, Y., Feng, X., and Hongyan, W. (2018). Research progress of silt solidification treatment (in Chinese). South-to-North Water Transf. Water Sci. Technol. 16 (05), 128–138. doi:10.13476/j.cnki.nsbdqk.2018.0134

Ministry of Transport (2015). Technical rules for the construction of highway pavement base (in Chinese) (JTG/TF 201/2015).

Rui, R., Ruoyu, H., Di, L., Weixing, B., and Hongpeng, L. (2022). Study on road performance and freeze-thaw resistance of low liquid limit silty clay cured by alkali excitation materials (in Chinese). Chin. J. Eng. Geol. 30 (2), 327–337. doi:10.13544/j.cnki.jeg.2021-0134

Ruimin, C., Wenbin, J., Xiaofang, Z., and Zehua, F. (2022). Experimental study on performance improvement of silt-solidified soil by CSFG-FR synergistic effect. Rock Soil Mech. 43 (04), 1020–1030. doi:10.16285/j.rsm.2021.1017

Vichan, S., and Rachan, R. (2013). Chemical stabilization of soft Bangkok clay using the blend of calcium carbide residue and biomass ash. Soils Found. 53 (2), 272–281. doi:10.1016/j.sandf.2013.02.007

Wang, Y., Han, F., and Mu, J. (2018). Solidification/Stabilization mechanism of Pb (II), Cd(II), Mn (II) and Cr (III) in fly ash based geopolymers. Constr. Build. Mater. 160, 818–827. doi:10.1016/j.conbuildmat.2017.12.006

Wang, Y., Liu, X., Zhang, W., Li, Z., Zhang, Y., et al. (2020). Effects of Si/Al ratio on the efflorescence and properties of fly ash based geopolymer. J. Clean. Prod. 244, 118852. doi:10.1016/j.jclepro.2019.118852

Wang, A., Zhang, Y., Ni, J., Rong, H., Zhan, Q., and Huang, Z. (2024). Performance and microcharacteristics of synergistic solidification of sludge by industrial waste residue and bentonite. J. Environ. Eng. 18 (03), 857–865.

Xin, L., Linbo, H., Liu, Y., and Yi, W. (2024). Thinking and discussion on the development of construction waste treatment industry under the new background. Constr. Technol. Engl. Chin, 1–9.

Xu, L., Wang, J., Huang, R., Wang, Y., Ran, B., Hu, X., et al. (2025). Effects of accelerated carbonation on the chemical and microstructural evolution of recycled different SCMs blended cement pastes. Cem. Concr. Compos. 164, 106259. doi:10.1016/j.cemconcomp.2025.106259

Xueqi, Z., Yongxiang, Z., Yang, H., Peng, Z., and Jing, W. (2023). Study on the strength of cement-based composite curing agent curing acid laterite. Build. Sci. 39 (11), 82–88. doi:10.13614/j.cnki.11-1962/tu.2023.11.010

Yang, C., Lv, X., Tian, X., Wang, Y., and Komarneni, S. (2014). An investigation on the use of electrolytic manganese residue as filler in sulfur concrete. Constr. J. Build. Mater. 2014, 73305–73310. doi:10.1016/j.conbuildmat.2014.09.046

Yong, L., Xiaoming, L., Zepeng, L., Ren, Y., Wang, Y., and Zhang, W. (2021). Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J. Clean. Prod. 284, 124777. doi:10.1016/j.jclepro.2020.124777

Keywords: sludge solidification, waste concrete, industrial solid waste, new building materials, microstructure analysis

Citation: Wang S, Wang A, Fu X, Hong X, Zhang Y, Zhang X, Li Z, Wang Y, Li S and Shen Y (2025) Experimental study on solidification of sludge by mixing reclaimed activated micro powder of waste concrete with industrial solid waste. Front. Built Environ. 11:1683228. doi: 10.3389/fbuil.2025.1683228

Received: 10 August 2025; Accepted: 17 September 2025;

Published: 26 November 2025.

Edited by:

Lei Xu, Swiss Federal Institute of Technology Lausanne, SwitzerlandReviewed by:

Tong Lv, Tianjin University, ChinaYongming Xiong, Changsha University of Science and Technology, China

Shunquan Zhang, Anhui University of Technology, China

Zihan Ma, The Hong Kong Polytechnic University, Hong Kong SAR, China

Rihao Mai, University of Technology Malaysia, Malaysia

Copyright © 2025 Wang, Wang, Fu, Hong, Zhang, Zhang, Li, Wang, Li and Shen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xinliang Hong, aG9uZ3hsMjAwNkAxNjMuY29t

Shuai Wang1,2

Shuai Wang1,2 Xinliang Hong

Xinliang Hong